Professional Documents

Culture Documents

2 02

Uploaded by

Kuber Bogati0 ratings0% found this document useful (0 votes)

19 views18 pages1

Original Title

2-02

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views18 pages2 02

Uploaded by

Kuber Bogati1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 18

smaller land area.

However, the cost of the tower in-

creases as the anchor distance decreases. The approxi-

mate relationship of cost to anchor distance for a repre-

sentative 1,200 ft television broadcast tower is shown

in Figure 2.2-1.

It is often possible to position a guyed tower on an

irregularly shaped plot or to obtain long term lease

agreements or easements for guy paths and anchor

locations in order to minimize the tower cost without

obtaining large, rectangular land areas.

Self-Supporting Towers

Self-supporting towers may be either square or trian-

gular in cross section. While it is usually more econom-

ical to use a triangular cross section, there are situations

Figure 2.2-1. Effects of anchor distance on cost of a 1,200 foot

guyed TV broadcast tower using ANSI/TIA/EIA Standard 222-

F-1996.

2.2

DESIGN, ERECTION, AND MAINTENANCE

OF ANTENNA STRUCTURES

JOHN WINDLE, P.E.

CONSULTING STRUCTURAL ENGINEER, WEST CHESTER, PA

THOMAS J. HOENNINGER, P.E.

STAINLESS, INC., NORTH WALES, PA

TOWER LIGHTING SECTION BY:

LEWIS WETZEL

HUGHEY & PHILLIPS, INC., WENHAM, MA

INTRODUCTION

The purpose of this chapter is to provide broadcast

engineers and managers information concerning the

design, erection, and maintenance of antenna struc-

tures. While fundamental principles of the design and

behavior of these structures will be discussed, this

chapter is not intended to enable readers to design and

build their own tower, but provides instead a basic

understanding of these unique structures to facilitate

planning, modifying, and maintaining broadcast facil-

ities.

TOWER CHARACTERISTICS

All towers may be classied in one of the two basic

groups, guyed or self-supporting. As their names im-

ply, guyed towers depend on cables extending from

the tower to anchors located some distances from the

tower base for their structural integrity, while self-

supporting towers rely solely on their own construction

as a cantilevered space truss.

With only a few exceptions, the cost of the actual

tower structure and foundations is considerably less

for a guyed tower than for one that is self-supporting.

The advantage of the self-supporting tower is relatively

small land area required. Therefore, the choice between

guyed or self-supporting depends to a large degree on

the availability and cost of real estate.

A self-supporting tower requires a nearly square

plot of land with equal sides that are 8% to 20% of

the towers height, provided local zoning rules do not

require tower height radius of land.

The amount of land required for a guyed tower

depends on the distance between the tower base and

the guy anchors. This distance is preferably between

70% and 80% of the height, which would require a

rectangular plot having sides equal to 125% and 145%

of the height.

Because of the great exibility in guyed tower de-

sign, it is possible to reduce the anchor distance to as

little as 35% of height, thereby requiring a much

2 0 1

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 201

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

where a square cross section is a better choice. The

principle structural elements are the legs, the web brac-

ing in each face, and if required for stability, horizontal

diaphragm bracing. The legs are usually sloped (ta-

pered) to provide adequate strength and stability as

the height increases. The degree of slope is an option

of the designer to suit the equipment supported, the

required rigidity, and the available land area. The slope

is sometimes varied within a tower to maintain a desir-

able balance between the costs of leg members and

bracing, or to reduce the foundation loads. Frequently,

the legs in the top section of the tower will be parallel to

simplify the mounting of equipment (see Figure 2.2-2).

There are several different congurations of bracing

members for the individual truss panels. The choice

is inuenced by the width of the panel, the magnitude

of the wind and ice loads imposed, the location of

equipment and required stability. Continuity in trans-

ferring the applied loads through the structure without

signicant eccentricity is essential regardless of the

conguration used.

Guyed Towers

Guyed towers are almost always of triangular cross

section although there are a few unique conditions for

microwave and panel type FM and TV antenna sup-

ports where a square cross section is advantageous.

The principle structural elements are the legs, the web

bracing in each face, and the guy support systems (see

Figure 2.2-3). Except for sections at the tower base

and locations where the width changes, the legs are

parallel. The width of the tower is usually constant

throughout the height of the tower with the exception

of sections supporting antennas requiring a specic

width of support structure. The base section is often

tapered to a single point to provide a pivot support to

eliminate large bending and torsional moments.

Theoretically, there are an innite number of ar-

rangements of guy cables to support a tower. The most

common arrangement is three cables spaced at 120

with one attached to each leg, as shown in Figure

2.2-4(a). This is the minimum number of cables that

can be used. When the tower supports equipment,

which imposes large twisting moments (torque), it is

necessary to provide six cables at a level to maintain

torsional stability. If the torque is localized, the guys

at this location may be attached to triangular frames as

shown in Figure 2.2-4(b). If the torque occurs through-

out the height, it may be desirable to double-guy the

tower at every level as shown in Figure 2.2-4(c).

The number of guy cable levels required to support

the tower is dependent on a number of factors including

the height of the tower, width, location of equipment

and the environmental loading conditions. Because the

tower is an axially compressed column, its strength is a

function of its slenderness. While design codes permit

2 0 2

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 202

Figure 2.2-2. Elevation view typical self supporting tower.

Figure 2.2-3. Elevation view typical guyed tower.

D E SIG N , ER E C TIO N , A N D M A IN TE N A N C E O F A N TE N N A STR U C TU R E S

2 0 3

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 203

slenderness ratios resulting in triangular towers having

a span-to-width ratio as great as 49, it is usually eco-

nomical to limit the ratio to a maximum of 30. While

there is no upper limit to the number of guy levels

imposed by any code, a practical limit for economical

design is ten.

The position of equipment on the tower is an im-

portant factor in determining the location of guy levels.

Preferably, guy attachments should not be located

within the apertures of side mounted TV and FM

broadcast antennas. Equipment producing large local-

ized wind loads, such as microwave antennas or clus-

ters of two-way radio cabinets and antennas, should not

be positioned near the center of a span between guys.

If the tower will be subjected to ice loading, it is

desirable to reduce the number of guy levels to mini-

mize loads imposed on the tower by ice accumulation

on the guy cables.

The number of anchors in each guy direction is

dependent on several factors including the number

of guy levels, the soil conditions, topography, and

obstacles. As a general guideline, it is desirable to

limit the number of guy levels attached to a single

anchor to ve. However, there is nothing absolute

about this number, and other conditions may dictate

using an anchor for a greater number. There are some

soil conditions where it may be economical to provide

two or more smaller anchors, while another instance

the use of one large anchor might be desirable. If

minimizing the area within which the tower would fall

in the event of collapse is a consideration, a minimum

of two anchors should be used in each direction. Where

the elevations of the anchors differ from the tower

base, it is desirable to vary the distance of the anchors

from the tower base to maintain nearly equal initial

tensions in the guy cables. Anchors higher than the

tower base should be moved toward the tower; and

anchors that are lower, away from the tower. The

designer should specify the amount of movement.

Materials

Nearly all broadcast towers are made from steel

because it provides the most economical structure. The

selection of the grade and shape of steel is obviously

an important design consideration.

Steel used for towers commonly has low carbon

content with yield strengths in the range of 36,000 to

60,000 psi. These materials have good ductility and

are suitable for welding. Some towers have been built

using higher grade materials with yield strengths up

to 100,000 psi, but the savings in weight are more than

offset by higher base prices and increased fabrication

costs. Regardless of the grade of material, the steels

mechanical and chemical properties should be certied

by the producing mill to ensure that it conforms to the

design requirements.

The shape of the material as well as its size and

strength affects the towers load carrying capacity. The

shape also has a signicant effect on the magnitude

of loads produced by wind. Design standards permit

a reduced wind load on round members as little as

57% of the wind load for at or angular members of

the same width. For this reason, solid round bars, round

structural tubes and pipe are often used. This advantage

in wind load is offset somewhat by increased fabrica-

tion costs, due to the necessity of welding plates to

connect the various members.

There is no one grade or shape of materials that is

best. The choice depends to a large degree on the

preference of the designer and the type of fabricating

facilities available.

A factor equally as important as the selection of the

grade and shape of the structural steel is the design

of the connections. For shop welded connections, the

Figure 2.2-4. Typical guy arrangements.

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

loaded. They are advantageous for connecting

closely spaced insulators where the length of dead

end grips is unacceptable.

Wedge Type Sockets are available for guys up to

1-1/4 in. diameter and develop 100% of their

strength. They are most advantageous for guys larger

than those for which dead end grips are available.

A serving is a connection made by rolling the indi-

vidual wires of a strand back on the strand itself.

This method has for the most part been replaced

with dead end grips, but it is advantageous for small

guys with closely spaced insulators.

Insulators

Insulators in radio frequency applications must with-

stand mechanical and electrical stress in a varied,

changing exterior environment. Selection of insulators

should be made with these factors in mind. Insulators

primarily designed for 60 Hz applications are unsuit-

able, particularly at high RF powers.

The most common insulating material is a wet pro-

cess porcelain, which has excellent compressive

strength and good insulating capabilities for frequen-

cies up to 2 MHz. Synthetic materials are also used.

Some other types of insulators are as follows:

Base insulators for AM towers are made from porce-

lain with appropriate steel end plates or ferrous/non-

ferrous castings. For guyed towers, a rocking ar-

rangement is provided in the form of a convex plate

and pin at the top, or a pivot pin at the bottom of

the assembly to hold the tower in place and relieve

the porcelain from bending loads which could cause

cracking. For self-supporting towers, the insulators

are bolted between the tower leg and base pier, and

are designed to sustain both uplift and download

while keeping the porcelain in compression.

Sectionalizing insulators are sometimes required to

isolate sections of a guyed tower. Where a compres-

sion load only is applied, a guyed tower base with

minor modications can be used. If a tension load

is anticipated, a push-pull insulator similar to the type

used for self-supporting towers is required. Under no

circumstances should the porcelain be put in tension.

Guy insulators are available for primary insulation

and for break-up purposes. Primary insulation (insu-

lators next to the tower) should be selected to with-

stand the full voltage appearing at the guy attachment

point. This is to ensure that sufcient insulation re-

mains if all thebreak-upinsulators intheguylineash

over. Break-up insulators, used to reduce reradiation,

are selected to withstand the transmitter induced volt-

age and static voltage. Break-up insulators are usually

low voltage types, sometimes protected from ash-

over and subsequent power arc by a static dissipation

device. Guy insulators are available in many styles

classied as either compression or tension types.

Finishes

Steel is susceptible to deterioration from atmo-

spheric corrosion. To prevent deterioration, the tower

members and hardware must be given a protective

2 0 4

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 204

compatibility of the base and ller metals and required

preheat temperatures must be considered. The proce-

dures used must be qualied and the welders certied

to use them. Inspection procedures should be compati-

ble with the weld design.

Bolts for eld assembly may be of various types.

Usually those for the main load carrying members are

high strength. If positive resistance to slippage of the

connections is required, they should be designed as

friction connections.

Guys

The most common material for tower guys is galva-

nized strand. This material has excellent strength and

durability. Its structural elongation due to seating of

the individual wires in the strand is small and can be

almost entirely eliminated by pre-stressing the strand

to 50% of its breaking strength at the factory. This

should be performed for guys on tall towers with fac-

tory connected end ttings.

For guys on AM towers, and those close to FM

and TV antenna apertures, a nonconductive material

is sometimes desirable. Two such materials that have

been used are Kevlar rope and berglass rods. When

using these materials, careful attention must be given

to protection against corona effects, fatigue, and deteri-

oration due to exposure to ultraviolet light. Also, their

elongation characteristics under load must be evalu-

ated. They require delicate handling at all times.

Just as for the tower structure, the connections for

the guys are as important as the guy material itself.

Some of the most common connections are as follows:

Sockets of forged or cast steel attached with molten

zinc or epoxy resins develop the full strength of the

guy. They are normally installed at the factory and

proof loaded to 50% of the guy breaking strength.

This type of tting is most common for the larger

guys used on tall towers.

Dead end grips are preformed spiral wire loops in

the shape of large hairpins. The two legs of the

hairpin are wrapped around the guy with its closed

end forming an eye. These grips are used for guys

up to 1 in. in diameter and usually develop their full

strength. They are easily installed in the eld, but

the ends must be completely snapped into place and a

protective device installed to prevent ice fromsliding

down the guy and loosening the grip.

Clips used to clamp the ends of guys (when properly

applied and tightened) develop 90% of the guys

strength for sizes up to and including 7/8 in. and

80% for larger sizes. To install them it is necessary

to bend the strand back on itself to form a loop;

thus, the use of clips on large cables is difcult. The

saddle of U-bolt type clips must be installed on the

load side and not the dead end side, which provides

another potential error in their installation.

Swaged sleeves develop between 85% to 100% of a

guys strength depending on the size of the guy and

equipment used to squeeze the sleeve. These ttings

are usually installed at the factory and can be proof

D E SIG N , ER E C TIO N , A N D M A IN TE N A N C E O F A N TE N N A STR U C TU R E S

also requires that any continuous ladder more than 20

ft in height be equipped with a safety device. This

device consists of a continuous rail, either rigid or

cable, running up the center of the ladder. A clamping

device attached to the climbers safety belt rides along

this rail. As long as the climber is in a normal position,

the clamp slides freely; if the person begins to fall, a

cam actuated mechanism freezes the clamp to the rail

and prevents the person from falling.

Elevators

For tall towers supporting multiple antennas, it is

often desirable to install an elevator. Most tower eleva-

tors are of the power, cable driven type with a capacity

of 500 to 750 lbs. and a speed between 80 and 100 ft

per minute. They consist of a drive mechanism, car,

guide rails, hoist cable with supporting sheaves, ten-

sion weights, electronic controls and a two-way com-

munications system.

Considerable attention must be given to elevator

safety features. These should include limit switches to

prevent travel beyond the upper and lower landings

on the tower, an automatic brake on the driving mecha-

nism that is activated by an interruption in power, a

mechanism to automatically clamp the car to the rails

in the event of a broken hoist cable and interlocks to

prevent operation with the car gate open. It is advisable

to determine the applicable state or municipal govern-

ment regulations that may apply and whether permits,

tests and inspections are required before the tower and

elevator system are designed.

The added wind and dead loads from an elevator

system are substantial and must be considered in the

tower design. Also, careful attention must be given to

the positioning of the ladder, RF transmission lines

and electrical conduits in relationship to the elevator.

The ladder must be positioned so it is accessible from

the elevator car and can be used for an emergency

descent. While the elevator hoist cables can be re-

strained in guides on the return side, they are free

to move about under wind load on the lifting side.

Therefore, the conduits and transmission lines must

be protected from hoist cables striking and damaging

them. If a side mounted TV or FM antenna produces

a high RF eld within the hoistway, protection must

be provided to prevent arcing between the hoist cables,

the tower structure, and other appurtenances.

Transmission Line Bridges

To allow for the different thermal expansion and

contraction characteristics of broadcast towers and

transmitter buildings, it is necessary to keep the tower

separated from the transmitter building. Unless the

transmission line is placed underground, it is necessary

to provide a structural support for it at a height compat-

ible with the transmitter location in the building. The

top of the support can be covered with steel grating

or plate to protect the line from falling ice. The details

of this structure can become quite involved for sites

with multiple antennas, uneven terrain and roadways,

or obstacles between the tower and building.

coating. This coating is usually zinc, which has excel-

lent resistance to corrosion, and, because it is higher

in the electrochemical series of the periodic table of

elements, it provides cathodic protection to exposed

steel surfaces adjacent to it. Even though the zinc

coating may be scraped or otherwise damaged, it con-

tinues to inhibit corrosion of these exposed areas, and

rust will not develop beneath adjacent zinc coats.

There are several methods for applying the zinc in-

cludinghot dipgalvanizing, amespraying, electroplat-

ing and painting. All must be applied to clean surfaces.

Hot dip galvanizing consists of dipping the steel into

a bath of molten zinc. A metallurgical bond develops

between the steel and the zinc, which adheres to it.

When galvanizing tubular members, it is necessary

to provide holes in both ends to ensure that the inside

surfaces are coated. Careful attention must be given

to the type of base and weld metals used, as well

as to the welding and forming procedures used in

fabrication, to safeguard against possible embrittle-

ment of the steel when galvanized. When properly

applied, this process provides the most durable

coating.

Flame spraying consists of spraying molten zinc at

high pressure onto the steel surfaces. The bond in

this process is mechanical rather than metallurgical.

The coating produced is more porous and has less

resistance to abrasion than the hotdip galvanized

coating. It cannot be used for the inside of hollow

sections or other cavities where access is difcult.

Electroplating, while suitable for small objects, does

not produce a coating thick enough to withstand a

hostile environment. This method is not recom-

mended for tower parts or hardware.

Zinc rich paint consists of extremely nely divided

zinc in an inorganic or organic vehicle. It is not a

metal coating method, but rather a painting proce-

dure. Its resistance to abrasion and durability are less

than hotdip galvanizing. This procedure is, however,

useful for maintenance.

Ice Prevention

Coatings are available to reduce the adherence of

water to surfaces and subsequently the formation of

ice on them. However, no reliable means exists to

completely remove the risk of severe ice accretion.

Access Facilities

A tower must have some access facilities in order

to maintain it and the equipment the tower supports.

For small towers, the bracing members of the tower

itself often serve as steps, or step bolts are attached

to one leg or face.

Ladders

For taller broadcast towers, a xed ladder inside the

tower is desirable. The Occupational Safety and Health

Administration (OSHA) standards for these ladders

require a minimum clear width between side rails of

16 in. and a maximum rung spacing of 12 in. OSHA

2 0 5

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 205

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

Stairways

The lower landing for a tall, guyed broadcast tower

with an elevator is often 30 ft or more above ground

level. A stairway may be desirable to permit easier

access to the landing. This structure can be combined

with the transmission line support bridge, or it may

be completely separate. It may also be desirable to

install a small capacity boom above the lower landing

to lift radio cabinets or other equipment onto the

landing.

ANTENNA STRUCTURE REGISTRATION

REQUIREMENTS

On November 30, 1995, the FCC adopted rules to

streamline the Commissions antenna structure clear-

ance process by requiring owners to register their an-

tenna structures with the Commission by June 1998.

The registration generally applies to structures more

than 60.96 m (200 ft) above ground or located near an

airport. Detailed information concerning registration is

available from the FCCs Forms Distribution Center

at 1-800-418-FORM or through the Internet at http://

www.fcc.gov/wtb/antstruc.html.

Upon registering an antenna structure with the Com-

mission, an owner will receive a Registration (FCC

Form 854R) containing a Registration Number which

uniquely identies the structure. The owner must pro-

vide each tenant licensee and permittee with a copy

of the Registration. In turn, licensees and permittees

must reference this registration number on all subse-

quent Commission lings.

Marking and Lighting Antenna Structures to

Meet FAA/FCC Requirements

Unless otherwise specied by the Commission, each

new or altered antenna structure to be registered on

or after July 1, 1996, must conform to the FAAs

marking and lighting recommendations set forth on

the structures FAA determination of No Hazard, as

referenced in the following FAA Advisory Circulars:

AC 70/7460-1H, Obstruction Marking and Lighting

and AC 150/5345-43D, Specication for Obstruction

Lighting Equipment. These documents contain FAA

recommendations for marking and lighting structures

which pose a potential hazard to air navigation. The

Commission considers these specications, standards

and general requirements stated in these documents to

be mandatory. The Advisory Circulars listed above

may be obtained from the U.S. Department of Trans-

portation, Subsequent Distribution Ofce, Ardmore

East Business Center, 3341 Q 75th Avenue, Landover,

Maryland 20785. Fax requests for these publications

may be sent to (301) 386-5394.

CERTIFICATION PROCEDURE FOR FAA

APPROVED LIGHTING EQUIPMENT

To assure that all lighting equipment manufactured to

meet the specications in the FAA Advisory Circulars,

a certication program was established. On January 1,

1990, ETL Testing Laboratories, Inc., began adminis-

tering the certication program for airport and obstruc-

tion lighting equipment. Lighting equipment approved

by the FAA prior to January 1, 1990, continued its

approved status without additional product qualica-

tion testing for a period of ve years through a grand-

father clause, provided sufcient documentation exists

to support the certied status.

The FAAs Advisory Circular 150/5345-53, Ap-

proved Airport Equipment lists the certied lighting

equipment that ETL has veried as meeting the appli-

cable FAAspecications. When building or modifying

an antenna structure that involves the use of obstruction

lighting equipment, it would be wise to check the FAA

approved lighting equipment list or require a certicate

of compliance from the manufacturer.

FCC Lighting Requirements

During construction of an antenna structure for

which obstruction lighting is required, a temporary

light must be installed at the uppermost point of the

structure. This light shall be similar in type and inten-

sity to the permanent light that is required for that

level. In addition, as the height of the structure exceeds

each level at which permanent obstruction lights will

be required, another level of temporary lighting must

be installed. If practical, the permanent obstruction

lights may be installed and operated at each required

level as construction progresses.

Inspection of Antenna Structure Lights and

Associated Control Equipment

The owner of any antenna structure which is regis-

tered with the Commission and has been assigned light-

ing specications:

(a) (1) Shall make an observation of the antenna struc-

tures lights at least once each 24 hours either

visually or by observing an automatic properly

maintained indicator designed to register any fail-

ure of such lights, to insure that all such lights are

functioning properly as required: or alternatively.

(2) Shall provide and properly maintain an auto-

matic alarm system designed to detect any failure

of such lights and to provide indication of such

failure to the owner.

(b) Shall inspect at intervals not to exceed three

months all automatic or mechanical control de-

vices, indicators, and alarm systems associated

with the antenna structure lighting to insure that

such apparatus is functioning properly.

Notication of Extinguishment or Improper

Functioning of Lights

The owner of each antenna structure which is regis-

tered with the Commission and has been assigned light-

ing specications:

(a) Shall report immediately by telephone or fax to

the nearest Flight Service Station or ofce of the

2 0 6

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 206

D E SIG N , ER E C TIO N , A N D M A IN TE N A N C E O F A N TE N N A STR U C TU R E S

when the northern sky illuminance reaching a vertical

surface falls belowa level of 60 footcandles (645.8 lux)

but should occur before it drops below 35 footcandles

(376.7 lux). These lights should switch from their twi-

light to night mode of operation when the level falls

below 5 footcandles (53.8 lux) but should occur before

reaching a level of 2 footcandles (21.5 lux). The control

device should reverse intensity changes when going

from night to twilight to day within these same levels.

Options for Marking and Lighting Antenna

Structures

Red obstruction lights are used to increase conspicu-

ity during nighttime. Painting is required for daytime

and twilight marking. The red obstruction lighting sys-

tem is composed of ashing omnidirectional beacons

(L-864) and steady burning lights (L-810). When the

system is comprised of more than one level of ashing

beacons, the beacons should ash simultaneously.

Medium Intensity Flashing White Lighting System

Mediumintensity ashing white (L-865) obstruction

lights provide conspicuity both day and night and elim-

inates the need to paint the structure. The medium

intensity ashing white light system is composed of

ashing omnidirectional lights. These systems are used

on structures up to 500 ft (153 m).

Dual Red and White Flashing Medium Intensity

Lighting System

The dual lighting system includes red ashing bea-

con or beacons (L-864) and steady burning red lights

(L-810) for nighttime and medium intensity ashing

white lights (L-865) for daytime and twilight use.

These systems may be comprised of a red ashing

beacon (L-864) and a medium intensity ashing bea-

con (L-865) or a single beacon which incorporates

both the red and white ashing beacons (L-864/

L-865). These systems are used on structures up to 500

ft (153 m) and eliminate the need to paint the structure.

High Intensity Flashing White Lighting System

Lighting with high intensity ashing white obstruc-

tion lights (L-856) provides the highest degree of con-

spicuity both day and night. When this system is oper-

ated 24 hours a day, other methods of marking and

lighting may be omitted. These systems are used on

structures from 500 ft. (153 m) to the maximum height

allowed by the FAA.

Dual Red and White Flashing High Intensity

Lighting System

The dual lighting system includes ashing red lights

(L-864) and steady burning red lights (L-810) for

nighttime and high intensity ashing white lights

(L-856) for daytime and twilight use. When using this

system, marking the structure with paint is eliminated.

These systems are used on structures from 500 ft

(153 m) to the maximum height allowed by the FAA.

FAAany observed or otherwise known extinguish-

ment or improper functioning of any top steady

burning light or any ashing obstruction light, re-

gardless of its position on the antenna structure,

not corrected within 30 minutes. Such reports shall

set forth the condition of the light or lights, the

circumstances which caused the failure, the proba-

ble date for restoration of service, the FCCAntenna

Structure Registration Number, the height of the

structure (AGL and AMSL), and the name, title,

address, and telephone number of the person mak-

ing the report. Further notication by telephone or

fax shall be given immediately upon resumption

of normal operation of the light or lights.

(b) An extinguishment or improper functioning of a

steady burning side intermediate light or lights,

shall be corrected as soon as possible, but notica-

tion to the FAA of such extinguishment or im-

proper functioning is not required.

Recording of Structure Light Inspections in the

Owner Record

The owner of each antenna structure which is regis-

tered with the Commission and has been assigned light-

ing specications must maintain a record of any

observed or otherwise known extinguishment or im-

proper functioning of a structure light and include the

following information for each such event:

(a) The nature of such extinguishment or improper

functioning.

(b) The date and time the extinguishment or improper

operation was observed or otherwise noted.

(c) The date and time of FAA notication, if appli-

cable.

(d) The date, time and nature of adjustments, repairs

or replacements made.

Time When Lights Should be Exhibited

Red obstruction lights may be operated by a control

device adjusted so the lights will be turned on when

the northern sky illuminance reaching a vertical surface

falls below a level of 60 footcandles (645.8 lux) but

before reaching a level of 35 footcandles (376.7 lux).

The control device should not turn the lights off until

the northern sky illuminance rises to a level of at least

60 footcandles (645.8 lux). The lights may also remain

on continuously.

Medium intensity white and dual obstruction lights

should be operated by a control devise so the lights

will switch from their day/twilight to night mode of

operation when the northern sky illuminance reaching

a vertical surface falls below a level of 5 footcandles

(53.8 lux) but before reaching a level of 2 footcandles

lux). The control device should reverse intensity

changes when going from night to day/twilight mode.

High intensity white and dual obstruction lights

should be operated by a control device so the lights

will switch fromtheir day to twilight mode of operation

2 0 7

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 207

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

Other Electrical Circuits to Consider in

Antenna Structure Planning

During the planning and design stages for an antenna

structure, there are other electrical circuits that are

necessary or should be considered to make its operation

more efcient and provide a source for future income.

Most tall antenna structures require deicing circuits

with their associated control devices. An ac utility

circuit can provide access to 120 volt power at selected

elevations on the structure and will reduce costly main-

tenance time. If the structures height justies an eleva-

tor, control circuits for the elevator are necessary.

Circuits to provide power and multi-pair cables to

various platforms are needed for rental communication

system customers.

DESIGN STANDARDS

The vast majority of towers in the United States have

been designed in accordance with the EIA-222, Struc-

tural Standards for Steel Antenna Towers and Antenna

Supporting Structures. This standard has been used

since 1959 when it replaced the Radio Electronic Tele-

vision Manufacturers Association (RETMA) Standard

TR-116. The current revision F of EIA-222 was

issued in 1996. The standard has been approved by

the American National Standards Institute and carries

the designation ANSI/TIA/EIA-222-F-1996.

This standard is intended to provide minimum crite-

ria for specifying and designing steel antenna towers

and antenna supporting structures. Unlike general

specications and building codes, it is applicable only

to antenna tower and supporting structures. As such

it contains criteria specic to these structures that are

not readily available elsewhere. Therefore, it is always

advisable to specify that your tower must conform to

this standard.

Appendix A: Purchase Checklist of this standard is

provided to alert the purchaser to the most common

area where site-specic data may be required to supple-

ment the minimum criteria of the standard.

Statutory

Most municipal and state governments have statu-

tory codes regulating the design of structures. Many

of these are patterned after or include one of several

model codes. The most common of these are:

Building Ofcials and Code Administrator Interna-

tional (BOCA) Basic Building Code.

International Conference of Building Ofcials

(ICBO) Uniform Building Code.

Southern Building Code Congress (SBC) Standard

Building Code.

These codes cover all types of structures and are

directed primarily toward conventional types of build-

ings. As such, they do not contain all the criteria neces-

sary to design broadcast towers. For example, none of

them includes a recommended safety factor for guy

cables.

The industry standard ANSI/TIA/EIA-222-F-1996

is compatible with these codes. In fact, its use for

calculating and applying wind loads is required by

the BOCA Basic Building Code and, as an approved

American National Standard, is permitted by the ICBO

Uniform Building Code.

Since it is necessary to comply with the applicable

statutory requirements, it is important to determine

what these requirements are and include them in the

purchase specications for the tower.

Loads, Analysis & Safety Factors

In addition to a towers own dead weight and the

dead weight of the appurtenances and equipment it

supports, the tower must withstand the forces of nature,

wind, ice, temperature changes, and earthquakes.

Wind Load

Wind produces a principal load on tower structures.

For design purposes it is represented as a horizontal

static force.

Wind load is specied in terms of a basic wind

speed at 10 m (33 ft) above ground level. The ANSI/

TIA/EIA-222-F-1996 standard provides a tabulation

of recommended minimum values for this speed for

each county in the United States. This standard also

gives specic procedures and factors for calculating

wind loads considers the following:

Wind pressure is proportional to the square of

wind speed.

Wind speed and, consequently, wind pressure vary

with respect to the height above ground.

The effects of gusts of brief duration, which exceed

the fastest mile basic wind, speed.

The effects of the conguration, size, proportions,

shape and orientation with respect to the wind direc-

tion of the structural components of the tower and

its appurtenances.

An example of wind load calculation for a typical

broadcast tower is given in Figure 2.2-5.

Since the wind may act from any direction it is

necessary to apply the calculated wind loads in any

horizontal direction to determine the maximum

stresses produced in the structure. For a triangular

tower, three directions must be considered; while for

a square tower, two are sufcient (see Figure 2.2-6).

In addition to this direct load in the direction of the

wind (drag), there may also be a component of load

perpendicular to the wind direction (lift). These lift

components are calculated in a manner similar to that

for drag forces using different shape coefcients that

vary with respect to the angle of attack between the

members geometric axis and the wind direction. They

are most signicant for wind acting on guy cables,

microwave antennas and rectangular waveguides.

Ice Loads

Ice accumulations have two effects on a tower. The

weight of the ice acts directly on the structure in the

same manner as the dead weight. The ice accumulation

2 0 8

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 208

2 0 9

National Assoc. of Broadcasters (NJ) (PS8295) PKF 02-10-99 12:52:33 CH2x2 Page 209

Figure 2.2-5. Wind force calculations for latticed towers using ANSI/TIA/EIA-222-F-1996.

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

2 1 0

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 210

tic deformations from stress changes. The effects are

greatest for those cables having the attest angle with

the ground. While the stresses produced are consider-

ably less than those produced by wind and ice loads,

they should be considered in the design of guyed tower.

Seismic Loads

Loads due to earthquakes are considered to act hori-

zontally and are dependent on the mass and stiffness

of the tower. They are usually less than those produced

by wind but are distributed in a different manner.

Procedures for calculating these loads are given in

some of the design standards including ASCE 7, but

not in ANSI/TIA/EIA-222-F-1996. While a tower

properly designed for wind loads is usually adequate

for seismic forces, they cannot be neglected in areas

with frequent and intense earthquake occurrences.

Structural Models & Analysis

A self-supporting tower may be described structur-

ally as a cantilevered space frame or truss. Although

it may have many different members, it is a relatively

simple structure, and the determination of the forces

in the individual members due to the applied static

loads is easily done using fundamental principles of

structural mechanics. The potential modes of failure

are buckling of individual leg or bracing members

under compressive loads, and shear or tension failures

of the connections.

A guyed tower is a much more complex structure

than a self-supporting tower. Whereas there is only

one basic path through a self-supporting tower for the

loads to be transferred to the ground, there are several

for a guyed tower. The distribution of the loads among

these paths is dependent upon the relative stiffness of

guy systems and the tower shaft.

Each span of the tower has a stiffness with respect

to relative deections from axial and shear forces and

bending and torsional moments. This stiffness is a

also increases the area exposed to the wind and conse-

quently the load produced by the wind. This increase

is substantial on small components such as guy cables,

tension rods, ladders, small diameter transmission lines

and reector screens for antennas. It is also possible

for the ice accumulation to alter the aerodynamic shape

of members, thereby requiring the use of a different

coefcient in calculating the wind load. An example

is a set of closely spaced parallel coaxial lines. Without

ice each would be considered a round cylindrical mem-

ber. With accumulated ice, they would present a large

at area to the wind requiring a different coefcient.

Ice produces an entirely different stress distribution

in a tower than wind, so it is not reasonable to merely

increase the design wind load to provide for ice accu-

mulation. It is also a misconception that ice will break

up and blow off the tower, and therefore, ice and wind

need not be considered simultaneously. The ANSI/

TIA/EIA-222-F-1996 Standard states that unless other-

wise specied by the purchaser, 75% of the wind load

shall be applied in combination with the ice load. This

is equivalent to reducing the basic wind speed by a

factor of 0.866. In areas where ice is likely to form,

it is advisable to specify a basic wind speed to act

concurrently with the ice load as well as the basic

wind speed without ice), (70 mph with ice and 80 mph

without ice).

While the ANSI/TIA/EIA-222-F-1996 Standard

emphasizes the need to consider ice loads, it does not

provide specic recommendations for the magnitude

of the accumulation. This responsibility is left with

the purchaser.

Temperature Changes

Changes in temperature have no signicant load

producing effects on self-supporting towers, but they

can on guyed towers. Because of their differences in

length, the guy cables expand and contract different

amounts than the tower itself and thereby require elas-

Figure 2.2-6. Wind directions to be considered.

D E SIG N , ER E C TIO N , A N D M A IN TE N A N C E O F A N TE N N A STR U C TU R E S

beyond safe limits indicating a potential failure condi-

tion. Considering the usual fundamental periods of tall

guyed towers, it appears that towers taller than 1,200

to 1,300 ft. should be investigated dynamically as well

as statically.

There are two other phenomena related to the dy-

namics of wind that are important in guyed tower

design. These are aeolian vibrations and galloping,

both of which involve periodic loading.

Aeolian vibrations are low amplitude, high fre-

quency movements, which occur in the tower guy

cables due to a phenomenon known as vortex shedding.

If they are not suppressed through the use of dampers,

they can result in destruction of the laments in the

tower lights at the least, or fatigue failure of guy cable

and collapse of the tower at the worst. Dampers

attached at one or both ends of the guy cables have

proven effective in controlling these vibrations and

should be considered for all tall, guyed towers.

Galloping is a condition of instability involving

large amplitude, low frequency movements. It is

caused by the perpetual amplications of periodic

loads due to the motion of the body itself. The most

dramatic and well-known example of galloping is the

collapse of the Tacoma Narrows suspension bridge

in 1940.

For tower structures, galloping is usually associated

with the guy cables on tall towers, but in at least one

instance it was related to a large rectangular wave-

guide. There have been several different methods

involving detuning and energy dissipation used for

preventing galloping in guy cables that appear to be

successful. In the case of the rectangular waveguide,

galloping was controlled by moving the waveguide

inside the tower along the centroidal axis from its

original position on the outside of one face. This re-

duced the torsional rotation of the structure, which was

the source of the perpetuating force. Based on this

experience, it would appear prudent to always install

this type of waveguide inside the tower unless adequate

torsional rigidity is provided throughout the height of

the tower.

Allowable Stresses & Safety Factors

Towers, like all other structures, are designed so

that the maximum anticipated stresses are less than

those which would cause failure. This ratio of failure

stress to maximum allowable stress is known as the

safety factor. It is intended to provide for several varia-

tions from the ideal conditions assumed for design

including loads greater than anticipated, imperfections

in materials and tolerances in fabrication and con-

struction.

The ANSI/TIA/EIA-222-F-1996 Standard refers to

the American Institute of Steel Construction (AISC)

Specication for the Design, Fabrication and Erection

of Structural Steel for Buildings for the design of the

structures members and to the American Concrete

Institute (ACI) Building Code Requirement for Rein-

forced Concrete Structures for the design of the rein-

forced concrete foundations and guy anchors.

2 1 1

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 211

function of several variables, including the geometric

conguration, the mechanical properties and the sizes

of the individual members.

Each guy cable also has a stiffness with respect to

movement of its attachment point to the tower that is

a function of the amount of initial tension, the magni-

tude of ice load, and the magnitude and direction of

wind load on the cables. By evaluating all of these, it

is possible to simulate all the guys at a given level as

a spring having a specic stiffness. Because of the

nonlinearity of some of the relationships involved, the

spring constant derived is only valid for a specic

set of conditions and for a nite range of translation.

Similarly, a torsional spring constant can be derived.

It is interdependent with the translation stiffness and

is also valid for only a nite range of translation.

Another difference between a guyed and self-sup-

porting tower is the magnitude and signicance of the

axial load. For a self-supporting tower this is composed

only of the gravity loads from the tower, its appurte-

nances and any ice load. It is independent of wind

load, and its effects on individual member loads are

relatively small. The axial load for a guyed tower

includes in addition to the gravity loads, the vertical

components of the tensions in the various guys. Since

these tensions are directly affected by the wind load,

the axial load is now dependent upon wind load and

its effects on the individual leg members are relatively

large. Tension in the guy wires also produces an

additional bending moment on the tower equal to the

product of the axial load and the deection of the

tower.

Despite the complexity of the relationships in-

volved, the availability and widespread use of com-

puter systems permits accurate structural analysis of

guyed towers. There are several different structural

models that may be used.

One of the most commonly used idealizes the tower

shaft as a continuous beam-column on nonlinear elastic

supports (the guys) subjected to simultaneous trans-

verse (wind and or seismic) and axial (dead, ice and

vertical components of guy tensions) loads.

The modes of failure are buckling of individual leg

or bracing members under compressive loads; rupture

of bracing members, guys, or guy anchor arms under

tensile loading; and shear or tension failures of the con-

nections.

Dynamic Considerations

As previously mentioned, even though wind and

earthquakes involve kinetic energy, their effects are

simulated by equivalent static loads determined in ac-

cordance with the design standards. In recent years

there have been more sophisticated efforts to investi-

gate the actual response of tower structures to the

dynamic aspects of wind gusts. A conclusion drawn

from these studies is that the bending moments in the

upper portions of tall, guyed towers are considerably

higher than those determined by the usual static analy-

sis. Consequently, the loads imposed on the vertical

legs and their splice connections would be amplied

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

For towers under 700 ft in height the allowable

stresses given in the AISC specication may be in-

creased by one third. For towers 1,200 ft or taller, no

increase is permitted. For towers between 700 and

1,200 ft, the amount of increase permitted is deter-

mined by linear interpolation.

In a similar manner, the required reinforced concrete

strength for towers under 700 ft in height must equal

1.3 times the calculated reactions and for towers 1,200

ft and taller, 1.7 times the calculated reactions. Linear

interpolation between these two values is used for

towers between 700 and 1,200 ft to determine the

required strength.

The minimum safety factor for guy cables is 2 for

towers under 700 ft in height and 2.5 for towers 1,200

ft and taller with linear interpolation applied between

these two heights.

EFFECTS OF ANTENNAS AND

TRANSMISSION LINES

Except for AM radiators, the tower is the necessary

evil to support the broadcast antennas and transmission

lines at a suitable height above ground. Thus the effects

of this equipment are of paramount importance.

Loads

Every antenna imposes a wind load and a dead load

on the tower. If the antenna is mounted atop the tower,

it also imposes an overturning moment. If it is mounted

on a side of the tower, the antenna imposes a torsional

moment. For TV and FM broadcast and microwave

antennas, these loads are relatively large, and their

location has a signicant effect on the placement of

guy cables.

Transmission lines feeding the various antennas also

impose wind and dead loads on the tower. These loads

are distributed uniformly between the antenna and their

entry point near the base of the tower. The total pro-

duced by a coaxial line or waveguide is frequently

greater than that produced by the antenna itself. The

shape of the transmission line inuences the magnitude

of the wind load, with circular or elliptical lines having

loads that are 60% of those for rectangular lines with

the same projected area.

It is important not to overlook the support system

required for transmission lines. Some large waveguides

have support systems that require nearly continuous

vertical structural members that add substantial wind

and dead loads. Small, exible lines require supports

at a maximum interval of 3 to 4 ft, which is often less

than the vertical spacing of horizontal members in

the tower. Thus, it may be necessary to provide an

additional support structure for these lines, again add-

ing to the total load.

An important consideration when locating transmis-

sion lines is that the ANSI/TIA/EIA-222-F-1996 Stan-

dard permits linear appurtenances that are attached to

the tower face, and do not extend in width beyond the

normal projected area of the face, to be treated as

structural components rather than individual appurte-

nances for purposes for purposes of calculating wind

load. The effect of this is to substantially reduce the

magnitude of the calculated wind load on these appur-

tenances (see Figure 2.2-7). When this procedure is

used, it is mandatory that the transmission lines be

installed as specied in the design. This may not be

2 1 2

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 212

Figure 2.2-7. Effects of linear appurtenance locations on calculated wind loads.

D E SIG N , ER E C TIO N , A N D M A IN TE N A N C E O F A N TE N N A STR U C TU R E S

above to minimize interference with the guy cables.

The guy system and web bracing at these levels must

be designed to provide adequate torsional rigidity.

Capacity for small antennas may be provided at

various locations throughout the height of the tower.

One arrangement for a large number of antennas is to

provide a platform around the outside of the tower

that is large enough to support the radio equipment

for these antennas. The antennas can be mounted on

the outside railing of the platform, thereby requiring

only a short run of coax. Electrical power must be

provided to the platform. This arrangement imposes a

large concentrated load at the platform location with

a relatively small uniform load between the tower base

and the platform. If the same number of antennas were

mounted along the tower and each fed by an individual

coax line from the base, there would be only small

concentrated loads at the antenna locations, but a rela-

tively large uniform load due to the lines. This is an

entirely different distribution of load, and would have

a pronounced effect on the design.

Another important consideration for future antennas

or height extension is the electrical system. If an exten-

sion in height is planned, the wiring for the aircraft

warning light system should be designed so that any

additional lights can be connected to the system with-

out adding or replacing wires in the existing conduit.

The same holds true for any circuits required for future

antennas. If the necessary wiring cannot be provided

during the initial installations, capacity should be pro-

vided for additional conduits to hold the future circuits.

Replacement, Relocation, or Additions to

Existing Towers

Since every tower has been designed for a specied

arrangement of equipment, changes should not be

made without considering their effects on the structural

adequacy of the tower.

Two common misconceptions related to changes in

equipment are lower is better, and smaller is better.

Neither is necessarily correct, especially for guyed

towers. Decisions based on these premises can have

serious consequences.

It is much better to have a structural analysis of the

tower made by a structural engineer experienced in

tower design. Because of the signicant changes that

have been made in the methods of specifying loads in

the various revisions of the design standard, the analy-

sis should be made using the same criteria for wind

and ice loads used for the original design and also for

the current revision of the standard. This analysis will

determine if any overstresses would occur in the tower

or its foundations, and what modications and rein-

forcing would be required to retain the structural integ-

rity. To perform this analysis, it is necessary for the

engineer to have complete data on the tower and its

foundation including conguration, member sizes, and

material strengths. It is also necessary for the customer

to provide the engineer with a complete inventory of

existing antennas and transmission lines on the tower

along with the proposed equipment. Aplan viewdraw-

2 1 3

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 213

easily controlled for lines installed in the future. There-

fore, if the installation location of both the initially

installed and future transmission lines can not be regu-

lated, it may be prudent to prohibit the use of this

procedure.

Width Restrictions

Some antennas impose restrictions on the width of

the supporting tower. One common example is a side

mounted FM antenna requiring a maximum width of

18 to 24 in. For antennas with more than eight bays,

this results in a very slender structure. When placed

at the top of a tall, guyed tower, the design of the guy

system for this structure becomes extremely critical.

Use of a cantilevered pole structure above the top of

the main tower should be considered for these cases.

Another example of width restriction is a panel-type

TV or FM antenna mounted on the faces of the tower.

Here, too, it is often better to support these antennas

on a cantilevered structure above the main tower rather

than placing guys within the aperture of the antenna.

As previously mentioned, it is desirable to place

large waveguides inside the tower near the vertical

centroidal axis to prevent large torsional loads. This

requires a tower having a minimum face width in the

range of 7 to 8 ft to accommodate the waveguide and

its supports.

Initial and Future Considerations

Because the antennas and transmission lines have

such a signicant effect on the tower design, it is

important to consider all possible uses for a tower

before it is designed. It is better to have unused capacity

than to undergo expensive modications or replace-

ment in several years to obtain additional height or

accommodate another antenna. This has become ap-

parent in recent years with the proliferation of micro-

wave, two-way communications, cellular and personal

communication systems.

When providing for multiple antennas, it is im-

portant to determine not only the number and type of

antennas and lines, but also their location on the tower.

The distribution of load is equally important as mag-

nitude.

Triangular top platforms (candelabras) to support

broadcast antennas on each corner have been success-

fully used for many years. They have the advantage

of placing all antennas at the same height. A variation

of this platform to support only two antennas (tee-

bars) has also been used. Both of these systems require

multiple guy cables at the top platform to provide

adequate torsional stability. It is possible to design the

tower for a multiple antenna support platform without

installing all antennas at the same time.

Another arrangement of multiple antennas is stack-

ing (installing one antenna atop the tower and arrang-

ing others along the tower, one below the other). This

arrangement can also be combined with a multiple

antenna support platform.

If capacity for microwave antennas is required, it

should be provided near guy levels and preferably

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

ing of the tower, showing where the transmissions

lines, conduits, ladder, etc. are located, is also required.

The use of presumptive values can result in an analysis

with little value.

FOUNDATIONS AND ANCHORS

It is most difcult to predict the cost of the foundation

systemof a tower installation. This is due to the nonho-

mogeneous nature of soils, and the uncertainty of the

conditions that may exist below grade. Therefore, it

is necessary to have an investigation made of the sub-

surface soil conditions.

It is important to note that the soil design parameters

given in the ANSI/TIA/EIA-222-F-1996 Standard are

intended to serve only as a basis for preliminary design

and estimating of foundation cost prior to obtaining

specic soil data. They should not be used for the nal

design without verication by geotechnical investi-

gation.

Soil Investigation

The soil investigation should be made by an engi-

neering rm, which specializes in soil investigation

and evaluation, and is familiar with the general area

of the tower site. It should consist of making a test

boring at each foundation and guy anchor location,

analysis of soil samples taken from the borings, deter-

mination of ground water levels, recommendations of

parameters for designing the foundations, identica-

tion of any special construction procedures required,

and recommended backll specications. Other soil

characteristics or properties may be required because

of local conditions, such as the soil resistivity to deter-

mine if any special corrosion control methods should

be implemented. If piles or rock anchors are necessary,

recommendations related to these should be provided.

It should also address requirements for frost protection

and buoyancy effects.

Because the loads imposed on tower foundations are

unique from those for conventional buildings (tower

foundations have large uplift and horizontal compo-

nents), it is important to provide the soil engineer

with the loading conditions before they make their

investigation. This will enable the engineer to plan

their work in a manner suitable for obtaining and re-

porting the characteristics relevant to designing for the

projected foundation loads.

Self-Supporting Tower Foundations

Except for relatively small towers with narrow base

spreads, isolated foundations at each leg are usually

more economical than a single mat for all legs. These

foundations may be spread footings, drilled caissons

or driven piles. If sound rock is present at shallow

depths it is often economical to anchor the footing to

the rock. These anchors should be proof-loaded to

ensure their holding capacity in uplift.

Since these foundations are subjected to large uplift

forces, it is important to consider buoyancy effects if

ground water is present. Also, if driven or cast-in-

place piles are used, they must be adequately anchored

to the reinforced concrete cap.

Guyed Tower Base Foundations

These foundations may be spread footings, drilled

caissons or driven piles. Since they are subject only

to downloads with relatively small horizontal forces,

they require no special anchorage details for uplift,

unless they are placed above expansive soils. Buoy-

ancy is usually not a problem.

Guy Anchors

Deadmen (buried reinforced concrete blocks),

drilled caissons or driven piles may be used for these

foundations. If sound rock is present at shallow depths

it is often economical to anchor the foundation to

the rock.

These foundations are subject to large horizontal

forces as well as vertical uplift. Therefore, deadmen

must have a large enough frontal area bearing against

the soil to resist sliding; drilled caissons must have

sufcient diameter and depth to prevent excessive lat-

eral deections as well as pull out from uplift; and

driven piles must be sloped to prevent large lateral

loads being imposed on them. Rock anchors may be

installed along the slope of the resultant of the hori-

zontal and vertical loads, or they may be installed

vertically and post-tensioned to clamp the concrete cap

to the rock to prevent sliding. Because of the uplift

forces, it is important to consider buoyancy due to

ground water and to provide adequate anchorage for

driven or cast-in-place piles.

Construction

Since nearly the entire foundation system will be

belownished grade and not subject to later inspection,

it is important to carefully monitor its construction.

The following items should be veried:

Location and alignment of anchors in plan and ele-

vation.

Condition of excavation surfaces on which concrete

will be placed.

Position, size and grade of reinforcement steel.

Placement of concrete to prevent voids and air

pockets.

Strength of concrete using test cylinders for 7 and

28 day break tests.

Protection of concrete against freezing during the

curing period.

Placement and compaction of backll.

Driving records and/or load tests of piles.

Proof loading and post-tensioning of rock anchors.

For towers with extensive foundation systems, it is

advisable to retain an independent inspection service

for this work. Often the rm making the subsurface

soil investigation can also provide this service.

ERECTION

The erection of towers is a highly specialized eld and

should be performed only by rms having the proper

2 1 4

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 214

D E SIG N , ER E C TIO N , A N D M A IN TE N A N C E O F A N TE N N A STR U C TU R E S

Assembly of the tower sections should be done on

a level bed to ensure that they will be straight and not

racked or twisted. Bolts must be properly tightened

and have a locking device. For high strength galva-

nized bolts, tightening by the turn-of-the-nut method

is preferable to using a calibrated torque wrench.

Stacking

For a guyed tower, the rst group of three to six sec-

tions are often joined together on the ground and then

lifted into place using a crane. This portion of the tower

is then guyed with temporary cables, and the remaining

section are erected one at a time using a vertical boom

or gin pole. This boomis moved or jumped up the tower

as each section is installed. This arrangement is shown

in Figure 2.2-9. Temporary guys to stabilize the tower

should be used when instructed by the designer.

For a self-supporting tower, a crane is often used

to lift as many of the tower sections as possible, after

which a gin pole is installed and used for the upper

sections beyond the cranes reach.

Temporary aircraft warning lights must be installed

at the top of the construction at the end of each day.

The tower should be grounded as soon as the rst

section is in place.

Guy Installation

When the tower reaches a guy attachment level, the

cables at that level are installed. The guys in all three

directions should be pulled out simultaneously to pre-

vent any large unbalanced loads on the tower.

The tower should be checked for plumbness as each

set of guys is installed and tensioned. Maintaining a

plumb tower during erection eliminates the need for

time-consuming adjustments later. Final tensioning of

the guy cables and a plumbness check are done after

the entire tower is erected.

REINFORCEMENT AND MODIFICATIONS

OF EXISTING TOWERS

When equipment is replaced, relocated or added to a

tower it is often necessary to reinforce or replace ex-

equipment and experienced rigging personnel. It is

also important that the rm have adequate insurance

coverage including workmans compensation, general

and automobile liability, and builders all-risk for di-

rect damage to the tower and antennas being erected.

Owners Preparation

Prior to the arrival on site of the erection crew, the

site should be made ready for work to begin. These

preparations include:

Access. Suitable access from public roads for deliv-

ery of the tower materials and erection equipment

is required. While a paved roadway is not necessary,

the access must be able to handle heavy trucks and

construction equipment.

Permits. All necessary building and construction per-

mits should be obtained and posted as required. Any

inspections required during construction should be

noted.

Clearing. A work area must be cleared to permit

unloading, sorting, and assembling the tower. Paths

from the tower base to the guy anchors must be

cleared for a width adequate to permit hauling the

guy cables to the anchors and pulling them to the

tower. Paths must also be cleared for the hoist line

from the tower base to the hoist location, and for

the tag line used to stabilize the loads as they are

lifted. The sizes and locations of these cleared areas

should be agreed upon beforehand with the erector.

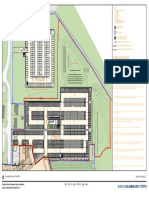

A typical layout is shown in Figure 2.2-8.

Electrical Power. Power for operating temporary

aircraft warning lights must be available before erec-

tion begins.

Assembly

The usual procedure for erecting a guyed tower is

to assemble the individual sections on the ground and

then lift them one at a time as an assembled unit. For

a self-supporting tower, the wider sections near the

bottom of the tower are often assembled in the air as

the tower is constructed.

2 1 5

National Assoc. of Broadcasters (NJ) (PS8295) PKF 01-06-99 09:34:51 CH2x2 Page 215

Figure 2.2-8. Typical layout for guyed tower.

Figure 2.2-9. Typical erection setup for guyed tower.

SE C TIO N 2 : B R O A D C A ST TO WE R S A N D SYSTE M S

isting structural components. The details and specifica-

tions for this work must be developed by the structural

engineer who analyzes the tower.

Leg members may be strengthened by installing

additional bracing or by eld-welding additional mate-

rial to them. Specic procedures in accordance with the

American Welding Society Structural Welding Code

must be provided and followed if eld welding is re-

quired.

Bracing members and guy cables may be replaced

with stronger components. Careful attention must be

given to the connections for the new components to

ensure their compatibility with the existing tower, as

well as providing the required strength for the new

components. When replacing components it is essential

that temporary bracing or guy cables be installed before

removing any existing component, and that it remain

in place until the new component has been installed.

It is necessary that damage to the protective nish

on existing members due to eld welding or reaming

be repaired. If required, the affected areas must be

painted for aviation obstruction marking.

Foundations and guy anchors are the most difcult

components to strengthen, and they may prove to be

the limiting factor in determining a towers capacity.

The nature and feasibility of strengthening these com-

ponents depend on the specic soil conditions.

INSPECTION AND MAINTENANCE

PROCEDURES

To ensure trouble-free performance of a tower and

its appurtenances, it is desirable to have a regular

inspection and maintenance program. Portions of the

program can be done by station personnel while others

require experienced tower personnel.

Safety precautions should be observed at all times

when working on or around the tower. If the tower

itself is energized or if a high intensity RF eld exists

from antennas mounted on it, no work should be done

on the tower without clearing it with the station engi-

neer. When climbing the tower, safety belts and climb-

ing devices should always be used. Automatic safety

features on elevators should never be bypassed to save

time. It is a good idea to never work alone. Failure to

observe proper safety measures can result in serious

injury or death.

Tower Structure

A visual inspection should be made of the entire

tower structure to determine if any of the members

have been deformed or damaged. Any bowed or kinked

member should be noted as to type, location in tower,

and nature and magnitude of deformation or damage.

This information should be reported to the tower de-

signer for evaluation and recommended action.

Condition of Paint

A visual inspection should be made of the entire

tower structure to determine the condition of the paint.

If the painting of the tower is for aircraft observation

marking only, and not for corrosion protection, it is

necessary only to note any general deterioration rather