Professional Documents

Culture Documents

Crossarm Design 3071/1 3071/2 Crossarm Applications 3072: Description DWG Description DWG

Uploaded by

iobtec0 ratings0% found this document useful (0 votes)

37 views4 pagescross arm details

Original Title

Section 06 Crossarms

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcross arm details

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

37 views4 pagesCrossarm Design 3071/1 3071/2 Crossarm Applications 3072: Description DWG Description DWG

Uploaded by

iobteccross arm details

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

DESCRIPTION DWG DESCRIPTION DWG

Ergon Energy Corporation Ltd

ABN 50 087 646 062

FILE: 5 35 3070 1

DISTRIBUTION DESIGN - OVERHEAD

CROSSARMS

INDEX

APPROVED

DATE

PASSED

DRAWN

M. Kavanagh Index

24.5.01

Sh 1

J . Brooks

A.Croft

A ORIGINAL ISSUE

Crossarm design 3071/1

3071/2

Crossarm Applications 3072

A ORIGINAL ISSUE

DISTRIBUTION DESIGN OVERHEAD

CROSSARMS

CROSSARM DESIGN

Ergon Energy Corporation Ltd

ABN 50 087 646 062

APPROVED

DATE

PASSED

DRAWN

FILE: 5 35 3071 1

Dwg

30/04/01

C.Noel

Sh 1

3071

B

24/02/03 B

CROSSARMS

CROSSARM DESIGN

The Queensland Electricity Supply Industry Technical Specification for

Hardwood Crossarms TS 07-02-01 specifies that timber shall generally

be visually stress graded in accordance with AS 2082. The minimum

stress grade for timber supplied to the specification is F17 except that

only Structural Grade No 1 or 2 shall be accepted.

The F17 stress grade may be achieved by a number of combinations of

strength group and structural grades. The minimum strength group

allowable is S3, however the majority of crossarms supplied generally

come into the strength group S2 and the additional specification

requirement that the top surface be without visual defects effectively

means that the actual F grade is generally somewhat better than F17.

Timber stresses are to be based generally in accordance with AS 1720.1

1997 using a limit state approach.

Crossarms are specified with dimensional tolerance of + 3mm and are

supplied generally in an unseasoned state. Design stresses are therefore

based on values for unseasoned timber and used in conjunction with the

minimum undertolerance value.

Crossarm duties are to comply with the most onerous of the following

conditions:

Maximum Wind load case using a limit state design wind pressure on

conductors of 1200Pa in defined cyclone prone areas and 900Pa

elsewhere.

Permanent or Long Duration load case based on standard conductor

tensions at 15C under no wind conditions.

Maintenance load case to account for loads generated during

construction or maintenance activities based on 100Pa wind loads at

15C.

For Intermediate crossarms, it is assumed that there is a nominal

longitudinal tension of 5% of the conductor tension.

Design of bolted connections In accordance with AS1720.1 Section

4.4 using joint group J2. In general this will not be a limitation for the

expected structure duties.

Timber stresses and load factors to be used for these load cases are

as follows:

Maximum Wind Load

Design timber stress in Bending 37.8 MPa

Design timber stress in tension 22.4 MPa

Load factors are as follows:

Allowance for wind loads shall be provided based on limit state

wind pressure appropriate to the location.

Vertical dead loads from non conductor loads

(insulator and crossarm self weight) 1.1

Vertical conductor loads 1.25

Longitudinal conductor loads based on limit state

design wind pressure applied to appropriate MES. 1.0

Permanent or Long Duration Load

Design timber stress in Bending 18 MPa

Design timber stress in tension 11 MPa

Load factors are as follows:

No allowance to be provided for wind load

Vertical dead loads from non conductor loads

(insulator and crossarm self weight) 1.0

Vertical conductor loads 1.0

Longitudinal conductor loads based on conductor

EDT at 15C. 1.0

Ergon Energy Corporation Ltd

ABN 50 087 646 062

FILE: 5 35 3071 2

DISTRIBUTION DESIGN - OVERHEAD

CROSSARMS

CROSSARM DESIGN

APPROVED

DATE

PASSED

DRAWN

M. Kavanagh Dwg

30.06.05

3071 B Sh 2

J . Brooks

A.Croft

A ORIGINAL ISSUE

B 24.2.03

CROSSARMS

CROSSARM DESIGN

Maintenance Load Case

Design timber stress in Bending 30.6 MPa

Design timber stress in tension 18.3 MPa

Load factors are as follows:

Allowance for wind loads based on nominal wind pressure

of 100Pa

Vertical dead loads from non conductor loads 1.1

Vertical conductor loads 1.5

Longitudinal conductor loads based on 100Pa

wind pressure applied to appropriate MES 1.5

Weight of men and equipment 2.0

Allowance to be provided for pole top rescue loads

assuming weight of man at 1.0kN with mechanical advantage

2.0 on lowering line (ie. load multiplication factor 1.5) applied

800mm from the pole.

A ORIGINAL ISSUE

DISTRIBUTION DESIGN OVERHEAD

CROSSARMS

CROSSARM APPLICATIONS

Ergon Energy Corporation Ltd

ABN 50 087 646 062

APPROVED

DATE

PASSED

DRAWN

FILE: 5 35 3072 1

Dwg

03/05/01

C.Noel

Sh

3072

B

24/02/03

B

CROSSARMS

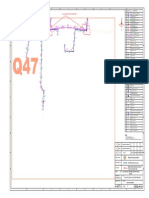

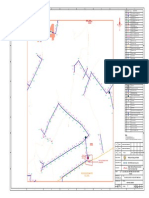

CROSSARM APPLICATIONS

Standard crossarm sizes for general application are as follows:

Intermediate pin structure both Flat and Delta

11kV 2400x100x100

2400x100x125

22/33kV 2700x100x100

2700x100x125

Strain / Termination

11kV 2400x150x100 single or double

2400x175x125 single or double

22/33kV 2700x150x100 single or double

2700x175x125 single or double

Fuse Crossarms

22/33kV Flat Intermediate

3000x100x100

3000x100x125

Required crossarm sizes for a range of typical applications are listed in

the section Pole Structures and can also be determined by using the

program Crossarm Design which will give the allowable weight span for

a specified application.

Laminated Crossarms

Use of laminated softwood crossarms is an option to the use of hardwood

crossarms and can be substituted on a size for size basis.

You might also like

- Sky Light - 1Document32 pagesSky Light - 1Nazar Bazaraa100% (1)

- Tes P 122 181213130429Document31 pagesTes P 122 181213130429Ahmed AboelgoodNo ratings yet

- AS/NZS7000 STANDARD ELECTRICAL AND MECHANICAL DESIGN OF INSULATORSDocument15 pagesAS/NZS7000 STANDARD ELECTRICAL AND MECHANICAL DESIGN OF INSULATORSerkamlakar2234No ratings yet

- SEC Standard - TES-P-122.05PII-R1Document28 pagesSEC Standard - TES-P-122.05PII-R1daimi143x7787No ratings yet

- Overhead Line DesignDocument37 pagesOverhead Line DesignPramod B.Wankhade100% (4)

- 2.3. Purlin System Specific Design PDFDocument6 pages2.3. Purlin System Specific Design PDFMuhammad FirdausNo ratings yet

- Design Calculation-Skylight StructureDocument7 pagesDesign Calculation-Skylight Structuremsiddiq1No ratings yet

- Toaz - Info Design Calculation Skylight Structure PRDocument7 pagesToaz - Info Design Calculation Skylight Structure PRAbdul khaliquNo ratings yet

- Dhofar Power Company SAOGDocument1 pageDhofar Power Company SAOG54045114No ratings yet

- Curtain Wall-Report REv 1-10-21Document11 pagesCurtain Wall-Report REv 1-10-21MuraleedharanNo ratings yet

- Tes P 122 181213125606Document34 pagesTes P 122 181213125606Sukant BhattacharyaNo ratings yet

- Design SheetsDocument18 pagesDesign SheetsMuraleedharanNo ratings yet

- Technical Specification: Haryana Vidyut Prasaran Nigam LimitedDocument9 pagesTechnical Specification: Haryana Vidyut Prasaran Nigam LimitedAdmin 3DimeNo ratings yet

- OWEMES Fatigue Design 2003 Tcm4-29402Document15 pagesOWEMES Fatigue Design 2003 Tcm4-29402yuxi liuNo ratings yet

- Design Proceduresfor Wooden TransmissionDocument11 pagesDesign Proceduresfor Wooden TransmissionCharizamaneNo ratings yet

- Precast Concrete Manholes: A Review and Upgrade of Current PracticeDocument17 pagesPrecast Concrete Manholes: A Review and Upgrade of Current PracticeTahirJabbarNo ratings yet

- LT Buckling Beam Design - Simple Method - 2upDocument5 pagesLT Buckling Beam Design - Simple Method - 2upberto2008No ratings yet

- DESIGN CALCULATIONS FOR ALUMINIUM GLAZINGDocument8 pagesDESIGN CALCULATIONS FOR ALUMINIUM GLAZINGmsiddiq1100% (1)

- Training ManualDocument55 pagesTraining ManuallaxmikantNo ratings yet

- DESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m HeightDocument15 pagesDESIGN CALCULATIONS - CW-13794 - Mullion 3.8m at 5m Heightmsiddiq1100% (2)

- Jackson & Salim-Web Crushing en 1992Document8 pagesJackson & Salim-Web Crushing en 1992Rm1262No ratings yet

- DESIGN CALCULATIONS - GL-03 2509 - 4.0mDocument17 pagesDESIGN CALCULATIONS - GL-03 2509 - 4.0mmsiddiq1No ratings yet

- Calculation Note For Control Building - Rev A1Document83 pagesCalculation Note For Control Building - Rev A1maniaxpdfNo ratings yet

- Monopole Design & TestDocument17 pagesMonopole Design & TestHosam Alzubairy100% (1)

- Transmission Engineering Standard TES-T-111.19 GuideDocument10 pagesTransmission Engineering Standard TES-T-111.19 GuideNauman Habib KhanNo ratings yet

- Member Design: Partial Factors For Resistance Classification of Cross Sections Resistance of Cross SectionsDocument14 pagesMember Design: Partial Factors For Resistance Classification of Cross Sections Resistance of Cross SectionsARSENo ratings yet

- Saer 5711Document161 pagesSaer 5711sethu1091100% (1)

- Chapter 9 - Strength and Serviceability Requirements: CommentaryDocument3 pagesChapter 9 - Strength and Serviceability Requirements: CommentarywaheedamerNo ratings yet

- ContentDocument23 pagesContentajay katrojNo ratings yet

- Bridge Design Project (HKUST CIVL 395Document92 pagesBridge Design Project (HKUST CIVL 395mohammed_fathelbabNo ratings yet

- Cooling Tank Support StructureDocument44 pagesCooling Tank Support Structurevj8584100% (1)

- Combinations of LoadsDocument9 pagesCombinations of LoadsKing Ferdinand P. ConstatinoNo ratings yet

- Technical Session Transmission Line - IIIDocument80 pagesTechnical Session Transmission Line - IIIKaushal Ghimire100% (2)

- Instructional Materials Principles of Reinforced Conrete Cien 30183Document251 pagesInstructional Materials Principles of Reinforced Conrete Cien 30183Aichelle Ann BersabeNo ratings yet

- Types of OHTL Conductors PDFDocument7 pagesTypes of OHTL Conductors PDFRenyRkrNo ratings yet

- Design Calculations For The Dome Structure-Type 1Document6 pagesDesign Calculations For The Dome Structure-Type 1msiddiq1100% (2)

- Types of OHTL ConductorsDocument7 pagesTypes of OHTL ConductorsIslam MasoudNo ratings yet

- Tower Design CodesDocument10 pagesTower Design CodesMaribel Isaura Cunurana YapuchuraNo ratings yet

- Design Verification CalculationsDocument15 pagesDesign Verification CalculationsKarthik KrNo ratings yet

- 12" CMU wall design for RJC Hotel appendixDocument10 pages12" CMU wall design for RJC Hotel appendixgabi_xyzNo ratings yet

- Bonald: Dhofar Power Company SAOGDocument1 pageBonald: Dhofar Power Company SAOG54045114No ratings yet

- Burj Vista F1 12 Panel Design Rev0 22feb16Document71 pagesBurj Vista F1 12 Panel Design Rev0 22feb16Kilaru HareeshNo ratings yet

- Structures, Towers and PolesDocument4 pagesStructures, Towers and PolesHeidi ELmesiryNo ratings yet

- Partial Prestressing: Department of Applied Mechanics Sardar Vallabhbhai National Institute of Technology SURAT-395 007Document14 pagesPartial Prestressing: Department of Applied Mechanics Sardar Vallabhbhai National Institute of Technology SURAT-395 007Ammar CivilNo ratings yet

- Circular WTanks 2012 16 9 2012Document85 pagesCircular WTanks 2012 16 9 2012Andres CI100% (1)

- Design Calculations For Aluminium Profile 13794Document14 pagesDesign Calculations For Aluminium Profile 13794Wilson PesantezNo ratings yet

- Design Calculation of Louvers-1Document7 pagesDesign Calculation of Louvers-1vj8584No ratings yet

- TIA 222 Codes and Dielectric Antenna Design March 2021 Final 3Document6 pagesTIA 222 Codes and Dielectric Antenna Design March 2021 Final 3kheang mengNo ratings yet

- Isolated Footing Design PDFDocument45 pagesIsolated Footing Design PDFChau Suktana Enling0% (1)

- DSS Lecture Note 3 - Lateral Loads - Wind LoadDocument49 pagesDSS Lecture Note 3 - Lateral Loads - Wind LoadMrSamspartNo ratings yet

- Oral Question Dubai Municipality G+12 Exam. 1. What Is Story DriftDocument6 pagesOral Question Dubai Municipality G+12 Exam. 1. What Is Story Driftarman malikNo ratings yet

- Oral Question Dubai Municipality G+12 Exam. 1. What Is Story DriftDocument6 pagesOral Question Dubai Municipality G+12 Exam. 1. What Is Story Driftarman malikNo ratings yet

- Design of Circular Concrete Tanks DesignDocument85 pagesDesign of Circular Concrete Tanks DesignLuizZz LuizZzNo ratings yet

- Circular WTanks 2019 2020Document90 pagesCircular WTanks 2019 2020Javier gonzagaNo ratings yet

- Structural Design Report 07.06.2016Document22 pagesStructural Design Report 07.06.2016Gihan ChathurangaNo ratings yet

- Chapter 4.0 - Serveciability and Durability PDFDocument43 pagesChapter 4.0 - Serveciability and Durability PDFfhatiha atikaNo ratings yet

- C Microwave TowersDocument17 pagesC Microwave TowersprakashvsNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- 4 Transmission Structures Fact SheetDocument2 pages4 Transmission Structures Fact SheetiobtecNo ratings yet

- Opa EefDocument47 pagesOpa EefiobtecNo ratings yet

- Masnry 2Document1 pageMasnry 2iobtecNo ratings yet

- Aksum CH 3Document27 pagesAksum CH 3iobtecNo ratings yet

- PMP Exam FormulasDocument1 pagePMP Exam FormulasupendrasNo ratings yet

- At 30 Form Box Step Two Praposed in Autocad-ModelDocument1 pageAt 30 Form Box Step Two Praposed in Autocad-ModeliobtecNo ratings yet

- Iran Form BoxDocument1 pageIran Form BoxiobtecNo ratings yet

- CER Example RegistryDocument46 pagesCER Example RegistryKinza FaisalNo ratings yet

- Charikar & Doshi Control Building Tiles & Fixture HeightsDocument1 pageCharikar & Doshi Control Building Tiles & Fixture HeightsiobtecNo ratings yet

- You're Reading A Free Preview: Not LikedDocument1 pageYou're Reading A Free Preview: Not LikediobtecNo ratings yet

- Meter BoxDocument1 pageMeter BoxiobtecNo ratings yet

- SAG11 - 2x LV - ABC 120Document1 pageSAG11 - 2x LV - ABC 120iobtecNo ratings yet

- Style Characteristics Opening EndingDocument2 pagesStyle Characteristics Opening EndingiobtecNo ratings yet

- 16 II.6 StringingDocument30 pages16 II.6 Stringingashok10577100% (1)

- SAG11 - 2x LV - ABC 120Document1 pageSAG11 - 2x LV - ABC 120iobtecNo ratings yet

- 15M Pole Main Road Crossing: No Legend Description 1 2 3 4Document1 page15M Pole Main Road Crossing: No Legend Description 1 2 3 4iobtecNo ratings yet

- SAG11 - 2x LV - ABC 120Document1 pageSAG11 - 2x LV - ABC 120iobtecNo ratings yet

- MV and LV line layout diagram legend guideDocument1 pageMV and LV line layout diagram legend guideiobtecNo ratings yet

- Concrete Pole Inspection & Test PlanDocument7 pagesConcrete Pole Inspection & Test PlaniobtecNo ratings yet

- 15M Pole Main Road Crossing: No Legend Description 1 2 3 4Document1 page15M Pole Main Road Crossing: No Legend Description 1 2 3 4iobtecNo ratings yet

- Electric pole legend and descriptionsDocument1 pageElectric pole legend and descriptionsiobtecNo ratings yet

- Deadman Anchor Foundation Bending Schedule and Design ParametersDocument1 pageDeadman Anchor Foundation Bending Schedule and Design ParametersiobtecNo ratings yet

- Criteria for Design of RCC Staging for Overhead Water TanksDocument44 pagesCriteria for Design of RCC Staging for Overhead Water TanksSyed Mohd MehdiNo ratings yet

- 15M Main Road Crossing Above Existing MV Line: No Legend Description 1 2 3 4Document1 page15M Main Road Crossing Above Existing MV Line: No Legend Description 1 2 3 4iobtecNo ratings yet

- CPWD Speci Civil 2009 Vol1Document544 pagesCPWD Speci Civil 2009 Vol1supriyo.podder100% (2)

- Lot - 5 - Khulm Consumer Load ListDocument1 pageLot - 5 - Khulm Consumer Load ListiobtecNo ratings yet

- Pole Design Drawings MDocument1 pagePole Design Drawings MiobtecNo ratings yet

- 28MPADocument3 pages28MPAiobtecNo ratings yet

- DemDocument4 pagesDemiobtecNo ratings yet

- Storm Drain Computation Sheet: Route Section CountyDocument2 pagesStorm Drain Computation Sheet: Route Section CountyiobtecNo ratings yet

- Research PaperDocument4 pagesResearch PaperPradip SoseNo ratings yet

- CET302 - SyllabusDocument13 pagesCET302 - SyllabusdipinnediyaparambathNo ratings yet

- Structural Theory Lecture NotesDocument151 pagesStructural Theory Lecture NotesCharizza Montarin CENo ratings yet

- Design of Bridge PierDocument12 pagesDesign of Bridge PierSunita Chaurasia88% (8)

- CH-2-Analysis of Statically Determinate StructuresDocument18 pagesCH-2-Analysis of Statically Determinate StructuresyareqNo ratings yet

- Thermoforming Design Guide (GE Plastics)Document57 pagesThermoforming Design Guide (GE Plastics)Mario Daniel Conejo100% (2)

- SimplySupportedBeam PointloadDocument6 pagesSimplySupportedBeam PointloadNeelakantheswar KunkulaguntaNo ratings yet

- AS LAB Man IDocument84 pagesAS LAB Man IVadivel AeroNo ratings yet

- Bending of BeamsDocument26 pagesBending of BeamsJovelyn DayonNo ratings yet

- Counterfort Retaining WallsDocument1 pageCounterfort Retaining WallsAzis Ali WibowoNo ratings yet

- Graduate Vibrations ProjectDocument27 pagesGraduate Vibrations ProjectJohn AlvarezNo ratings yet

- Shaft Align 1Document5 pagesShaft Align 1rajishrrrNo ratings yet

- Arthur W. Leissa (Auth.), I. H. Marshall (Eds.) - Composite Structures 4 - Volume 1 Analysis and Design Studies (1987, Springer Netherlands)Document647 pagesArthur W. Leissa (Auth.), I. H. Marshall (Eds.) - Composite Structures 4 - Volume 1 Analysis and Design Studies (1987, Springer Netherlands)Shivareddy KondakindiNo ratings yet

- Report Without Drawing (Final)Document72 pagesReport Without Drawing (Final)stormxeron100% (1)

- TC Bvau 7106Document235 pagesTC Bvau 7106FrancescoNo ratings yet

- PomeDocument17 pagesPomeAnirudh KaushikNo ratings yet

- Bridge DesignDocument33 pagesBridge DesignMaiwand KhanNo ratings yet

- Me8593 QBDocument29 pagesMe8593 QBAslam AhamedNo ratings yet

- BS en 13706-2-2002 - (2019-07-02 - 04-58-54 PM) PDFDocument44 pagesBS en 13706-2-2002 - (2019-07-02 - 04-58-54 PM) PDFLuis Miguel UribeNo ratings yet

- Biswajit 6'18Document11 pagesBiswajit 6'18Qurrain MirNo ratings yet

- Beam Bending Lab Sheet and Short Report SheetDocument4 pagesBeam Bending Lab Sheet and Short Report SheetAhsen Alam0% (1)

- Design and Analysis of RC BeamsDocument12 pagesDesign and Analysis of RC BeamsmyidmaranNo ratings yet

- Design of Edge Beams in Slim Floors Using Precast Hollow Core SlabsDocument9 pagesDesign of Edge Beams in Slim Floors Using Precast Hollow Core SlabsPaloma ValeNo ratings yet

- Compression Members in Rigid FramesDocument74 pagesCompression Members in Rigid Framesjuan jr lucenaNo ratings yet

- Syllabus of BCECE.Document281 pagesSyllabus of BCECE.Rohit SinghNo ratings yet

- Mechanical PapersDocument23 pagesMechanical PapersSachin AgrawalNo ratings yet

- OTC-25779-MS Chain Out of Plane Bending (OPB) Joint Industry Project (JIP) Summary and Main ResultsDocument22 pagesOTC-25779-MS Chain Out of Plane Bending (OPB) Joint Industry Project (JIP) Summary and Main ResultsMuhammad Rafiq RavinNo ratings yet

- Unit 4 NotesDocument60 pagesUnit 4 NotesVikas RathodNo ratings yet

- RC DESIGN COURSEDocument8 pagesRC DESIGN COURSENidhya Sudesh SinghNo ratings yet

- AnchorDocument51 pagesAnchorrobiyullahNo ratings yet