Professional Documents

Culture Documents

HW D 0187

Uploaded by

Luiggi Zuñiga BarahonaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HW D 0187

Uploaded by

Luiggi Zuñiga BarahonaCopyright:

Available Formats

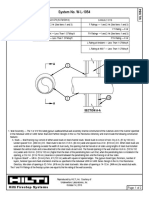

System No.

HW-D-0187

March 29, 2006

Assembly Ratings 1 and 2 Hr (See Items 2 and 3)

Max Joint Width - 2 In.

Class II Movement Capabilities - 20 % Compression or Extension

1. Floor Assembly Min 4-1/2 in. thick steel reinforced lightweight or normal weight (100-150 pcf) structural concrete.

Floor may also be constructed of any min 6 in. thick UL Classified hollow-core Precast Concrete Units* .

See Precast Concrete Units (CFTV) category in the Fire Resistance Directory for names of manufacturers

2. Wall Assembly The 1 or 2 hr fire rated gypsum board/steel stud wall assembly shall be constructed of the materials

and in the manner described in the individual U400 Series Wall or Partition Design in the UL Fire Resistance Directory and

shall include the following construction features:

A. Steel Floor and Ceiling Runners Floor and ceiling runners of wall assembly shall consist

of galv steel channels sized to accommodate steel studs (Item 2B). Ceiling runner to be

provided with 1 in. flanges. When U-shaped deflection channel (Item 3A) is used, ceiling runner

installed within the U-shaped deflection channel with a 1-1/2 in.gap maintained between the top

of ceiling runner and top of deflection plate. When deflection channel is not used, the ceiling

runner shall have min 2-3/4 in. flanges. Ceiling runner secured to floor assembly with steel

fasteners spaced a max 12 in. OC.

A1. Light Gauge Framing* Clipped Ceiling Runner As an alternate to the ceiling runner

in Item 2A, clipped runner to consist of galv steel channel with clips preformed in track flanges

which positively engage the inside flange of the steel studs (Item 2B). Track sized to

accommodate steel studs (Item 2B). Track flanges to be min 3-1/4 in. Clipped ceiling runner

secured to lower surface of floor with steel fasteners spaced max 12 in. OC. When clipped

ceiling runner is used, deflection channel (Item 3A) shall not be used. For 1 hr systems, bond

breaker tape to be applied to clipped ceiling runner on both sides of wall.

TOTAL STEEL SOLUTIONS L L C Snap Trak

B. Studs Steel studs to be min 3-1/2 in. wide. Studs cut 1-1/2 in. less in length than

assembly height. When deflection channel is used, studs shall be installed with bottom nesting

in and resting on floor runner and with top nesting in ceiling runner. Studs secured to floor and

ceiling runner with sheet metal screw. As an alternate to securing the studs to the ceiling

runner, the ceiling runner may be notched with the Snip N\' Slide tool used to provide positive

securement of the studs within the ceiling runner without the screws. When deflection channel

is not used, studs shall be secured to ceiling runner, however, the ceiling runner may be

notched with the Snip N\' Slide tool. Stud spacing not to exceed 24 in. OC.

C. Batts and Blankets* (Not Shown) Mineral wool or fiberglass insulation batts, friction-fitted

between studs and ceiling and floor runners, as required in the individual Wall and Partition

Design.

D. Gypsum Board* Gypsum board sheets installed to a min total thickness of 5/8 in. and 3/4

in. on each side of wall for 1 and 2 hr rated assemblies, respectively. Wall to be constructed as

specified in the individual Wall and Partition Design in the UL Fire Resistance Directory, except

that a nom 1-1/2 in. gap shall be maintained between the top of the gypsum board and the

bottom of the steel floor units and the top row of screws shall be installed into the studs 4 to

4-1/2 in. below the lower surface of the floor.

3. Joint System Max separation between bottom of floor and top of wall at time of installation of joint system is 2 in. The

joint system is designed to accommodate a max 20 percent compression or extension from its installed width. The joint

system consists of an optional deflection channel, gypsum wallboard strips, a forming material and a fill material, as

follows:

A. Deflection Channel (Optional) A nom 3-11/16 in. wide by 3 in. deep min No. 22 gauge

steel U-shaped channel. Deflection channel secured to floor assembly with steel fasteners (Item

1A) spaced max 12 in. OC. The ceiling runner (Item 2A) is installed within the deflection

channel to maintain a 1-1/2 in. gap between the top of the ceiling runner and the top of the

deflection channel. The ceiling runner is not fastened to the deflection channel.

B. Gypsum Board* When the thickness of gypsum board installed on each side of wall is

less than 1-1/4 in., a min 12 in. wide strip of min 1/2 in. thick gypsum board shall be installed

over the full sheets of gypsum board on each side of wall. The top edge of the strip shall be

flush with the top edge of the full sheets and shall be secured to steel studs with 1-5/8 in. long

Type S steel screw spaced max 6 in. OC. Strip also secured to full sheets midway between

studs with 1-5/8 in. long Type G steel laminating screws spaced max 6 in. OC vertically.

Uppermost screw securing the strip shall be located 4 to 4-1/2 in. below the lower surface of the

floor. Joints of strip to be offset from joints of full sheets. Joints covered with paper tape and

joint compound.

See Gypsum Board (CKNX) category for names of manufacturer.

C. Forming Material* Min 1-1/4 in. thickness of min 4 pcf mineral wool insulation cut larger

than the the max 2 in. wide gap above the top of the gypsum wallboard, compressed 33 percent

in width, and firmly packed into the flutes and the gap between the top of the wallboard and the

bottom of the floor assembly, flush with both surfaces of the wall.

ROCK WOOL MANUFACTURING CO Delta Board.

D. Fill, Void or Cavity Material* Min 1/8 in. wet thickness of fill material sprayed or troweled

on each side of the wall to completely cover mineral wool forming material and to overlap a min

of 1/2 in. onto wallboard and concrete floor on both sides of wall.

RECTORSEAL Metacaulk 1200 Spray, Metacaulk 1200 Caulk Grade.

*Bearing the UL Classification Mark

You might also like

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093No ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- D502Document5 pagesD502Gustavo Adolfo Quintero RuizNo ratings yet

- Transactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173From EverandTransactions of the American Society of Civil Engineers, Vol. LXX, Dec. 1910 A Concrete Water Tower, Paper No. 1173No ratings yet

- HWD0194Document2 pagesHWD0194Ever Nina LauraNo ratings yet

- Rev DrainDocument6 pagesRev DrainRaj RahulNo ratings yet

- Design No. I504Document1 pageDesign No. I504KaylaNo ratings yet

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviNo ratings yet

- System No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- System No. W-L-2199 Firestop SystemDocument2 pagesSystem No. W-L-2199 Firestop SystemDatNo ratings yet

- Roof Specification Requirements for ContractorsDocument30 pagesRoof Specification Requirements for ContractorsZulHilmi ZakariaNo ratings yet

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- AIR DISTRIBUTIOnDocument5 pagesAIR DISTRIBUTIOngauravconstructiondevelopersNo ratings yet

- W L 1176Document1 pageW L 1176shama093No ratings yet

- W L 1054Document2 pagesW L 1054shama093No ratings yet

- DuctworkDocument5 pagesDuctworkducatti996chNo ratings yet

- Shaftwall7.0 001Document9 pagesShaftwall7.0 001Wissam AlameddineNo ratings yet

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamNo ratings yet

- Technical Specifications CanopyDocument5 pagesTechnical Specifications CanopyNaman SharmaNo ratings yet

- BXUV.P204 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P204 Fire Resistance Ratings - ANSI/UL 263AlexNo ratings yet

- Specification For Chain Link Fence and GatesDocument8 pagesSpecification For Chain Link Fence and GatesSuresh BabuNo ratings yet

- System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRDocument2 pagesSystem No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaNo ratings yet

- Fire Resistance Ratings of Load Bearing Steel Stud Walls With Gypsum Wallboard ProtectionDocument8 pagesFire Resistance Ratings of Load Bearing Steel Stud Walls With Gypsum Wallboard Protectionjbatista_njg4152No ratings yet

- Assembly Manual: Thermasteel CorporationDocument28 pagesAssembly Manual: Thermasteel CorporationSarmishtha DeNo ratings yet

- Chain Link Fences and GatesDocument11 pagesChain Link Fences and Gatesمحمد عبد السلام الصوافNo ratings yet

- BXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqDocument4 pagesBXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqEmanuel Ciprian CiucurNo ratings yet

- Finishes Section Provides Details on Plaster, Tiles, Stones and MoreDocument54 pagesFinishes Section Provides Details on Plaster, Tiles, Stones and MoresothilingamnNo ratings yet

- Reinforced concrete pipe for small dams and leveesDocument10 pagesReinforced concrete pipe for small dams and leveesHans Hans SadzNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilingDocument5 pagesITCC in Riyadh Residential Complex J10-13300 09547-1 Metal CeilinguddinnadeemNo ratings yet

- A421-A426 Curtain WallDocument8 pagesA421-A426 Curtain WallronniedakingpouNo ratings yet

- Item F-161 Wire Fence With Steel Posts (Class C and D Fence)Document4 pagesItem F-161 Wire Fence With Steel Posts (Class C and D Fence)Wansa Pearl FoundationsNo ratings yet

- General Specification (Building) 30-01-21 198-380Document183 pagesGeneral Specification (Building) 30-01-21 198-380shujaNo ratings yet

- SECTION 02822 Chain Link Fences and Gates Part 1 - GeneralDocument4 pagesSECTION 02822 Chain Link Fences and Gates Part 1 - GeneralEmad KhanNo ratings yet

- C Aj 1609Document2 pagesC Aj 1609vhin84No ratings yet

- Res Spec SampleDocument5 pagesRes Spec SampleBryan Sacramento De LeonNo ratings yet

- CAJ1353Document1 pageCAJ1353Anonymous PCsoNCt0mFNo ratings yet

- ICC-ES Evaluation Report ESR-2218Document12 pagesICC-ES Evaluation Report ESR-2218Mark J LeingangNo ratings yet

- System No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDocument2 pagesSystem No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDatNo ratings yet

- Street LightingDocument2 pagesStreet LightingKamutura Ga TerereNo ratings yet

- Two-Storey Residential SpecsDocument7 pagesTwo-Storey Residential SpecsJayson Hernandez75% (32)

- Gi Conduit LayingDocument5 pagesGi Conduit LayingPrasad PanchatsaramNo ratings yet

- Site All Construction-ChecklistDocument8 pagesSite All Construction-Checklistjiguparmar20094903No ratings yet

- Concrete Joints GuideDocument4 pagesConcrete Joints GuideVSMS8678No ratings yet

- Fire Resistance Ratings for Metal Building Exterior WallsDocument4 pagesFire Resistance Ratings for Metal Building Exterior WallsbzakriaNo ratings yet

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulNo ratings yet

- U412 - 2 HourDocument4 pagesU412 - 2 Hourmaher58No ratings yet

- Specification For General Construction FroilanDocument6 pagesSpecification For General Construction FroilanRafael Luis So100% (1)

- BXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQDocument6 pagesBXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQEmanuel Ciprian CiucurNo ratings yet

- Drywall-Steel Framed SystemsDocument52 pagesDrywall-Steel Framed SystemsbuboynanayNo ratings yet

- Wire Fence With Steel Posts (Classes C and D Fences)Document4 pagesWire Fence With Steel Posts (Classes C and D Fences)Devrim GürselNo ratings yet

- Piping Design RequirementsDocument6 pagesPiping Design RequirementsTONNo ratings yet

- Diffuser ConnectionDocument4 pagesDiffuser Connectionbsh1978No ratings yet

- LTA PADEL COURT DATA SHEET GUIDEDocument14 pagesLTA PADEL COURT DATA SHEET GUIDEGilles PoggiNo ratings yet

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliNo ratings yet

- Struct EvalDocument8 pagesStruct EvalrxNo ratings yet

- Boq AliaDocument126 pagesBoq AliaMuhammad Shakil JanNo ratings yet

- CVS3 HVAC Duct Metal Work Specifications FINALDocument8 pagesCVS3 HVAC Duct Metal Work Specifications FINALMohammed MohieNo ratings yet

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlNo ratings yet

- FL - Sleeves and Sleeve Seals For Plumbing Piping - BudDocument5 pagesFL - Sleeves and Sleeve Seals For Plumbing Piping - BudAntonius HarrisNo ratings yet

- PFS Question Bank WatermarkDocument94 pagesPFS Question Bank WatermarkManjuladevi PNo ratings yet

- Provincial Architecture of KashmirDocument5 pagesProvincial Architecture of KashmirpayalNo ratings yet

- CISDI's Blast Furnace Overhaul Technology and PracticeDocument6 pagesCISDI's Blast Furnace Overhaul Technology and PracticeJJNo ratings yet

- Bahir Dar Institute of Technology: Chemical Engineering Department Thesis Project OnDocument67 pagesBahir Dar Institute of Technology: Chemical Engineering Department Thesis Project OnOlyad JemalNo ratings yet

- Department of Construction Sessional Examination (Spring Semester)Document9 pagesDepartment of Construction Sessional Examination (Spring Semester)Harry LaiNo ratings yet

- Cembrit CladdingDocument24 pagesCembrit CladdingNicky LimNo ratings yet

- Method Statement All-Hbc PDFDocument62 pagesMethod Statement All-Hbc PDFĐoàn Anh ĐứcNo ratings yet

- Fosroc Nitoflor EU10: Constructive SolutionsDocument4 pagesFosroc Nitoflor EU10: Constructive SolutionsVincent JavateNo ratings yet

- Lecture 1 Concrete TechnologyDocument24 pagesLecture 1 Concrete TechnologyadamNo ratings yet

- SEJ BoardDocument2 pagesSEJ BoardShodhan M AminNo ratings yet

- Epoxy Flake Flooring Application GuideDocument2 pagesEpoxy Flake Flooring Application GuidesyNo ratings yet

- Chapter Seven Structural Design of PavementDocument61 pagesChapter Seven Structural Design of PavementRobeam SolomonNo ratings yet

- Lexsha's BoqDocument81 pagesLexsha's BoqJan Lawrence AlbertoNo ratings yet

- Highway Restaurant Case Study: EL CAMIONDocument11 pagesHighway Restaurant Case Study: EL CAMIONAkshitha Nomula100% (1)

- Bills of Quantities For Majak Maker ProjectDocument19 pagesBills of Quantities For Majak Maker ProjectMalith NakNo ratings yet

- Design of Precast Concrete Structures With Regard To Accidental LoadingDocument11 pagesDesign of Precast Concrete Structures With Regard To Accidental LoadingSudhakaran PilicodeNo ratings yet

- Timber Yielding Plants of District HamirpurDocument15 pagesTimber Yielding Plants of District HamirpurSHIVANI ThakurNo ratings yet

- 20105-AR-GED-04-001-02 Rev 02Document1 page20105-AR-GED-04-001-02 Rev 02Bahaa MohamedNo ratings yet

- Quantity Estimate of 600 SS RCC GumbaDocument10 pagesQuantity Estimate of 600 SS RCC GumbaKale DaiNo ratings yet

- Keyed Through Tenon JointsDocument4 pagesKeyed Through Tenon JointsJerry ZhangNo ratings yet

- Level 2 Numbers GuideDocument1 pageLevel 2 Numbers GuideHumberto MorenoNo ratings yet

- PlasticsDocument48 pagesPlasticsPavan MehataNo ratings yet

- 12 Material ApprovalDocument1 page12 Material ApprovalDawit SolomonNo ratings yet

- FagorDocument47 pagesFagorahmeed1995alhadiNo ratings yet

- Damp Proof CourseDocument2 pagesDamp Proof CourseTHUSHAR PREMACHANDRAN KNo ratings yet

- Earthworks and road construction processesDocument5 pagesEarthworks and road construction processesmemekenya100% (3)

- Portfolio For Internship - Divyansh MishraDocument12 pagesPortfolio For Internship - Divyansh MishraDivyansh MishraNo ratings yet

- FRP Guide SpecificationDocument9 pagesFRP Guide SpecificationkuhomikzNo ratings yet

- Civil Engineering: FormworkDocument28 pagesCivil Engineering: FormworkSreenivas NaiduNo ratings yet

- HUGHES - Cator and Cribbage Construction of Northern PakistanDocument12 pagesHUGHES - Cator and Cribbage Construction of Northern PakistanFayaz JerovNo ratings yet

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetFrom EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetRating: 3.5 out of 5 stars3.5/5 (4)

- Knitting for Anarchists: The What, Why and How of KnittingFrom EverandKnitting for Anarchists: The What, Why and How of KnittingRating: 4 out of 5 stars4/5 (51)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Crochet Lace: Techniques, Patterns, and ProjectsFrom EverandCrochet Lace: Techniques, Patterns, and ProjectsRating: 3.5 out of 5 stars3.5/5 (3)

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (9)

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- Crafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsFrom EverandCrafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsRating: 1.5 out of 5 stars1.5/5 (3)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- Creative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsFrom EverandCreative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsRating: 4.5 out of 5 stars4.5/5 (2)

- Knit a Box of Socks: 24 sock knitting patterns for your dream box of socksFrom EverandKnit a Box of Socks: 24 sock knitting patterns for your dream box of socksNo ratings yet

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- Crochet: Fun & Easy Patterns For BeginnersFrom EverandCrochet: Fun & Easy Patterns For BeginnersRating: 5 out of 5 stars5/5 (3)

- Sew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsFrom EverandSew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsRating: 5 out of 5 stars5/5 (3)

- Cozy Minimalist Home: More Style, Less StuffFrom EverandCozy Minimalist Home: More Style, Less StuffRating: 4 out of 5 stars4/5 (154)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)

- Modern Granny Stitch Crochet: Make clothes and accessories using the granny stitchFrom EverandModern Granny Stitch Crochet: Make clothes and accessories using the granny stitchRating: 5 out of 5 stars5/5 (1)

- Sharpie Art Workshop: Techniques & Ideas for Transforming Your WorldFrom EverandSharpie Art Workshop: Techniques & Ideas for Transforming Your WorldRating: 3 out of 5 stars3/5 (16)

- Delicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreFrom EverandDelicate Crochet: 23 Light and Pretty Designs for Shawls, Tops and MoreRating: 4 out of 5 stars4/5 (11)

- Celestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesFrom EverandCelestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesRating: 3.5 out of 5 stars3.5/5 (6)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsFrom EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsRating: 4.5 out of 5 stars4.5/5 (10)

- Modern Crochet…For the Beach Babe Goddess: Easy to Use StitchesFrom EverandModern Crochet…For the Beach Babe Goddess: Easy to Use StitchesRating: 3 out of 5 stars3/5 (2)

- Layers of Meaning: Elements of Visual JournalingFrom EverandLayers of Meaning: Elements of Visual JournalingRating: 4 out of 5 stars4/5 (5)

- Irene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsFrom EverandIrene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsRating: 5 out of 5 stars5/5 (2)

- Learn to Crochet Granny Squares and Flower Motifs: 26 projects to get you startedFrom EverandLearn to Crochet Granny Squares and Flower Motifs: 26 projects to get you startedNo ratings yet