Professional Documents

Culture Documents

JL 06 March April 1

Uploaded by

Batisxuta MichaelOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

JL 06 March April 1

Uploaded by

Batisxuta MichaelCopyright:

Available Formats

14 PCI JOURNAL

Effect of Allowable Compressive

Stress at Release on Prestress

Losses and on the Performance

of Precast, Prestressed Concrete

Bridge Girders

W. Micah Hale, Ph.D., P.E.

Assistant Professor

The University of Arkansas

Fayetteville, Ark.

Bruce W. Russell, Ph.D., P.E.

Associate Professor

Oklahoma State University

Stillwater, Okla.

This paper presents the results of a research program that examined

prestress losses in high-performance concrete bridge girders and the

effects, if any, of compressive stresses at release exceeding the current

allowable stress limit of 0.60 f

ci

. Four I-shaped girders were cast

and tested with compressive release stresses ranging from 0.57 f

ci

to

0.82 f

ci

. Two of the four girders were made with air-entrained concrete;

prestress losses were measured on these as well and compared with

losses in girders made with non-air-entrained concrete. The measured

prestress losses were then compared with prestress losses estimated

using: (1) the 2004 American Association of Highway Transportation

Ofcials load-resistant factor design (AASHTO LRFD) Bridge Design

Specications (rened method), (2) the PCI Design Handbook method

described by Zia et al., and (3) the method proposed in the National

Cooperative Highway Research Program (NCHRP) Report 496

(detailed method). Of the three methods to estimate losses, the NCHRP

Report 496s Detailed Method for Estimating Prestress Losses most

accurately predicted the measured losses, followed by the Zia et al.

equations, and then the 2004 AASHTO LRFD equations. A second

objective of the research was to provide additional data measuring

prestress losses for cases where the actual compressive stresses at

release exceed the allowable compressive stresses at release. The

research results support increasing the allowable compressive stress

at release from 0.60 f

ci

to 0.70 f

ci

.

DURABILITY

MarchApril 2006 15

O

ver time, the initial prestressing force that is ap-

plied to a member decreases in magnitude. During

a period of approximately ve years, a prestressed

concrete member may lose as much as 25% of the initial pre-

stress force.

1,2

Elastic shortening, creep, shrinkage, and re-

laxation are the four primary contributors to prestress losses

in pretensioned beams. Of the four, elastic shortening is the

only loss that is not time dependent.

There are many methods used to estimate the effective

prestress force f

se

(prestress force existing after all losses).

The three most widely accepted methods are: (1) the Rened

Estimates of Time Dependent Losses method found in the

2004 American Association of Highway Transportation Of-

cials load-resistant factor design (AASHTO LRFD) Bridge

Design Specications, (2) the PCI Design Handbook method,

described by Zia et. al., and (3) lump sum estimates.

35

A new method is outlined in the recently published Na-

tional Cooperative Highway Research Program (NCHRP)

Report 496, the Detailed Method for Estimating Prestress

Losses.

6

The method in NCHRP Report 496 was developed

specically for girders cast with high-strength concrete.

In the research program reported herein, the prestress loss-

es of four I-shaped girders were measured and compared with

losses calculated using the following methods: the AASHTO

LRFD Bridge Design Specications, the PCI Design Hand-

book, and the recommendations from the NCHRP Report

496.

4

In addition, the beams and their respective prestressing

forces were designed to impose compressive stresses at re-

lease that exceeded the allowable release stresses found

in both AASHTO LRFD Bridge Design Specications

and the ACI Building Code Requirements for Structural

Concrete (ACI 318-05).

7

Currently, AASHTO LRFD and

ACI 318 limit the concrete compressive stresses after release

to 60% of the concretes release strength (0.60 f

ci

).

This research program examines whether compressive

stresses in excess of 0.60 f

ci

will cause a lasting detrimental

effect to the prestressed concrete member, and whether the

allowable compressive stress can be increased beyond its cur-

rent limit of 0.60 f

ci

.

LITERATURE REVIEW

Prestress Losses

Several ongoing research projects have been conducted

recently to determine the accuracy of design equations used

for estimating prestress losses in high-performance concrete

(HPC) bridge girders. Roller et al. examined the prestress

losses in HPC bridge girders.

8

Along with prestress losses,

they also measured the creep and shrinkage of the concrete.

Five girders were cast, but prestress losses were reported for

only Girder BT3 and Girder BT5.

The two girders were subjected to two different curing

regimens. Girder BT3 was steam cured for 24 hours at 140 F

(60 C). Curing continued on Girder BT3 for an additional 10

hours until the forms were removed. Girder BT5 was cured

under a waterproof tarpaulin for 10 hours. The forms were

removed 12 hours after casting.

Prestress losses were measured using internal strain meters.

The research results showed that the AASHTO equations over-

estimated the losses by approximately 50% at 18 months for

Girder BT3. The researchers reported, however, that the steam

curing of Girder BT3 may have affected the prestress losses.

Compared with the early age losses of Girder BT5 (non-steam

cured), those of Girder BT3 were signicantly lower.

The results also showed that the AASHTO equations for

estimating creep and shrinkage may be overly conservative

for high strength concrete. The researchers recommended

further study of the creep and shrinkage behavior of HPC to

determine whether the AASHTO equations can be modied.

Roller et al. again examined the prestress losses, but this

research program examined the losses in a bridge built by the

Louisiana Department of Transportation and Development.

Construction of the bridge was completed in October 1999.

9

The prestress losses were reported for 12 months. The mea-

sured losses were approximately 35% less than the calculated

losses. These results were consistent with the Roller et al.

research.

8

Pessiki et al. examined the effective prestress force in

bridge girders that were 28 years old.

10

Load tests were per-

formed on the girders to determine the decompression load.

Visual observations, strain gauges, and displacement trans-

ducers were used in obtaining the decompression loads. The

average prestress loss for both girders was 18%, compared

with a loss of 33% predicted by the AASHTO equations.

Azizinamini et al.

also examined the available prestress in

an existing bridge girder, investigating the effective prestress

force in a 25-year-old girder.

11

The girder testing showed that

the prestress loss after 25 years of service was 20.7%, which

was less than the 25.7% predicted by the AASHTO equations.

Idriss measured the prestress losses of HPC bridge gird-

ers during construction and during service.

12

Deformation

sensors were placed in the girders to measure the prestress

losses. After ve months of service, the measured losses

were less than the losses predicted by AASHTO and the

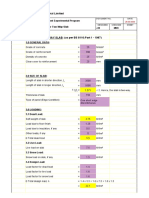

Table 1. Target Release Stresses and Air Content of the Four Girders.

Girder

Targeted Allowable Compressive Stresses ( f

bot

/ f'

ci

)

Targeted Total

Air Content (%)

0.60 0.75 2 6

1 - X X -

2 - X - X

3 X - - X

4 X - X -

16 PCI JOURNAL 16 PCI JOURNAL

PCI Design Handbook. The AASHTO and PCI equations

predicted losses of 28% and 22.6%, respectively, which are

both greater than the measured losses of 11%. The reported

losses were measured after only ve months of service, how-

ever.

In comparison, the calculated values are nal losses for

the entire service life of the beams. Naturally, as the girders

age, they will continue to lose prestress force. The total losses

considering the fullness of service life can be expected to dif-

fer from losses measured at only ve months of age.

The research demonstrates that the AASHTO equations

consistently overestimate the total prestress losses; instead of

arguing for changes to the prediction methods, however, most

researchers agree that more testing needs to be done before

the prediction equations are modied. The NCHRP Report

496 is an outgrowth from efforts of the Transportation Re-

search Board and afliate members to further document and

support alterations to the loss equations.

Allowable Compressive Stress at Release

The AASHTO LRFD Bridge Design Specications, the

ACI 318 Building Code, and the PCI Design Handbook limit

the concrete release stress in compression to 60% of the com-

pressive strength at release (0.60 f

ci

).

3,4,7

The reported pur-

pose of the limit is to control creep deformation and damage

due to micro-cracking.

13

Practitioners suggest, however, that

the limit for compressive stresses is articial and the beam

performance is not reduced by exceeding the compressive

stress limit at release.

In many design cases, strict adherence to the rule effec-

tively increases the need for harping strands or, alternatively,

increases the number and length of debonded strands in the

end regions of girders. In this manner, the current limit for

compressive release stresses effectively increases production

time and creates additional need for steam curing.

14

Unfortunately, little data exist to support increasing the al-

lowable compressive stress at release. Despite the dearth of

published supporting data, many precast, prestressed con-

crete manufacturers, as part of their standard practice, release

strands as long as resulting compressive stresses stay within

75% of the concrete strength. In support of this practice, the

PCI Standard Design Practice reports that no problems have

been reported by allowing compression as high as 0.75 f

ci

.

15

Pang investigated the effects of large compressive stresses

on the hardened properties of concrete.

16

He conducted creep

tests on concrete cylinders loaded at one day of age to 60%,

70%,

and 80% of the concretes one-day breaking strengths.

Cylinders loaded to 70% of breaking strength demonstrated no

adverse effects from the sustained loading at early ages.

One of the cylinders that was loaded to 80% of breaking

strength failed under sustained loading, possibly indicating

that 0.80 f

ci

is too large of a compressive stress. Pang fur-

ther reported that the creep at higher stress levels was not

excessive and was similar to creep experienced by concrete

stressed at lower levels. Pang also concluded that the allow-

able compressive limit could be raised to at least 0.70 f

ci

.

Noppakunwijai et al. conducted an experimental research

program that examined the effects of high release stresses

on precast, prestressed concrete girders.

17

Two girders with

compressive stresses at release of 0.79 f

ci

and 0.84 f

ci

were

cast. The prestress losses of the girders were measured. They

concluded that higher release stresses did not have a negative

impact on the test specimen.

Despite these recent data, the amount of data on the release

stresses of prestressed concrete is very limited, particularly

experimental data on bridge girders. Therefore, the justica-

tion for increasing the allowable compressive stress limits at

release primarily has been based on common practices in the

precast/prestressed concrete industry.

EXPERIMENTAL PROGRAM

Scope

Four prestressed concrete girders were cast with targeted

release stresses of 0.60 f

ci

or 0.75 f

ci

. The girder variables

are described in Table 1. Girders 2 and 3 were cast with air-

entrained concrete, whereas Girders 1 and 4 used non-air-

entrained concrete. Release stresses for Girders 1 and 2 were

targeted at 0.75 f

ci

. Targeted release stresses for Girders 3

and 4 were 60% of the concrete release strength.

The research results provide data to examine whether the

allowable compressive stress should be increased beyond the

current limit. Prestress losses were measured for each girder

for one year.

Materials

Type III cement was used in all mixtures. The coarse ag-

gregate was a crushed limestone from Davis, Okla., with a

nominal maximum size of

3

/

8

in. (9.5 mm). The ne aggre-

Table 2. Mixture Proportions for Girders 1 through 4.

Girders 1 and 4 Girders 2 and 3

Cement (lb/yd

3

) 900 900

Coarse aggregate (lb/yd

3

) 1790 1790

Fine aggregate (lb/yd

3

) 1217 1040

Water (lb/yd

3

) 234 234

Water-cementitions ratio 0.26 0.26

Targeted total air content (%) 2 6

Calculated unit weight (lb/ft

3

) 153.4 146.8

Note: 1 lb/yd

3

= 0.5933 kg/m

3

; 1 lb/ft

3

= 16.02 kg/m

3

.

MarchApril 2006 17

gate was washed river sand from Dover, Okla., conforming

to ASTM C 33. To provide adequate workability, a water re-

ducing admixture and a high-range water reducing admixture

were used.

An air-entraining admixture was used to attain the required

target total air content. The girders contained 0.60-in.-diameter

(15.2 mm), low-relaxation prestressing strand with a modu-

lus of elasticity of 28,500 ksi (197,000 MPa) and Grade 60

(414 MPa) mild bar reinforcement. All prestressing strands

conformed to ASTM A 416.

Mixtures

The mixtures were designed based on workability and

strength, and are listed in Table 2. Girders 1 and 4 were cast

with the same concrete and did not include air entrainment.

The concrete batched for Girders 2 and 3 included air entrain-

ment, with a sand content adjusted to reect the increased

volume of air contained in the concrete.

The only differences between the two mixtures were the

air content and quantity of sand used. Girders 1 and 4 had a

targeted total air content of 2%, whereas Girders 2 and 3 had

a targeted total air content of 6%. Girders 2 and 3 used pro-

portionately, by volume, less sand than Girders 1 and 4.

Girder Design and Fabrication

The dimensions and cross sections of the girders are shown

in Fig. 1, which was used for all four girders. Each girder

had a depth of 24 in. (0.61 m) and was cast to a length of

24 ft (7.3 m). The gross and transformed section properties are

shown in Table 3.

For Girders 1 and 4, the release strength was targeted

at 8000 psi (55 MPa) with a design strength of 13,000 psi

(90 MPa) at 56 days. For Girders 2 and 3, the release strength

was targeted at 6700 psi (46 MPa) with a 56-day design strength

of 11,000 psi (76 MPa). The strand patterns were varied and were

designed to possess an effective prestress of 185 ksi (1250 MPa)

after elastic shortening but before other time-dependent losses.

Ten fully pretensioned prestressing strands were deployed in

each line for casting; some strands, however, were debonded

through the full length of the girders. The full-length debonding

details are depicted in Fig. 1. For example, Girders 1 and 4 were

cast in the same line using the same mixture for both girders.

Girder 1, however, required ten fully bonded prestressing strands

in order to attain the targeted compressive stresses at release,

whereas Girder 4 required only eight strands.

Because Girders 1 and 4 required the same concrete but

different compressive stresses at release, two strands in

Girder 4 were debonded along the full length to effectively re-

duce the compressive stresses after release. Girders 2 and 3 also

required some debonding to achieve the desired compressive

stresses at release. Split plastic sheathing, taped at each end, was

used to ensure debonding.

The girders were cast at Coreslab Structures Inc. of Oklaho-

ma City, Okla. Strands were tensioned individually. The jacking

stresses that are reported in Table 3 were computed from elonga-

tion measurements that were made before and after strand stress-

ing. Elongation measurements were made after the strand chucks

were seated, so the reported jacking stress accounts for seating

losses. For all girders, the jacking stress ranged from approxi-

mately 200 ksi to 204 ksi (1380 MPa to 1410 MPa).

Fig. 1. Shown is the cross section of the girders.

Note: 1 in. = 25.4 mm.

0.6" dia. P/S strand

Table 3. Gross and Transformed Section Properties.

Section Properties Girder 1 Girder 2 Girder 3 Girder 4

A

g

(in.

2

) 163.25 163.25 163.25 163.25

A

tr

(in.

4

) 173.38 175.71 173.40 169.19

A

tr

(in.

4

) 13.75 13.75 13.75 13.75

y

tr

(in.) 13.32 13.20 13.35 13.48

I

g

(in.

4

) 12,399.47 12,399.47 12,399.47 12,399.47

I

tr

(in.

4

) 13,223.48 13,488.50 13,215.80 13,007.65

e

tr

(in.) 6.90 7.20 6.40 7.75

A

ps

(in.

2

) 2.17 1.953 1.736 1.736

Jacking stress after seating loss (ksi) 204.25 202.20 200.76 204.47

Note: 1 in. = 25.4 mm; 1 in.

2

= 645 mm

2

; 1 in.

4

= 416,230 mm

4

; 1 ksi = 6.895 MPa.

18 PCI JOURNAL 18 PCI JOURNAL

Instrumentation

Prestress losses were calculated from measured concrete

surface strains. Concrete strains were measured using de-

tachable mechanical strain (DEMEC) gauges targets. The

DEMEC target points were glued to the concrete surfaces

after the forms were removed but prior to release of the pre-

tensioning force. Strain measurements were initialized prior

to release and were taken again immediately after release.

The difference in readings gives the total concrete strain

within a pair of DEMEC target points.

The DEMEC targets were placed on each side of the bot-

tom bulbs (4.5 in. [113 mm] from the bottom of the gird-

er) and on the top surface of the girders. The targets were

placed 60 in., 68 in., and 76 in. (1.5 m, 1.7 m, and 1.9 m)

from each end and also at 144 in., 152 in., and 160 in. (3.7 m,

3.9 m, and 4.m) from one end.

The distances of 60 in., 68 in., and 76 in. (1.5 m,

1.7 m, and 1.9 m) from the girders ends were chosen because

at this distance the prestress forces are fully effective. Also,

strain readings measured at midspan veried that the prestress

forces at 60 in. (1.5 m) were fully effective. The placement of

the targets along the bulb of the girders is shown in Fig. 2.

By knowing the strains at the top of the girder and also the

strains at 4.5 in. (114 mm) from the bottom, the steel strain

at the center of the steels gravity was then calculated. The

DEMEC dial gauges were accurate in estimating stress levels

within 0.20 ksi (1.34 MPa).

Total measured prestress losses were obtained by measur-

ing the concrete strain between the DEMEC targets and then

multiplying the measured strain by the elastic modulus for

prestressing strands. This method does not account for the

loss in prestress force due to relaxation of the prestressing

strands. The loss due to relaxation is not accompanied by a

corresponding change in strain.

Figures 3 and 4 show the DEMEC target points that are ad-

hered to the concrete. In Fig. 3, DEMEC target points are lo-

cated on the bottom bulb of the beam, 4.5 in. (114 mm) from

the bottom of the cross section. Figure 4 shows the DEMEC

target points that were glued to the top of the cross section.

Strain readings were taken before cutting the prestressing

strands and immediately (within one or two hours) after cut-

ting the strands. Measurements were taken periodically until

the girders were one year old.

RESULTS OF TEST PROGRAM

Fresh and Hardened Concrete Properties

Concrete temperature, slump, fresh air content, unit weight,

and ambient temperature were measured during casting of the

girders. The fresh concrete properties are reported in Table 4.

Girders 1 and 4 were cast with non-air-entrained concrete using

the concrete from the same batch. Girders 2 and 3 were cast

with air-entrained concrete using concrete made from the same

batch.

Table 4 indicates that the air content for Girders 1 and 4

was 2.3%, whereas the air content for Girders 2 and 3 was

6.2%. Unit weights and concrete slump are consistent with

measurements made during trial batching when the mixture

proportions were developed.

Hardened concrete properties are shown in Table 5. Each

reported value of compressive strength (ASTM C 39) is the

average of at least three individual tests. Likewise, the report-

ed elastic moduli (ASTM C 469) are the averages of at least

three individual tests. The compressive strength and modu-

lus of elasticity were measured from 4 in. 8 in. (100 mm

Fig. 2. Pictured are the detachable mechanical strain gauge

target locations along the side of the girder.

Fig. 3. The detachable mechanical strain gauge targets are

shown on the bulb of the girder.

Fig. 4. The detachable mechanical strain gauge targets are

shown on the top of the girder.

DEMEC locations

DEMEC targets

DEMEC targets

MarchApril 2006 19

200 mm) cylinders cast from the same concrete as the gird-

ers and cured alongside the girders.

The data show that the concrete compressive strength in-

creased with time for both sets of girders. Likewise, the elas-

tic modulus also increased over time. Compressive strengths

and the modulus of elasticity are reported for a time frame

spanning 360 days, or approximately one year.

Prestress Losses

Prestress losses over time are reported in Table 6. The

data indicate that Girder 2 had the greatest prestress losses

and Girder 4 had the least losses of the four beams. Concrete

strains were measured at irregular intervals after the beams

were cast and prestress release occurred. Time equals zero on

the day of casting.

The data also demonstrate that prestress losses increased

over time, as expected. Table 4 also includes the locations

where the girders were stored and where prestress losses

were measured: the girders were stored outside at Coreslab

;

inside at Fears Structural Engineering Laboratory

(FSEL);

and outside at FSEL.

**

At each location, the girders were simply supported with

cribbing and bracing located 12 in. (305 mm) from each end.

Typical support cribbing and bracing can be viewed in Fig. 2,

where the girders are stored outside FSEL.

The reported losses are prestress losses corresponding to

the center of gravity (cg) for the prestressing strands. Strain

readings are taken at DEMEC targets located on the sides of

each girders bottom bulb and at the DEMEC targets located

on the very top of each girder. The strain at the cg is then

determined from the strain readings taken from the DEMEC

target points.

The reported losses are then computed from the cg strains

by multiplying the strain by the strands elastic modulus.

Table 6 lists losses at the ends (average of the two ends) and

at the center of the girder.

Table 6 also lists the ratio of maximum compressive stress

at release to compressive strength at release. For Girder 4, the

compressive stress at the extreme bottom ber is computed to

be 4950 psi (34.1 MPa), or 56.9% of the concretes one-day

strength (that is, 8700 psi [60 MPa]).

Likewise, for Girder 1, the computed compressive stress

at the bottom ber is 5650 psi (40 MPa), or 64.9% of the

concretes one-day strength. For Girder 3, the computed

compressive stress at the bottom ber is 4250 psi (29.3 MPa),

or 69.3% of the concretes one-day strength (that is, 6130 psi

[42.3 MPa]). Finally, the highest ratio of stress to strength

occurred on Girder 2, where the maximum compressive stress

at release was 82.1% of the concretes compressive strength.

In engineering practice, the concrete is presumed to be lin-

Table 4. Fresh Concrete Properties for Girders 1 Through 4.

Fresh Concrete Properties Girders 1 and 4 Girders 2 and 3

Fresh concrete temperature (F) 68 60

Slump (in.) 10.0 9.75

Air content (%) 2.3 6.2

Unit weight (lb/ft

3

) 151.1 146.9

Air temperature (F) 36 35

Note: C = (

5

/

9

)(F -32); 1 in. = 25.4 mm; 1 lb/ft

3

= 16.02 kg/m

3

.

Table 5. Hardened Concrete Properties of Girders 1 through 4.

Age of Test Girders 1 and 4 Girders 2 and 3

Average Compressive Strength (psi)*

1 day (at release) 8700 6130

14 days 10,190 7110

28 days 11,060 8390

56 days 12,440 9200

180 days 14,460 10,850

360 days 15,610 11,460

Average Modulus of Elasticity (ksi)*

1 day (at release) 5600 4700

14 days 5800 4900

28 days 6000 5500

56 days 6300 5400

180 days 6800 5500

360 days 6900 6000

* Reported values are the average of three tests.

Note: 1 psi = 0.006895 MPa; 1 ksi = 6.895 MPa.

20 PCI JOURNAL 20 PCI JOURNAL

ear and elastic for stress calculations. In other words, stresses

are proportional to strains and the relationship is dened by

the elastic modulus. Accordingly, the normal engineering

practice to compute the bottom ber precompression stress is

given by the equation:

f

bot

= F

si

1

A

tr

+

e

tr

S

b

( )

tr

where F

si

is the prestress force immediately prior to release

and the cross-section properties are all transformed.

If gross properties are used, then the prestress force used

in the equation must be the prestress force immediately after

prestress release to obtain reasonably accurate estimates for

concrete stress. By using the transformed cross-section prop-

erties, the exact computation of concrete stresses (and elas-

tic shortening losses) can be obtained without iteration.

The equation shown, however, assumes Hookes Lawa

linear relationship between stress and strain. In actual gird-

ers, however, with compressive stresses approaching and ex-

ceeding 60% of the compressive strength of the concrete, the

stress versus strain relationships are decidedly nonlinear.

To account for that nonlinearity, an effective modulus of

elasticity (E

eff

) was determined and employed in the calcula-

tion of transformed section properties. The effective modulus

was obtained from the parabolic stress versus strain relation-

ship widely known as Hognestads model and given by the

expression

18

:

f

c

f

c

'

= 2

r

c

r

o

[

\

|

)

j

~

r

c

r

o

[

\

|

)

j

2

|

|

|

|

|

|

|

|

The effective modulus was obtained from the slope of a

secant drawn from the origin to a point on the stress versus

strain parabola with the corresponding concrete stress re-

quired to provide equilibrium. The effective moduli range

from 500 ksi to 900 ksi (3.4 GPa to 6.2 GPa) less than the

measured modulus.

It should be noted that a lesser concrete modulus will re-

sult in a proportionately greater elastic shortening loss. The

effective modulus (E

eff

) was used to compute stresses in the

concrete after release and the elastic shortening losses.

The losses reported in Table 6 do not include losses due to

steel relaxation. Because relaxation occurs without an accom-

panying change in strain, relaxation cannot be measured with

DEMEC points. Relaxation losses were estimated using the

current AASTHO LRFD equations and are incorporated in the

total loss calculations that are discussed later in the paper.

DISCUSSION OF TEST RESULTS

Fresh Concrete Properties

One goal of the research was to develop HPC that could

easily be used in the local precast concrete industry. The

sponsor of the project, the Oklahoma Department of Trans-

port, was also interested in our ability to produce air-en-

trained HPC suitable for fabrication of bridge girders.

The slumps of the two mixtures were 9.75 in. and 10 in.

(246 mm and 254 mm), indicating that both mixtures had suf-

cient workability to produce the girders. As can be seen in Fig.

5 and 6, the girders had a smooth nish and there were no hon-

eycombed areas.

Girders 1 and 4 had a targeted air content of 2%, and Girders 2

and 3 had a targeted air content of 6%. One mixture was batched

for Girders 1 and 4, and another mixture was batched for Gird-

ers 2 and 3. The measured total air contents for both mixtures

were within 0.50% of the targeted air contents indicating our

ability to produce concrete within specied air content ranges.

Table 6. Measured Prestress Losses.

Average Measured Prestress Losses (ksi)

*

Beam

Age

(Days)

Temperature

(F)

Girder 1 Girder 2 Girder 3 Girder 4

f

bot

/ f'

c

= 64.9% f

bot

/ f'

c

= 82.1% f

bot

/ f'

c

= 69.3% f

bot

/ f'

c

= 56.9%

Ends

Center Ends

Center Ends

Center Ends

Center

1 (at

release)

36

27.8 27.8 32.8 33.6 24.4 23.4 25.6 24.8

16 40

39.6 40.0 51.2 52.0 41.2 40.2 36.6 35.61

29 65

40.2 40.2 53.8 55.4 42.2 41.4 37.2 36.8

43 65

46.0 46.0 61.8 62.4 49.2 48.6 42.8 42.6

60 51

44.6 44.2 59.2 60.2 46.4 46.0 40.6 40.8

84 63

46.2 46.0 63.0 64.2 49.6 48.6 43.2 43.8

120 71

48.0 47.6 64.4 66.0 50.6 50.6 44.6 45.2

180 90

52.4 49.8 69.0 71.6 56.4 55.0 48.4 49.4

360 63

56.8 53.4 72.0 74.0 59.2 58.4 51.6 51.8

*

Measured losses do not include relaxation losses.

Cured outside at Coreslab Structures.

Cured inside at Fears Structural Engineering Laboratory.

**

Cured outside at Fears Structural Engineering Laboratory.

End losses are the average losses from both ends of the girder.

Note: C = (

5

/

9

)(F -32); 1 ksi = 6.895 MPa.

MarchApril 2006 21

Note that air content and unit weight were measured in the

plant prior to placing concrete in the forms. During beam

casting, one batch of concrete was discarded due to an exces-

sively high air content of 9%.

The unit weights of the mixtures were inversely correlated

to the air contents of the mixtures. The mixture for Girders 1

and 4 had a higher unit weight than the mixture for Girders

2 and 3, as expected. The measured unit weights for all mix-

tures were within 1.5% of the calculated unit weight. The dif-

ferences between the measured and calculated unit weights

were considered acceptable.

Hardened Concrete Properties

The strength gain of the two mixtures cast at Coreslab is

shown in Fig. 7. The difference between the two mixtures is

the total air content within them. The rate of strength gain for

the two mixtures is almost identical, but for each age tested,

the mixture with additional entrained air had a reduced com-

pressive strength by roughly 30%.

Prestress Losses

The measured total losses and the predicted total losses

are shown in Table 7, which also shows the estimated losses

using the three different methods discussed. The AASHTO

method and the PCI Design Handbook method (Zia et al.

equations) both overestimate the total losses, whereas the

recommendations from the NCHRP Report 496 slightly

underestimate total losses. The measured losses in Table 7

include the estimates for relaxation losses and for the self-

weight of the girder where necessary. Relaxation losses were

calculated using the AASHTO equation (rened method) and

ranged from 2.0 ksi to 2.8 ksi (13.8 MPa to 19.3 MPa).

3

Due

to girder size, the compensation for girder self-weight ranged

from 0.05 ksi to 0.09 ksi (0.34 MPa to 0.62 MPa).

Table 8 shows the ratio of predicted losses to measured

losses for each set of prediction equations. Again, the 2004

AASHTO (rened) and Zia et al. equations overestimate

losses.

3,5

For all the girders (at both midspan and ends), the

AASHTO equations overestimate the prestress losses by

18%. The Zia et al. equations also overestimate the losses by

an average of 13%.

5

On the other hand, the detailed method from NCHRP Re-

port 496 predicted losses that were more accurate than the

other two methods.

5

The average difference between the mea-

sured losses and predicted losses was 6%.

In comparing the measured total losses with the predicted

losses from the various methods, it should be noted that total

losses are estimated over the whole life of the prestressed

concrete member, which may easily be several decades. On

the other hand, measured losses are reported only for one

year. Equations from the ACI 209 report indicate that shrink-

age may increase 10% from one year to fty years and creep

strains may increase as much as 25% after one year of age.

Therefore, one must conclude that the measured losses are

not the whole loss that will be experienced by the member.

Table 9 lists the measured prestress losses at one day versus

the estimated experienced elastic shortening losses from the

three methods. The AASHTO and NCHRP methods employ

transformed cross-section properties and the exact method

to compute elastic shortening so these two methods agree.

The PCI Design Handbook contains an approximate method

that varies somewhat from the other two methods.

For all four girders, the difference between the prestress

loss measured at one day and the predicted elastic shortening

Fig. 6. The girder is photographed with a smooth nish.

0 50 100 150 200 250 300 350 400

2.3 % Air

6.2 % Air

18,000

16,000

14,000

12,000

10,000

8000

6000

4000

2000

0

Age (Days)

Fig. 7. Pictured is the strength gain for the Coreslab mixtures.

Note: 1000 psi = 6.895 MPa.

Fig. 5. The photograph of the girder shows no honeycombing.

C

o

m

p

r

e

s

s

i

o

n

S

t

r

e

n

g

t

h

(

p

s

i

)

22 PCI JOURNAL 22 PCI JOURNAL

loss was 4.6 ksi (32 MPa). The differences are accounted for

in that the measured losses include the effects of both shrink-

age and creep, whereas the computed elastic shortening loss

is a theoretical calculation based solely on elastic material

properties.

Figure 8 shows the increase in prestress losses over time.

Inspection of the gure reveals two interesting points. One

point is that as time increases, the total prestress loss also in-

creases. The charts, however, clearly show that the losses tend

to level out as time increases beyond 180 days. The second

point, therefore, is that the higher the compressive stress at

release, as expressed as a percentage of the one-day compres-

sive strength, the larger the total amount of prestress losses.

The gure clearly shows the progression where Girder

4, stressed to 56.9% of its one-day strength, has the lowest

amount of total loss, whereas Girder 2, stressed to 82.1% of

its one-day compressive strength, experiences much larger

prestress losses.

Release Stresses and Comparison to Allowable Stresses

Table 10 shows the transformed cross-sectional properties

for the girders based on the effective elastic modulus for con-

crete, as discussed. For each case, the maximum compressive

stress occurs at the bottom ber. Maximum stresses, immedi-

ately after release, are reported both in absolute terms and also

as a percentage of each girders one-day compressive strength.

In essence, the table shows that the maximum release stress

ranges from a low of 56.9%, which is an allowable stress

within the current code, to 82.1%. The maximum compres-

sive stress in three of the four girders exceeds the allowable

stress given in the AASHTO LRFD and ACI 318.

The targeted maximum release stresses of 0.60 f

ci

and

0.75 f

ci

were not attained because the one-day compressive

strengths for Girders 1 and 4 were higher than targeted and

the one-day compressive strengths for Girders 2 and 3 were

lower than targeted. The release strengths for Girders 1 and

4 were targeted at 8000 psi (55 MPa) based on trial batching

in the laboratory and at Coreslab. The compressive strengths

of Girders 1 and 4, however, were 8700 psi (60 MPa) at one

day.

Girder 1 was designed to have an allowable compressive

stress at release of 0.75 f

ci

, but due to the unexpectedly high

one-day compressive strength, this value was only 0.65 f

ci

.

Similarly, Girder 4 was designed to have allowable com-

pressive stress of 0.60 f

ci

, but this value was only 0.57 f

ci

.

The 700 psi (4.8 MPa) increase in strength beyond targeted

Table 7. Total Prestress Losses.

Girders Location

Total Prestress Losses (ksi)

Measured

(1 year)

*

AASHTO

2004 Zia et al. NCHRP

Report 496

1

Ends 58.9 81.7 72.4 55.3

Center 55.5 81.3 72.1 55.1

2

Ends 74.0 80.7 82.9 71.1

Center 76.1 80.3 82.4 70.7

3

Ends 61.2 67.1 65.8 58.9

Center 60.6 66.7 65.4 58.6

4

Ends 54.6 74.3 65.0 50.5

Center 54.5 73.9 64.7 50.2

*

Measured losses include relaxation losses and compensation for self-weight.

AASHTO: American Association of Highway Transportation Ofcials.

NCHRP: National Cooperative Highway Research Program.

Note: 1 ksi = 6.895 MPa.

Table 8. Ratio of Predicted to Measured Losses.

Girders Location

Ratio of Measured to Predicted Losses

AASHTO

*

2004 Zia et al. NCHRP

Report 496

1

Ends 0.72 0.81 1.07

Center 0.68 0.77 1.01

2

Ends 0.92 0.89 1.04

Center 0.95 0.92 1.08

3

Ends 0.93 0.94 1.05

Center 0.92 0.94 1.05

4

Ends 0.73 0.84 1.08

Center 0.74 0.84 1.09

Average 0.82 0.87 1.06

*

AASHTO: American Association of Highway Transportation Ofcials.|

NCHRP: National Cooperative Highway Research Program.

Note: 1 ksi = 6.895 MPa.

MarchApril 2006 23

strength was due to the steam curing used by Coreslab.

Likewise, the one-day compressive strengths of Girders 2

and 3 were lower than targeted. This resulted in higher com-

pressive stresses at release. Girder 2 was designed to have an

allowable compressive stress at release of 0.75 f

ci

. Because

the compressive strength of 6130 psi (42.3 MPa) was lower

than targeted, the maximum compressive stress at release was

0.82 f

ci

.

Similarly, Girder 3 was designed to have an allowable com-

pressive stress at release of 0.60 f

ci

, but the stress was 0.69

f

ci

. The low one-day compressive strength resulted from ex-

tremely low ambient temperatures after nightfall, which pre-

vented the steam in the prestressing beds from attaining its

normal temperature.

As noted above, three of the four girders had allowable

compressive stresses at release greater than 0.60 f

ci

. In all

cases, it is worth noting that the prestressing forces were

adequately transferred to the concrete (demonstrated by the

strain measurements that occurred within the end regions of

each girder) and no external signs of distress were visible.

Although the high release stresses did not appear to affect

the girder performance otherwise, higher prestress losses re-

sult from higher compressive stresses at release. This result

is in line with expectations. The total measured losses for the

four girders and the allowable compressive stress at release

are shown in Table 6. As shown in Fig. 8, the girders with the

greatest release stress had the most prestress loss.

The effects of large compressive release stresses are ex-

amined in Table 11. In the rst column, Table 11 lists the

maximum release stress as a percentage of the one-day com-

pressive strength of the concrete. As noted in Table 11 and

elsewhere, the compressive stresses ranged from 56.9% to

82.1% of release strength. The second column in Table 11

lists the measured prestress losses, which are the average

losses for the ends at each girder. Total losses ranged from a

low of 51.6 ksi (356 MPa) to a high of 72.0 ksi (496 MPa).

The third column of Table 11 lists the jacking stress (ksi) of

the strand immediately prior to release. The reported jacking

stress is based on the elongation measurements made during

stressing of the strands and includes the seating losses. The

jacking stresses listed in the third column, however, do not

include relaxation losses that occur in the 24 hours between

tensioning and release. The fourth column of Table 11 ex-

presses the measured losses as a percentage of the jacking

stresses. In other words, the 27.8% loss reported for Girder 1

is obtained by dividing the total measured loss in the second

column by the jacking stress in the third column.

The table clearly shows that increases in the maximum re-

lease stress result in increased prestress losses. The question

becomes, in the cases where the allowable stress provisions of

the specications were exceededas was the case for Gird-

ers 1, 2, and 3whether the losses indicate that a damaged

condition exists in the concrete due to excessive compressive

stresses at release.

The fth column addresses that issue by listing the ratio of

prestress losses divided by the release stress. Both losses in

the fourth column and the release stress in the rst column

are expressed as a percentage. According to the information

in the fth column, the ratio of losses to release stresses is

approximately the same for all four beams regardless of the

amount of compressive release stresses. This occurs over a

fairly broad range of values ranging from Girder 4, which

has release stresses within the allowable limits, to Girder 2,

with a release stress that is 82% of the compressive strength

of the concrete.

Table 9. Elastic Shortening Losses.

Girders Location

Prestress Losses Due to Elastic Shortening (ksi)

1

Measured AASHTO Predicted Zia et al. NCHRP 496

1

Ends

2

27.8 23.3 20.9 23.3

Center 27.8 23.2 20.8 23.2

2

Ends 32.8 27.4 24.6 27.4

Center 33.6 27.2 24.4 27.2

3

Ends 24.4 20.7 18.7 20.7

Center 23.4 20.6 18.6 20.6

4

Ends 25.6 20.4 18.4 20.4

Center 24.8 20.3 18.2 20.3

Average elastic shortening 27.5 22.9 20.6 22.9

Note: 1 ksi = 6.895 MPa.

0

10

20

30

40

50

60

70

80

0 50 100 150 200 250 300 350 400

Girde r 2 , f

b o t

/f

c i

= 8 2.1 %

Girde r 3, f

bo t

/f

c i

= 6 9 .3 %

G irde r 1 , f

bo t

/f

c i

= 6 4 .9 %

Girde r 4 , f

bo t

/f

c i

= 5 6 .9 %

Age (Days)

Fig. 8. Shown are the measured losses for the girders at ends.

24 PCI JOURNAL 24 PCI JOURNAL

It is the authors view that these data provide strong evi-

dence that the allowable release strength of 0.60 f

ci

can be

relaxed to allow higher compressive stresses to be imposed

on the concrete immediately after release.

CONCLUSION

Both the AASHTO LRFD Specications and the ACI

Building Codes currently limit the compressive stress at re-

lease stress to 0.60 f

ci

. In this research study, three of four pre-

tensioned concrete girders had release compressive stresses

that exceeded the allowable limit. Maximum release stresses

ranged from 56% to 82% of the concretes one-day compres-

sive strength. In all beams, the high compressive stresses

did not cause any adverse effects to the prestressed concrete

member. Furthermore, the losses that were measured for one

year were in line with expectations and were reasonably pre-

dicted by current methods.

Concrete used in this research included both air-entrained

concrete and non-air-entrained concrete. The performance

of the concrete, as measured by prestress losses, was not af-

fected by the inclusion of air entrainment. In other words, the

girders made with air-entrained concrete did not exhibit ex-

traordinary levels of prestress losses. Furthermore, the losses

measured in air-entrained concrete members were predicted

with the same level of accuracy as were the losses measured

in the non-air-entrained concrete.

The 2004 AASHTO (rened method) prediction equations

overestimated the total losses for all girders, predicting losses

that were approximately 50% greater than the measured loss-

es for Girders 1 and 4. For all girders, the Zia et al. equations

estimated losses that were more accurate than the AASHTO

equations.

The NCHRP Report 496 loss equations (detailed method),

which were developed specically for high-strength con-

crete, predicted losses that were on average within 6% of the

measured losses.

At the release stress of 0.82 f

ci

, all methods (AASHTO,

Zia et al., and NCHRP Report 496) predicted losses that were

within 10% of the measured losses. Increasing the allowable

compressive stress at release resulted in greater prestress

losses. For all girders, the prestress losses increased with

higher release stresses.

RECOMMENDATIONS

Based on the results of this research, it is recommended

that the allowable stress limit for compression stresses imme-

diately after release be increased from 0.60 f

ci

to 0.70 f

ci

.

ACKNOWLEDGMENT

The authors express their deep gratitude to Coreslab Struc-

tures Inc., Oklahoma City, for donating the materials and

fabricating the four prestressed concrete girders at its plant.

The authors also want to thank Oklahoma State University

in Stillwater for the use of its facilities and in particular to

express their appreciation to the personnel of the Fears Struc-

tural Engineering Laboratory for their care and diligence in

carrying out the testing.

Table 10. Girder Properties and Allowable Compressive Stresses.

Parameter Girder 1 Girder 2 Girder 3 Girder 4

f

ci

(psi) 8700 6130 6130 8700

E

eff

(ksi) 5022 3862 4159 5122

A

tr

(in.

4

) 173.38 175.71 173.40 169.19

y

tr

(in.) 13.32 13.20 13.35 13.48

I

tr

(in.

4

) 13,223.68 13,488.50 13,215.80 13,007.65

e

tr

(in.) 6.90 7.20 6.40 7.75

Jacking stress (ksi) 204.25 202.20 2000.76 204.47

f

bot

(ksi) 5.646 5.030 4.245 4.949

f

bot

/ f'

c

(%) 64.9 82.1 69.3 56.9

Note: 1 in. = 25.4 mm; 1 in.

2

= 645 mm

2

; 1 in.

4

= 416,230 mm

4

; 1 psi = 0.006895 MPa; 1 ksi = 6.895 MPa.

Table 11. Effects of Large Compressive Stresses at Release.

Girders

1 2 3 4 5

Release Stress

(%)

Measured Pre-

stress Loss (ksi)

Jacking Stress

(ksi)

(2)/(3) (%) (4)/(1)

1 64.9 56.8 204.25 27.8 0.43

2 82.1 72.0 202.20 35.6 0.43

3 69.3 59.2 200.76 29.5 0.43

4 56.9 51.6 204.47 25.2 0.44

Note: 1 ksi = 6.895 MPa.

MarchApril 2006 25

APPENDIX: NOTATION

A

g

= gross area of concrete section

A

tr

= transformed area of concrete section

I

g

= moment of inertia of gross concrete section

I

tr

= moment of inertia of transformed concrete section

y

g

= distance from bottom ber to center of gravity of gross

section

y

tr

= distance from bottom ber to center of gravity of transformed

section

e

tr

= eccentricity of prestress force of transformed section

f

ci

= concrete compressive strength at release

A

ps

= area of prestressed reinforcement

E

eff

= effective modulus of elasticity at release

f

bot

= bottom ber concrete stress at release

S

tr

= bottom ber section modulus

REFERENCES

1. Nawy, E. G., 1996, Prestressed Concrete, A Fundamental

Approach, Prentice-Hall, Upper Saddle River, NJ.

2. Lin, T. Y. and Burns, N. H., 1981, Design of Prestressed

Concrete Structures, John Wiley & Sons, New York, NY.

3. AASHTO, 2004, AASHTO LRFD Bridge Design Specications,

Third Edition, American Association of State Highway and

Transportation Ofcials, Washington, DC.

4. Precast/Prestressed Concrete Institute, 1999, PCI Design

HandbookPrecast and Prestressed Concrete, Fifth Edition,

Chicago, IL.

5. Zia, P., Preston, H., Scott, N., and Workman, E., June 1979,

Estimating Prestress Losses, Concrete International, V. 1, No.

6, pp. 3238.

6. NCHRP, 2003, Prestress Losses in Pretensioned High-Strength

Concrete Bridge Girders, NCHRP Report 496, Transportation

Research Board, Washington, DC.

7. ACI Committee 318, 2005, Building Code Requirements for

Structural Concrete (ACI 318-05) and Commentary (ACI

318R-05), American Concrete Institute, Farmington Hills, MI.

8. Roller, J., Russell, H., Bruce, R., and Martin, B., November

December 1995, Long Term Performance of Prestressed,

Pretensioned High Strength Concrete Bridge Girders, PCI

Journal, V. 40, No. 6, pp. 4859.

9. Roller, J., Hassett, B., and Bruce, R., September 2527, 2000,

Evaluation of High Performance Concrete in Louisianas First

HPC Bridge, PCI/FHWA/FIB International Symposium on

High Performance Concrete, Orlando, FL, pp. 707718.

10. Pessiki, S., Kaczinski, M., and Wescott, H., November

December 1996, Evaluation of Effective Prestress Force in 28-

Year-Old Prestressed Concrete Bridge Beams, PCI Journal, V.

41, No. 6, pp. 7889.

11. Azizinamini, A., Keeler, B., Rohde, J., and Mehrabi, A., May

June 1996, Application of a New Nondestructive Evaluation

Technique to a 25-Year-Old Prestressed Concrete Girder, PCI

Journal, V. 41, No. 3, pp. 8295.

12. Idriss, R. L., July 2001, Monitoring of a High Performance

Prestressed Concrete Bridge with Embedded Optical Fiber

Sensors During Fabrication, Construction, and Service,

Structural Faults and Repair Conference, London, England.

13. Huo, X., Savage, J., and Tadros, M., MarchApril 1995,

Reexamination of Service Load Limit Compressive Stress in

Prestressed Concrete Members, ACI Structural Journal, V. 92,

No. 2, pp. 199210.

14. Huo, X., and Tadros, M., January-February 1997, Allowable

Compressive Strength of Concrete at Prestress Release, Open

Forum Section, PCI Journal, V. 42, No. 1, pp. 9599.

15. PCI Technical Activities Council and PCI Committee on

Building Code, JulyAugust 1996, PCI Standard Design

Practice, PCI Journal, V. 41, No. 4, pp. 3143.

16. Pang, J. P., 1997, Allowable Compressive Stresses for Prestressed

Concrete, Masters thesis, University of Oklahoma.

17. Noppakunwijai, P., Tadros, M., Ma, Z., and Mast, R., January

February 2001, Strengthening Design of Pretensioned Flexural

Concrete Members at Prestress Transfer, PCI Journal, V. 46,

No. 1, pp. 3452.

18. MacGregor, J., 1997, Reinforced Concrete, Mechanics and

Design, Prentice Hall, Upper Saddle River, NJ.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Design of CLT Structures PDFDocument49 pagesDesign of CLT Structures PDFCharbel Saad SaadNo ratings yet

- Design of Welded JointsDocument7 pagesDesign of Welded JointsmohammadNo ratings yet

- NeopreneDocument15 pagesNeopreneEnriPatNo ratings yet

- C580 Flexural & ElasticityDocument5 pagesC580 Flexural & ElasticityPedro SánchezNo ratings yet

- Analysis & Design of Composite & Metallic Flight Vehicle Structures - Abbott - 2016 - First EditionDocument154 pagesAnalysis & Design of Composite & Metallic Flight Vehicle Structures - Abbott - 2016 - First EditionRamesha AswathanarayanappaNo ratings yet

- Precast, Prestressed Concrete BridgesDocument24 pagesPrecast, Prestressed Concrete BridgesTeodora PopovicNo ratings yet

- Aluminum DesignDocument8 pagesAluminum Designxhq08100% (1)

- Two Way Slab Design.Document9 pagesTwo Way Slab Design.tuansteelsNo ratings yet

- GPC Training 2Document18 pagesGPC Training 2zeNo ratings yet

- B53 3312 - Aço Soldavel Lam Frio (E275-335-390D)Document4 pagesB53 3312 - Aço Soldavel Lam Frio (E275-335-390D)Thiago SilvaNo ratings yet

- Basis of Design Case Study BuildingDocument49 pagesBasis of Design Case Study BuildingAnonymous AV90SAXa5V0% (1)

- Mechanical Engineering ReviewerDocument2 pagesMechanical Engineering Reviewertiburciomadlangtuta100% (2)

- Designing Integral Bridges Without Movement JointsDocument32 pagesDesigning Integral Bridges Without Movement Jointspmullins_11100% (5)

- TCVN 6073 2005 - Unprotected PDFDocument17 pagesTCVN 6073 2005 - Unprotected PDFBatisxuta MichaelNo ratings yet

- TCVN 5760-1993 HT Chua Chay Yeu Cau KT - LD - Su DungDocument5 pagesTCVN 5760-1993 HT Chua Chay Yeu Cau KT - LD - Su DungSuSi AothunthoitrangNo ratings yet

- TCVN 9361 2012 Cong Tac Nen Mong - Thi Cong Nghiem ThuDocument67 pagesTCVN 9361 2012 Cong Tac Nen Mong - Thi Cong Nghiem ThuBatisxuta MichaelNo ratings yet

- Construction Project Documentation: Discussions on Building WorksDocument120 pagesConstruction Project Documentation: Discussions on Building WorksCuong Nguyen Tien100% (1)

- TCVN 9360 2012Document61 pagesTCVN 9360 2012Batisxuta MichaelNo ratings yet

- Doko - VN 154419 Tong Hop Text Tieng Anh On Thi Cong ChucDocument45 pagesDoko - VN 154419 Tong Hop Text Tieng Anh On Thi Cong ChucBatisxuta MichaelNo ratings yet

- COÄNG HOØA XAÕ HOÄI CHUÛ NGHÓA VIEÄT NAMDocument6 pagesCOÄNG HOØA XAÕ HOÄI CHUÛ NGHÓA VIEÄT NAMBatisxuta MichaelNo ratings yet

- Quy Hoach Do Thi 1Document71 pagesQuy Hoach Do Thi 1Batisxuta MichaelNo ratings yet

- Bia 1Document1 pageBia 1Batisxuta MichaelNo ratings yet

- Tieu Chuan Coc EpDocument41 pagesTieu Chuan Coc EpMinhBáNo ratings yet

- Dien Able TechDocument22 pagesDien Able TechBatisxuta MichaelNo ratings yet

- Gia Giao Thau - Phung R0Document7 pagesGia Giao Thau - Phung R0Batisxuta MichaelNo ratings yet

- IHMC Literature Review On Concept MappingDocument108 pagesIHMC Literature Review On Concept MappingBatisxuta MichaelNo ratings yet

- PCI Bridge Design Manual Appendix A Notation GuideDocument20 pagesPCI Bridge Design Manual Appendix A Notation GuideBatisxuta MichaelNo ratings yet

- AASHTO BEAMS Standard DimentionsDocument16 pagesAASHTO BEAMS Standard Dimentionsjedidestroyer100% (1)

- JL 06 March April 5Document12 pagesJL 06 March April 5Batisxuta MichaelNo ratings yet

- Writing: SENTENCE TRANSFORMATION: Choose The Correct AnswerDocument25 pagesWriting: SENTENCE TRANSFORMATION: Choose The Correct AnswerBatisxuta MichaelNo ratings yet

- L X L XL .X: 4. Tìm Taûi Roïng Giôùi Haïn Baèng Phöông Phaùp Toå Hôïp Cô CaáuDocument2 pagesL X L XL .X: 4. Tìm Taûi Roïng Giôùi Haïn Baèng Phöông Phaùp Toå Hôïp Cô CaáuBatisxuta MichaelNo ratings yet

- Behavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsDocument16 pagesBehavior of Prestressed Concrete Box-Beam Bridges Using CFRP TendonsBatisxuta MichaelNo ratings yet

- JL 06 March April 3Document12 pagesJL 06 March April 3Batisxuta MichaelNo ratings yet

- Writing: SENTENCE TRANSFORMATION: Choose The Correct AnswerDocument25 pagesWriting: SENTENCE TRANSFORMATION: Choose The Correct AnswerBatisxuta MichaelNo ratings yet

- ONTAP p2-2009Document83 pagesONTAP p2-2009Batisxuta MichaelNo ratings yet

- 1000 Cautracnghiem TrietDocument161 pages1000 Cautracnghiem TrietDuy TanNo ratings yet

- Dich Tieng AnhDocument10 pagesDich Tieng AnhBatisxuta MichaelNo ratings yet

- Writing: SENTENCE TRANSFORMATION: Choose The Correct AnswerDocument25 pagesWriting: SENTENCE TRANSFORMATION: Choose The Correct AnswerBatisxuta MichaelNo ratings yet

- A Field Trial For Soft Clay Consolidation Using Electric Vertical DrainsDocument19 pagesA Field Trial For Soft Clay Consolidation Using Electric Vertical DrainsBatisxuta MichaelNo ratings yet

- Grammar ReviewsDocument52 pagesGrammar ReviewsBatisxuta MichaelNo ratings yet

- Strut Tie Model - STMDocument10 pagesStrut Tie Model - STMshish0iitrNo ratings yet

- MomDocument61 pagesMomMOAZNo ratings yet

- General Properties of HydrogelsDocument15 pagesGeneral Properties of HydrogelsJimmy NelsonNo ratings yet

- 2020 Mathematical Modelling of Superhydrophobic Surfaces For Determining The Correlation Between Water Contact Angle and Geometrical ParametersDocument10 pages2020 Mathematical Modelling of Superhydrophobic Surfaces For Determining The Correlation Between Water Contact Angle and Geometrical Parametersmanoj nikamNo ratings yet

- Nano Technology in Textiles A ReviewDocument6 pagesNano Technology in Textiles A ReviewMohammed Atiqul Hoque Chowdhury100% (1)

- ExperimentDocument7 pagesExperimentgosaye desalegnNo ratings yet

- Issue No 47 - Yield Strength and Other Near-Elastic PropertiesDocument2 pagesIssue No 47 - Yield Strength and Other Near-Elastic Properties6541646No ratings yet

- Defects in Liquid Crystals - Maurice KlemanDocument101 pagesDefects in Liquid Crystals - Maurice KlemanAlexCooksNo ratings yet

- Elemen MesinDocument23 pagesElemen MesinMonika NikaNo ratings yet

- Tensile Testing of Metals Proficiency Testing Program Round 4Document39 pagesTensile Testing of Metals Proficiency Testing Program Round 4Pinku MaitiNo ratings yet

- MSE 203 Continuum Mechanics: Examples and Questions David DyeDocument22 pagesMSE 203 Continuum Mechanics: Examples and Questions David DyeAnonymous rPXCmKhx27No ratings yet

- Styro Lution Tds 400900240714Document3 pagesStyro Lution Tds 400900240714vrjrNo ratings yet

- I S 613 - 2000Document11 pagesI S 613 - 2000Hariprasad gantyalaNo ratings yet

- IFEM Solution Ch14Document3 pagesIFEM Solution Ch14Sajjad AhmadNo ratings yet

- At The Completion of The CourseDocument2 pagesAt The Completion of The Courseoday albuthbahakNo ratings yet

- Mec 201Document27 pagesMec 201Lovepreet SinghNo ratings yet

- Design of BoltsDocument47 pagesDesign of BoltsVp RsmengrNo ratings yet

- Las Shs Gen - Chem Melc 7 q2 Week-4Document12 pagesLas Shs Gen - Chem Melc 7 q2 Week-4Kim Francis Beluso Dollete IINo ratings yet

- Tensile Test of SteelDocument7 pagesTensile Test of Steelcristina23No ratings yet