Professional Documents

Culture Documents

Nam Nadu

Uploaded by

sankarsuper830 ratings0% found this document useful (0 votes)

28 views27 pagessadsdg

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsadsdg

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views27 pagesNam Nadu

Uploaded by

sankarsuper83sadsdg

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 27

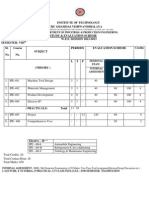

2011-2012

MECHANICAL ENGINEERING | Mr.Vaibhav V Naik

AUTOMOBILE

ENGINEERING

BRAKES

Automobile Engineering

Module No 02 2 Vaibhav Vithoba Naik

BRAKES

1. Requirements of the brake

2. Classification of Brakes

3. Mechanical Brakes

4. Hydraulic Brakes

5. Electro and Vaccum brakes

6. Disc brakes

7. Braking of the front wheel

8. Rear wheel and four wheel brakes

9. Brake trouble shooting

10. Introduction Antilock braking system

Automobile Engineering

Module No 02 3 Vaibhav Vithoba Naik

Q1. - List the functions of the brake? State its essential requirement?

Answer: -

BRAKE :-

It is a device used for slowing, stopping & controlling the vehicle.

In braking operation, the kinetic energy of vehicle is converted into heat,

which is dissipated to atmosphere.

FUNCTIONS OF VEHICLE BRAKING

There are two main functions of brakes:

1) To slow down or stop the vehicle in the shortest possible time at the

time of need.

2) To control the speed of vehicle at turns and also at the time of driving

down on a hill slope.

REQUIREMENTS OF THE BRAKE

1) The brakes should stop the vehicles in shortest possible distance and

time.

2) The brake should work equally good on fair or bad road.,

3) Paddle effort applied by the driver should not be more so as not to

strain the drivers.

4) Brake should work equally good in all weather.

5) It should have less wearing parts

6) It should require less maintenance.

7) Brakes, when applied should not disturb steering geometry.

8) There should be minimum sound when brakes are applied.

Automobile Engineering

Module No 02 4 Vaibhav Vithoba Naik

Q2. - Define the principle on which brake works? Classify the brakes

Answer: -

PRINCIPLE OF VEHICLE BRAKING

Braking of a vehicle depends upon the static function that acts between

tyres and road surface.

Brakes work on the following principle to stop the vehicle:

The kinetic energy due to motion of the vehicle is dissipated in the form of

heat energy due to friction between moving parts (wheel or wheel drum)

and stationary parts of vehicle (brake shoes).

The heat energy so generated due to application of brakes is dissipated

into air. Brakes operate most effectively when they are applied in a

manner so that wheels do not lock completely but continue to roll without

slipping on the surface of road.

Automobile Engineering

Module No 02 5 Vaibhav Vithoba Naik

Q2. Give the Classification of the brakes?

Answer: -

CLASSIFICATION OF BRAKES

Brakes may be classified in the following ways.

a. With respect to application: -

1. Foot brake :- service brake

2. Hand brake :- parking brake

b. With respect to number of wheels to which brake is applied

1. Two wheel brake

2. Four wheel brake

c. With respect to construction

1. Drum brake

2. Disc brake

d. On the Basis of Mode of Operation

1. Mechanical brakes

2. Hydraulic brakes

3. Air brakes

4. Vacuum brakes

5. Electric brakes.

Automobile Engineering

Module No 02 6 Vaibhav Vithoba Naik

Q3.: - Explain the Drum Brake /Internal Expanding brakes ?

Answer: -MECHANICAL BRAKES

DRUM BRAKE: -

1. In this type, a brake drum is attached concentric to axle hub.

2. Two brake shoes are anchored on the back plate as shown in figure.

3. Friction linings are mounted on the brake shoes.

4. One or two retractor springs are used to keep the brake shoes away

from the drum when the brakes are not applied.

5. The brake shoes are anchored at one end, whereas on the other end

force F is applied by means of some brake actuating mechanism,

which forces the brake shoe against the revolving drum, thereby

applying the brakes.

6. An adjuster is also provided to compensate for wear of friction lining

with use.

Automobile Engineering

Module No 02 7 Vaibhav Vithoba Naik

Q4.: - Explain the Hydraulic brake working with its principle ?

Answer: HYDRAULIC BRAKES

Principle: -

Force applied on the brake pedal is transmitted to brake shoe through a

confined liquid known as brake fluid.

OR

Hydraulic brakes work on the principle of Pascals law which states that

pressure at a point in a fluid is equal in all directions in space. According

to this law when pressure is applied on a fluid it travels equally in all

directions so that uniform braking action is applied on all four wheels.

Construction: -

Hydraulic braking system consists of

1. Master cylinder

2. Wheel cylinder

3. Brake drum

4. Brake shoes

5. Brake fluid with brake lines.

Automobile Engineering

Module No 02 8 Vaibhav Vithoba Naik

1. MASTER CYLINDER: -

a. It consists of two main chambers, fluid reservoir & compression chamber.

b. Reservoir supplies fluid to brake system through two ports.

c. Larger port is called as intake port whereas smaller port is called as

d. By pass port.

e. To prevent leakage, there are rubber seals on both sides of piston in the

compression chamber.

f. Towards the break line side of compression chamber, there is a fluid

check valve with a rubber cup inside. It serves to retain residual pressure

in the brake lines even after the brakes are released.

2. WHEEL CYLINDER :-

a. Wheel cylinders are provided to force the brake shoes against the drums.

b. Each wheel cylinder is provided with piston, rubber seal, and rubber seal

spreaders, springs etc.

c. The brake line from the master cylinder is attached to the inlet port of

wheel cylinder.

d. A bleeder port is provided to bleed the air whenever necessary.

Automobile Engineering

Module No 02 9 Vaibhav Vithoba Naik

Automobile Engineering

Module No 02 10 Vaibhav Vithoba Naik

WORKING: -

1. The master cylinder is connected by brake lines to wheel cylinder at each of

four wheels.

Each wheel cylinder consists of a cylinder brake drum, which is mounted

on inner side of wheel & revolves with it.

Inside the brake drum, two brake shoes are fitted with friction brake lining

on their surfaces.

2. When the brake pedal is pressed, which is connected to master cylinder by

means of piston rod, it causes the piston of master cylinder to move. It

increases the pressure of fluid inside the master cylinder & in entire

hydraulic system. This pressure is instantly transferred to all four wheel

cylinders.

3. As soon as the pressurized oil comes inside the wheel cylinder through inlet

port, the pistons in the wheel cylinder moves outwards moving the brake

shoes out against the brake drum. Thus the brakes are applied.

4. When the driver releases the brake pedal, the master cylinder piston returns

to its original position due to return spring, dropping fluid pressure. Brake

shoe retracting springs contract & pulls the brake shoes out of contact with

brake drum to their original position & brakes are released.

Automobile Engineering

Module No 02 11 Vaibhav Vithoba Naik

Q5.: - Give the advantages and disadvantages of Hydraulic brake ?

Answer: -

ADAVANTGE OF HYDRAULIC BRAKE SYSTEM

The advantages of hydraulic brake system are,

1. Mechanical linkages, joints etc. are eliminated so as to have simple

construction.

2. Equal braking effort at all points to all four wheels.

3. Self lubricating

4. High mechanical advantage i.e. less effort required to operate brake

5. Differential braking action can be permitted by using wheel cylinders of

different sizes for front & rear wheels.

6. It gives higher efficiency than any other hydraulic system.

DISADVANTAGES OF HYDRAULIC BRAKE SYSTEM

The disadvantages of hydraulic brake system are,

1. Fails the whole system when there is leakage or damage to any part of

system.

2. Due to leakage of fluid, damage to brake shoes & linings happens.

3. This system is used to apply brakes intermittently. For parking purposes,

separate mechanical linkage has to be used.

Automobile Engineering

Module No 02 12 Vaibhav Vithoba Naik

Q8. - Explain the construction and working of Master Cylinder?

Answer: MASTER CYLINDER:

Construction of Master Cylinder

1. The Master Cylinder is the heart of the hydraulic brake system.

2. It consists of two main chambers.

3. The fluid reservoir which contains the fluid to supply to the brake system,

and the compression chamber in which the piston operates.

4. The reservoir supplies fluid to the brake system through two ports.

5. The larger port is called the filler or intake part and is connected to the

hollow portion of the piston between the primary and secondary cups

which act as piston seals.

6. The smaller port is called the relief, bypass or compensating port which

connects the reservoir directly with the cylinder and lines when the

piston is in the released position.

Automobile Engineering

Module No 02 13 Vaibhav Vithoba Naik

Working of Master Cylinder

1. When the brake pedal is depressed, the master cylinder piston moves

forward to force the liquid under pressure into the system. The relief port

is sealed out of the system. The liquid pressure is conducted to the

wheel cylinders, where it forces the wheel cylinder pistons out wards.

These pistons force the brake shoes out against the brake drums.

2. When brake pedal is released, the return spring quickly forces the

master cylinder piston back against the piston stop. Because the fluid in

the lines returns rather slowly, a vacuum tends to form in the cylinder in

front of the piston. This causes the primary cup to collapse to allow the

liquid to flow from the reservoir through the filter port past the piston to fill

the vacuum.

Automobile Engineering

Module No 02 14 Vaibhav Vithoba Naik

Q8.: - Explain WHEEL CYLINDER ?

Answer: WHEEL CYLINDER :

1. Wheel cylinder is the second important hydraulic brake system. It

consists of two pistons which can move in opposite directions by the fluid

pressure. It is rigidly mounted on the brake shield or backing plate. The

boots protect the cylinders from foreign substances. Bleeder valves are

provided in the cylinder to permit air and liquid to be pumped out of the

system during of the bleeding operation .

2. Piston cup fits tightly in the cylinder against each piston and seal the

mechanism against leakage of the brake fluid. A Spring serves to hold

the cups against the piston when the pressure is decreased.

3. When the brakes are applied the brake fluid enters the cylinder from a

brake line connection inlet between the two pistons. It causes to force

out the two pistons in opposite directions. This motion is transmitted to

the brake shoe. Directly or through links force them against the brake

drum, thus applying the brake.

Automobile Engineering

Module No 02 15 Vaibhav Vithoba Naik

Q8. - Explain the Pneumatic brake?

State its advantage and disadvantages?

Ans: PNEUMATIC BRAKE

Construction of Pneumatic brake

The pneumatic brake system consists of the following parts.

1. Air compressor

Generally the reciprocating compressor is used to build the air pressure in

the reservoir. The compressor is driven by the engine.

2. Unloaded valve

It maintains the constant pressure in the reservoir.

The excess of the pressure is relieved by the unloaded valve.

Figure: Block Diagram of Pneumatic Brake

3. Reservoir

It is the tank in which the air at high pressure is stored.

4. Brake Valve

It is located between air reservoir and air line of the brake cylinder.

Brake valve is used to control the braking action.

Brake valve may be operated by the brake pedal.

Automobile Engineering

Module No 02 16 Vaibhav Vithoba Naik

5. Brake Chamber

It is the housing in which brake shoe linkages are connected to the

diaphragm.

The movement of the diaphragm due to high pressure air actuated brakes

shoes towards brake drum.

6. Quick release valve

Quick release valve is used in from of brake liners to accelerate the quick

release of the pressure.

7. Relay valve

It speeds up the braking action and release of the air from brake chamber.

It supplies the air to the brake chamber directly from the reservoir and also

retains the air from rears brake chamber directly into atmosphere.

Figure: Air Brake

Automobile Engineering

Module No 02 17 Vaibhav Vithoba Naik

Working of the Pneumatic brake

1. In pneumatic brake, the brake shoes are operated by means of air

pressure.

2. Engine drives a compressor, which is used to compress the air and

stores in air reservoir.

3. Brake cylinder is connected to air re4servious by means of the flexible

linkages.

4. When the brake pedal is pressed, the compressed air enters in wheel

cylinder to push the diaphragm which in turn pushes the brake shoe to

apply the brake.

5. When the pressure is released from the brake pedal, it comes back

with retracting spring as result in closing of the brake valve and

releases the pressure inside the brake chamber.

Advantage of Pneumatic Brake

1. These are very powerful as compared to the mechanical or hydraulic

brakes.

2. Its location and working is very easy and simple.

3. Available compressed air also used for wiper.

Disadvantage of Pneumatic Brake

1. Compressor consumes the part of the engine power.

2. Construction of each component is complicated.

3. System is costly.

Automobile Engineering

Module No 02 18 Vaibhav Vithoba Naik

Q9. - Explain the Power brake?

Ans: ELECTRO AND VACUUM BRAKES (POWER BRAKE)

Construction of the Vacuum Brake

1. POWER BRAKE is designed to reduce the pedal effort required to stop

the vehicle.

2. Power brake used engine manifolds to assist the driver in applying the

brakes.

3. Power brake consist of the three basic parts

Automobile Engineering

Module No 02 19 Vaibhav Vithoba Naik

4. The vacuum of engine manifolds or separate exhauster can be used in

vacuum or power brake.

5. System consists of vacuum reservoir connected through the non return

valve to inlet manifolds of engine.

6. The two connections from vacuum reservoir go to the servo cylinder and

control unit.

7. The control unit has two valves.

8. The lower valves control the connection between the reservoir and right

sides of servo cylinder piston.

9. The other side of the piston of control unit is actuated by pedal by means

of master cylinder.

Working of the Vacuum Brake

1. When the brake pedal is OFF position, the lower valve of control unit is

open and upper valve is closed. This disconnects the atmospheric air

and vacuum form the reservoir is created on the both side of the piston

of the servo cylinder.

2. When the brakes are applied, it closes the lower valve of control unit and

opens the upper valve of atmospheric air to push piston in servo cylinder

towards the right to apply brakes. In these ways driver effort are utilized

to control the position of the drive in the control unit.

3. If failure occur in vacuum power system because of stalled engine, the

brake should still be applied to stop the car, but by greater effort.

Automobile Engineering

Module No 02 20 Vaibhav Vithoba Naik

Q10.: - Explain the construction and working of disc brakes?.

Answer: -DISC BRAKE:

Construction:

1. It consists of a cast iron disc bolted to the wheel hub & stationery

housing called as the caliper.

2. The caliper is connected to some stationery part of vehicle like stub axle.

3. This caliper is cast in to two parts each containing a piston.

4. In between each piston & the disc there is a friction pad held in position

by retaining pins or springs.

5. The passages are drilled in the caliper for the fluid to enter or leave in

each housing.

Automobile Engineering

Module No 02 21 Vaibhav Vithoba Naik

Working :

1. When the brakes are applied, hydraulically actuated pistons make the

friction pads into contact with the disc, applying equal & opposite forces

on the disc, causing the friction & hence slowing it down.

2. When brakes are released, hydraulic pressure on the friction pads is

released. The piston moves inwards & breaks their contact with the disc.

Q11.: - Explain the advantages of disc brakes over drum brakes.

Ans: -

ADVANTAGES OF DISC BRAKES OVER DRUM BRAKES

The advantages of disc brakes over drum brakes are,

1. In case of disc brakes, friction surfaces are directly exposed to air,

whereas in drum type, the friction occurs on the internal surfaces, so

heat dissipation problem occurs.

2. The friction pads in case of disc brakes are flat as compared to curved

friction linings in case of drum brakes. Therefore there is uniform wear of

friction pads in case of disc brakes. This helps in easy selection of

material for pads.

3. The design of disc brake is such that there is no loss of efficiency due to

expansion. In case of drum brake, as the system becomes hot, the

expansion of a drum of internally expanding shoe type brake tends to

move the friction surfaces apart, causing a loss of effective pedal travel.

On the other hand, disc expansion merely changes the relative positions

on friction surface causing no loss.

4. Disc brakes weigh less than drum brake.

5. Design of disc brakes is very simple & involves less number of parts to

wear.

6. Easy replacement of friction pads.

Automobile Engineering

Module No 02 22 Vaibhav Vithoba Naik

Q12. - Short notes on Brake Bleeding.

Answer: -

BLEEDING OF BRAKES

When air enters, into the brake system and any brake line is

disconnected, bleeding of brakes has to be done.

Since air is compressible so any presence of air inside brake lining does

not allow to transmit brake force to apply brakes.

Therefore, the system must be free from presence of air.

Bleeding is the process of removal of air from the braking system.

Bleeding Procedure

Following steps are followed for bleeding of brakes

1. Remove all dirt from the master cylinder filler plug. Then fill the master

cylinder up to lower edge of the filler neck by removing the filler plug.

2. Clean all the bleeding connections provided on all wheel cylinders.

3. After this bleeder hose and fixture is connected to that wheel cylinder

which has longest brake line. The other rend of bleeder hose is placed in

a glass jar, and submerge this end in the brake fluid.

4. How bleeder valve is opened by half to three quarter turn.

5. Then press the foot pedal and allow it to return back slowly.

6. This pumping action must be continued till all the air along with some

brake fluid comes out through bleeding hose.

7. After this bleeding operation is carried out on all wheel cylinders.

8. This completes the bleeding operation. At the end master cylinder is

filled with brake fluid to required level.

Automobile Engineering

Module No 02 23 Vaibhav Vithoba Naik

Q13.: - Short notes on Brake Setting or Brake Adjustments

Answer: -

ADJUSTMENT OF BRAKES

1. When pedal is pressed to apply brake, there should be atleast 1/2 inch

free pedal movement before breaking action starts. This may vary from

company to company.

2. The brakes are adjusted as per the above mentioned recommendation

before they are ready to use. This is done by following a definite

procedure.

a. List the wheels by screw jack.

b. Loosen the lock nut for the forward brake shoe and keep it in this

position.

c. Turn the eccentric with other wrench towards the front of automobile

till the brake shoe touches the drum.

d. Release the eccentric while turning the wheel with one hand, till

wheel turns freely.

e. Hold the eccentric in this position and tighter the lock nut.

f. Repeat the same operation to adjust other shoe, but turn the

eccentric if the backward direction of the vehicle.

g. Above procedure is repeated for all the four wheels.

Automobile Engineering

Module No 02 24 Vaibhav Vithoba Naik

Q14.: - Short notes on Parking brake or Emergency Brake?

Answer: -

PARKING BRAKE OR EMERGENCY BRAKE

1. Parking brakes or emergency brakes are essentially mechanical brakes

operated by hand.

2. These are used to prevent the motion of vehicle when parked at a place

or when parked on slopes.

3. In cars, these brakes are generally attached to rear wheels.

4. In this type, a cable connects the hand lever to the brake.

5. Brakes are applied by pulling the lever and released by pushing a button

(provided on lever) and pressing the lever down.

Automobile Engineering

Module No 02 25 Vaibhav Vithoba Naik

Q15.: - Short notes on Brake Adjusting Mechanism?

Ans: -

Brake Show Adjustment Mechanism

1. There are various methods to adjust the brake shop,

2. The most common types important ones are the

A. Micram adjuster

B. Screw adjuster.

Automobile Engineering

Module No 02 26 Vaibhav Vithoba Naik

A. MICRAM TYPE ADJUSTMENT OF BRAKE SHOES

1. This system is very effective and simple in construction as shown in

figure.

2. The mechanism consists two scroll members provided one for each

brake shoe to adjust them. each scroll member is mounted between the

brake shoe and the member M is fixed to the actuating plunger.

3. The brake shoe bears on the pin of the scroll member and the scroll

member itself bears on a locking tooth or ridge of the member M.

4. The scroll member is provided with toothed cam and can be turned by a

screw driver when there is desire to the shoe adjustment. The position of

the adjustment is locked by securing the tooth of the cam in the ridge of

the member M. this system is generally used in hydraulic brakes.

Automobile Engineering

Module No 02 27 Vaibhav Vithoba Naik

B. TAPER SCREW ADJUSTER

1. In this system the shoes are adjusted by a screw which is known as 'star

adjusting screw'.

2. The upper ends of the shoes are pivoted in the projections of the anchor

pin ant the lower ends are connected by the 'star adjusting screw' as

shown in the figure.

3. The expander Unit is provided just below the anchor pin and shoes are

held with the unit by the return sprigs.

Figure : Taper Screw Adjuster

4. Another helical spring is provided at the lower side to hold the shoed on

the ends of the adjusting screw.

5. Whenever the brakes are required to be adjusted then the adjusting

screw is turner with the help of a lever or screw driver through the

window provided in the back plate

6. This results in the expansion of the shoes out wards and thus reducing

the clearance between the linings and the drum .

7. Screw type adjuster is used in mechanical as well as hydraulic

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 16 PpeDocument1 page16 Ppesankarsuper83No ratings yet

- Walkitoff FinalDocument6 pagesWalkitoff Finalapi-242242591No ratings yet

- Autism: Signs and SymptomsDocument1 pageAutism: Signs and Symptomssankarsuper83No ratings yet

- Centrifugal PumpDocument5 pagesCentrifugal Pumpsankarsuper83No ratings yet

- ME 1994 UnsolvedDocument10 pagesME 1994 UnsolvedAnjit SuryaNo ratings yet

- Autism: Signs and SymptomsDocument1 pageAutism: Signs and Symptomssankarsuper83No ratings yet

- Answer: Ethanol (Which Is Also Called Ethyl Alcohol or Grain Alcohol, and Abbreviated AsDocument1 pageAnswer: Ethanol (Which Is Also Called Ethyl Alcohol or Grain Alcohol, and Abbreviated Assankarsuper83No ratings yet

- HDFC Credit Card Limit Enhancement FormDocument1 pageHDFC Credit Card Limit Enhancement Formranju93No ratings yet

- ME 1991 Unsolved PDFDocument13 pagesME 1991 Unsolved PDFSathya ThyaguNo ratings yet

- TNEB Online PaymentDocument1 pageTNEB Online Paymentsankarsuper83No ratings yet

- Autism: Signs and SymptomsDocument1 pageAutism: Signs and Symptomssankarsuper83No ratings yet

- Centrifugal PumpDocument5 pagesCentrifugal Pumpsankarsuper83No ratings yet

- Ipe-Viii13 11 13Document7 pagesIpe-Viii13 11 13sankarsuper83No ratings yet

- Author InstructionsDocument2 pagesAuthor InstructionsKanesan MuthusamyNo ratings yet

- Vi Sem Before Revaluation Result Apr2014Document18 pagesVi Sem Before Revaluation Result Apr2014sankarsuper83No ratings yet

- PH DDocument7 pagesPH Dsankarsuper83No ratings yet

- By Prime Mover: Internal Combustion Engines PlantDocument1 pageBy Prime Mover: Internal Combustion Engines Plantsankarsuper83No ratings yet

- Mtech Energy Engg 2012Document35 pagesMtech Energy Engg 2012Ssheshan PugazhendhiNo ratings yet

- RF Combustion Air RequirementsDocument68 pagesRF Combustion Air Requirementssankarsuper83No ratings yet

- Energy Question BankDocument5 pagesEnergy Question Banksankarsuper83No ratings yet

- Jaya Agencies Distributor DataDocument3 pagesJaya Agencies Distributor Datasankarsuper83No ratings yet

- SathyabamaUniv PlacementMaster 2015 Mech2Document182 pagesSathyabamaUniv PlacementMaster 2015 Mech2sankarsuper83100% (1)

- Add On Card Application PDFDocument2 pagesAdd On Card Application PDFraom_2No ratings yet

- Cam LabDocument6 pagesCam Labsankarsuper83No ratings yet

- EA, C&M NotesDocument10 pagesEA, C&M NotesLove AkhilNo ratings yet

- Boilers Operation ManualDocument34 pagesBoilers Operation ManualSaurav KumarNo ratings yet

- NamveeduDocument6 pagesNamveedusankarsuper83No ratings yet

- Below 20 Revaluation Requisition LetterDocument1 pageBelow 20 Revaluation Requisition Lettersankarsuper83No ratings yet

- Blood Test Report Normal Values Observation Complete Blood Count (CBC)Document0 pagesBlood Test Report Normal Values Observation Complete Blood Count (CBC)agaramugaramNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cilindro de EmbreagemDocument25 pagesCilindro de EmbreagemGerleton SantosNo ratings yet

- (TOYOTA) Manual de Taller Diagrama Electrico Toyota Prius 2010 PDFDocument466 pages(TOYOTA) Manual de Taller Diagrama Electrico Toyota Prius 2010 PDFjuaneromarinero100% (1)

- Unit 6: Braking Systems and ClutchesDocument34 pagesUnit 6: Braking Systems and ClutchesMarthandeNo ratings yet

- Anti Lock BrakesDocument44 pagesAnti Lock BrakesyogendranathbommuNo ratings yet

- Brake SystemDocument151 pagesBrake SystemHassan ZAFFA CISNEROSNo ratings yet

- DBA Friction Buyers GuideDocument21 pagesDBA Friction Buyers GuideLucasNo ratings yet

- Hand Break SystemDocument6 pagesHand Break SystemfekaduNo ratings yet

- Overhaul BrakesDocument50 pagesOverhaul BrakesjovenalNo ratings yet

- Penerimaan Barang Ptbintangmasles 230807174229Document40 pagesPenerimaan Barang Ptbintangmasles 230807174229Irene IreneNo ratings yet

- Copia de Base para Creacion Articulos Sistemas 12-07-2017Document90 pagesCopia de Base para Creacion Articulos Sistemas 12-07-2017Camilo Andres Bonilla GonzalezNo ratings yet

- Abs 2Document2 pagesAbs 2Radu AlexNo ratings yet

- Air Brakes PDFDocument10 pagesAir Brakes PDFacairalexNo ratings yet

- Brake System: PrecautionDocument75 pagesBrake System: PrecautionRoger SwensonNo ratings yet

- BrakesDocument47 pagesBrakesCristiano Gustafson LopesNo ratings yet

- Sapura Machining CorpDocument5 pagesSapura Machining CorpMEjiNasRiz0% (1)

- Seminar on Disk Brakes: History, Types, Advantages & DisadvantagesDocument14 pagesSeminar on Disk Brakes: History, Types, Advantages & DisadvantagesYuvaraj100% (1)

- Automatic Slack Adjusters, Brake Shoe Components and Parts ListDocument60 pagesAutomatic Slack Adjusters, Brake Shoe Components and Parts ListMgs RepuestosNo ratings yet

- 206-09 ABS and Stability Control - Removal and Installation - Hydraulic Control Unit HCUDocument5 pages206-09 ABS and Stability Control - Removal and Installation - Hydraulic Control Unit HCUTrung HồNo ratings yet

- Industrial Brake Catalogue - Web 1Document15 pagesIndustrial Brake Catalogue - Web 1ashraf elsayedNo ratings yet

- Disc BrakesDocument52 pagesDisc BrakesLin AzizNo ratings yet

- Electromagnetic Braking SystemDocument16 pagesElectromagnetic Braking SystemGallant Info100% (1)

- Brake Fluid: BleedingDocument4 pagesBrake Fluid: BleedingDannyDDannyDNo ratings yet

- Pathfinder 2005 - Parking BrakeDocument10 pagesPathfinder 2005 - Parking BrakePaper-FaceNo ratings yet

- Report BrakeDocument11 pagesReport BrakeNguyễn Quốc ThanhNo ratings yet

- Dynamic Analysis of Mechanical Braking System: January 2019Document9 pagesDynamic Analysis of Mechanical Braking System: January 2019Ammu JessyNo ratings yet

- Hydraulic Brakes - Parts, Working, Diagram, Advantages and DisadvantagesDocument16 pagesHydraulic Brakes - Parts, Working, Diagram, Advantages and DisadvantagesKishoreChowdaryNalaboluNo ratings yet

- Skoda Kodiaq Brake System EngDocument132 pagesSkoda Kodiaq Brake System EngFrancisco MoraNo ratings yet

- Drum Brake Operating PrinciplesDocument12 pagesDrum Brake Operating Principleskyaw thatNo ratings yet

- The ID.4 Electromechanical Brake Servo (eBKV) : Self Study Program 861213Document23 pagesThe ID.4 Electromechanical Brake Servo (eBKV) : Self Study Program 861213António FernandesNo ratings yet

- Bendix Brake Catalog 2023Document828 pagesBendix Brake Catalog 2023Javier AvendañoNo ratings yet