Professional Documents

Culture Documents

Cooling Water Demand Calc

Uploaded by

zamijakaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cooling Water Demand Calc

Uploaded by

zamijakaCopyright:

Available Formats

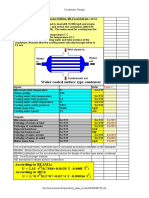

CLIENT : CONTRACTOR :

[A] SUMMARY

Heat duty Water Demand

kW kg/hr

E-170 MS Cooler 198.00 17036 (Note-2)

P-160 A/B Feed Pump - 3000 (Note-4) Used as water sealing

P-100 A/B Fractionation Reflux Pump - 3000 (Note-4) Used as water sealing

P-140 A/B Kerosene Pump - 0 (Note-4) Used as water sealing

P-150 A/B Diesel Pump - 0 (Note-4) Used as water sealing

23036

P-201 A/B NHT Feed Pump - 3000 (Note-4) Used as water sealing

P-203 A/B Stripper Bottom Pump - 3000 (Note-4) Used as water sealing

P-202 A/B Stripper Reflux Pump - 3000 (Note-4) Used as water sealing

P-206 NHT Wash Water Pump - 30 (Note-4) Used as washing water

9030.00

P-302 Caustic Recycle Pump - 0 (Note-4) Used as water sealing

E-302 HP Absorber Feed Cooler 210.00 18069 (Note-4) (Note-3)

P-301 A/B Separator Bottom Pump - 3000 (Note-4) Used as water sealing

P-303 A/B LPG absorber Bottom Pumps - 3000 (Note-4) Used as water sealing

E-305 Reformate Trim Cooler 512.00 44054 (Note-4) (Note-3)

E-304 Stabilizer Overhead Cooler 350.00 30115 (Note-4) (Note-3)

P-304 A/B Stabilizer Reflux and Distillate Pump - 3000 (Note-4) Used as water sealing

P-305 A/B Stabilizer Reboiler Pump - 3000 (Note-4) Used as water sealing

E-309 LPG Product Trim Cooler 12.00 1033 (Note-4) (Note-3)

E-307 Deethanizer Condenser 128.00 11013 (Note-4) (Note-3)

116282.98

P-402 Heavy Napfta Pump - 0 (Note-4) Used as water sealing

P-404 Low Octane Pump - 0 (Note-4) Used as water sealing

P-401 A/B Truck Loading Pump - Light Product - 0 (Note-4) Used as water sealing

P-401 C/D Truck Loading Pump - Heavy Product - 0 (Note-4) Used as water sealing

P-415 Truck Fillling Shed Pump - 0 (Note-4) Used as water sealing

P-413 Make up Water Pump - 0 (Note-4) Used as water sealing

P-405 Cooling Water Circulation Pump - 3000 (Note-4) Used as water sealing

P-407 Booster Pump - 0 (Note-4) Used as water sealing

P-410/420 Electric/Diesel Fire Pump - 3000 (Note-4) Used as water sealing

P-460 Jockey Pump - 3000 (Note-4) Used as water sealing

P-400 Flare KO Drum Pump - 0 (Note-4) Used as water sealing

9000

188819 kg/hr 189 m3/hr

43236 kg/hr 43 m3/hr

Notes :

1 The calculation of cooling water demand is based on differential temperature of 10

o

C across the exchanger.

2 The off-spec cooler is intermittent basis, use during commissioning/ start-up Fractionation Unit.

During commissioning of fractionation there is no requirement of cooling water on the CRU.

3 The cooling water demand for CRU is calculated based on heat duty requirement from Axens (for NHT & CRU Capacity 2500 BOPD)

Assumption temperature differential of 10

o

C across exchanger.

4 Cooling water consumption for pump is given as per Vendor information and be summarised as below and used for mechanical sealing :

Assume that for pump with power more than 5 bkW will utilize sealing water

Cooling Water Demand Power

m

3

/h bkW

P-160 A/B 3 5.20 During normal operation

P-100 A/B 3 8.20 During normal operation

P-140 A/B 0 3.00 During normal operation

P-150 A/B 0 4.10 During normal operation

P-201 A/B 3 48.00 During normal operation

P-203 A/B 3 71.00 During normal operation

P-202 A/B 3 7.00 During normal operation

P-206 0.03 2.20 Intermittent

P-302 0 4.20 During normal operation

P-301 A/B 3 26.00 During normal operation

P-303 A/B 3 20.00 During normal operation

P-304 A/B 3 27.00 During normal operation

P-305 A/B 3 43.00 During normal operation

P-402 0 4.30 During normal operation

P-404 0 4.30 During normal operation

P-401 A/B 0 4.80 During normal operation

P-401 C/D 0 4.80 During normal operation

P-415 0 3.50 During normal operation

P-413 0 1.00 During normal operation

P-405 3 51.00 During normal operation

P-407 0 0.07 During normal operation

P-410/420 3 132.00 Intermittent

P-460 3 13.00 During normal operation

P-400 0 2.13 During normal operation

CFU 5000 BPD

ENGINEERING, PROCUREMENT AND CONSTRUCTION FOR

5,000 BPD CAPACITY CONDENSATE FRACTIONATION

PLANT

COOLING WATER CONSUMPTION CALCULATION

Remarks Description Equipment Tag Number Plant

UTILITY

Total water demand =

Total water demand =

Pump Tag No. Remarks

NHT 2500 BPD

UTILITY

CRU 2500 BPD

Total water demand =

Total water demand =

Total (with 20%margin)

CFU 5000 BPD Area

NHT 2500 BPD Area

Total sealing water (with 20%margin)

CRU 2500 BPD Area

FANKAM REFINERY LTD

P.T. ISTANA KARANG

LAUT

CLIENT : CONTRACTOR :

COOLING WATER CONSUMPTION CALCULATION

[A] CALCULATION FOR EACH COOLER

1 CFU 5000 BPD

E-170 (MS Cooler)

Duty = 198 kW 1.0 kW = 1.0 kW = 3600.0 kJ/hr

712800 kJ/hr

Cp of water = 4.184 kJ/kg

o

C

T = 10

o

C

m = Q

Cp x T

m = 17036 kg/hr

So, the cooling water flowrate of E-170 is = 17036 kg/hr

2 CRU 2500 BPD

E-302 (HP Absorber Feed Cooler)

Duty = 210 kW

756000 kJ/hr

Cp of water = 4.184 kJ/kg

o

C

T = 10

o

C

m = Q

Cp x T

m = 18069 kg/hr

So, the cooling water flowrate of E-302 is = 18069 kg/hr

3 E-304 (HP Stabilizer Overhead Cooler)

Duty = 350 kW

1260000 kJ/hr

Cp of water = 4.184 kJ/kg

o

C

T = 10

o

C

m = Q

Cp x T

m = 30115 kg/hr

So, the cooling water flowrate of E-304 is = 30115 kg/hr

4 E-305 (Reformate Trim Cooler)

Duty = 512 kW

1843200 kJ/hr

Cp of water = 4.184 kJ/kg

o

C

T = 10

o

C

m = Q

Cp x T

m = 44054 kg/hr

So, the cooling water flowrate of E-305 is: 44054 kg/hr

5 E-307 (Deethanizer Condenser)

Duty = 128 kW

460800 kJ/hr

Cp of water = 4.184 kJ/kg

o

C

T = 10

o

C

m = Q

Cp x T

m = 11013 kg/hr

So, the cooling water flowrate of E-307 is = 11013 kg/hr

6 E-309 (LPG Product Trim Cooler)

Duty = 12 kW

43200 kJ/hr

Cp of water = 4.184 kJ/kg

o

C

T = 10

o

C

m = Q

Cp x T

m = 1033 kg/hr

So, the cooling water flowrate of E-309 is = 1033 kg/hr

ENGINEERING, PROCUREMENT AND

CONSTRUCTION FOR 5,000 BPD

CAPACITY CONDENSATE

FRACTIONATION PLANT

Conversion Factor :

P.T. ISTANA

KARANG LAUT

FANKAM REFINERY LTD

Refer to Axen Document for 2500 BPD NHT & CRU will have typical man power as below :

1

1/2

1/4

Then, here is summary of man power demand operating the plant

[A] NHT area

4 employee

2 employee

1 employee

Total : 7 employee (assumed)

[B] CRU area

4 employee

2 employee

1 employee

Total : 7 employee (assumed)

[C] CFU + UTILITY area

4 employee

2 employee

1 employee

1 employee

Total : 8 employee (assumed)

[D] E & I Department

2 employee

1 employee

Total : 3 employee (assumed)

[E] MECHANICAL Department

4 employee

1 employee

Total : 5 employee (assumed)

[F] HSE Department

1 employee

Board/DCS operator per shift :

Supervisor per shift :

Field operator per shift :

Board/DCS operator per shift :

Field operator per shift :

Board/DCS operator per shift :

Supervisor per shift :

Field operator per shift :

Supervisor per shift :

Technician per shift :

Supervisor per shift :

Supervisor per shift :

Field operator per shift :

Board/DCS operator per shift :

Supervisor per shift :

Plant Mng :

Technician per shift :

HSE staff per shift :

1 employee

Total : 2 employee (assumed)

[G] FACILITY ENGINEERING Department

1 employee

1 employee

1 employee

1 employee

1 employee

1 employee

Total : 6 employee (assumed)

[I] SUMMARY

38 employee (assumed)

[J] PLANT AREA

3000

m

2

refer to plant layout

3750

m

2

refer to plant layout

6750

m

2

employee or m

2

liter/m

2

/day liter/person/day

38 employee - 2~5

38 employee - 0~75

38 employee - 5~70

- - -

6750 m2 50 -

188.8

m

3/

hr

831.3 gpm

45

o

C

Total =

Supervisor per shift :

Total of employee :

Engineering Spt :

Engineering Mng :

Process Engineer :

Instrumentation Engineer :

Mechanical Engineer :

Electrical Engineer :

Recirculation Cooling Water Flow :

Hot Water Temperature :

Cleaning process area

-

Drinking water

Sanitation services

Bathing

Emergency shower/eye

wash/face wash

CFU & SRU Area :

NHT & CRU Area :

Total of plant area :

RANGE RECOMMENDED MINIMUM

Total =

PURPOSE

liter/person/day

5

20

15

NUMBER OF

PEOPLE OR

PLANT SURFACE

AREA

-

113

o

F

30

o

C

86

o

F

15

o

C

27

o

F

16.8 gpm

3.8

m

3/

hr

2.0 %

10

0.4

m

3/

hr

1.9 gpm

0.0

m

3/

hr

0.0 gpm

4.2

m

3/

hr

18.7 gpm

4.3

m

3

/hr as permeate

4.8

m

3

/hr as raw water

(if using branckish water)

8.6

m

3

/hr as raw water

(if using sea water)

Blow Down Rate :

Drift + Other Loss Rate :

Temperature Difference :

Evaporation Rate :

Cycle of Concentration :

Cooling Tower Water Make Up Rate :

Cold Water Temperature :

Water Treatment Package Capacity :

PERMEATE

REJECT

RAW WATER

REVERSE

RAW WATER

KATION

EXCHANG

ANION

EXCHANG

4.3

m

3

/hr

19.0 gpm

Duty : 1 x 100%

4.8

m

3

2.1 m as ID

1.4 m as H

Balance Volume : 1.00

8.7

m

3

2.5 m as ID

1.7 m as H

Balance Volume : 1.00

4.4

m

3

2.0 m as ID

1.4 m as H

Balance Volume : 1.00

19.3

m

3/

hr

Raw Water Tank Capacity : residence time is 1 hr

residence time is 1 hr

residence time is 1 hr

Raw Water Tank Capacity :

Raw Water Tank Capacity :

Raw Water Pump Capacity : 15 minutes filling time for raw water tank

Water Treatment Package Capacity :

CLEAN WATER

RAW WATER

TANK

RAW WATER PUMP

34.7

m

3

/hr

17.4

m

3

/hr

Duty : 2 x 100%

8.6

m

3

2.5 m as ID

1.7 m as H

Balance Volume : 1.00

0.05

m

3/

hr

Duty : 2 x 100%

0.07

m

3/

hr

Duty : 2 x 100%

5.00

m

3/

hr

Duty : 1 x 100%

Cleaning Pump Capacity : 10 % tolerance

Distribution Pump Capacity : 10 % tolerance

Distribution Pump Capacity : 10 % tolerance

Raw Water Pump Capacity :

15 minutes filling time for raw water tank

15 minutes filling time for raw water tank

Product Water Tank Capacity : residence time is 2 hr (Note-1)

Note-1 : residence time for product water tank capacity is longer than at raw water tank capacity refer to longer duration

time during regeneration of water treatment package

Raw Water Pump Capacity :

PRODUCT

WATER TANK

CLEANING PUMP

DISTRIBUTION

EMERGENCY SHOWER

188.82

m

3/

hr

Duty : 1 x 100%

188.82

m

3/

hr

Duty : 2 x 100%

43.24

m

3/

hr

Duty : 2 x 100%

43.2

m

3

5.3 m as L

1.5 m as H

Cooling Tower Capacity : 20 % tolerance

Sealing Water Collection Pit Capacity : residence time is 1 hr

Recirculating Water Pump Capacity : 20 % tolerance

Sealing Pit Pump Capacity : 20 % tolerance

COOLING TOWER

RECIRCULATING WATER PUMP

SEALING PIT PUMP

AG

UG

SEALING WATER COLLECTION

5.4 m as W

Continuous Intermittent

liter/day m

3

/hr

190 - Treated water

760 - Treated water

570 - Treated water

- 4.5 Treated water

0.06 m3/hr

1000 - Un - treated water

(assumed that cleaning is conducted daily but partially which density is 1000 liter for 20 m

2

area per day)

0.04 m3/hr

Treated (clean) water

Un - treated (raw) water

TYPE OF WATER

WATER DEMAND

15 minutes filling time for raw water tank

15 minutes filling time for raw water tank

15 minutes filling time for raw water tank

Note-1 : residence time for product water tank capacity is longer than at raw water tank capacity refer to longer duration

time during regeneration of water treatment package

(assumed that cleaning is conducted daily but partially which density is 1000 liter for 20 m

2

area per day)

Raw Water Pump

Recirculatin

g Water

River

Oily Water

from NHT

2500 BPD -

Continuously

Oily Water from

Tank Area - during

hard rain -

Intermittent

Oily Water - if any

- Intermittent

[1] To Condensate-Column

Overhead Vapor Heat

Exchanger

[2] To Flare System

[1] Vapor-Liquid from

Air Cooled Overhead

Condenser

[2] From Fuel Gas

System

Water from Deep

Well

Reverse

Osmosis/Demineralize

d

[1] Reductor

[2] Antiscalant

[3]

Permeate as CT Make

Up Water -

Reject -

Cooling Tower

[assumed : wet type]

CT Blow Down

- Continuously

[1] Antiscalant

[2] Microbiologycal

Treatment

[3] pH Adjusment

Reflux

Accumulator

Reflux back to top of CFU

Oily Water

Collection Pit

Oily Water

from CRU

2500 BPD -

Continuousl

API

Separator

Equalizing Pond

Slop HC

Tank

Oil back to

Condensate Feed

Tank

Effluent

Treatment

Package

Water from Slop HC

Tank - Intermittent

Water from API

Separator -

Continuously

Used chemical after

regeneration -

Raw Water

Tank

Water as cleaning of

plant area -

Heat Exchangers in

Plant

Cold

Hot Water

Sealing Water

Collection Pit

Pumps in Process

Plant Area

Evaporation + Drift

Water purpose for

drinking, sanitation,

Cleaning

Product

Water Tank

Distribution

Emergency Shower Pump

Water purpose for

emergency shower during

Sealing Pit

Pump

Reduce to 390 ppm TDS CW from 400 ppm

Evap = 75 L/s

TDS = 0 mg/L

CW = 5000 L/s

TDS = 400 mg/L

2,000,000 mg/s RCW =

TDS =

Maintain 400 ppm TDS CW

Evap = 75 L/s

TDS = 0 mg/L

CW = 5000 L/s

TDS = 400 mg/L

FILL/SPLASH BAR

OF

COOLING TOWER

FILL/SPLASH BAR

OF

COOLING TOWER

2,000,000 mg/s RCW =

TDS =

BD = 125 L/s

TDS = 406 mg/L

50,761 mg/s

With blowdown :

CW = 5000

TDS = 1,951,239

390

4925 L/s

406 mg/L

2,000,000 mg/s Without Blow Down :

CW = 4925

TDS = 2,000,000

MU = 75

TDS = 2000

MU = 200 L/s

TDS = 10 mg/L TDS = 400.4

2000 mg/s

BD = 11 L/s

TDS = 406 mg/L

4,277 mg/s

With Blow Down :

CW = 5000

TDS = 2,000,000

400

BASIN

OF

COOLING TOWER

BASIN

OF

COOLING TOWER

4925 L/s

406 mg/L

2,000,000 mg/s Without Blow Down :

CW = 4925

TDS = 2,000,000

MU = 75

TDS = 4277

MU = 86 L/s

TDS = 50 mg/L TDS = 400.86

4277 mg/s

L/s

mg/s

mg/L

L/s

mg/s

L/s

mg/s

mg/L

L/s

mg/s

mg/L

L/s

mg/s

L/s

mg/s

mg/L

You might also like

- Basic Cooling Water Management IIDocument32 pagesBasic Cooling Water Management IIDiaa GobranNo ratings yet

- Side Stream Filter For Cooling TowersDocument4 pagesSide Stream Filter For Cooling TowersdkmauryaNo ratings yet

- Calculator GWR Contact Time Calculator v9Document16 pagesCalculator GWR Contact Time Calculator v9HeruNo ratings yet

- Pressure Loss & Performance Fan Calculation: Input Data Edit Comp & Fitg View Graph View Chart & DRWGDocument11 pagesPressure Loss & Performance Fan Calculation: Input Data Edit Comp & Fitg View Graph View Chart & DRWGHerawan HeriNo ratings yet

- Datasheet AcDocument9 pagesDatasheet AcMohan VarkeyNo ratings yet

- BN Eg UE109 Vessel SizingDocument40 pagesBN Eg UE109 Vessel Sizingbadelitamarius100% (1)

- ChillerDocument2 pagesChillersiruslara6491100% (1)

- Thermal Conductivity of FRP CompositesDocument69 pagesThermal Conductivity of FRP Compositesjppmj100% (1)

- Utility Balance (Water Air)Document9 pagesUtility Balance (Water Air)Probonogoya Erawan SastroredjoNo ratings yet

- CIS7:2014Document66 pagesCIS7:2014Ken ChuahNo ratings yet

- PSV-Tag No.: K K CFDocument3 pagesPSV-Tag No.: K K CFoas217No ratings yet

- Mechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundDocument2 pagesMechanical Vapour Recompression System For The Evaporation of Water From Salt Containing Solution: BackgroundjokishNo ratings yet

- Ac Sizing - Duct SizingDocument9 pagesAc Sizing - Duct SizingHarpreet SinghNo ratings yet

- Side Stream FiltrationDocument8 pagesSide Stream FiltrationAhmed WagihNo ratings yet

- Pump Calculations, Pump EquationsDocument3 pagesPump Calculations, Pump EquationsKehinde AdebayoNo ratings yet

- Condenser DesignDocument1 pageCondenser DesignNaqqash SajidNo ratings yet

- Pressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientDocument9 pagesPressure Drop in Pipe Fittings and Valves - Equivalent Length and Resistance CoefficientRapee PuaksungnoenNo ratings yet

- 7.steam Headers and OfftakesDocument6 pages7.steam Headers and Offtakessandeep kumarNo ratings yet

- Spreadsheet Program For Calculating The PH - Coagulant Dosage RelationshipDocument7 pagesSpreadsheet Program For Calculating The PH - Coagulant Dosage RelationshipMohamed TallyNo ratings yet

- Pump Head CalculationDocument1 pagePump Head CalculationMFaiz RHamiraNo ratings yet

- Cooling Tower Basics Calculation Formulas - Cooling Tower EfficiencyDocument9 pagesCooling Tower Basics Calculation Formulas - Cooling Tower EfficiencySantosh JayasavalNo ratings yet

- Line SizingDocument2 pagesLine SizingHarryBouterNo ratings yet

- Recent Advances in Desalination Technologies Final 1Document190 pagesRecent Advances in Desalination Technologies Final 1walidghoneim1970No ratings yet

- Air Stripping TowerDocument5 pagesAir Stripping Towerchristian_ignacioNo ratings yet

- 4 KL Reactor Data SheetDocument4 pages4 KL Reactor Data Sheetpankil patelNo ratings yet

- Condenser DesignDocument2 pagesCondenser DesignRahul ChandrawarNo ratings yet

- Cooling Tower CalculationsDocument10 pagesCooling Tower CalculationsRadu ReluNo ratings yet

- Dokumen - Tips Pipe Insulation THK Calculation 55846188ba816Document9 pagesDokumen - Tips Pipe Insulation THK Calculation 55846188ba816Diksha surekaNo ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Flowrate Calculation For A Draining TankDocument2 pagesFlowrate Calculation For A Draining TankAnonymous bHh1L1No ratings yet

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- Turbidity & TSSDocument3 pagesTurbidity & TSSashim_ju983902No ratings yet

- Gas chlorinator-MTP1Document2 pagesGas chlorinator-MTP1Achira Chanaka PeirisNo ratings yet

- Water Pressure Loss Calculator Colebrook WhiteDocument5 pagesWater Pressure Loss Calculator Colebrook Whitebahus911No ratings yet

- Calc-Plum Fire IrtankDocument6 pagesCalc-Plum Fire IrtankAmro Metwally El HendawyNo ratings yet

- Water DemandDocument9 pagesWater Demandraveena athiNo ratings yet

- Instrument Process Datasheet (IPDS)Document3 pagesInstrument Process Datasheet (IPDS)Vraja KisoriNo ratings yet

- EDI Current CalculationDocument2 pagesEDI Current Calculationjpmaurya77No ratings yet

- 4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsDocument48 pages4 - Best Practices For Sodium Hypochlorite Storage and Metering SystemsZain Ali100% (1)

- TOP For Water SystemDocument35 pagesTOP For Water SystemNaresh PattanaikNo ratings yet

- Pressure Drop in Steam Lines CalculatorDocument7 pagesPressure Drop in Steam Lines CalculatorHiranthaNo ratings yet

- Line Sizing Spreadsheet ComparisonDocument2 pagesLine Sizing Spreadsheet Comparisonaalbuhse0% (1)

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Cartridge Filter Application NotesDocument5 pagesCartridge Filter Application NotesSamik MukherjeeNo ratings yet

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Calculation Pressure DropDocument9 pagesCalculation Pressure DropdasubhaiNo ratings yet

- Principles of Water TreatmentDocument36 pagesPrinciples of Water Treatmentnermeen ahmedNo ratings yet

- Side Stream FiltrationDocument1 pageSide Stream FiltrationAmit ChaudharyNo ratings yet

- BZ Est PD 002 Control Philosophy TestDocument55 pagesBZ Est PD 002 Control Philosophy TestMertoiu GabrielNo ratings yet

- Calculating Expansion TanksDocument4 pagesCalculating Expansion TanksanescuveronicaNo ratings yet

- Expansion Tank SizingDocument1 pageExpansion Tank Sizinghaysam0% (2)

- Steam Orifice TrapsDocument31 pagesSteam Orifice TrapsPhanhai KakaNo ratings yet

- Tower SizingDocument6 pagesTower SizingNagwa MansyNo ratings yet

- Heavy Metal Removal (Mon)Document36 pagesHeavy Metal Removal (Mon)Cyrus HongNo ratings yet

- Loadsheet Demin Water Pump PU-1202 ABDocument13 pagesLoadsheet Demin Water Pump PU-1202 ABGunturMudaAliAkbarNo ratings yet

- Air Receivers Volume CalculationDocument123 pagesAir Receivers Volume CalculationsdgthdtrtretNo ratings yet

- Plumbing Calculation For BMWDocument9 pagesPlumbing Calculation For BMWSenghy MaoNo ratings yet

- Grundfos CHDocument12 pagesGrundfos CHnightmare_hong5818No ratings yet

- Z-8000-BB-4076 - Water Injection SystemDocument158 pagesZ-8000-BB-4076 - Water Injection Systembhuvanchaudhari100% (2)

- Heat Recovery Presentation Rev 130213Document32 pagesHeat Recovery Presentation Rev 130213Budhi SaputraNo ratings yet

- AspenPhysPropModelsV7 2 RefDocument229 pagesAspenPhysPropModelsV7 2 Refferchosb12No ratings yet

- FluidsElectrolytesandAcid BaseBalanceDocument67 pagesFluidsElectrolytesandAcid BaseBalancea8e968c8No ratings yet

- Hemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityDocument49 pagesHemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityzamijakaNo ratings yet

- Kinetics Lecture NotesDocument31 pagesKinetics Lecture NoteschweetomahiNo ratings yet

- Boiler Heat FluxDocument8 pagesBoiler Heat FluxMubarik Ali100% (1)

- Solving Liquid Hammer Problems Using Pipenet Vision and Caesar IiDocument7 pagesSolving Liquid Hammer Problems Using Pipenet Vision and Caesar IiGopal SinghNo ratings yet

- Aspen OLI Standard Getting Started 2006 PDFDocument93 pagesAspen OLI Standard Getting Started 2006 PDFzamijakaNo ratings yet

- AfterCooler Seperators Drains PDFDocument11 pagesAfterCooler Seperators Drains PDFzamijakaNo ratings yet

- PSMDocument62 pagesPSMzamijakaNo ratings yet

- Pipenet Vision Spraysprinkler ModuleDocument48 pagesPipenet Vision Spraysprinkler ModuleElton Situmeang50% (2)

- Activated Sludge: January 2016 7-1 Design Criteria Ch. 7Document17 pagesActivated Sludge: January 2016 7-1 Design Criteria Ch. 7zamijakaNo ratings yet

- Design Stanadards For Waste Water Treatment Plants PDFDocument48 pagesDesign Stanadards For Waste Water Treatment Plants PDFGAMalik0% (1)

- Spray Chapter2 PDFDocument45 pagesSpray Chapter2 PDFzamijakaNo ratings yet

- Design Stanadards For Waste Water Treatment Plants PDFDocument48 pagesDesign Stanadards For Waste Water Treatment Plants PDFGAMalik0% (1)

- Design Aeration1Document64 pagesDesign Aeration1zamijakaNo ratings yet

- MAE 4230/5230: Introduction To CFD: Rajesh BhaskaranDocument26 pagesMAE 4230/5230: Introduction To CFD: Rajesh BhaskaranzamijakaNo ratings yet

- Oil-Water Separator 2Document34 pagesOil-Water Separator 2job_pNo ratings yet

- The Lecture Deals With:: Module 1: Introduction To Finite Difference Method and Fundamentals of CFDDocument10 pagesThe Lecture Deals With:: Module 1: Introduction To Finite Difference Method and Fundamentals of CFDrautrajeshvNo ratings yet

- L.Y.M. Gicquel and O. VermorelDocument8 pagesL.Y.M. Gicquel and O. VermorelzamijakaNo ratings yet

- 14-Vertical Multiphase FlowDocument9 pages14-Vertical Multiphase FlowzamijakaNo ratings yet

- Properties of Hazardous MixturesDocument63 pagesProperties of Hazardous MixtureszamijakaNo ratings yet

- An Intro To Computational Fluid DynamicsDocument21 pagesAn Intro To Computational Fluid DynamicsRorldanNo ratings yet

- HAC MAterialDocument123 pagesHAC MAterialzamijaka100% (2)

- NX3 Training MaterialDocument746 pagesNX3 Training MaterialMATHI KRISHNAN100% (2)

- Alcohol Resistance Foam - NFPA 11 2010 EditionDocument2 pagesAlcohol Resistance Foam - NFPA 11 2010 EditionzamijakaNo ratings yet

- Oil Water Separator SizingDocument6 pagesOil Water Separator Sizingzamijaka100% (2)

- Breather Valve CalcDocument12 pagesBreather Valve CalczamijakaNo ratings yet

- Transient Letter PDFDocument413 pagesTransient Letter PDFzamijakaNo ratings yet

- Alcohol Resistance Foam - NFPA 11 2010 EditionDocument2 pagesAlcohol Resistance Foam - NFPA 11 2010 EditionzamijakaNo ratings yet

- CorrosionDocument2 pagesCorrosionzamijakaNo ratings yet

- Unit-3: Grid FrameworkDocument44 pagesUnit-3: Grid FrameworkMUKESH KUMAR P 2019-2023 CSENo ratings yet

- Proposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Document1 pageProposed Bedroom Enhancement: Jenel C. Tangonan Archi 1A (Stem) Architectural Design Plate No.1Jehan TangonanNo ratings yet

- Part PabrikDocument2 pagesPart PabrikNaldy NaldyNo ratings yet

- Gulika in Vedic AstrologyDocument8 pagesGulika in Vedic AstrologyCatchdgreen100% (1)

- Chapter-01 Introduction: Sonadanga Residential Area (1st Phase)Document17 pagesChapter-01 Introduction: Sonadanga Residential Area (1st Phase)MAFRID HAYDARNo ratings yet

- 10 To 11-ClassDocument111 pages10 To 11-ClassVikaas SagerNo ratings yet

- Hira - For Shot Blasting & Upto 2nd Coat of PaintingDocument15 pagesHira - For Shot Blasting & Upto 2nd Coat of PaintingDhaneswar SwainNo ratings yet

- Better Place - Heaven or HellDocument3 pagesBetter Place - Heaven or HellToto SammyNo ratings yet

- Van Pham Tieng Anh Co Ban Nang CaoDocument18 pagesVan Pham Tieng Anh Co Ban Nang CaoookuroooNo ratings yet

- TP260SR Tier 3 TC002-1037Document1 pageTP260SR Tier 3 TC002-1037Jorge GalarceNo ratings yet

- SuctioningDocument58 pagesSuctioningAyusa PradhanNo ratings yet

- WhittleMIME 413-513 Workshop 1 2014Document26 pagesWhittleMIME 413-513 Workshop 1 2014Diana Catalina Munera0% (1)

- 365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusDocument10 pages365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusER Aditya DasNo ratings yet

- Hibon - SN Ingersoll Rand BlowerDocument7 pagesHibon - SN Ingersoll Rand BlowermarquezsiemNo ratings yet

- Chemistry Lab ReportDocument9 pagesChemistry Lab Reportapi-327824087No ratings yet

- Calibrating Images TutorialDocument14 pagesCalibrating Images TutorialtrujillomadrigalNo ratings yet

- Vocal TractDocument16 pagesVocal TractniroelNo ratings yet

- Methodology of Static Pile Load TestDocument33 pagesMethodology of Static Pile Load Testraju_420034520100% (1)

- Uptime KitsDocument3 pagesUptime KitsMtto Materia PrimaNo ratings yet

- Lake Superior RoadmapDocument2 pagesLake Superior RoadmapWDIV/ClickOnDetroitNo ratings yet

- Details of Placed Students in Academic Session 2022-23Document10 pagesDetails of Placed Students in Academic Session 2022-23Rahul MishraNo ratings yet

- CEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesDocument4 pagesCEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesAngel FaneitezNo ratings yet

- Mardi Gras Recipe Sampler by Mitchell Rosenthal, Author of Cooking My Way Back HomeDocument13 pagesMardi Gras Recipe Sampler by Mitchell Rosenthal, Author of Cooking My Way Back HomeThe Recipe Club100% (1)

- Manual de Servico Samsung Sgh-I677-Eplis-11Document10 pagesManual de Servico Samsung Sgh-I677-Eplis-11Anselmo Antunes0% (1)

- 9500 MPR Wireless TransmissionDocument46 pages9500 MPR Wireless TransmissionMahdi AhmadiNo ratings yet

- ELK-3 550 1HC0000742AFEnDocument20 pagesELK-3 550 1HC0000742AFEnOnur FişekNo ratings yet

- The Poet of NatureDocument31 pagesThe Poet of NaturejulyNo ratings yet

- Vein Type DepositDocument7 pagesVein Type DepositHarisArmadiNo ratings yet

- Economics 526 - Mathematics For Economists: Day(s) Time LocationDocument5 pagesEconomics 526 - Mathematics For Economists: Day(s) Time LocationGaurav JakhuNo ratings yet

- CP Inf4Document357 pagesCP Inf4Rugwed JadhavNo ratings yet