Professional Documents

Culture Documents

Earth Moving Machine

Uploaded by

jillianixOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Earth Moving Machine

Uploaded by

jillianixCopyright:

Available Formats

Earthmoving Machine

Design Evolution

19

th

Mechanical Engineering Safety Seminar

NSW Dept. of Primary Industry

Olympic Park, Homebush

Hayden J ones

Caterpillar Global Mining

What drives changing technologies?

?

Evolving Regulations

Competitive Challenge

Manpower Skill Levels

Technology Advances

Safety Enhancements

A Question of Balance?

Varying Customer

Requirements

Business Needs

International & Regional

Regulations

EMESRT Group

1 Access & Egress

2 Working at Heights

3 Noise

4 Whole Body Vibration

5 Fire

6 Dust

7 Isolation of Energy (inc. parking)

8 Visibility/Collision Detection &

Avoidance

9 Machine stability / slope indication

10 Guarding

11 Displays & Controls (inc. labeling)

12 Tyres & Rims

13 Manual Materials Handling

14 Work postures

15 Confined space

Earth Moving Equipment

Safety Round Table

(EMESRT)

BHP Billiton, Xstrata, Rio Tinto, Anglo American, Vale,

Barrick, Newmont, Freeport McMoRan

EMESRT engagement with OEMs paves the way for earthmoving equipment

that ensures the safety and well-being of operators and maintainers.

Caterpillar Safety Compliance

In Iron Safety Audit

On-machine compliance reviews by EMESRT members

written into Caterpillar Safety Design Guidelines.

Unprecedented customer access to new machine designs

during the development phases.

EMESRT Design Philosophies

1 Access & Egress

2 Working at Heights

3 Noise

4 Whole Body Vibration

5 Fire

6 Dust

7 Isolation of Energy (inc. parking)

8 Visibility/Collision Detection &

Avoidance

9 Machine stability / slope indication

10 Guarding

11 Displays & Controls (inc. labeling)

12 Tyres & Rims

13 Manual Materials Handling

14 Work postures

15 Confined space

15 areas of concern8 areas given priority

1 Access & Egress

2 Working at Heights

3 Noise

4 Whole Body Vibration

5 Fire

6 Dust

7 Isolation of Energy (inc. parking)

8 Visibility/Collision Detection &

Avoidance

9 Machine stability / slope indication

10 Guarding

11 Displays & Controls (inc. labeling)

12 Tyres & Rims

13 Manual Materials Handling

14 Work postures

15 Confined space

Access Systems - OHT

Improved Ladder

Rear Access

600 mm Wide

Access to Cab

Stairways

Eliminated Step

Down to Catwalk

Improved Secondary

Egress

Access to the

rear of the cab

Optional factory

powered access

ladder

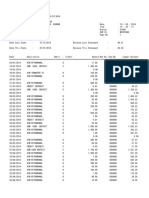

F-series Mining Trucks

Access Systems - OHT

785

797

789

793

795

CAT standard

Off-side ground access

EMESRT Option

Cab side ground access

Encourages light

vehicles to park on the

cab side of the truck

In development for all

new LOHT models

Customer demand

signal required for

release

Rear Access Egress System (RAES)

Replaces LH lower platform ladder

Lifts & lowers operator or service

technician to stairwell platform

Other improvements

Access on both sides of machine

Kickrails

600 mm wide stairways

Roading Fenders to reduce mud

build-up on stairs

Access Systems Wheel Loaders

993K Wheel Loader

Access Systems Track-type Tractors

D11T Tractor

Robust Design; cast steel hinge

Locks out of danger of damage

Hydraulic powered pivot design

Rear cab window access also

available

Corporate 6 Sigma project

Safety & Design Guides updated for

tie-off location requirements

Implemented into 2008 NPI programs

(New Product Introduction)

Safety Harness Tie-off Points

when working at heights cannot be avoided

Working at Heights - OHT

Reduced need for Working at Heights

Working at Heights

793D

793F

Ground Level Service

& Sight Gauges

Batteries now located

in Front Bumper

No PM Service items

on RH deck of F-series

trucks

Rear Medium

Range

Rear Short Range

Side Medium

Range

Side Medium

Range

Front Medium

Range

Front Short

Range

Collision Detection & Avoidance

Caterpillar Integrated Object Detection System

50 - 60% of accidents reported by mine sites are due to poor

visibility at low speeds (data from various companies and MSHA).

An effective object detection is expected to eliminate a significant

number of these incidents.

The system consists of:

An interactive display in the cab

Medium Range Radar front & rear

(~ 30 metre range)

Short Range Radar front, rear & sides

(~ 7 metre range)

Cameras on all 4 sides of the machine

A vision onlysystem will also be

available, upgradeable to full object

detection system

Expected availability - Sept 09

Collision Detection & Avoidance

Collision Detection & Avoidance

Visual alert if object enters cautionalarm zone (5 20 metres)

Audible alert if object remains inside 5 metre criticalalarm zone in

direction of machines intended path if the operator engages gear and

hasnt acknowledged alarm to full screen view.

Electro-Hydraulic Controls

Electrical sensor input

(commonly joystick)

Solenoid controlled hydraulic

valves

Unmatched control and

precision

. a foundational technology

for machine design

Electro-Hydraulic Controls

1997

1997 STIC Steer Released on 994

1998

2007

Electro-Hydraulic Controls

1997

1998 E/H Implement Control D11R

1998

2007

Electro-Hydraulic Controls

1997

Numerous Models

1998

2007

Electro-Hydraulic Controls

1997 1998

2007

M Series Graders

Electro-Hydraulic Controls

Some of Caterpillars

smaller machines

are also designed

with EH controls

Electro-Hydraulic Controls M Series

Safety Benefits of E/H Controls

Visibility

Intuitive operation

Operator Fatigue

H-Series

M-Series

Electro-Hydraulic Controls M Series

Fatigue 78% Arm Movement Reduction

Electro-Hydraulic Controls

Today:

Integration with

Machine Control &

Guidance Technology

Operator Assistance

Features

Future:

Foundation for Remote

Control / Automation

Programs

Electro-Hydraulic Automation

blade tilt angle

Angle Sensor

Angle Sensor

main fall angle

AccuGrade Display

Rotation Sensor

Circle Rotation

blade tilt angle

Angle Sensor

blade tilt angle

Angle Sensor

Angle Sensor

main fall angle

Angle Sensor

main fall angle

AccuGrade Display

Rotation Sensor

Circle Rotation

Rotation Sensor

Circle Rotation

Off Machine Earthmoving Development

Caterpillar recognises that safety

within the earthmoving industry

extends beyond what can be built

into machines:

Basic Safety Information

PPE, Warning Labels

Service Technician Safety

Toolbox Talks

Safety Videos

Machine Operation / Safety

Walkaround Inspections

Maintenance Checklists

Pre-start, Operating Tips

One Safe Source for all CAT

Safety-related media

Launch of Safety.CAT.com

Safety.cat.com

Machine Simulators

Wheel Loader

Off Highway Truck

Motor Grader

The D7E Track-Type Tractor

The culmination of many innovative technologies

AC Electric Drive

Enhanced operator visibility

Reduced cab noise levels

Greater powertrain efficiency

Reduced fuel consumption and

emissions

Reduced maintenance

requirements

Higher productivity

Reduced operating cost

Sustainable Machine Development

D7E Video

Thank You

You might also like

- New 24 Mining Motor Grader: Project ScopeDocument10 pagesNew 24 Mining Motor Grader: Project ScopeWilliams ArayaNo ratings yet

- 6050 - 6050FS SpecsDocument32 pages6050 - 6050FS SpecsBasti GhuzzNo ratings yet

- Pedp7028 02Document20 pagesPedp7028 02atulnalawade1980100% (1)

- 004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFDocument12 pages004 - Cat-6040AC - CAMP-SIL-BCS4 - E-Motor and Powertrain PDFMiguel RodriguezNo ratings yet

- Cat Certified Rebuild: Machines Power Train Engines Hydraulics ComponentsDocument12 pagesCat Certified Rebuild: Machines Power Train Engines Hydraulics ComponentsEmilio Castillo TamayoNo ratings yet

- 797B Commissioning Guidebook 07 (Procesos) PDFDocument65 pages797B Commissioning Guidebook 07 (Procesos) PDFwilmer100% (1)

- All The Right Choices Large Track Type Undercarriage-PEDJ0201-05Document12 pagesAll The Right Choices Large Track Type Undercarriage-PEDJ0201-05Carlos Indigoyen LimaymantaNo ratings yet

- MinMach HomePage15Document46 pagesMinMach HomePage15miningnova2No ratings yet

- ETF Truck Presentation April 2011 PDFDocument43 pagesETF Truck Presentation April 2011 PDFwilledworkerNo ratings yet

- CAT 992G Wheel LoaderDocument20 pagesCAT 992G Wheel LoaderarnoldNo ratings yet

- More Than Meets The Eye: Inside The 793F PowertrainDocument13 pagesMore Than Meets The Eye: Inside The 793F PowertrainMisael Josue Castro Huancayo100% (1)

- 776d Tractors 777d TrucksDocument7 pages776d Tractors 777d TrucksJavier Pagan TorresNo ratings yet

- Hydraulic Shovel: Engine Bucket Operating SpecificationsDocument32 pagesHydraulic Shovel: Engine Bucket Operating SpecificationserallatuasanNo ratings yet

- Comparacion 797B 797FDocument20 pagesComparacion 797B 797FpsalaspaNo ratings yet

- Get Maximum Return On Your Investment: CAT Certified Power Train RebuildDocument4 pagesGet Maximum Return On Your Investment: CAT Certified Power Train RebuildJean Claude EidNo ratings yet

- 86 507Document2 pages86 507AliceAlormenuNo ratings yet

- RM400 Wear Part TrainingDocument18 pagesRM400 Wear Part TrainingMp pmNo ratings yet

- Undercarriage SystemsDocument2 pagesUndercarriage SystemsGUILLERMO SEGURANo ratings yet

- Cat 789c PDFDocument28 pagesCat 789c PDFzugupubexe0% (1)

- PEHJ0069-03 Filters Hydraulik Adn TrainDocument4 pagesPEHJ0069-03 Filters Hydraulik Adn TrainErick Alarcon100% (1)

- Cartilla Especificaciones Camion 793 PDFDocument32 pagesCartilla Especificaciones Camion 793 PDFKianna Ospino AlmenarezNo ratings yet

- Komatsu AfterMarket - E PDFDocument6 pagesKomatsu AfterMarket - E PDFtehsintariqNo ratings yet

- Cargador de Ruedas 993K - LRC - Z4ZDocument1 pageCargador de Ruedas 993K - LRC - Z4ZMónica Rada UrbinaNo ratings yet

- CAT CylindersDocument32 pagesCAT CylindersРинат Сагидов100% (3)

- Oil Sampling IntervalsDocument3 pagesOil Sampling IntervalsshivNo ratings yet

- Motor Grader: Engine WeightsDocument20 pagesMotor Grader: Engine Weightsagegnehutamirat100% (2)

- FS 6050Document32 pagesFS 6050Victor Raul Osnayo MamaniNo ratings yet

- Hystory and RegulationDocument126 pagesHystory and RegulationHarveyParraMuñozNo ratings yet

- CAT HighwallDocument16 pagesCAT HighwallJelena IvazNo ratings yet

- D9T Component HoursDocument1 pageD9T Component HoursjogremaurNo ratings yet

- ISO Numero Control ContaminacionDocument42 pagesISO Numero Control ContaminacionOctavio Morales100% (4)

- 793 793b 793cDocument8 pages793 793b 793cJulio Elias Mayta RamosNo ratings yet

- Hydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsDocument28 pagesHydraulic Mining Shovel: 2x Cat C27 1209 KW / 1,620 1141 KW / 1,529 294 Tonnes / 324 Tons 30 Tonnes / 33 TonsZaita FregaNo ratings yet

- TDTO Pehp7506Document4 pagesTDTO Pehp7506ngilaNo ratings yet

- Bucyrus 8750 MaquetaDocument12 pagesBucyrus 8750 MaquetaForomaquinasNo ratings yet

- 24HDocument73 pages24HJavier CerdaNo ratings yet

- R30CDocument4 pagesR30CEnrique MurgiaNo ratings yet

- Mining Truck: Engine Weights - Approximate Operating SpecificationsDocument28 pagesMining Truck: Engine Weights - Approximate Operating SpecificationsLuis AlvarezNo ratings yet

- Final Reporting GuidelinesDocument183 pagesFinal Reporting GuidelinesAkhmad NuzulNo ratings yet

- Caterpillar Underground EquipmentDocument52 pagesCaterpillar Underground EquipmentsyaniliffaNo ratings yet

- 365B L Your Working Advantage (AEDC0603-01)Document16 pages365B L Your Working Advantage (AEDC0603-01)suwarjitechnic100% (1)

- Machine Profiles: D11R Track-Type TractorsDocument6 pagesMachine Profiles: D11R Track-Type TractorsJavier Pagan TorresNo ratings yet

- TransAlta Job Report 2009 - 9018-0Document4 pagesTransAlta Job Report 2009 - 9018-0Tiagohowpy Ramos100% (1)

- 24 Motor Grader E9Z00001-UP (MACHINE) POWERED by C27 Engine (M0090327 - 15) - DocumentationDocument7 pages24 Motor Grader E9Z00001-UP (MACHINE) POWERED by C27 Engine (M0090327 - 15) - DocumentationenricoNo ratings yet

- Caterpillar - System Selection GuideDocument11 pagesCaterpillar - System Selection GuidefvmattosNo ratings yet

- Series High Efficiency Fuel FiltersDocument5 pagesSeries High Efficiency Fuel FiltersTeo Sil CasNo ratings yet

- Cat FleetDocument16 pagesCat FleetANGELA ARACELLY PAREDES PEREZNo ratings yet

- Bucyrus 495BII vs. Bucryus 495HR Super 2 (Caterpillar 7495) : Bucyrus 495HR - Side Profile Bucyrus 495HR - Side ProfileDocument4 pagesBucyrus 495BII vs. Bucryus 495HR Super 2 (Caterpillar 7495) : Bucyrus 495HR - Side Profile Bucyrus 495HR - Side ProfileManuel VargasNo ratings yet

- Caterpillar Machines With Acert Technology: For More Information VisitDocument4 pagesCaterpillar Machines With Acert Technology: For More Information VisitAllan LariosaNo ratings yet

- Retroexcavadora Cat 385CDocument24 pagesRetroexcavadora Cat 385CMax Tapia Castillo100% (1)

- Labor Guidelines Overview For Dealer 22.09.15 TRGDocument17 pagesLabor Guidelines Overview For Dealer 22.09.15 TRGJean Claude Eid100% (1)

- Codigos VimsDocument42 pagesCodigos VimsJuan Ricardo Bolivar PilcoNo ratings yet

- 6040 6040FS Eng PDFDocument32 pages6040 6040FS Eng PDFGabriel TeixeiraNo ratings yet

- Bus002 - SGD - V4 (Cat Lit)Document78 pagesBus002 - SGD - V4 (Cat Lit)Joseph Emmanuel ParedesNo ratings yet

- Dynamic Braking-LiebherrDocument38 pagesDynamic Braking-LiebherrJose Manuel Rodriguez DiazNo ratings yet

- RH120EDocument8 pagesRH120EEbied Yousif AlyNo ratings yet

- Drive Train Parts QualityDocument67 pagesDrive Train Parts QualityAnonymous Dq7m7Hq7ar100% (4)

- Ge Mining Cas Smart Group 17 Oct 2013Document81 pagesGe Mining Cas Smart Group 17 Oct 2013Eleazar DavidNo ratings yet

- Minda Valeo Security Systems Pvt. LTDDocument38 pagesMinda Valeo Security Systems Pvt. LTDAjay Kumar DubeyNo ratings yet

- Gear Shift SystemDocument21 pagesGear Shift SystemMihai Cosmin PaunNo ratings yet

- OctoDocument27 pagesOctojillianixNo ratings yet

- Risk AssesmentDocument5 pagesRisk AssesmentjillianixNo ratings yet

- Measurement Units Style Guide: Some Common Units Basic RulesDocument4 pagesMeasurement Units Style Guide: Some Common Units Basic RulesjillianixNo ratings yet

- Guidance On The Management of Lifts, Escalators and Similar ProductsDocument20 pagesGuidance On The Management of Lifts, Escalators and Similar ProductsjillianixNo ratings yet

- Tadano GR-800XL-1: Load ChartsDocument17 pagesTadano GR-800XL-1: Load ChartsjillianixNo ratings yet

- Local Order 61 of 1991 EnglishDocument42 pagesLocal Order 61 of 1991 EnglishjillianixNo ratings yet

- Gearabc B PDFDocument40 pagesGearabc B PDFhjgajjarNo ratings yet

- Fem 5.019Document26 pagesFem 5.019jillianixNo ratings yet

- CC EN14439 enDocument27 pagesCC EN14439 enmax_kool100% (3)

- 2011 Ref GuideDocument47 pages2011 Ref GuidejillianixNo ratings yet

- Alloy Chain Sling Working Load LimitsDocument14 pagesAlloy Chain Sling Working Load LimitsjillianixNo ratings yet

- Industry Requests Revision of Standards To Ensure Safe Operation of Cranes and Reduce CasualtiesDocument1 pageIndustry Requests Revision of Standards To Ensure Safe Operation of Cranes and Reduce CasualtiesjillianixNo ratings yet

- ILO 152 Lifting GearDocument18 pagesILO 152 Lifting GearADL123100% (1)

- ManualDocument44 pagesManualjillianixNo ratings yet

- En 500Document10 pagesEn 500jillianixNo ratings yet

- Mobile Crane 80tDocument53 pagesMobile Crane 80tjillianixNo ratings yet

- English Idioms - Sayings & SlangDocument0 pagesEnglish Idioms - Sayings & SlangMuhammad FurquanNo ratings yet

- Elec. & Hydraulic Lift ChecklistDocument2 pagesElec. & Hydraulic Lift Checklistjillianix100% (1)

- DM PH&SD P4 TG21Document2 pagesDM PH&SD P4 TG21jillianixNo ratings yet

- DACReq 016Document19 pagesDACReq 016jillianixNo ratings yet

- Service ManualDocument30 pagesService ManualYoni CativaNo ratings yet

- PW Unit 8 PDFDocument4 pagesPW Unit 8 PDFDragana Antic50% (2)

- Simavi - Project Officer PROPOPIDocument4 pagesSimavi - Project Officer PROPOPIAgus NugrahaNo ratings yet

- TP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Document12 pagesTP1743 - Kertas 1 Dan 2 Peperiksaan Percubaan SPM Sains 2023-20243Felix ChewNo ratings yet

- Power For All - Myth or RealityDocument11 pagesPower For All - Myth or RealityAshutosh BhaktaNo ratings yet

- Introduction Into Post Go-Live SizingsDocument26 pagesIntroduction Into Post Go-Live SizingsCiao BentosoNo ratings yet

- Bank Statement SampleDocument6 pagesBank Statement SampleRovern Keith Oro CuencaNo ratings yet

- Sign Language To Speech ConversionDocument6 pagesSign Language To Speech ConversionGokul RajaNo ratings yet

- TQM BisleriDocument27 pagesTQM BisleriDishank ShahNo ratings yet

- Vicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Document10 pagesVicente, Vieyah Angela A.-HG-G11-Q4-Mod-9Vieyah Angela VicenteNo ratings yet

- Indictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17Document6 pagesIndictment - 17-Cr-00601-EnV Doc 1 Indictment 11-1-17C BealeNo ratings yet

- Donation Drive List of Donations and BlocksDocument3 pagesDonation Drive List of Donations and BlocksElijah PunzalanNo ratings yet

- Review of Accounting Process 1Document2 pagesReview of Accounting Process 1Stacy SmithNo ratings yet

- Rehabilitation and Retrofitting of Structurs Question PapersDocument4 pagesRehabilitation and Retrofitting of Structurs Question PapersYaswanthGorantlaNo ratings yet

- ISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanDocument4 pagesISP Flash Microcontroller Programmer Ver 3.0: M Asim KhanSrđan PavićNo ratings yet

- Cds13041 Yamaha PWC Plug-In EcuDocument1 pageCds13041 Yamaha PWC Plug-In EcuGérôme ZélateurNo ratings yet

- Product Manual: Panel Mounted ControllerDocument271 pagesProduct Manual: Panel Mounted ControllerLEONARDO FREITAS COSTANo ratings yet

- Data Mining - Exercise 2Document30 pagesData Mining - Exercise 2Kiều Trần Nguyễn DiễmNo ratings yet

- Understanding Consumer and Business Buyer BehaviorDocument47 pagesUnderstanding Consumer and Business Buyer BehaviorJia LeNo ratings yet

- Huawei Core Roadmap TRM10 Dec 14 2011 FinalDocument70 pagesHuawei Core Roadmap TRM10 Dec 14 2011 Finalfirasibraheem100% (1)

- Scope: Provisional Method - 1994 © 1984 TAPPIDocument3 pagesScope: Provisional Method - 1994 © 1984 TAPPIМаркус СилваNo ratings yet

- Between:-Mr. Pedro Jose de Vasconcelos, of Address 14 CrombieDocument2 pagesBetween:-Mr. Pedro Jose de Vasconcelos, of Address 14 Crombiednd offiNo ratings yet

- Kayako Support Suite User Manual PDFDocument517 pagesKayako Support Suite User Manual PDFallQoo SEO BaiduNo ratings yet

- Quantity DiscountDocument22 pagesQuantity Discountkevin royNo ratings yet

- BMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Document9 pagesBMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Siva MohanNo ratings yet

- LT1256X1 - Revg - FB1300, FB1400 Series - EnglishDocument58 pagesLT1256X1 - Revg - FB1300, FB1400 Series - EnglishRahma NaharinNo ratings yet

- Department of Labor: 2nd Injury FundDocument140 pagesDepartment of Labor: 2nd Injury FundUSA_DepartmentOfLabor100% (1)

- Design & Construction of New River Bridge On Mula RiverDocument133 pagesDesign & Construction of New River Bridge On Mula RiverJalal TamboliNo ratings yet

- Minor Project Report Format MCADocument11 pagesMinor Project Report Format MCAAnurag AroraNo ratings yet