Professional Documents

Culture Documents

Type Tested Panels Abb

Uploaded by

Muhammed Talha Qureshi0 ratings0% found this document useful (0 votes)

768 views20 pagesabb

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentabb

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

768 views20 pagesType Tested Panels Abb

Uploaded by

Muhammed Talha Qureshiabb

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 20

IEC 61439

The new standard for low-voltage

switchgear and controlgear ASSEMBLIES

11 | 2010

2 IEC 61439 The new standard

IEC 61439 The new standard 3

Content

Page

Introduction ....................................................................... 4

The current IEC 60439 ....................................................... 5

The new IEC 61439 ........................................................... 6

Main changes .................................................................... 7

Responsibilities .................................................................12

FAQ .................................................................................14

Summary and conclusion ...................................................16

4 IEC 61439 The new standard

A low-voltage switchgear and controlgear assembly

(ASSEMBLY) is a combination of low-voltage switching

devices together with associated equipment (for control-

ling, measuring, signalling, etc.) complete with all the

internal mechanical and electrical interconnections and

structural parts. As with every component of an electrical

installation, the ASSEMBLY also has to comply with its

appropriate standard.

In January 2009 the IEC 61439, the new standard for low-

voltage switchgear and controlgear ASSEMBLIES, was

published. This was the aim of an international project group

which had been working on a task named radical restructuring

and revision of IEC 60439 series since 1998. This initiative

was introduced by several countries following dissatisfaction

with the IEC 60439 series. The purpose was to harmonise

and define all general requirements for low-voltage electrical

ASSEMBLIES.

Reaching an agreement has proven extremely challenging,

but the first parts of the new standards have been published.

For each type of electrical ASSEMBLY only two parts of the

standard are necessary to determine all requirements:

the basic standard IEC 61439-1 General rules

the specific ASSEMBLY standard

The aim of this guide is to allow panel builders, electrical

installers, planners or purchasers to familiarise themselves

with the new standards and to point out the main changes

that have been introduced as well as elements that remain

unchanged.

Introduction

IEC 61439 The new standard 5

The current IEC 60439

The current IEC 60439 standard applies to enclosures

for which the rated voltage is under or equal to 1000 V AC

(at frequencies not exceeding 1000 Hz) or 1500 V DC.

The standard makes a distinction between type-tested

assemblies (TTA) and partially type-tested assemblies

(PTTA).The following parts are mentioned and have equal

weighting. There is not a formal hierarchy. Each part is a

complete entity and can be used on an individual basis:

IEC 60439-1

type-tested and partially type-tested assemblies

IEC 60439-2

particular requirements for busbar trunking systems

(busways)

IEC 60439-3

particular requirements for low-voltage switchgear and

controlgear assemblies which are to be installed in locations

where unskilled persons have access for their use.

IEC 60439-4

particular requirements for assemblies for

construction sites (ACS)

IEC 60439-5

particular requirements for assemblies intended

to be installed outdoors in public places Cable distribution

cabinets (CDCs) for power distribution in networks

The standard remains valid until 2014

6 IEC 61439 The new standard

IEC 61439-1

Relationship between the two standards

is as shown in the table below:

IEC 61439-2 replaces

IEC 60439-1

(still valid until 2014)

IEC 61439-6 will replace

IEC 60439-2

(still valid)

IEC 61439-3 will replace

IEC 60439-3

(still valid)

IEC 61439-4 will replace

IEC 60439-4

(still valid)

IEC 61439-5 will replace

IEC 60439-5

(still valid)

The new IEC 61439 standard applies to enclosures

for which the rated voltage is under 1000 V AC

(at frequencies not exceeding 1000 Hz) or 1500 V DC.

The standard defines the design verified ASSEMBLIES

and eliminates completely the categories TTA and PTTA.

In order to conform to the standard, type tests have been

replaced by a design verification which can be carried

out by the three following equivalent and alternative

methods: testing, calculation/measurement or

application of design rules.

The following parts are mentioned and do not have equal

weighting. There is a formal hierarchy. Each part can not be

used individually:

IEC 61439-1 General rules

IEC 61439-2 Power switchgear and

controlgear ASSEMBLIES

IEC 61439-3 Distribution boards

IEC 61439-4 ASSEMBLIES for construction sites

IEC 61439-5 ASSEMBLIES for power distribution

IEC 61439-6 Busbar trunking systems

Part 1 is the general rules part and cannot be used alone to

specify an ASSEMBLY.

Part 2 defines the specific requirements of power switchgear

and controlgear ASSEMBLIES (PSC ASSEMBLIES) and must

be used with Part 1. This is the only part that has a double

role, it covers PSC ASSEMBLIES and any ASSEMBLY which

is not covered by any other specific parts.

Parts 3-X are still under preparation but are already men-

tioned in Part 1. These could be more than four, as additional

parts may be developed as the need arises.

Summarising: With the currently used IEC 60439, the rule

is one part for each type of ASSEMBLY. With the new

IEC 61439 the rule is two parts for each type of ASSEM-

BLY. The compliance of an ASSEMBLY is declared refer-

ring to the specific ASSEMBLY standard (e.g. IEC 61439-2),

and the compliance with the general rules (IEC 61439-1) is

always implicit. The sentence TTA switchgear according to

IEC 60439-1 is now replaced by Power switchgear and

controlgear ASSEMBLIES according to IEC 61439-2, design

verified ASSEMBLY.

The validity of the two standards will overlap until 2014 and

prior to this date, ASSEMBLIES can be manufactured accord-

ing to IEC 61439 or IEC 60439.

The new IEC 61439

IEC 61439 The new standard 7

The new IEC 61439 includes the following significant

technical changes with respect to the last edition of

IEC 60439.

Responsibility split:

New terms have been introduced and there is a split in

product responsibility between the Original manufacturer

(e.g. ABB, responsible for carrying out the original design

and the associated verification of an ASSEMBLY)

and the ASSEMBLY manufacturer (e.g panel builder

using an ASSEMBLY system from an Original Manufacturer)

assuming responsibility for the completed ASSEMBLY.

The Assembly Manufacturer may be a different organisation

to the Original Manufacturer. Where the ASSEMBLY Manu-

facturer introduces changes to the ASSEMBLY configuration

tested by the Original Manufacturer, he is deemed to be the

Original Manufacturer in respect of these changes and has to

carry out the design verification.

Design verification replaces TTA and PTTA categories:

Design verification replaces type tests so the discrimination

between type-tested assemblies (TTA) and partially type-

tested assemblies (PTTA) is eliminated.

Three different but equivalent types of verification of

requirements are introduced:

Verification by testing (test made on a sample of an ASSEM-

BLY or on parts of ASSEMBLIES to verify that the design

meets the appropriate requirements. This method is equiva-

lent to the currently implemented type tests).

Verification by calculation/measurement (calculations applied

to a sample of an ASSEMBLY or to parts of ASSEMBLIES to

show that the design meets the appropriate requirements).

Verification by application of design rules (specified rule to

verify the design of an ASSEMBLY).

The selection of the appropriate verification method has to be

made according to annex D, which explains the available veri-

fication options for each characteristic which is to be verified,

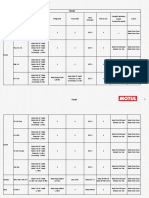

as shown in the table below:

Main changes

More than a single digit change

Characteristic to be verified

Verification options available

Verification

by testing

Verification

by calculation

Verification

by design rules

10.2 Strength of material and parts Yes No No

10.3 Degree of protection of enclosures Yes No Yes

10.4 Clearances and creepage distances Yes Yes Yes

10.5.2 Effective continuity between parts and PE Yes No No

10.5.3 Effectiveness of the ASSEMBLY for external faults Yes Yes Yes

10.6 Incorporating of apparatus No No Yes

10.7 Internal electrical circuits and connections No No Yes

10.8 Terminals for external conductors No No Yes

10.9.2 Power frequency withstand voltage Yes No No

10.9.3 Impulse withstand voltage Yes No Yes

10.10 Temperature rise limits Yes Yes Yes

10.11 Short-circuit withstand strength Yes Yes Yes

10.12 EMC Yes No Yes

10.13 Mechanical operation Yes No No

8 IEC 61439 The new standard

s

y

s

t

e

m

m

a

n

u

f

a

c

t

u

r

e

r

m

a

n

u

f

a

c

t

u

r

e

r

o

f

t

h

e

A

S

S

E

M

B

L

Y

ASSEMBLY

low-voltage switchgear and controlgear ASSEMBLIES

type tests for verification of conformity

TTA

type-tested ASSEMBLIES

type-tested units not type-tested units

PTTA

partial type-tested

ASSEMBLIES

routine test

completed ASSEMBLY

IEC 60439

Tests that have been made in accordance with IEC 60439

and that fulfil the requirements of the new IEC 61439 need

NOT be repeated.

The second stage verification is the routine verification. This

is performed to verify that the materials and workmanship are

in accordance with the requirements of the standard. Rou-

tine verification replaces the current routine test. It is more

detailed but essentially the new requirements are the same

as in the IEC 60439. This verification has to be carried out for

each completed ASSEMBLY and it is the responsibility of the

ASSEMBLY Manufacturer.

Main changes

More than a single digit change

Comparison between the current and the new verification flow:

IEC 61439 The new standard 9

o

r

i

g

i

n

a

l

m

a

n

u

f

a

c

t

u

r

e

r

A

S

S

E

M

B

L

Y

m

a

n

u

f

a

c

t

u

r

e

r

o

r

i

g

i

n

a

l

m

a

n

u

f

a

c

t

u

r

e

r

ASSEMBLY

low-voltage switchgear and controlgear ASSEMBLIES

testing calculation

ASSEMBLY system

application of design rules

routine verification

The ASSEMBLY manufacturer can decide:

to manufacture the ASSEMBLY according to the guidelines of the original manufacturer

t o deviate from the guidelines of the original manufacturer. Where the ASSEMBLY

manufacturer incorporates his own arrangements not included in the original manufacturers

verification, the ASSEMBLY manufacturer is deemed to be the original manufacturer

in respect of these arrangements.

completed ASSEMBLY

IEC 61439

design verification carried out by the original manufacturer

10 IEC 61439 The new standard

Tests described in IEC 61439-1 in comparison with the type tests described in IEC 60439

Additional verification:

New requirements from the standard IEC 62208

(Empty enclosures for ASSEMBLIES) have been added:

verification of resistance to UV radiation for

outdoor plastic enclosures

verification of corrosion resistance

mandatory declaration and confirmation of

an impulse rating

lifting, mechanical impact and marking

Other changes

Temperature rise

Temperature rise requirements have been explained more

clearly and have been adapted to the state of the art.

One of the following methods is allowed for verification:

testing with current

derivation (from a tested design)

of ratings for similar variants

calculation

(see also FAQ chapter)

Main changes

More than a single digit change

No. Characteristics to be verified Clause/Subclause

Comparable type test

from 60439-1

1 Strength of material and parts 10.2

Not required as

Type test but as

Design and

construction rules

on paragraph 7 or on

subsidiary standard

Resistance to corrosion 10.2.2

Properties of insulating materials 10.2.3

Thermal stability 10.2.3.1

Resistance of insulating materials to normal heat 10.2.3.2

Resistance to abnormal heat and fire due to internal electric effects 10.2.3.3

Resistance to ultra-violet (UV) radiation 10.2.4

Lifting 10.2.5

Mechanical impact 10.2.6

Marking 10.2.7

2 Degree of protection of enclosures 10.3 8.2.7

3 Clearances and creepage distances 10.4 8.2.5

4 Protection against electric shock and integrity of protective circuits 10.5

8.2.4

Effective continuity between the exposed conductive

parts of the ASSEMBLY and the protective circuit

10.5.2

Effectiveness of the ASSEMBLY for external faults 10.5.3

5

Incorporation of switching devices and components 10.6

Not required as

Type test but as

Design and

construction rules

on paragraph 7 or on

subsidiary standard

6

Internal electrical circuits and connections 10.7

7

Terminals for external conductors 10.8

8 Dielectric properties 10.9

8.2.2 Power -frequency withstand voltage 10.9.2

Impulse withstand voltage 10.9.3

9 Temperature rise limits 10.10 8.2.1

10 Short-circuit withstand strength 10.11 8.2.3

11 Electromagnetic compatibility (EMC) 10.12 + Annex J 8.2.8 + Annex H

12 Mechanical operation 10.13 8.2.6

IEC 61439 The new standard 11

RDF

The rated diversity factor is covered in more detail. In

practice it is assumed that multiple functional units are not

fully loaded simultaneously. (see also FAQ chapter)

Labels

Labels have to be subjected to testing to verify their legibility.

The following information is required on the label:

ASSEMBLY Manufacturers name

Identification number

Date of manufacture (NEW!)

IEC 61439-X (the specific part X has to be specified)

(NEW!)

Grey areas

A number of grey areas have been clarified:

neutral conductors will have a current rating equal to 50%

of the corresponding phases if not otherwise specified

agreements between Customer and Manufacturer have

been more detailed, extended and listed in annex C

it is mandatory to specify the rated current of the

ASSEMBLY

a technical report IEC 61439-0 Guide for specifying

ASSEMBLIES is under development for a better

understanding of the new standard

questions regarding the internal form of separation

have been clarified

(e.g. a moulded case circuit breakers casing provides

separation from other functional units)

Summary table with the main changes

IEC 60439 IEC 61439

IEC 60439-1

Type-tested and partially type-tested assemblies

IEC 61439-2

Design verified ASSEMBLIES

Mix of different rules and demands in each part

Clear structure:

IEC 61439-1 General rules

IEC 61439-2 -6 Subsidiary parts (product standard)

Each part is a complete entity and can be used on an individual basis

Each subsidiary part is based on the general rules (Part 1)

and includes only the specific additional rules for the specific product

Testing each type of ASSEMBLY:

Partially type-tested or type-tested

Three alternative methods for verification:

Test, calculation/measurement, design rules

Annex E:

Agreements between Customer and Manufacturer

Annex C:

Agreements between Customer and Manufacturer are

more detailed and extended

Shared responsibility:

Original Manufacturer vs. ASSEMBLY Manufacturer

Technical changes and clarifications:

Diversity factor, verification of temperature rise,

mechanical characteristics, neutral conductor 50%,

additional verification (from IEC 62208)

12 IEC 61439 The new standard

Some hypothetical examples:

An Original Manufacturer (e.g. ABB) assembles a

complete ASSEMBLY and sells it to a panel builder

the panel builder is only the ASSEMBLY Manufacturer,

if he installs the ASSEMBLY as it is.

the panel builder is the ASSEMBLY Manufacturer and

becomes the Original Manufacturer if he makes some

modifications to the ASSEMBLY.

A panel builder assembles a complete ASSEMBLY

(according to the rules of the Original manufacturer)

the panelbuilder is the ASSEMBLY Manufacturer and

is responsible for the ASSEMBLY, providing the electrical

installer installs the ASSEMBLY without making any

alterations.

A panel builder assembles a complete ASSEMBLY

(according to the rules of the Original manufacturer) that

has been partially assembled by an external supplier

the panel builder is the ASSEMBLY Manufacturer and

is responsible for the ASSEMBLY.

With regard to responsibilities, the general and obvious

rule is: the manufacturer of the ASSEMBLY is responsible

for the ASSEMBLY!

For a better explanation of this concept we can say:

the Original Manufacturer usually makes design verifications

and assumes responsibility for the proper functionality of

prototype ASSEMBLIES. He provides a portfolio of verified

ASSEMBLIES and each actor in the electrical market, who

becomes the ASSEMBLY Manufacturer, can manufacture

a design verified ASSEMBLY by following the instructions

supplied in the Original Manufacturers instruction manual or

catalogue; the ASSEMBLY Manufacturer assumes responsibil-

ity for the ASSEMBLY, he labels the ASSEMBLY and it is his

responsibility to declare that the ASSEMBLY complies with the

relevant standards. In practice he has two options:

he decides to manufacture the ASSEMBLY according to

the rules of the Original Manufacturer. In this case, the

ASSEMBLY Manufacturer has to perform only the second

stage verification, namely routine verification.

he decides NOT to manufacture the ASSEMBLY according

to the rules of the Original Manufacturer. In this case, the

ASSEMBLY Manufacturer incorporates his own arrange-

ments, so that he is deemed to be the Original Manufacturer.

Regarding these arrangements and he must then carry

out both the first and the second stage verification: design

verification and routine verification.

Responsibilities

IEC 61439 The new standard 13

14 IEC 61439 The new standard

FAQ

Is it possible to substitute a device within an

ASSEMBLY? What about temperature rise and short

circuit strength?

The new IEC 61439 clearly defines a device substitution in

respect of temperature rise and short circuit strength.

Temperature rise: it is possible to substitute a device without

repeating the design verification, provided that the new device

from the same or another series has identical or better values,

regarding power loss and terminal temperature rise, in com-

parison with those of the original device, as tested in accord-

ance with the product standard.

Short circuit: it is possible to substitute a device without

repeating the design verification, provided that the new device

is identical. If different, it has to be from the same manufactur-

er who has to certify that it is equivalent or better with regard

to all relevant short circuit characteristics.

Is the verification of the short circuit withstand strength

required for all circuits of an ASSEMBLY?

No, it is not required for:

An ASSEMBLY having a rated short-time withstand current

or rated conditional short circuit current not exceeding

10 kA r.m.s.

An ASSEMBLY protected by current-limiting devices having

a cut-off current not exceeding 17 kA at the maximum

permitted prospective short-circuit current at the terminals

of the incoming circuit of the ASSEMBLY.

Auxillary circuits of an ASSEMBLY intended to be connect-

ed to transformers whose rated power does not exceed

10 kVA for a rated secondary voltage of not less than 110 V,

or 1.6 kVA for a rated secondary voltage less than 110 V,

and whose short circuit impedance is not less than 4%.

All other circuits have to be verified.

Until what point is it possible to manufacture and to

install ASSEMBLIES in accordance with IEC 60439?

The validity of the two standards will overlap until 2014 and

prior to this date, ASSEMBLIES can be manufactured accord-

ing to IEC 61439 or IEC 60439.

If tests on the ASSEMBLY have been conducted in

accordance with IEC 60439, is it necessary to repeat

them in accordance with the new IEC 61439?

No, if the conducted test results fulfil the requirements of

the new IEC 61439 it is not necessary to repeat them.

It is necessary to test only the additional verification that

has been introduced by the new standard.

Is it possible to manufacture an ASSEMBLY in accordance

with the new IEC 61439, with enclosures from ABB,

busbars from another manufacturer, circuit breakers from

another manufacturer, etc.?

Yes, it is possible but it is not easy and it is expensive. The

panel builder that decides to mix different elements from dif-

ferent manufacturers is not only the ASSEMBLY Manufacturer,

but becomes the Original Manufacturer and has to perform

both the first and the second stage verification: design verifi-

cation and routine verification.

The routine verification is similar to the present routine test

and is relatively straightforward. The design verification how-

ever includes some characteristics which are easily verified,

and others that can only be verified through laboratory

testing.

What is the Rated Diversity Factor (RDF)?

The RDF is the per unit value of the rated current, to which

outgoing circuits of an ASSEMBLY can be continuously and

simultaneously loaded (the mutual thermal influences have to

be taken into account). It can be declared for groups of

circuits or for the whole ASSEMBLY. The RDF has to be as-

signed by the ASSEMBLY Manufacturer (if not specified it is

assumed to be equal to 1). In practice it is recognised that not

all circuits in an ASSEMBLY operate at rated current

continuously and this allows efficient use of materials and

resources.

IEC 61439 The new standard 15

Does the verification of temperature

rise remain unchanged?

Temperature rise requirements have been explained in further

detail. Three different methods are now allowed for verification

(the Original Manufacturer is responsible for choosing the

suitable verification methods):

1) Testing with current:

Three different test methods are permitted and the Original

Manufacturer has to determine the best method. When

a number of variants of an ASSEMBLY have to be verified,

the most onerous configuration has to be tested and the

ratings of the less onerous (and similar) variants can be

derived without testing.

2) Derivation:

(from a tested design) of ratings for similar variants

The standard defines a series of sub-clauses that help

define, how non-tested variants can be verified by

derivation from similar arrangements verified by test.

3) Calculation:

two calculation methods are allowed

Single compartment ASSEMBLY with rated current not

exceeding 630 A (done by calculating the total power loss

of the ASSEMBLY if certain conditions are fulfilled).

Multiple compartment ASSEMBLY with rated current not

exceeding 1600 A (done by calculation in accordance with

the method of IEC 60890 if certain conditions are fulfilled).

Flow chart to establish how to verify the temperature rise

I

nA

630 A

Single

compartment?

Yes Yes

Yes

Yes No

Yes No

No No

No

I

nA

1600 A

Are the IEC 61439

and IEC 60890

conditions fulfilled?

Are the IEC 61439

conditions fulfilled?

Calculation in accordance

with IEC 60890

Testing with current OR

derivation (if a tested prototype is available)

Calculation of the

total power loss

16 IEC 61439 The new standard

Summary and conclusion

The new standard IEC 61439 introduces important

modifications in comparison with the current standard

IEC 60439 on low-voltage switchgear and controlgear

ASSEMBLIES.

The structure of the new standard is clearer with a general

part and product specific parts. New definitions have been

written (e.g. Original Manufacturer and ASSEMBLY Manu-

facturer). New compulsory characteristics have to be specied

(e.g. rated current of the ASSEMBLY).

A new design verified ASSEMBLY concept has been speci-

fied. This new concept completely discards the categories

TTA and PTTA, and the compliance of an ASSEMBLY can now

not only be verified by means of tests, but also with alterna-

tive methods: calculation/measurement and design rules.

The new standard is more precise, eradicating the grey

areas contained in the previous standard. The responsibilities

for an ASSEMBLY are clearly defined, making the job of each

actor on the electrical market easier nowadays.

18 IEC 61439 The new standard

Notes

Contact us

You can find the address of your local sales organisation

on the ABB homepage:

www.abb.com/contacts

> Low Voltage Products and Systems

K

-

0

1

1

9

-

K

M

-

1

1

/

2

0

1

0

-

V

1

2

C

P

C

0

0

0

1

1

9

L

0

2

0

1

Note: We reserve the ri ght to make techni cal changes or modi fy

the contents of this document without prior notice. With regard

to purchase orders, the agreed parti cul ars shal l prevai l .

ABB AG does not accept any responsibility whatsoever for poten-

tial errors or possible lack of information in this document.

We reserve all rights in this document and in the subject matter

and illustrations contained therein. Any reproduction, disclosure to

third parties or utilization of its contents in whole or in parts is

forbidden without prior written consent of ABB AG.

Copyright 2010 ABB

All rights reserved

You might also like

- 5 - SMDBDocument4 pages5 - SMDBKhyle Laurenz DuroNo ratings yet

- Professional Classification Manual For Health PractitionersDocument55 pagesProfessional Classification Manual For Health PractitionersMarsFriendNo ratings yet

- Cea Notes For Mining 513Document22 pagesCea Notes For Mining 513Vivek AgarwalNo ratings yet

- LT Aerial Bunch Cable (3C X 95 SQMM)Document541 pagesLT Aerial Bunch Cable (3C X 95 SQMM)Biju100% (5)

- ABB (Pro-E Type Test) - PanelDocument16 pagesABB (Pro-E Type Test) - Panelari bowoNo ratings yet

- Specification of LT Capcitor PannelDocument12 pagesSpecification of LT Capcitor PannelPrashant TrivediNo ratings yet

- Guide to Cable Trays and AccessoriesDocument5 pagesGuide to Cable Trays and AccessoriesPeter AntonyNo ratings yet

- LT Power Cable - Data SheetDocument9 pagesLT Power Cable - Data SheetAnagha DebNo ratings yet

- Goel Power Engineers AMF Panel Price-ListDocument1 pageGoel Power Engineers AMF Panel Price-Listrdeepak99100% (1)

- Electromech BOQDocument3 pagesElectromech BOQCoreg ToNo ratings yet

- Gland PL 01.09Document2 pagesGland PL 01.09anantkumbhar1100% (2)

- Cable CapacityDocument15 pagesCable Capacityvijay_raina3114No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVBS09CXSWY2003C004SA002S Date: Rev No.bharathNo ratings yet

- Material Inspection SummaryDocument34 pagesMaterial Inspection SummarySUDDHA CHAKRABARTYNo ratings yet

- 04 Electrical SpecificationDocument49 pages04 Electrical SpecificationVishal NarkhedeNo ratings yet

- Color Code For Electrical - PDMSDocument1 pageColor Code For Electrical - PDMSarvindNo ratings yet

- Principles of Cable SizingDocument5 pagesPrinciples of Cable SizingUmang PatelNo ratings yet

- 11 KV VCB With 1250A IC OG 6 Panel Board - FinalDocument16 pages11 KV VCB With 1250A IC OG 6 Panel Board - FinalAbhinav TewariNo ratings yet

- Power Demand Calculation: 1.1. Features of FacilityDocument12 pagesPower Demand Calculation: 1.1. Features of Facilitytaochiuthuaco102No ratings yet

- Powerful Energy Analyser for Load Management and Power Quality AnalysisDocument4 pagesPowerful Energy Analyser for Load Management and Power Quality AnalysisKhushal shendeNo ratings yet

- List of Electrical Standard Specifications: Power Control Centres, Motor Control Centres Document STD002.U07 1/33 Rev. ADocument33 pagesList of Electrical Standard Specifications: Power Control Centres, Motor Control Centres Document STD002.U07 1/33 Rev. Avaithy1990No ratings yet

- Electrical thumb rules and equations for engineersDocument2 pagesElectrical thumb rules and equations for engineersRajj Pruthivi100% (1)

- 20 - Technical Data & FormulationsDocument11 pages20 - Technical Data & FormulationsSnzy DelNo ratings yet

- Electrical InstallationDocument3 pagesElectrical InstallationAmpumuza AdrianNo ratings yet

- 2240 162 Pve U 004 SHT 3 3 01Document13 pages2240 162 Pve U 004 SHT 3 3 01Anagha DebNo ratings yet

- Rudolf RTXDocument15 pagesRudolf RTXNuengruthai WeerawattanaNo ratings yet

- AS222ER01 - G08 Distribution Transformer Cable Trench: Typically - 500mmx500mm Trench Is Shown in The DrawingDocument7 pagesAS222ER01 - G08 Distribution Transformer Cable Trench: Typically - 500mmx500mm Trench Is Shown in The Drawingsivaram_kvNo ratings yet

- Reference TG - Cable ScheduleDocument21 pagesReference TG - Cable Scheduleerkamlakar2234No ratings yet

- Earthing & Lightning BOQDocument1 pageEarthing & Lightning BOQBijaya Kumar MohantyNo ratings yet

- KSEB Tender for Cable Laying and RMU InstallationDocument8 pagesKSEB Tender for Cable Laying and RMU InstallationLakshika AshaniNo ratings yet

- Trench SpecificationsDocument4 pagesTrench SpecificationsFatoni Gea AirlanggaNo ratings yet

- Selection of Main & Branch CB As Per NEC-210 (14.1.14)Document16 pagesSelection of Main & Branch CB As Per NEC-210 (14.1.14)casaouis02No ratings yet

- Tariff Metering PanelsDocument2 pagesTariff Metering PanelsSaraswatapalitNo ratings yet

- Abstract of IS 694-1554-11892Document2 pagesAbstract of IS 694-1554-11892Jignesh ParmarNo ratings yet

- Module 3 block diagram water system Suratgarh TPSDocument5 pagesModule 3 block diagram water system Suratgarh TPSSatender KumarNo ratings yet

- Lightening Arrester 500kVTest Report EnglishDocument20 pagesLightening Arrester 500kVTest Report Englishashwani2101No ratings yet

- Short-Circuit AC V2.0Document15 pagesShort-Circuit AC V2.0Terefe TadesseNo ratings yet

- HDPE Sheath, Power CablesADocument6 pagesHDPE Sheath, Power CablesAkolombo1776No ratings yet

- Bill Excel WorksheetDocument30 pagesBill Excel Worksheetfiroj bagNo ratings yet

- Electrical Cable Sizing Calculation for 80KW LoadDocument5 pagesElectrical Cable Sizing Calculation for 80KW LoadacecNo ratings yet

- REC Construction Standards: Name of The SpecificationDocument9 pagesREC Construction Standards: Name of The SpecificationJasmin ShethNo ratings yet

- Calculate Bus Bar SizeDocument22 pagesCalculate Bus Bar Sizevjvijay88No ratings yet

- 33KV WTG Switchyard BOMDocument4 pages33KV WTG Switchyard BOMManohar Potnuru100% (1)

- Technical Specs Distribution BoardsDocument55 pagesTechnical Specs Distribution Boardsnavinchopra1986No ratings yet

- Abb Switchgear PricelistDocument360 pagesAbb Switchgear PricelistH.S Engineering worksNo ratings yet

- 33 KV Pooling Station & Metering YardDocument12 pages33 KV Pooling Station & Metering YardMadhukar PadipallyNo ratings yet

- Switchboards, Distribution Boards and Control PanelsDocument45 pagesSwitchboards, Distribution Boards and Control PanelsRachel IngramNo ratings yet

- How To Read A Motor NameplateDocument8 pagesHow To Read A Motor Nameplateabdulyunus_amirNo ratings yet

- Guarantee Technical ParametersDocument3 pagesGuarantee Technical ParametersDramebaaz SandeepNo ratings yet

- Earthing PitDocument4 pagesEarthing PitChaitanya ShakyaNo ratings yet

- ABB TransformatoriDocument1 pageABB TransformatoridgngNo ratings yet

- MV Cable Termination (Heat Shrink)Document25 pagesMV Cable Termination (Heat Shrink)Muhammad SajjadNo ratings yet

- Busbar TrunkDocument16 pagesBusbar Trunkabhi_0302No ratings yet

- DETUNED FILTER CAPACITOR SELECTIONDocument3 pagesDETUNED FILTER CAPACITOR SELECTIONsalmanNo ratings yet

- Power Cable StandardsDocument3 pagesPower Cable StandardsJamie 'Bear' ReaderNo ratings yet

- IEC - Panel RegulationDocument20 pagesIEC - Panel RegulationAsith SavindaNo ratings yet

- IEC 61439 standards for LV switchgear assembliesDocument4 pagesIEC 61439 standards for LV switchgear assembliesSameerEkriemNo ratings yet

- Presentation On IEC 61439Document95 pagesPresentation On IEC 61439Youwan Lee100% (1)

- The Change From Iec 60439 To Iec 61439 James Hunt Voltimum S Managing Editor Introduces This TopicDocument3 pagesThe Change From Iec 60439 To Iec 61439 James Hunt Voltimum S Managing Editor Introduces This TopicThanis SribovornmongkolNo ratings yet

- IEC 61439 - 2011 New Standard PDFDocument21 pagesIEC 61439 - 2011 New Standard PDFSamsung JosephNo ratings yet

- Iec-61439 Se6461Document32 pagesIec-61439 Se6461carlosmandopintoNo ratings yet

- Load Center DMT FinalDocument1 pageLoad Center DMT FinalMuhammed Talha QureshiNo ratings yet

- TransformersDocument7 pagesTransformersMuhammed Talha QureshiNo ratings yet

- BS882Document14 pagesBS882Muhammed Talha Qureshi0% (1)

- Traffic sign messagesDocument8 pagesTraffic sign messagesWaseem GullNo ratings yet

- Certificate of Good Standing Request FormDocument1 pageCertificate of Good Standing Request FormprofarmahNo ratings yet

- 1-2005Document8 pages1-2005Somkene Mbakwe0% (1)

- Answers Mock Exam 5Document6 pagesAnswers Mock Exam 5Muhammed Talha QureshiNo ratings yet

- FFDocument2 pagesFFMuhammed Talha QureshiNo ratings yet

- 56-SDMS, Specs For 13.8KV Unit Substation PDFDocument14 pages56-SDMS, Specs For 13.8KV Unit Substation PDFA. Hassan100% (1)

- 16129Document6 pages16129Muhammed Talha QureshiNo ratings yet

- Thaleya cluster restaurants electromechanical design scopeDocument2 pagesThaleya cluster restaurants electromechanical design scopeMuhammed Talha QureshiNo ratings yet

- Minimum Sle RequirmentsDocument1 pageMinimum Sle RequirmentsArsalan BangashNo ratings yet

- Mock 7 AnswersDocument5 pagesMock 7 AnswersMuhammed Talha QureshiNo ratings yet

- Distribution Panels SpecDocument4 pagesDistribution Panels SpecMuhammed Talha QureshiNo ratings yet

- Bus DuctDocument2 pagesBus DuctMuhammed Talha QureshiNo ratings yet

- Application ReportDocument6 pagesApplication ReportMuhammed Talha QureshiNo ratings yet

- MT Ele 11 Transformers (Rejected)Document3 pagesMT Ele 11 Transformers (Rejected)Muhammed Talha QureshiNo ratings yet

- Low Voltage Transformer Through Fault Protection-A System ApproachDocument8 pagesLow Voltage Transformer Through Fault Protection-A System ApproachSreeram PanigrahiNo ratings yet

- ExampleDocument4 pagesExampleMuhammed Talha QureshiNo ratings yet

- Recommendation Letter FormDocument1 pageRecommendation Letter FormprofarmahNo ratings yet

- Ethics For Health PractitionersDocument60 pagesEthics For Health PractitionersMuhammed Talha QureshiNo ratings yet

- ExampleDocument4 pagesExampleMuhammed Talha QureshiNo ratings yet

- Business Letter SampleDocument3 pagesBusiness Letter SampletoingunhulonNo ratings yet

- Merkblatt EngDocument2 pagesMerkblatt EngMuhammed Talha QureshiNo ratings yet

- F00938en 01Document7 pagesF00938en 01Muhammed Talha QureshiNo ratings yet

- Power Technical Guide 04Document71 pagesPower Technical Guide 04Muhammed Talha QureshiNo ratings yet

- Merkblatt EngDocument2 pagesMerkblatt EngMuhammed Talha QureshiNo ratings yet

- Hancock Series 5505Document8 pagesHancock Series 5505Ricardo CastroNo ratings yet

- Architectural Lighting - March April 2013Document116 pagesArchitectural Lighting - March April 2013HomoSapiens Urbano Santiago100% (1)

- India's Largest Coal Miner Coal India ContactsDocument5 pagesIndia's Largest Coal Miner Coal India ContactsRathinder RathiNo ratings yet

- Arbitrage Models of Commodity Prices - SlidesDocument36 pagesArbitrage Models of Commodity Prices - SlidesTraderCat SolarisNo ratings yet

- Marketing ReportDocument83 pagesMarketing ReportHimadri SNo ratings yet

- Chapter 4 Motorola R56!09!01 05Document100 pagesChapter 4 Motorola R56!09!01 05gomozalipanNo ratings yet

- List of Maharatna, Navratna and Miniratna CPSEsDocument3 pagesList of Maharatna, Navratna and Miniratna CPSEsraviNo ratings yet

- Guía de Lubricación de Motos Honda PDFDocument3 pagesGuía de Lubricación de Motos Honda PDFMartin LabatNo ratings yet

- Energy Utilization IndexDocument3 pagesEnergy Utilization IndexRobertNo ratings yet

- Električne Bicikle PDFDocument72 pagesElektrične Bicikle PDFdvazanski-1No ratings yet

- Language of Trends - Using PrepositionDocument2 pagesLanguage of Trends - Using PrepositionMai Anh Le0% (1)

- LPRVP - Admissible Load On BranchesDocument2 pagesLPRVP - Admissible Load On Branchesrebelde1986No ratings yet

- 2014 - Reference FormDocument287 pages2014 - Reference FormUsiminas_RINo ratings yet

- Case Study: Capacity Expansion For Transportation Project - San Antonio's Project, BoliviaDocument3 pagesCase Study: Capacity Expansion For Transportation Project - San Antonio's Project, BoliviaMuhammad ImranNo ratings yet

- Annual Report Electricity of Vietnam 2012-2013Document41 pagesAnnual Report Electricity of Vietnam 2012-2013Nguyen Quang VinhNo ratings yet

- CA2019 - Fleetmap Operações de Estádios V1 2Document8 pagesCA2019 - Fleetmap Operações de Estádios V1 2Paulo Ignacio Prouza CruzatNo ratings yet

- IndScan Projects Newsletter August 2010 Highlights/TITLEDocument63 pagesIndScan Projects Newsletter August 2010 Highlights/TITLEAnush UnoNo ratings yet

- Castillo ProfileDocument46 pagesCastillo ProfileprabhumanocNo ratings yet

- Flex Pump 47Document2 pagesFlex Pump 47Alex Castañeda100% (1)

- IRobot Scooba 450 ManualDocument32 pagesIRobot Scooba 450 ManualDutu Sergiu SimotaNo ratings yet

- Gri 101 Foundation 2016 PDFDocument30 pagesGri 101 Foundation 2016 PDFIlhamAkbarN.NasutionNo ratings yet

- Vibration Monitoring 1Document4 pagesVibration Monitoring 1Anonymous DKv8vpNo ratings yet

- APR48Document29 pagesAPR48ariess22009No ratings yet

- N26 Carbon AssesmentDocument6 pagesN26 Carbon Assesmentfannyw2001No ratings yet

- Performance Evaluation of Alaoji Thermal Power PlantDocument8 pagesPerformance Evaluation of Alaoji Thermal Power PlantIjaems JournalNo ratings yet

- Marine LED LightsDocument7 pagesMarine LED LightsSagar TanksaliNo ratings yet

- Servomax India: Leading Power Solutions Provider Since 1982Document81 pagesServomax India: Leading Power Solutions Provider Since 1982UdayNo ratings yet

- Vol2 TL-S1-6 3626 PGCBDocument124 pagesVol2 TL-S1-6 3626 PGCBabhi120783No ratings yet

- AHRIDocument3 pagesAHRISithuNo ratings yet

- Canon's CSR Profile and ConflictsDocument11 pagesCanon's CSR Profile and ConflictsJzevonimher C. EjeraNo ratings yet