Professional Documents

Culture Documents

Degumming

Uploaded by

Khairi Maulida Azhari100%(1)100% found this document useful (1 vote)

146 views3 pagesdegummig

Original Title

degumming

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdegummig

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

146 views3 pagesDegumming

Uploaded by

Khairi Maulida Azharidegummig

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

ENZYMATIC DEGUMMING OF FEEDSTOCKS

(VEGETABLE OIL) FOR BIO-DIESEL A REVIEW

Savita Dixit* & Sangeeta Kanakraj**

Received: 10th Oct.2010 Accepted: 29th Dec. 2011

Abstract

GBiodiesel is one of the alternative energy outstanding on the

forefront of energy business due to its biodegradability,

renewability, an excellent lubricity in low-sulfur diesel, high

cetane number, etc. Moreover, biodiesel production itself also

shows the outstanding reduction in CO generation

2

drastically Degumming is considered essential for purifying

vegetable oils and producing a quality feedstock for biodiesel.

Degumming removes contaminated phospholipids

(phosphorus-containing lipids composed of diacylglycerol

a phosphate groupand a simple organic molecule)

contained in crude vegetable oils and lowers the phosphorus

content of the oil to less than 10 parts per million.

The feed oil (feedstocks) contain impurities unfavorable for

biodiesel production, e.g., phosphorus, free fatty acid,

moisture. These impurities not only contaminate in biodiesel

product but reduce biodiesel yield as well. The feed oils were,

thus, pretreated to remove phosphorus (degumming), free

fatty acid (deacidification), and water (drying), before sent to

transesterification Some or all of these pretreatments were

carried out, in order to investigate the influences of the

respective pretreatments on the biodiesel yield and purity.

Crude vegetable oils contain phospholipids, which must be

removed from oil during refining process. For removing

phospholipids following methods were used: water, acid, and

TOP degumming and most important engymatic degumming.

Keywords: Enzymat i c degummi ng, Bi o- di esel ,

Phospholipids, Rapeseed Oil, Sunflower Oil, Refining

Process.

INTRODUCTION

The present work related to a method for producing fatty acid

alkyl esters, such as fatty acid methyl esters (FAME) and fatty

acid ethyl esters (Bio-diesel) with a low level of impurities

such as phospholipids (gums) from vegetable oil with the help

of enzymatic degumming. Degumming is the pre-treatment

of Feedstocks separation of gums, solid, water and free fatty

acid Technically, degumming is referred as an operation of

purification of seed oil ,which normally contain impurities in

the colloidal state or dissolved in them. In more simple

words, degumming is a process of removing the unwanted

gums, which will interference the stability of the oil product

(like Bio-diesel).The aim of this article is the study of

influence of enzymatic degumming on the amount of P, Mg

and Ca in rapeseed and sunflower oil and other feedstocks

(rich sources of phospholipids.) respectively.

Crude (feedstocks) oil contain variable amounts of non

glyceride impurities, including free fatty acids (FFA),

nonfatty materials generally classified as gums or

phosphatides, colour pigments, sterols, tocopherols, waxes,

hydrocarbons, pesticides, and traces of metals . Most of these

impurities, notably the phospholipids, are detrimental to

colour; flavour, foaming, and smoke stability of the finished

product and Phospholipids pose many problems for the

storage and processing of the crude oil and must be removed

by purification. However, for physical refining of vegetable

oil, water degumming is not sufficient, so degumming

process plays a critical role at physical refining of edible oil.

Traditional degumming processes, including water

degumming, super degumming, TOP degumming, acid

treatment and other ones, cannot guarantee the achievement

of low phosphorus contents required for physical refining,

and they are not always optimally suited for all oil qualities

because of the high content of NHPL (non-hydratable

phospholipids) (Copeland et al. 2005). The latest degumming

process is enzymatic degumming.

Three main degumming techniques (excluding Water

degumming) have been developed: (i) acid degumming; (ii)

acid-basic degumming; and (iii) soft degumming. Other

processes such as dry, membrane and the present enzymatic

degumm Acid degumming processes are generally carried out

at elevated temperatures using high-shear mixers. Phosphoric

acid is often used to make phospholipids hydratable; in this

case, the side reaction (i.e., increased phosphorus content in

the crude oil) can be suppressed either by using citric acid or

by reducing both the acid concentration and the treatment

time. In the super degumming process proposed by Unilever

milder, temperatures are used in a multiple holding-step

process, which makes the process rather complicated.

However, the residual phosphorus content is generally below

30ppm, probably because of the increased phosphate

hydration.

In acid-basic degumming processes, the oil is treated with a

degumming acid and partially neutralized with a NaOH

solution. The metalphospholipids complexes are dissociated

by a strong acid into insoluble metal salts and phospholipids

in their acid form, which are still soluble in oil. By raising the

pH with NaOH, the phospholipids are converted into Na salts,

which are more hydratable and therefore more easily removed

from the oil.

Among the other degumming processes, dry degumming is an

acid degumming process that uses concentrated acid followed

by mixing with bleaching earth. This process is limited to oils

with low phospholipids contents. Membrane degumming

consists of the formation of micelles when the oil rich in

57

Dixit etal./Journal of Engineering, Science and Management Education/Vol. 3, 2010/57-59

* HOD, Department of Chemistry, MANIT, Bhopal. E-mail:savitadixit1@gmail.com

** Research Scholar, Department of Chemistry, MANIT. E-mail:skskanakraj5@gmail.com

phospholipids comes in contact with hexane. The micelles are

separated from the oil by ultrafiltration. However, in practice

this process is costly in terms of capital and operating costs

and has not found industrial application.

In soft degumming, the crude or water-degummed Soft

degumming process involves a complete elimination of

phospholipids by a chelating agent, such as ethylene

diaminetetra acetic acid (EDTA), in the presence of

emulsifying agent. Different kind of crude oils were

degummed by Soft degumming method; the content of

phospholipids in the treated samples of the oils studied was

lowered approximately to 5 mg kg-1. However, the high cost

of EDTA could not allow use this method in industry (Choukri

et al. 2001).

ENZYMATIC DEGUMMING

The goal of this paper is to analyze the effect of enzymatic

degumming on reducing of phospholipids from crude oils

(feedstocks).

The enzymatic degumming process was firstly reported in the

1990s by Roehm and Lurgi Degumming is an important part

of refining process degumming with enzyme is a well-

established Industrial process for the physical refining of

vegetable oils. Principle of enzymatic degumming is to

convert non-hydratable phasphatides (NHP) to hydratable

phasphates.( HP) This facilitates gum removals.This

process is most suitable for crude oils containing relatively

low levels of phosphatides; with phosphatide-rich oil, a prior

water-degumming step is recommended.

There are two types of phospholipids: hydratable

phospholipids (HPL) and non-hydratable phospholipids

(NHPL), and they are removed from oil by the degumming

process. Most of the phospholipids in crude oil (feed stocks)

are hydratable and can be removed by water degumming

(Carelliet al. 1997). NHPL are not hydratable with water, can

not swell and form gels or precipitate from oil (Szydlowska-

Czerniak 2007). Removing of NHPL requires more complex

process like enzymatic degumming Nowadays, two kinds of

enzymes, such as Lecitase 10L (pancreatic phospholipase A2)

and Lecitase Novo (microbial lipase), are used for oil

degumming in the industry (Yang et al. 2006; Bo et al. 2006).

Significant of Lecitase ultra Enzyme is Lecitase ultra enzyme

was able to identify only the phospholipids as substrate and

did not hydrolyze the triglyceride in enzymatic oil

degumming system.

BENEFITS OF ENZYMATIC DEGUMMING

Compared to chemical and physical refining method The

benefits of enzymatic degumming are:-

Higher Yields

A large amount of soapstock is produced by the commonly

used process of refining, with caustic chemicals. Soapstock is

the material produced by the neutralization of fatty acids in

caustic refining, and there are large losses of oil during the

separation of the soapstock. Very little oil is lost in the process

.compared to the other methods due to the little water usage.

The higher the content of soapstock, the higher the oil

losses.The advantage of enzymatic degumming is that no

soapstock is produced, and so there are no losses caused by

soap stock separation. Generally speaking, more than 1%

higher refining yields can be obtained by enzymatic

degumming in comparison with the chemical method.

Zero Phosphorus Content

This has been verified by more than a years experience of

enzymatic degumming at Southseas. They have been able to

lower the phosphorous content in degummed soybean oil to

less than 10 ppm (parts per million), even reaching levels as

low as 3 ppm. This is comparable to the chemical process.

After decolorization, the phosphorus content in the oil is

reduced to virtually zero.

Environmentally Sound

The principle of enzymatic degumming is to convert non-

h y d r a t a b l e p h o s p h o l i p i d s i n t o h y d r o p h i l i c

lysophospholipids. Novozymes, in cooperation with some

scientific institutes, is currently carryingout research into how

to utilize these gum-like by-products. Conventional chemical

oil refining produces a large amount of soapstock, which

needs to be treated before disposal. The first step is acid-

cooking using sulphuric acid. Water also needs to be added in

the proportion of 10-15% of the total amount of crude oil. The

resulting wastewater is acidic and needs to be neutralized

using caustic chemicals. The whole process therefore requires

large amounts of harsh chemicals with a potentially negative

impact on the environment. In contrast, enzymatic

degumming produces minimal wastewater because only 1-

2% water needs to be added for efficient degumming. The

wastewater actually contains lysophospholipids that can be

recycled by mixing degumming water with oil seed meals or

recovered by evaporation. In this way, enzymatic degumming

becomes a refining process without waste products.. A low

dosage of enzyme Lacitase ultra is added only 30g enzyme

per ton oil. Enzymatic degumming is mainly focus on the

development of new enzyme and optimal process for the

reduction of phosphorus content Compared with the

conventional chemical refining process, physical refining is

becoming more and more popular. Enzymatic degumming

with Lecitase Ultra is a special type of physical degumming

that is proving to give good performance and higher oil yields.

CONCLUSION

Enzyme provides significant benefits in the simplified

refining processes utilized during preparation of seed oil for

biodiesel. These benefits include increased yield, reduced

chemical usage, improved operating efficiency, and reduced

waste by allowing a higher percentage of the vegetable oil

feedstock to be recovered and converted to biodiesel.

REFERENCES

1. Nick Fox, Greg Austic piedmont Biofuels LLC, Small

scale degumming technique for oil entering the bio-

diesel market. Comparative study of biodiesel

58

Journal of Engineering, Science and Management Education

production by akkaline transesterification from Low-

valued feeds.

2. Bo Yang. et al, J Am oil chem. Soc (2008) 85, Insight

into the Enzymatic Degumming Process of soybean oil

Acta chica slovaca vol.1.No.1,2008,321-328.

3. Oybek Zufarov et al, Degumming of rapeseed and

sunflower oils. Oil mill Gazetter. Volume 111, July

2005.

4. Enzymatic Degumming Improves oil Refining in

China. . VERENIUM the nature of Energy (purifine

Enzyme)

5. Gazetter, Convert Gums to oil Significantly Increase

oil yields No Increase in Free Fatty Acids, Volume 115,

July 2009.

6. Fangrui Ma, Milford A.Hanna Purifine, PLC:

Industrial application in oil degumming and

refiningOil mill Bioresource Technology, 70 (1999)

1-15

I

59

Journal of Engineering, Science and Management Education

Review of Recently Published Books

FOR KIND ATTENTION OF PUBLISHERS

To develop interest in the subject/area of study and also to promote healthy practices of

reading good books, the Journal of Engineering, Science and Management Education

(ISSN : 0976-0121) regularly publishes Book Review of latest books of various disciplines

and branches of Engineering, Computer Sciences, Pharmacy, Science, Management,

Entrepreneurship Development, Education and other Technical Education related areas.

Publishers and booksellers are requested to send two copies of their latest publications in

these areas for getting them reviewed by different stakeholders and publish in the Journal

for the benefit of teachers, students and other readers . We would acknowledge the receipt of

such books in our journals also. Publishers are requested to send their books to:

Editor

Journal of Engineering, Science and Management Education

National Institute of Technical Teachers Training and Research,

Shamla Hills,

Bhopal-462002

NITTTR, Bhopal

You might also like

- Green Vegetable Oil Processing: Revsied First EditionFrom EverandGreen Vegetable Oil Processing: Revsied First EditionWalter E. FarrRating: 3 out of 5 stars3/5 (1)

- Practical Handbook of Soybean Processing and UtilizationFrom EverandPractical Handbook of Soybean Processing and UtilizationD. R. EricksonRating: 3 out of 5 stars3/5 (3)

- Chapter 3 - Part 2 DegummingDocument34 pagesChapter 3 - Part 2 DegummingAzhan FikriNo ratings yet

- Carboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsFrom EverandCarboxylic Ortho Acid Derivatives: Preparation and Synthetic Applications: Preparation and Synthetic ApplicationsNo ratings yet

- LecithinDocument8 pagesLecithinDiana Martinez StaggNo ratings yet

- Refining and Degumming For OilDocument7 pagesRefining and Degumming For Oiljaymie_llanera100% (1)

- Degumming and Neutralization SolutionsDocument10 pagesDegumming and Neutralization SolutionsKellenchNo ratings yet

- Spices CoconutDocument61 pagesSpices CoconutAnupriya Anu100% (1)

- Green Diesel - A Second Generation BiofuelDocument11 pagesGreen Diesel - A Second Generation BiofuelChatkamol KaewbuddeeNo ratings yet

- Processing of Edible Oil (Palm Oil)Document34 pagesProcessing of Edible Oil (Palm Oil)HannyNo ratings yet

- Polymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3From EverandPolymer Syntheses: Organic Chemistry: A Series of Monographs, Vol. 3No ratings yet

- Lecithin - A Useful Byproduct of Edible Oil ExtractionDocument11 pagesLecithin - A Useful Byproduct of Edible Oil Extractionadda100% (1)

- Clearing The Path in Fats and Oils Refining: Alfa Laval Degumming and Neutralization SolutionsDocument12 pagesClearing The Path in Fats and Oils Refining: Alfa Laval Degumming and Neutralization SolutionsXavi X Qunqi100% (1)

- AOPCR14 - Leon Pablo - Fractionation of Palm Oil and Other Tropical Oils PDFDocument42 pagesAOPCR14 - Leon Pablo - Fractionation of Palm Oil and Other Tropical Oils PDFSergio Leon100% (2)

- Oleochemical Industry Future Through Biotechnology: ReviewDocument10 pagesOleochemical Industry Future Through Biotechnology: ReviewAmanda SartikaNo ratings yet

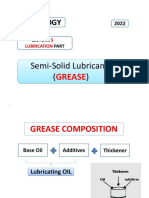

- LEC5 Lubrication 2022Document37 pagesLEC5 Lubrication 2022mohamed hodiriNo ratings yet

- Vakuumdestillation eDocument2 pagesVakuumdestillation ejesusNo ratings yet

- Assignment-2 (UCH850 - 101601010) PDFDocument7 pagesAssignment-2 (UCH850 - 101601010) PDFarpit thukralNo ratings yet

- Octane Boosters - Which Is BestDocument3 pagesOctane Boosters - Which Is Besttaufany99No ratings yet

- Water Reduction and Reuse in The Petroleum IndustryNovemberDocument57 pagesWater Reduction and Reuse in The Petroleum IndustryNovemberwaheed2286No ratings yet

- Recycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsDocument6 pagesRecycling Used Lubricating Oil Using Untreated, Activated and Calcined Clay MethodsTuribio SunnyNo ratings yet

- Styrene-Maleic Anhydride Copolymer Esters As Flow Improvers of Waxy Crude OilDocument9 pagesStyrene-Maleic Anhydride Copolymer Esters As Flow Improvers of Waxy Crude OilMichael MedinaNo ratings yet

- Degumming of OilDocument31 pagesDegumming of OilGOVIND KUMAR100% (2)

- Increasing PVAc Emulsion Polymerisation Productivity An Industrial ApplicationDocument9 pagesIncreasing PVAc Emulsion Polymerisation Productivity An Industrial ApplicationARHNo ratings yet

- Chemical Reactions of OilDocument51 pagesChemical Reactions of OilrosemagnaNo ratings yet

- 25 Hylube ProcessDocument2 pages25 Hylube Processramonchang100% (1)

- Liquid Paraffin Sovyet Urea-DewaxingDocument6 pagesLiquid Paraffin Sovyet Urea-DewaxingAndrek QueckNo ratings yet

- ECM SCM BulletinDocument2 pagesECM SCM BulletinkanNo ratings yet

- DegummingDocument41 pagesDegummingTan Han Kiat100% (2)

- Journal of Cleaner ProductionDocument19 pagesJournal of Cleaner ProductionPutri sinagaNo ratings yet

- Fatty Esters: Che 321 Oleochemical TechnologyDocument26 pagesFatty Esters: Che 321 Oleochemical TechnologyMohd RafiqNo ratings yet

- Soya LecithinDocument10 pagesSoya LecithinPanneerselvam Dhanushkodi100% (1)

- Amorphous Sugar ProductionDocument9 pagesAmorphous Sugar ProductionnghiNo ratings yet

- EODocument26 pagesEOdieego001100% (1)

- Kaleesuwari - Palani - Project Report 2018Document62 pagesKaleesuwari - Palani - Project Report 2018Raja' s100% (1)

- Recovery of Glycerine From Spent Palm Kernel Soap and Palm Oil Soap LyeDocument8 pagesRecovery of Glycerine From Spent Palm Kernel Soap and Palm Oil Soap LyeNadya Larasati KrdNo ratings yet

- Lube Oil ManufacturingDocument7 pagesLube Oil ManufacturingLakshya SaxenaNo ratings yet

- AS ProductCatalogue A4 070801 Reduced PDFDocument20 pagesAS ProductCatalogue A4 070801 Reduced PDFMercurius Setiawan100% (1)

- What Is Lubricant OilDocument5 pagesWhat Is Lubricant OilAicel Mari Castor PortugalNo ratings yet

- Deodorizer DetailsDocument19 pagesDeodorizer DetailsDinesh KumarNo ratings yet

- Determination of Formaldehyde ISO MethodDocument4 pagesDetermination of Formaldehyde ISO MethodAbuSayedNo ratings yet

- Oleochemical - WikipediaDocument3 pagesOleochemical - WikipediaNur Atiqah Ahmad100% (1)

- Waste Oil Re-Refining Syste..Document1 pageWaste Oil Re-Refining Syste..khandoo_amitNo ratings yet

- Improved Cold-Flow AdditivesDocument13 pagesImproved Cold-Flow AdditivesJudianto HasanNo ratings yet

- Oleochem Chap 1Document47 pagesOleochem Chap 1lolahonez100% (4)

- Deterioration of Bleachability of Palm Oil MillDocument5 pagesDeterioration of Bleachability of Palm Oil MillEffy SaifulNo ratings yet

- Purification by Liquid Liquid ExtractionDocument8 pagesPurification by Liquid Liquid ExtractionShivanand YadavNo ratings yet

- BP s25 Wwta-DataDocument20 pagesBP s25 Wwta-DatajnmanivannanNo ratings yet

- TI Keropur 3689 Feb13Document2 pagesTI Keropur 3689 Feb13Alcides MiramiraNo ratings yet

- Single Pot Processing-ColletteDocument16 pagesSingle Pot Processing-ColletterandatagNo ratings yet

- 0273e Fatty Alcohol EsterDocument6 pages0273e Fatty Alcohol Esterhada33100% (1)

- Solvent Extraction Technology For Used Oil TreatmentDocument2 pagesSolvent Extraction Technology For Used Oil TreatmentSanjyog DowerahNo ratings yet

- Contemporary Developments in Corrosion Inhibitors Review of PatentsDocument10 pagesContemporary Developments in Corrosion Inhibitors Review of PatentsMehmet AydinNo ratings yet

- Production of GreaseDocument7 pagesProduction of GreasevisharlanNo ratings yet

- WCAM 2013 Suzhou June 4 - 7Document35 pagesWCAM 2013 Suzhou June 4 - 7eduardoNo ratings yet

- Fractionation of Palm OilDocument10 pagesFractionation of Palm OilShriram PrasadNo ratings yet

- Cambridge Listening TC 4-4Document7 pagesCambridge Listening TC 4-4Khairi Maulida AzhariNo ratings yet

- Eating Is An Important Thing in People (TOEFL 1602)Document4 pagesEating Is An Important Thing in People (TOEFL 1602)Khairi Maulida AzhariNo ratings yet

- 20 Essential English Idioms For ESL StudentsDocument6 pages20 Essential English Idioms For ESL StudentsKhairi Maulida AzhariNo ratings yet

- STR Arco Practice Test 5 SCDocument5 pagesSTR Arco Practice Test 5 SCKhairi Maulida AzhariNo ratings yet

- STR Arco Practice Test 6 TCDocument5 pagesSTR Arco Practice Test 6 TCKhairi Maulida AzhariNo ratings yet

- Lect11 Combustion ProcessDocument28 pagesLect11 Combustion ProcessKhairi Maulida AzhariNo ratings yet

- STR Arco Practice Test 6 TCDocument5 pagesSTR Arco Practice Test 6 TCKhairi Maulida AzhariNo ratings yet

- TOEFL Announcement - Seminar Banda AcehDocument22 pagesTOEFL Announcement - Seminar Banda AcehKhairi Maulida AzhariNo ratings yet

- By The MidDocument14 pagesBy The MidKhairi Maulida AzhariNo ratings yet

- STR Arco Practice Test 5 SCDocument5 pagesSTR Arco Practice Test 5 SCKhairi Maulida AzhariNo ratings yet

- US Gasification DatabaseDocument9 pagesUS Gasification DatabaseKhairi Maulida AzhariNo ratings yet

- Ekspor Minyak Bumi Mentah Menurut Negara Tujuan Utama, 2008-2013Document3 pagesEkspor Minyak Bumi Mentah Menurut Negara Tujuan Utama, 2008-2013Khairi Maulida AzhariNo ratings yet

- Design of Shell & Tube HXDocument40 pagesDesign of Shell & Tube HXprateek_bhoirNo ratings yet

- Coal Liquefaction Technologies-Direct and Indirect Routes: Theo L.K. LeeDocument27 pagesCoal Liquefaction Technologies-Direct and Indirect Routes: Theo L.K. LeeKhairi Maulida AzhariNo ratings yet

- World Non US Gasification DatabaseDocument9 pagesWorld Non US Gasification DatabaseKhairi Maulida AzhariNo ratings yet

- In SeventeenthDocument11 pagesIn SeventeenthKhairi Maulida AzhariNo ratings yet

- 0210Document15 pages0210Khairi Maulida AzhariNo ratings yet

- The Adoption of A Fully CatalyticDocument10 pagesThe Adoption of A Fully CatalyticKhairi Maulida AzhariNo ratings yet

- NPR 6 (3) 232-234Document3 pagesNPR 6 (3) 232-234Khairi Maulida AzhariNo ratings yet

- Empowerment Technology Lesson 4 PDFDocument18 pagesEmpowerment Technology Lesson 4 PDFqueenless eightyoneNo ratings yet

- Scan WV1DB12H4B8018760 20210927 1800Document6 pagesScan WV1DB12H4B8018760 20210927 1800Sergio AlvarezNo ratings yet

- Bombas KMPDocument42 pagesBombas KMPReagrinca Ventas80% (5)

- EEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinDocument6 pagesEEE301 Digital Electronics Lecture 1 Part 3: Dr. A.S.M. MohsinAaa AaaNo ratings yet

- 19 Uco 578Document20 pages19 Uco 578roshan jainNo ratings yet

- Customer Service Metrics CalculatorDocument28 pagesCustomer Service Metrics CalculatorSelma Regita MahardiniNo ratings yet

- HP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningDocument2 pagesHP Scanjet Pro 2500 F1 Flatbed Scanner: Boost Productivity With Fast, Versatile ScanningParesh BabariaNo ratings yet

- DTS 600 GDO Installation ManualDocument12 pagesDTS 600 GDO Installation Manualpiesang007No ratings yet

- Naca Duct RMDocument47 pagesNaca Duct RMGaurav GuptaNo ratings yet

- 3DD5036 Horizontal.2Document6 pages3DD5036 Horizontal.2routerya50% (2)

- INJkon 01 4.0 ManualDocument93 pagesINJkon 01 4.0 ManualJansirani SelvamNo ratings yet

- Configuring Hyper-V: This Lab Contains The Following Exercises and ActivitiesDocument9 pagesConfiguring Hyper-V: This Lab Contains The Following Exercises and ActivitiesMD4733566No ratings yet

- Aicte Internship Approval Pending 1Document7 pagesAicte Internship Approval Pending 1Anisha KumariNo ratings yet

- Gates Crimp Data and Dies Manual BandasDocument138 pagesGates Crimp Data and Dies Manual BandasTOQUES00No ratings yet

- GP 09-04-01Document31 pagesGP 09-04-01Anbarasan Perumal100% (1)

- Chapter Two: General Design ConsiderationsDocument27 pagesChapter Two: General Design ConsiderationsTeddy Ekubay GNo ratings yet

- WT Capability Statement PE 2020Document1 pageWT Capability Statement PE 2020Muhannad SuliemanNo ratings yet

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerNo ratings yet

- EXPERIMENT 1 - Bendo Marjorie P.Document5 pagesEXPERIMENT 1 - Bendo Marjorie P.Bendo Marjorie P.100% (1)

- Chapter 3 - Methods of Circuit Analysis and Circuit TheoremsDocument125 pagesChapter 3 - Methods of Circuit Analysis and Circuit TheoremsNaim NizamNo ratings yet

- Combinational Logic-Part-2 PDFDocument25 pagesCombinational Logic-Part-2 PDFSAKSHI PALIWALNo ratings yet

- Auto CadDocument67 pagesAuto CadkltowerNo ratings yet

- Drsent PT Practice Sba OspfDocument10 pagesDrsent PT Practice Sba OspfEnergyfellowNo ratings yet

- Optimizing Stata For Analysis of Large Data SetsDocument29 pagesOptimizing Stata For Analysis of Large Data SetsTrần Anh TùngNo ratings yet

- Sustainable Development Precautionary PR 2Document12 pagesSustainable Development Precautionary PR 2PramodNo ratings yet

- GE Uno Downlight Backlit BLDocument2 pagesGE Uno Downlight Backlit BLChen KengloonNo ratings yet

- DAY 3 STRESS Ielts NguyenhuyenDocument1 pageDAY 3 STRESS Ielts NguyenhuyenTĩnh HạNo ratings yet

- Cambridge IGCSE ™: Combined ScienceDocument11 pagesCambridge IGCSE ™: Combined ScienceAhmed Jomaa Salem0% (1)

- Biography Worksheet: Name: Gerardo Angeles MartinezDocument1 pageBiography Worksheet: Name: Gerardo Angeles MartinezAlejandro AngelesNo ratings yet

- CUIT 201 Assignment3 March2023Document2 pagesCUIT 201 Assignment3 March2023crybert zinyamaNo ratings yet