Professional Documents

Culture Documents

CVS 1000L Electro Pneumatic Positioner

Uploaded by

adyro12Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CVS 1000L Electro Pneumatic Positioner

Uploaded by

adyro12Copyright:

Available Formats

Product Manual

CVS 1000L Electro-Pneumatic Linear Positioner

INTRODUCTION

Thank you for choosing the YT-1000L. Each product

is fully inspected after production to offer you the

highest quality. In order to fully utilize the product, we

strongly recommend users to read this manual

carefully.

The manual can be changed or revised without

any prior notice. Any changes in the products

specification, structure and/or any components

may not result in an immediate revised version of

the manual.

The manual should not be duplicated or

reproduced for any purpose without the approval

of CVS Controls Ltd.

MANUFACTURER WARRANTY

- For safety, it is imperative to follow instructions in the

manual. The manufacturer is not liable for any

damages caused by the users negligence.

- The manufacturer is not liable for any damages or

accidents as a result of alterations or modifications

made to the product or parts. If alterations or

modifications are required, please contact

CVS Controls Ltd.

- The manufacturer warrants the product from the

original date of purchase for one (1) year, except as

otherwise stated.

- The manufacturer warranty will be considered void

should the product be subjected to abuse, faulty

installation, lack of reasonable care, repair or service

in any way, that is not contemplated in the

documentation of the product, or if the model or serial

number has been altered, tampered with, defaced, or

removed; damages that occur in shipment, due to the

act of God, failure due to power surge, and cosmetic

damage. Improper or incorrectly performed

maintenance also voids the Limited Warranty.

PRODUCT DESCRIPTION

Main Features and Functions

It is designed for high durability and performance

in high vibration environments.

Proven Durability.

Short and accurate response time.

Simple part change can set a 1/2 Split Range.

Economical due to less air-consumption.

Direct/Reverse action can be easily set.

Simple zero and span adjustment process.

Easy feedback connection.

Operation Logic

As the input signal is increased, the flapper (2) get pushed by the force of the torque-motor (1). As the

gap between the flapper (2) and the nozzle (3) increases, air pressure bleeds from the pilot valve (4)

and the spool (5). As a result, the spool (5) rises and simultaneously opens the seat (7). This allows air

pressure to discharge through port OUT1 to the actuator (10). As the actuators inner pressure increases,

the actuator stem (12) will move, pushing on the feedback lever (13). This movement is transferred to

the cam (14) and pulls on the feedback spring (16). At the point of balanced force exerted by the input

signal and the feedback spring, the gap between the flapper (2) and the nozzle (3) will decrease,

stopping the movement to the actuator.

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

2

CVS Controls Ltd.

Process Management

And Instrumentation

3

CVS Controls Ltd.

Process Management

And Instrumentation

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

CATEGORY

YT - 1000L

Single Double

Input Signal 4 ~ 20mA DC *1

Impedance 25015

Supply Pressure 1.4 ~ 7.0kgf/cm

2

(20 ~ 100psi)

Stroke 10 ~ 150mm *2

Air Connection 1/4 NPT

Gauge Connection 1/8 NPT

Conduit Entry 1/2 NPT

Explosion Proof

CSA: Class 1, Zone 1, Group IIB, T5

Protection IP66

-40 ~ 60C

Linearity 1.0% F.S

Hysteresis 1.0% F.S

Sensitivity 0.2% F.S 0.5% F.S

Repeatability 0.5% F.S

Air Consumption 3LPM (Sup=1.4kgf/cm

2

, 20psi)

Flow Capacity 80LPM (Sup=1.4kgf/cm

2

, 20psi)

Material Aluminum Diecasting

Weight 2.7 kg (6.1 lbs)

Specification

Ambient Operating

Temperature

* 1: For 1/2 Split Control, it can be applied by adjusting zero and span.

* 2: For inquiries regarding strokes under 10mm or above 150mm, please contact CVS Controls Ltd.

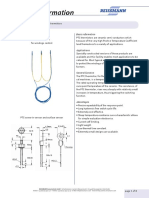

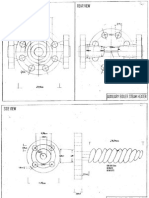

Parts and Assembly

Dimensions

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

4

CVS Controls Ltd.

Process Management

And Instrumentation

ZERO UNIT

TORQUE

MOTOR

BASE BODY

JUNCTION

BOX

COVER

PILOT VALVE

FEEDBACK

SHAFT

SPAN UNIT

VENT UNIT

FEEDBACK

LEVER

224.3

132.3

6

Conduit Entry

PT(NPT) 1/2

PF(G) 1/2 Out 2

NONE

45

1

2

2

1

6

6

.

2-M8x1.25P

45

2

3

2

7

3

2

.

5

4-M8x1.25P

35.5

91.8

8

37.2

8

0

.

2

5

3

3

2

6

.

5

4

3

.

5

Gauge

PT(NPT) 1/8

OUT 1

PT(NPT) 1/4

Supply

PT(NPT) 1/4

INSTALLATION

Safety Warning

When installing the positioner, please ensure you read

and follow the safety instructions.

All input and supply pressure to valve, actuator,

and other related devices must be turned off.

Use the bypass valve or other equipment to avoid

an entire system shut down.

Make sure there is no remaining pressure in the

actuator.

YT-1000L Installation

YT-1000L should be installed on a linear motion valve

such as a globe or gate valve using a spring return

type diaphragm or piston actuator. Before installation,

be sure to check for the following installation

components.

1. YT-1000L main body

2. Feedback lever and lever spring

3. Flange nut (bottom side of YT-1000L)

4. 4 pcs. of hexagon head bolts (M8 X 1.25P)

5. 4 pcs. of M8 plate washer

Installation Steps:

1. A proper bracket must be made in order to attach

the positioner on the actuator yoke. Please consider

the following when making a bracket.

i) Feedback level should be leveled at 50% of the

valve stroke. (Refer to step 7.)

ii) Feedback lever connection bar of actuator clamp

should be installed at the position that the valve stroke

and number, indicated on the feedback, should be

fitted. (Refer to step 8.)

2. Attach YT-1000L to the bracket, which was

produced in the earlier step, by using bolts. (Figure 2)

Please refer to the backside of the product for size of

bolts. The standard size of bolt is M8 X 1.25P.

3. Attach YT-1000L (with bracket) to the actuator yoke.

DO NOT TIGHTEN COMPLETLEY.

4. Connect YT-1000L feedback lever to the actuator

clamp. The gap on the YT-1000L feedback lever is

6.5mm. The connection bar thickness should be less

than 6.3mm. (Figure 3)

5. Connect the air filter regulator to the actuator tem-

porarily. Set supply pressure of the regulator in order

to position the actuator clamp at 50% of the valve

stroke.

(Figure 4 next page)

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

5

CVS Controls Ltd.

Process Management

And Instrumentation

M

a

x

.

6

.3

6.5mm

50

6. Insert connection bar into the YT-1000L feedback

lever. The connection bar should be inserted at the

50% point on the feedback lever, which would help to

reduce hysteresis.

(Figure 5)

7. If the connection bar does not point at the 50%

point, then adjust the bracket or feedback link bar

position. Failure to position at 50% would lower the

linearity of the positioner.

(Figure 6)

8. Check valve stroke. The stroke numbers are

indicated on the feedback lever. Position the

connection bar at the number on the feedback lever

according to the valve stroke. To adjust, move the

bracket or connection bar.

(Figure 7)

Stroke 70mm

NOTE: After installing the YT-1000L, operate the valve

from 0% to 100% stroke by using the air filter regulator

on the actuator. Both at 0% and 100%, the feedback

lever should not touch the lever stopper, which is

located on the backsideof the YT-1000L.

(Figure 8)

If the feedback lever touches the lever stopper,

YT-1000L should be installed further away from the

center of the yoke.

9. After the proper installation, tighten all the bolts on

the bracket, the feedback lever, and the connection

bar.

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

6

CVS Controls Ltd.

Process Management

And Instrumentation

YT-200

40 50 60

50%

9

0

20 30 40 50 60

40 50 60 70 20 30

70

Stroke 30mm

PIPING CONNECTION

NOTE:

To avoid moisture, oil, or dust from entering the

product, please carefully select the supply

pressure compressor.

Supply Pressure Condition

1. Dry air with at least 10C lower than ambient

temperature.

2. Keep away from dusty air. Filter can only sort 5

micron or larger.

3. Avoid oil.

4. Comply with ANSI/ISA-57.3 1975(R1981).

5. Not to be used beyond the range of

1.4 - 7 kgf/cm

2

(20 - 100 Psi).

6. Set air filter regulators supplied pressure 10%

higher than actuators spring range pressure.

Pipe Condition

1. Make sure the inside of the pipe is empty.

2. Do not use pipeline that is squeezed or has holes.

3. To maintain flow rate, use the pipeline that has

more than a 6mm inner diameter.

4. Do not use an extremely long pipeline system. It

may affect flow rate due to the friction inside the

pipeline.

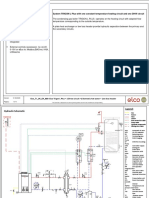

Piping Connection with Actuator

YT-1000 series single acting type is set out to use

OUT1 port. OUT1 port should be connected with the

supply pressure port from the actuator when using

single acting type spring return actuator. For double

acting, the piping connection can be changed due to

the operation direction. Please refer to the following

diagrams when piping.

(Figures 9 - 11)

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

7

CVS Controls Ltd.

Process Management

And Instrumentation

OUT1

OUT1

SUP.

AIR

SUPPLY

YT-200

OUT

AIR

SUPPLY

YT-200

OUT

OUT 1

OUT 2

OUT 2

SUP.

OUT 1

OUT 1

OUT 2

AIR

SUPPLY

AIR

SUPPLY

OUT 2

SUP.

OUT 1

INPUT

SIGNAL

4~20mA

DIRECT

ACTION

REVERSE

ACTION

OUT 2

OUT 1

OUT 2

SUP. OUT 1

POWER CONNECTION

Connection - Connection Port

1. Connection port size is 1/2 NPT.

NOTE: REFER TO THE CANADIAN ELECTRICAL

CODE FOR HAZARDOUS WIRING METHODS.

Connection Power

1. Open the terminal box cover.

2. Locate the poles and connect them properly.

Make sure to fasten the connection.

3. Close the terminal box cover. (Figure15)

ADJUSTMENT

Adjustment - Zero Point

1. Set supply signal at 4mA or 20mA and rotate

adjuster clockwise or counter-clockwise to adjust the

actuators initial point. When setting the initial point,

the specification of valve and system must be taken

into account. Please refer to Figure 17 for

increase/decrease of the zero point.

2. When a single acting actuator with spring is used,

please check if the pressure level, which is indicated

on the positioner, is the same as the supplied pressure

level.

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

8

CVS Controls Ltd.

Process Management

And Instrumentation

Upper Side

Lower Side

Ground

Red (+)

Black (-)

Adjustment - Span

1. After setting zero, supply 20mA or 4mA of signal.

Check the actuators stroke. If the stroke is too low,

adjust the span towards the (+) direction.

If the stroke point is too high, adjust the span towards

the (-) direction. (Figure 18)

2. Changing span points affects the zero point setting,

so the zero setting must be set again. After setting

zero point, confirm the span point. This step must be

repeated until both points are properly set.

3. After setting is completed, tighten lock screw.

Adjustment - A/M Switch (Auto/Manual)

1. A/M switch adjusts the valve operation to automatic

or manual.

2. When produced, YT-1000L is set at A(Automatic).

If user prefers the positioner setting as M(Manual),

the setting can be changed by turning the switch

counter-clockwise. (Figure 19)

3. If it is set as M(Manual), the air pressure will be

supplied to the actuator directly. Always set back to

A(Automatic) after setting change.

4. If OUT2 in single acting actuator or double acting

actuator is used, the A/M switch will not operate.

Adjustment - Seat Adjuster

1. Seat adjustment is set according to the customers

request before the positioner is delivered. Please do

not adjust the seat adjuster.

2. Seat adjuster is always used for double acting

actuators and adjusted when the pressure balance

point must be changed. Please do not touch the seat

adjuster, because it can affect the positioners

performance.

Adjustment - Orifice

1. If the size of the actuator is too small relative to the

flow rate, the positioner can have hunting. In order to

avoid hunting, orifice can be used. There are three

types of orifice.

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

9

CVS Controls Ltd.

Process Management

And Instrumentation

Lock Screw

Lock Screw

Seat Adjuster

Auto Manual Switch

Output

Pressure

Output

Pressure

Output

Pressure

High Pressure Balance

(0.9~1.0Ps) - Normal

Med. Pressure Balance

(0.5Ps) - Normal

Low Pressure Balance

(0.4~0.5Ps) - Normal

Balanced Point

Balanced Point

Balanced Point

Input Pressure

Ps=Supply Pressure

10

2. Remove the o-ring from OUT1 and OUT2 port and

insert appropriate orifice. After inserting orifice, replace

the o-ring. Make sure there are not any substances

entering into the port. (Figure 21)

3. If hunting persists after inserting the orifice, please

contact CVS Controls Ltd. or its appropriate agent.

TROUBLESHOOTING

Positioner does not respond to the input

signal.

1. Check supply pressure level. The lever must be at

least 1.4 kgf/cm

2.

For spring return type actuator, the

supply pressure level has to be larger than the springs

specification.

2. Check if the input signal is properly supplied to the

positioner. The signal should be 4~20mA DC.

3. Check if zero pint or span point is properly set.

4. Check if the positioners nozzle has been blocked.

Also, check if the pressure is supplied to

the positioner and the pressure is being exhausted

through the nozzle. If the nozzle has been blocked by

any substances, please send the product for repair.

5. Check if the feedback lever has been installed

properly.

The pressure of OUT1 reaches exhausting

pressure level and does not decrease.

1. Check A/M Switch. If the switch has been damaged,

replace the switch or pilot relay valve.

2. Check for a gap or damages between the nozzle

and the flapper. If damaged, pleae contact

CVS Controls Ltd.

The pressure is exhausted only by the A/M

switch.

1. Check if the positioners nozzle has been

blocked. Also, check if the pressure is supplied

to the positioner and the pressure is being

exhausted through the nozzle. If the nozzle has been

blocked by any substances, please contact

CVS Controls Ltd.

Linearity is too low

1. Check if the positioner is properly positioned.

Especially if the feedback lever is parallel to the

ground at 50% point.

2. Check if zero and span point have been properly

adjusted. If either one of the values is being adjusted,

another one must be adjusted as well.

3. Check if the supply air pressure level is stable from

the regulator. If the level is unstable, the regulator

must be replaced.

Hysteresis is too low

1. In case of a double acting actuator, check if seat

adjustment has been properly performed. Please

contact CVS for any further inquiries regarding the

seat adjustment.

2. Backlash can ccur when the feedback lever and

lever spring loosen. To avoid backlashing, please

adjust the lever spring.

3. Check if the connection bar to the feedback lever is

tightly fastened.

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

CVS Controls Ltd.

Process Management

And Instrumentation

Orifice Diameter

Orifice

O - Ring (P5)

OUT2

OUT1

Actuator Size Orifice Size Suffix Symbol

90 cm

3

less O 1 1

90 - 180 cm

3

O 2 2

180 cm

3

more none 3

NOTES:

CVS Controls Ltd.

Product Manual: CVS Rack & Pinion Actuator

11

CVS Controls Ltd.

Process Management

And Instrumentation

Head Office

3900 101 Street

Edmonton, Alberta, Canada T6E 0A5

Office: (780) 437-3055

Fax: (780) 436-5461

Calgary Sales Office

205, 2323 32 Avenue NE

Calgary, Alberta, Canada T2E 6Z3

Office: (403) 250-1416

Fax: (403) 291-9487

Website: www.cvs-controls.com E-Mail: info@cvs-controls.com

12

You might also like

- Cutler Hammer. SV9000 AF Drives - Application ManualDocument60 pagesCutler Hammer. SV9000 AF Drives - Application ManualmamasitaricaNo ratings yet

- Eco-Drain 32 Manual en 01-2405-v01Document36 pagesEco-Drain 32 Manual en 01-2405-v01adyro1275% (4)

- Weg Automation cfw-11 Users Manual PDFDocument91 pagesWeg Automation cfw-11 Users Manual PDFCARLOS100% (1)

- DS HZM AUS SITEC Xtend ADG Advanced Digital Governor eDocument6 pagesDS HZM AUS SITEC Xtend ADG Advanced Digital Governor eZeph DugangNo ratings yet

- XEROX Phaser 6700 Service ManualDocument106 pagesXEROX Phaser 6700 Service ManualnobodymagdesignNo ratings yet

- Xerox 3550 MPDocument37 pagesXerox 3550 MPjaag93No ratings yet

- Protech 203 ManualDocument40 pagesProtech 203 ManualLuciano SantanaNo ratings yet

- RMO-RMG Burner ControllerDocument21 pagesRMO-RMG Burner ControllerTiyyagura RoofusreddyNo ratings yet

- Cci PDFDocument4 pagesCci PDFKamlesh DalavadiNo ratings yet

- User's Manual: AD/DA Conversion UnitDocument194 pagesUser's Manual: AD/DA Conversion Unitmgkso706No ratings yet

- BV S - RMS621 PDFDocument87 pagesBV S - RMS621 PDFotipiNo ratings yet

- Product Catalogue For WUHAN HUAYING ELECTRIC POWER TECH&SCIENCE CO.,LTDDocument37 pagesProduct Catalogue For WUHAN HUAYING ELECTRIC POWER TECH&SCIENCE CO.,LTDhayanellNo ratings yet

- Good-Comparison of Friction Models Applied To A Control ValveDocument13 pagesGood-Comparison of Friction Models Applied To A Control ValvesayproNo ratings yet

- Electromagnetic Flowmeter User Manual: SHM "Gives You Trust"Document22 pagesElectromagnetic Flowmeter User Manual: SHM "Gives You Trust"Rudi SetiawanNo ratings yet

- Altivar 31 - ATV31HU40N4ADocument3 pagesAltivar 31 - ATV31HU40N4Avendas.ilimitadasNo ratings yet

- Rotork E370E AWT Range Installation and Maintenance InstructionDocument36 pagesRotork E370E AWT Range Installation and Maintenance Instructionahmedsalehawad100% (1)

- SKIIP09NAC125IT45Document1 pageSKIIP09NAC125IT45Charoon SuriyawichitwongNo ratings yet

- ICAF Comissioning Check List - MPE Catodic ASDocument4 pagesICAF Comissioning Check List - MPE Catodic ASBùi Công Lộc100% (1)

- NW User ManualDocument51 pagesNW User Manualscribdhas2006No ratings yet

- Series 47K Gas Detector: Operation ManualDocument32 pagesSeries 47K Gas Detector: Operation ManualGunawan MSNo ratings yet

- LEC1Document17 pagesLEC1christophermrequintoNo ratings yet

- SI 580E - Sehwa PDFDocument75 pagesSI 580E - Sehwa PDFrudiNo ratings yet

- Radar Level Measurement: Micropilot M / SDocument153 pagesRadar Level Measurement: Micropilot M / SDuong NguyenNo ratings yet

- Data Sheet PTCDocument8 pagesData Sheet PTCjjermanNo ratings yet

- Linc L471 Level Switch Data Sheet PDFDocument4 pagesLinc L471 Level Switch Data Sheet PDFBryan Pacheco TNo ratings yet

- S digital+Governor+Ed1SIDocument8 pagesS digital+Governor+Ed1SIazeemmet9924No ratings yet

- RE50214 Nivometer PDFDocument16 pagesRE50214 Nivometer PDFCaspar Heerkens100% (1)

- PF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListDocument5 pagesPF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListRaul quispe quispeNo ratings yet

- Governor Characteristics ForDocument29 pagesGovernor Characteristics ForCristian MontoyaNo ratings yet

- User Manual ATS22Document85 pagesUser Manual ATS22Vu Tuan AnhNo ratings yet

- 402 Centork Centronik Manual-Instruction Manuals-EnglishDocument66 pages402 Centork Centronik Manual-Instruction Manuals-EnglishEDVRICNo ratings yet

- 42-683.16 Switch MechanismsDocument36 pages42-683.16 Switch MechanismsJonathan AntillonNo ratings yet

- 133R0228 HLP-SK180 Series English Operating Manual V2013-04Document147 pages133R0228 HLP-SK180 Series English Operating Manual V2013-04salesiano05No ratings yet

- IMO Jaguar VXR ManualDocument216 pagesIMO Jaguar VXR ManualKeny PeraltaNo ratings yet

- Samson PRV Mounting and Operating InstructionDocument20 pagesSamson PRV Mounting and Operating InstructionRick CalaguiNo ratings yet

- SUMMIT 8800 HandbookDocument42 pagesSUMMIT 8800 HandbookPero Perić67% (3)

- Coolmay: EX3G PLC/HMI All in One Programming ManualDocument95 pagesCoolmay: EX3G PLC/HMI All in One Programming ManualMarcos Luiz Alves100% (1)

- ML434 V12 D758Document40 pagesML434 V12 D758darkchess76No ratings yet

- Mas711 FLYGTDocument150 pagesMas711 FLYGTRafael GaleasNo ratings yet

- P34x EN AD G54Document48 pagesP34x EN AD G54Adip Chy100% (1)

- Controlado QuemadorDocument19 pagesControlado QuemadorDaniel SrkNo ratings yet

- Sure Servo ManualDocument311 pagesSure Servo ManualTonya LakinNo ratings yet

- The FX Series of Programmable ControllerDocument382 pagesThe FX Series of Programmable ControllerNur Faizah SelamatNo ratings yet

- Original Operating Instructions Flame Scanner: Type: 2.0GT Document: BA 2.0GT EN Rev.3 Date: 21st January 2009Document48 pagesOriginal Operating Instructions Flame Scanner: Type: 2.0GT Document: BA 2.0GT EN Rev.3 Date: 21st January 2009Oscar VillaNo ratings yet

- S7 1200 ManualDocument348 pagesS7 1200 ManualVlada MilosevicNo ratings yet

- Mpu 82510Document16 pagesMpu 82510Muneeb KhanNo ratings yet

- Vortex FMDocument14 pagesVortex FMtirutkkNo ratings yet

- Model S214 Hydrogen Sulfide ManualDocument28 pagesModel S214 Hydrogen Sulfide ManualPeter Malone0% (1)

- Ds Acopos1022 1045 1090Document19 pagesDs Acopos1022 1045 1090Simon DrumsNo ratings yet

- Uipet-03 Manual 1Document6 pagesUipet-03 Manual 1Mohd SharimNo ratings yet

- RSTP & MRPDocument1 pageRSTP & MRPjaysonlkhNo ratings yet

- G-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionDocument12 pagesG-Series Pneumatic and Hydraulic Actuators: The Compact, Lightweight and Reliable SolutionRoo Fa100% (1)

- PLC Instruction ListDocument4 pagesPLC Instruction ListPrestoneKNo ratings yet

- Atv31 (E)Document220 pagesAtv31 (E)Santos Zosimo Ocas GoicocheaNo ratings yet

- Foxboro Eckardt Valve Pos e (HA031644 Issue 3)Document28 pagesFoxboro Eckardt Valve Pos e (HA031644 Issue 3)islamooov0% (1)

- Fieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005From EverandFieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Miguel Leon ChavezNo ratings yet

- Yt-2300 eDocument38 pagesYt-2300 eJohn Philip Rosario SabayleNo ratings yet

- 02X7815C0110 Rev03 09-11Document67 pages02X7815C0110 Rev03 09-11tinpenaNo ratings yet

- Instalación y Mantenimiento de Válvulas RotativasDocument4 pagesInstalación y Mantenimiento de Válvulas RotativasGustavo León CarreraNo ratings yet

- PositionerDocument13 pagesPositionerLeonidas PetrouNo ratings yet

- Actuador de Válvula FlowserveDocument8 pagesActuador de Válvula FlowserveemanuellesanchezNo ratings yet

- Cuptor ElectricDocument6 pagesCuptor Electricadyro12No ratings yet

- 3 TRIGON XL 1 CHP 1 Buffer LLH 1 VT Heating Circuit 2 Gemini CalorifiersDocument1 page3 TRIGON XL 1 CHP 1 Buffer LLH 1 VT Heating Circuit 2 Gemini Calorifiersadyro12No ratings yet

- 2 TRIGON XXL 1 CHP 2 Buffers PHE 1 VT Heating Circuit and 1 DHW Calorifier 1Document1 page2 TRIGON XXL 1 CHP 2 Buffers PHE 1 VT Heating Circuit and 1 DHW Calorifier 1adyro12No ratings yet

- 1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating CircuitsDocument5 pages1 X TRIGON L Plus Boiler LLH 1VT 1CT Heating Circuitsadyro12No ratings yet

- 1 X TRIGON L Plus Boiler LLH 1CT Heating Circuit 1 DHW Circuit With A CalorifierDocument4 pages1 X TRIGON L Plus Boiler LLH 1CT Heating Circuit 1 DHW Circuit With A Calorifieradyro12No ratings yet

- Delta Ia-Plc DVPPCC01 I Tse 20160503Document2 pagesDelta Ia-Plc DVPPCC01 I Tse 20160503adyro12No ratings yet

- Wgo Carlin Burner Manual 1Document29 pagesWgo Carlin Burner Manual 1adyro12No ratings yet

- Servomotoare HoneywellDocument2 pagesServomotoare Honeywelladyro12No ratings yet

- Mon2 Mon2 Mon2 Mon2 Mon2: Izvorne Upute Za RadDocument1 pageMon2 Mon2 Mon2 Mon2 Mon2: Izvorne Upute Za Radadyro12No ratings yet

- Aragaz Nelu - Parts1 PDFDocument22 pagesAragaz Nelu - Parts1 PDFadyro12No ratings yet

- ME ProgramDocument21 pagesME Programadyro12No ratings yet

- MeditationDocument130 pagesMeditationadyro12100% (2)

- Navicat enDocument195 pagesNavicat enadyro12No ratings yet

- AutoimmuneSolution FINALDocument24 pagesAutoimmuneSolution FINALadyro12100% (1)

- Aragaz Nelu Parts1Document10 pagesAragaz Nelu Parts1adyro12No ratings yet

- SIOV Leaded StandarD-1317152Document48 pagesSIOV Leaded StandarD-1317152adyro12No ratings yet

- 6th Gen Intel Core-Intel Xeon FactsheetDocument13 pages6th Gen Intel Core-Intel Xeon FactsheetTracy WilliamsNo ratings yet

- (Ebook - PDF) Lost Books of The Bible - Gospel of Thomas, Scholars' Translation PDFDocument13 pages(Ebook - PDF) Lost Books of The Bible - Gospel of Thomas, Scholars' Translation PDFadyro12No ratings yet

- File 1358196026Document18 pagesFile 1358196026adyro12No ratings yet

- Alev SensörüDocument10 pagesAlev Sensörüadana123No ratings yet

- RCDocument7 pagesRCadyro12No ratings yet

- EHP T 0,5-15L EngDocument2 pagesEHP T 0,5-15L Engadyro12No ratings yet

- File 1358194781Document1 pageFile 1358194781adyro12No ratings yet

- Vgu VG3Document3 pagesVgu VG3adyro12No ratings yet

- A.B Steam HeaterDocument2 pagesA.B Steam Heateradyro12No ratings yet

- EsabwDocument114 pagesEsabwadyro12No ratings yet

- Charging Set VGU Brochure 29072013Document2 pagesCharging Set VGU Brochure 29072013adyro12No ratings yet

- Dsa842000 181Document1 pageDsa842000 181adyro12No ratings yet

- Olaer VguDocument2 pagesOlaer Vguadyro12No ratings yet

- Design and Fabrication of Mechanical Power SteeringDocument18 pagesDesign and Fabrication of Mechanical Power SteeringPriyank AgrawalNo ratings yet

- Operating and Maintenance Instructions: Keystone Figure 79 Pneumatic ActuatorDocument13 pagesOperating and Maintenance Instructions: Keystone Figure 79 Pneumatic ActuatorjorgeNo ratings yet

- Zero Backlash in Rack and Pinion Drive SystemsDocument2 pagesZero Backlash in Rack and Pinion Drive Systemssuresh muthuramanNo ratings yet

- Project Report SynopsisDocument26 pagesProject Report SynopsisKRISHNA YELDINo ratings yet

- Design of Gears V1.0Document6 pagesDesign of Gears V1.0Cassandra DunnNo ratings yet

- Automobile Engg-UNIT-2Document37 pagesAutomobile Engg-UNIT-2Muthuvel MNo ratings yet

- Automatic Blackboard CleanerDocument25 pagesAutomatic Blackboard CleanerAwantika SinghNo ratings yet

- VW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)Document49 pagesVW Golf 5 - Electro-Mechanical Steering Gear, Servicing (Generation II)NPNo ratings yet

- 1 - Inspection Plan-HeaderDocument64 pages1 - Inspection Plan-HeadersapppqmmanloNo ratings yet

- SteeringDocument63 pagesSteeringPratik008No ratings yet

- The Hydraulic System of The Citroën DS Explained.Document47 pagesThe Hydraulic System of The Citroën DS Explained.eliahmeyer100% (1)

- Fenwal Phoenix 3-Way Directional ValveDocument10 pagesFenwal Phoenix 3-Way Directional ValveMohan ArumugavallalNo ratings yet

- Rebuilt at Right 2019Document6 pagesRebuilt at Right 2019RonfermNo ratings yet

- Steering Wheel AlignmentDocument46 pagesSteering Wheel AlignmentANIDHANo ratings yet

- Power Steering in Automobiles: - Presented byDocument21 pagesPower Steering in Automobiles: - Presented byKarthik KardekerNo ratings yet

- Gear Drive, Belt and Chain Drive - Lecture NotesDocument26 pagesGear Drive, Belt and Chain Drive - Lecture NotesVarun KavvampalliNo ratings yet

- Report On White Board Cleaner 2Document4 pagesReport On White Board Cleaner 2Manoz Thapa KajiNo ratings yet

- Whirlpool - 7mlsr7533jt4Document16 pagesWhirlpool - 7mlsr7533jt4AlejandroVCMXNo ratings yet

- Haris2016 2Document5 pagesHaris2016 2VanHieu LuyenNo ratings yet

- Steering System and TyresDocument32 pagesSteering System and TyresFraolNo ratings yet

- Pneumatic & Electric Actuator - Brochure - English - Imperial PDFDocument20 pagesPneumatic & Electric Actuator - Brochure - English - Imperial PDFcandratrikusumaNo ratings yet

- SteeringDocument30 pagesSteeringanisa yuliaNo ratings yet

- Accident Prevention Road.9675654.PowerpointDocument5 pagesAccident Prevention Road.9675654.PowerpointAshu sharmaNo ratings yet

- Fabrication of Automated Pneumatic Board Cleaning SystemDocument7 pagesFabrication of Automated Pneumatic Board Cleaning SystemVignesan MechNo ratings yet

- Gas Leakage Detection and Automatic Control System Using ArduinoDocument5 pagesGas Leakage Detection and Automatic Control System Using ArduinoAjayNo ratings yet

- Robotic Gripper DesignDocument22 pagesRobotic Gripper DesignHaider-e-KararNo ratings yet

- GacDocument20 pagesGacRhyzza Cortez100% (1)

- Automatic Assembly Transfer Systems PDFDocument12 pagesAutomatic Assembly Transfer Systems PDFSwami Anu DevNo ratings yet