Professional Documents

Culture Documents

Idd Intelligent Diagnostic Devices: Idd Can Be Configured For Analysis of Various

Uploaded by

Mario0 ratings0% found this document useful (0 votes)

30 views4 pagesdoble

Original Title

IDD General 09-08

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentdoble

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views4 pagesIdd Intelligent Diagnostic Devices: Idd Can Be Configured For Analysis of Various

Uploaded by

Mariodoble

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

IDD

IDD

INTELLIGENT DIAGNOSTIC DEVICES

Introduction

A family of continuous online diagnostic devices for power system apparatus intended

to detect incipient problems with bushings/CTs, transformers, and circuit breakers. Now,

progressive problems can be managed safely, and replacement can be deferred until

corrective action can be scheduled efciently.

Rugged and Reliable designed to oper-

ate reliably in electrically noisy substations

and in extreme weather conditions.

Self-Diagnostics the rmware will moni-

tor critical signals continuously for proper op-

eration of the IDD. Indication of the malfunc-

tion is given locally as well as remotely.

Web Browser PC interface The IDD can

be accessed via a standard web browser

available on all PCs. No special software

installation is required on the PC.

Description

The IDD, Intelligent Diagnostic Device, is a

cost-effective online diagnostic system used

to monitor electrical apparatus in the eld.

Each IDD is intended to be apparatus spe-

cic and can be mounted in existing enclo-

sures or in optional enclosures available from

Doble. The IDD is easy to install and, once

congured, operates continuously. The IDD

contains a state-of-the-art microprocessor-

based signal processing module, a control

panel for user interface, alert indications, an

RS-232 serial port for local PC access, as

well as options for remote communication.

The IDD software system acquires data

through the data acquisition board and ana-

lyzes this information using the eld-proven

expert diagnostic system. The software

provides an assessment of the apparatus

on a continuous basis. This eliminates the

need for an external server or database. An

IDD can be congured for analysis of various

subsystems by simply installing the appropri-

ate data acquisition board.

Features

Continuous Condition Assessment the

status of the apparatus is constantly being

evaluated by the eld-proven diagnostic

expert system, minimizing the need to per-

form routine testing.

Early Identifcation

of Problems re-

ned signal process-

ing and eld-proven

analysis will identify

abnormalities, an-

ticipate failures, and

eliminate false alerts.

Prioritized Alerts

based on the sig-

nicance of the in-

cipient problem, the

analysis will issue an

alert indicating the

criticality of the prob-

lem, providing a tool

to manage risk.

Specifes Cor-

rective Action

an alert identies

the problem and

prompts corrective

action required to

resolve the problem.

Simple and Easy Installation a self-con-

tained device which simply requires con-

necting sensors, input power, and optional

remote communication to complete instal-

lation. Minimum outage time and resources

are needed for installation.

The rmware automatically detects the

installed hardware and activates the appro-

priate expert system analysis. IDDs versatile

design allows easy hardware and software

upgrades in the eld.

The alphanumeric display shows the highest

level alert issued by the expert system. For

detailed measurement, the IDD can be ac-

cessed via a local PC via an RS-232 port. A

standard web browser is the only application

required for viewing alerts and data, as well

as conguring the IDD. The same functional-

ity is also offered with the remote communi-

cation options. The IDD can be congured to

display its web pages in the local language.

Contact Doble for more information about

which languages are currently available.

The IDD is designed to operate reliably under

extreme weather conditions and electrical

interference. The self-diagnostic continuously

tracks the condition of the unit and issues an

alert if an abnormality is detected.

The Doble Difference

Continuous online diagnostic assessment

of critical apparatus can help ensure

optimal asset utilization by identifying the

most appropriate and cost-effective cor-

rective action.

With more than 80 years of high voltage ap-

paratus expertise, Doble has designed and

engineered the IDD with a built-in expert di-

agnostic system. The expert system, when

appropriate, will issue a prioritized alert.

The alert identies any abnormalities in the

apparatus and indicates the severity along

with required corrective action. Alerts are

classied in three categories: information,

warning, and action. Action is the highest

level of alert, requiring an immediate correc-

tive response.

Built-in hardware and software diagnostics

continuously monitor the IDD and the as-

sociated sensors to verify proper installation

and functionality, making the IDD virtually

maintenance-free. Indication of a problem is

provided locally as well as remotely.

The IDD provides a Maintenance Mode fea-

ture, which allows the analysis to be placed

on standby when the apparatus is out of

service. This feature ensures the integrity

of the analysis and prevents unnecessary

alerts.

Protocol

Communication with the IDD is viewable

through any web browser and is accessible

locally over the RS232 port or remotely

through the Ethernet Modem, RS485, or

RS232 connections. No additional software

is required.

Remote Communication

Options

An IDD can be congured with any of the fol-

lowing remote communication options:

Ethernet TCP/IP

RS485 supports DNP3 and ASCII

Modem

Supervisory I/O

RS232 supports DNP3 and ASCII

The Supervisory I/O offers a SCADA interface

for the IDD. This communication option

consists of four outputs and two inputs. The

input serves to acknowledge and reset the

alerts. The outputs are potential-free contacts

that correspond to low, medium, and high

alerts and the status of the IDD.

IDD Conguration

One IDD will support:

12 Bushings, 4 sets of 3

Requires 2 Data Acquisition Boards

Each Data Acquisition Board accepts

inputs from 6 Bushings

Maximum of 2 Data Acquisition Boards

can be installed in an IDD

3 Inputs from moisture sensors

Requires IDD Converter Module Type

RS232/RS485, one for each sensor

3 Inputs from dissolved gas sensor

Requires IDD Converter Module Type

RS232/RS485, one for each sensor

Technical Specications

IDD Electrical Inputs:

Input Measuring Range ............................................................................. 0 - 100mA

Accuracy ........................................................................................ +/- 1% of reading

Resolution ......................................................................................................... 12 bit

Sampling rate .....................................................................................................5kHz

Isolation between phases ............................................... 2500V RMS, for one minute

Power Supply: ......................................90 - 264 VAC, 47 - 63 Hz or 100 - 280 Vdc

Environment:

Designed to meet:

Surge withstand .................................................. ANSI/IEEE C37.90.1-1989 (R1994)

ESD: EN 61000-4-2

Ambient Operating Temp ...............................................................-40 to 65 C

Storage Temp ................................................................................-40 to 85 C

Humidity ................................................................. 5% to 95% non-condensing

Physical dimensions:

17.25 in. H x 15.25 in. W x 3 in. D (438.2mm H x 387.4mm W x 76.2mm D) for control

cabinet mounting

Supervisory I/O:

Four output contacts:

ACTION ALERT!

WARNING ALERT!

INFORMATION ALERT!

Self Monitoring

Ratings:

Switching 10A @ 240Vac resistive, 3A @ 240Vac inductive, 0.5A @ 125Vdc, 0.25A @

250Vdc Dielectric Strength 3000Vac, coil to contacts, 1000Vac between contacts.

Surge Strength .............................................................. 6000V, coil to contacts.

Two inputs:

Remote ALERT! Acknowledge

Remote ALERT! Reset

Ratings:

Input Range ...................................................... 12V to 300Vdc, 12V to 264Vac

Input Current ........................................... 1mA @ 24Vdc, 2mA pk @ 264V RMS

Isolation voltage .............................................................. 2500V RMS, 1 minute

Specications are subject to change.

T

O

G

E

T

H

E

R

W

E

P

O

W

E

R

T

H

E

W

O

R

L

D

Doble Engineering Company

85 Walnut Street

Watertown, MA 02472 USA

tel +1 617 926 4900

fax +1 617 926 0528

For more information, email DobleInfo@doble.com

MKT-SL-IDDB-09/08

Doble is certied ISO 9001:2000

Doble is an ESCO Technologies company

You might also like

- Doble BrochuresDocument10 pagesDoble BrochuresmuthukumarNo ratings yet

- 319 204B2Document130 pages319 204B2sprt82No ratings yet

- Edwards Fire Alarm EquipmentDocument45 pagesEdwards Fire Alarm EquipmentБахтияр ЮмачиковNo ratings yet

- Vehicle Health Monitoring System Using ARDUINO and IOTDocument3 pagesVehicle Health Monitoring System Using ARDUINO and IOTEditor IJRITCCNo ratings yet

- Ser'S: AnualDocument69 pagesSer'S: AnualJ.A.R.No ratings yet

- FAAST FSA 8000 SpecificationDocument3 pagesFAAST FSA 8000 SpecificationJesús CPNo ratings yet

- Event Logger, Distrubance Recorder and Fault LocatorDocument12 pagesEvent Logger, Distrubance Recorder and Fault LocatorShila Nightingale Chittu100% (1)

- ProjectdocumentDocument10 pagesProjectdocumentSabarii SabariiNo ratings yet

- Wireless ADSL Router User Manual: Error! Style Not DefinedDocument15 pagesWireless ADSL Router User Manual: Error! Style Not DefinedSahibzada Wajid Ali BrugNo ratings yet

- Ness D8xD16x Installer ManualDocument88 pagesNess D8xD16x Installer ManualMarkAshNo ratings yet

- Partial Discharge BrochureDocument8 pagesPartial Discharge BrochurePriti KumariNo ratings yet

- Low Power Vlsi Circuits and Systems - Ajit PalDocument26 pagesLow Power Vlsi Circuits and Systems - Ajit PalAnushaNo ratings yet

- DigiWare SocomecDocument12 pagesDigiWare SocomecDimas Kusuma PutraNo ratings yet

- 186C1D5506 - Sharooq AhamedDocument37 pages186C1D5506 - Sharooq AhamedBalivada Anjani KumarNo ratings yet

- Home Monitoring/Automation System Using WSN by IotDocument21 pagesHome Monitoring/Automation System Using WSN by IotHarish KhanNo ratings yet

- 3.PDTacll 4208 Iris Qualitrol Brochure V2 11 20Document4 pages3.PDTacll 4208 Iris Qualitrol Brochure V2 11 20le hoai NamNo ratings yet

- DVP 04TCDocument41 pagesDVP 04TCEyder Camilo Rojas CorredorNo ratings yet

- Tarjeta Comunicacion EthernetDocument162 pagesTarjeta Comunicacion EthernetWalter Medina LopezNo ratings yet

- BCPM - SQD - z205387-0dDocument22 pagesBCPM - SQD - z205387-0dEduardo Gomes CytranguloNo ratings yet

- User Manual (GZF DW Vi)Document30 pagesUser Manual (GZF DW Vi)Luc Vu TienNo ratings yet

- C 107em SentinelDocument12 pagesC 107em SentinelMARCO FERNANDEZNo ratings yet

- Quick Start Guide: AED9101D AED9501ADocument108 pagesQuick Start Guide: AED9101D AED9501AEmpacadora del GolfoNo ratings yet

- ECE5 Thesis Topics Group 3Document31 pagesECE5 Thesis Topics Group 3Lemuel C. FernandezNo ratings yet

- Partial Discharge Monitor For GISDocument4 pagesPartial Discharge Monitor For GISAlauddin khanNo ratings yet

- DPM 3Document53 pagesDPM 3Anonymous a9iAtvUc5No ratings yet

- Kodak 5100 Install GuideDocument30 pagesKodak 5100 Install Guidejavohm100% (1)

- UVC-Series/U15 Laser Marking System: System Overview System ConfigurationDocument12 pagesUVC-Series/U15 Laser Marking System: System Overview System ConfigurationJhon Parker DimitrinskyNo ratings yet

- Radioshack Digital Multimetru Interfata PCDocument32 pagesRadioshack Digital Multimetru Interfata PCvodookNo ratings yet

- Overall Online Condition Monitoring: Expert Diagnostic SystemDocument12 pagesOverall Online Condition Monitoring: Expert Diagnostic SystemRoyyan Hasmi FadhillahNo ratings yet

- SushantDocument22 pagesSushantayushNo ratings yet

- 85001-0245 - Intelligent 4D Multisensor DetectorDocument6 pages85001-0245 - Intelligent 4D Multisensor DetectorInstalaciones y Servicios 2906, C.A. Amado IbarraNo ratings yet

- Arduino Based Security SystemDocument35 pagesArduino Based Security SystemSaurabh Deshmukh100% (1)

- Wireless Sensor Network For Monitoring Control ofDocument12 pagesWireless Sensor Network For Monitoring Control ofkristine cruzNo ratings yet

- Iris Power Agtracii: Continuous On-Line Air Gap Monitoring For Hydro GeneratorsDocument4 pagesIris Power Agtracii: Continuous On-Line Air Gap Monitoring For Hydro GeneratorsRamón GuillánNo ratings yet

- DN - 60832 NOTIFIER SWIFT Wireless DetectorsDocument2 pagesDN - 60832 NOTIFIER SWIFT Wireless DetectorsÍkaro FortesNo ratings yet

- Manuale SC200 enDocument42 pagesManuale SC200 ensakarisoNo ratings yet

- SIGA Smoke 3D PHSDocument4 pagesSIGA Smoke 3D PHSIsaac VelasquezNo ratings yet

- Csi 9420 enDocument10 pagesCsi 9420 enAldo RomanNo ratings yet

- 400 Series Summing Indicator Quick Start ManualDocument38 pages400 Series Summing Indicator Quick Start ManualIonel RacaruNo ratings yet

- JM74983-21F Um en CL-S621 631Document67 pagesJM74983-21F Um en CL-S621 631Lapan enam PuluhNo ratings yet

- Data Acquisition: Fig 2.1:-Parts of Measurement SystemDocument16 pagesData Acquisition: Fig 2.1:-Parts of Measurement SystemHayder AliNo ratings yet

- Manual 1 Carrier Infinity TermostatoDocument18 pagesManual 1 Carrier Infinity TermostatoJhonatan Sepulveda100% (1)

- Notifier DN 7112Document6 pagesNotifier DN 7112yakcomNo ratings yet

- Abb-Lwt Sil Functional Safety GuideDocument28 pagesAbb-Lwt Sil Functional Safety GuideKanasai 89No ratings yet

- Field Monitoring and Automation Using Iot in AgricultureDocument114 pagesField Monitoring and Automation Using Iot in AgriculturedileeppatraNo ratings yet

- Home Automation Using WifiDocument22 pagesHome Automation Using WifishubhamNo ratings yet

- Development of Scada Like Application Using Arduino WithDocument7 pagesDevelopment of Scada Like Application Using Arduino WithInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Vision v35035tr34Document10 pagesVision v35035tr34Erasmo Franco SNo ratings yet

- Protocol Converter NR PCS 9794Document3 pagesProtocol Converter NR PCS 9794kakakNo ratings yet

- Online: Permanent Monitoring of Production Assets With Ultrasound and VibrationDocument3 pagesOnline: Permanent Monitoring of Production Assets With Ultrasound and VibrationSemir PandžićNo ratings yet

- Manual: D-Link ™Document41 pagesManual: D-Link ™Jayvee Amoy AmolatoNo ratings yet

- SA Unit 4 - Session 1-1Document34 pagesSA Unit 4 - Session 1-1Yashi SinghNo ratings yet

- Partial Discharge Information 1Document3 pagesPartial Discharge Information 1Rey SjNo ratings yet

- 560P User Manual Rev 1.2Document80 pages560P User Manual Rev 1.2Reese VlogsNo ratings yet

- Manual: D-LinkDocument33 pagesManual: D-LinkSENo ratings yet

- 0124 UserDocument59 pages0124 Userisaacsaddek17No ratings yet

- MONTESTO-TenderSpecs Ver002 27.05.2019Document6 pagesMONTESTO-TenderSpecs Ver002 27.05.2019Mridu Ranjan SrivastavaNo ratings yet

- Draft Proposal For SCADA System Using Arduino in Monitoring ParameterDocument3 pagesDraft Proposal For SCADA System Using Arduino in Monitoring ParameterSteady BunnyNo ratings yet

- Automatic Grid Failure Detection and ControlDocument26 pagesAutomatic Grid Failure Detection and ControlAnuj TripathiNo ratings yet

- Voltage Regulation GeneratorsDocument29 pagesVoltage Regulation Generatorsprabhakaran_hdecNo ratings yet

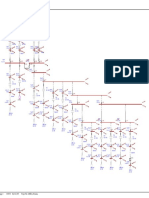

- OLV1 (Load Flow Analysis)Document1 pageOLV1 (Load Flow Analysis)MarioNo ratings yet

- ETAP Report With ACB 100kaDocument2 pagesETAP Report With ACB 100kaMarioNo ratings yet

- Brugg Cables User GuideDocument27 pagesBrugg Cables User GuideMehdi_Mashayekhi_172No ratings yet

- Katalog PeralatanDocument438 pagesKatalog PeralatanSurya Kazu MaruNo ratings yet

- Tech Bulletins CableDocument25 pagesTech Bulletins CableMarioNo ratings yet

- VLT Hvac Basic Drive FC 101Document45 pagesVLT Hvac Basic Drive FC 101MarioNo ratings yet

- PT 9017 P3 Dissimilar en PDFDocument6 pagesPT 9017 P3 Dissimilar en PDFMarioNo ratings yet

- Kabelindo NYY CableDocument11 pagesKabelindo NYY CableReza Putra PamungkasNo ratings yet

- Fiche Technique IMMERCAB® IMDocument1 pageFiche Technique IMMERCAB® IMMarioNo ratings yet

- Engine Data SheetEngine Data SheetEngine Data SheetEngine Data SheetDocument3 pagesEngine Data SheetEngine Data SheetEngine Data SheetEngine Data SheetHumayun Nawaz100% (1)

- Generator DroopDocument60 pagesGenerator DroopGanti1977100% (1)

- Termination and JointingDocument2 pagesTermination and JointingMarioNo ratings yet

- PQ Notes1 1Document26 pagesPQ Notes1 1bnewport1No ratings yet

- Conductor Joint US3668301Document11 pagesConductor Joint US3668301MarioNo ratings yet

- Insulation Testing of Low Voltage CablesDocument12 pagesInsulation Testing of Low Voltage Cablesmarkigldmm918100% (2)

- MVF024 PowervisionDocument3 pagesMVF024 PowervisionMarioNo ratings yet

- Aaacs SPLN 41Document1 pageAaacs SPLN 41MarioNo ratings yet

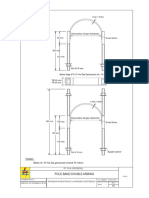

- Strain ClampDocument1 pageStrain ClampMarioNo ratings yet

- Schneider QA QCDocument64 pagesSchneider QA QCcharlesc5746No ratings yet

- Maximum Short Circuit ANSIDocument1 pageMaximum Short Circuit ANSIMarioNo ratings yet

- PPT EnglandDocument48 pagesPPT EnglandMarioNo ratings yet

- Pole Band Double Arming: Pt. PLN (Persero)Document1 pagePole Band Double Arming: Pt. PLN (Persero)MarioNo ratings yet

- Cathodic ProtectionDocument60 pagesCathodic ProtectionnoogeyNo ratings yet

- Substation Full Specification 2015Document9 pagesSubstation Full Specification 2015MarioNo ratings yet

- 1LA8355-4AB90-Z B31+B45+G50+K45+L1Y+M27+Y82 Datasheet enDocument1 page1LA8355-4AB90-Z B31+B45+G50+K45+L1Y+M27+Y82 Datasheet enMarioNo ratings yet

- Envpep120606en V0Document5 pagesEnvpep120606en V0MarioNo ratings yet

- Regulations For The Installation of Electrical Wiring EleDocument121 pagesRegulations For The Installation of Electrical Wiring EleKrishna Sankar100% (1)

- Final Assessment CSE 313: Computer Networks Spring-2021Document4 pagesFinal Assessment CSE 313: Computer Networks Spring-2021Al Shahriar HaqueNo ratings yet

- Acc Cable DataSheet K1200xxx AVT IOcable V2.4.1 enDocument4 pagesAcc Cable DataSheet K1200xxx AVT IOcable V2.4.1 enRritalLNo ratings yet

- Vision and Scope DocumentDocument7 pagesVision and Scope DocumentCyra ArifeenNo ratings yet

- Shobana GopiDocument2 pagesShobana GopiJigar SutariyaNo ratings yet

- Avaya Network-DesignDocument346 pagesAvaya Network-DesignAFS AssociatesNo ratings yet

- Belarc Advisor 22 Oct 2015Document14 pagesBelarc Advisor 22 Oct 2015Antonis HajiioannouNo ratings yet

- T Rec E.804.1 202010 P!!PDF eDocument29 pagesT Rec E.804.1 202010 P!!PDF eKOUHON Derou FabriceNo ratings yet

- Vishwa Pratap Sing SmsDocument87 pagesVishwa Pratap Sing SmsAnonymous V9E1ZJtwoENo ratings yet

- Huawei-4G-Router-B310 Datasheet: Get A QuoteDocument2 pagesHuawei-4G-Router-B310 Datasheet: Get A Quotewelltest vspNo ratings yet

- 56 Computer Tricks (AMAZING SECRETS & Hacks) : o o o o o o o o o o o o o o o o o o o o oDocument29 pages56 Computer Tricks (AMAZING SECRETS & Hacks) : o o o o o o o o o o o o o o o o o o o o oABDOULIENo ratings yet

- CFHP Course OutlineDocument4 pagesCFHP Course OutlineJuan Salvador JVNo ratings yet

- Parallel Registry Internet Explorer Registry (DC - GPO)Document6 pagesParallel Registry Internet Explorer Registry (DC - GPO)Samer BellarNo ratings yet

- TP-Link TL - WR740N WR741ND PDFDocument9 pagesTP-Link TL - WR740N WR741ND PDFnormalmannNo ratings yet

- 1410 Records - TelecommunicationDocument142 pages1410 Records - TelecommunicationPatentYogiNo ratings yet

- Gigaset Service Manual 347 SM A160 SuaDocument16 pagesGigaset Service Manual 347 SM A160 Suams0103No ratings yet

- Release Note BT200 GXP 1.2.3.5Document8 pagesRelease Note BT200 GXP 1.2.3.5Habib DatooNo ratings yet

- 901-01656-A05 S12 Series Technical Specifications PDFDocument29 pages901-01656-A05 S12 Series Technical Specifications PDFaliwafa100% (1)

- Installation of SPDocument38 pagesInstallation of SPAbhiNo ratings yet

- Network Engineering Director Cloud Manager in Tampa ST Petersburg FL Resume Craig CummingsDocument2 pagesNetwork Engineering Director Cloud Manager in Tampa ST Petersburg FL Resume Craig CummingsCraigCummings2No ratings yet

- BTWEthernetTechnicalProductHandbookV3 1Document26 pagesBTWEthernetTechnicalProductHandbookV3 1Tony SmithNo ratings yet

- HIGH Frequency and Low Out (Ut Impedance BufferDocument4 pagesHIGH Frequency and Low Out (Ut Impedance BufferDeepak BishtNo ratings yet

- 0160-DF433 MFT Manual PDFDocument33 pages0160-DF433 MFT Manual PDFSelvaraj JohnNo ratings yet

- Premium and Atrium Using Unity Pro: Fipway Network User ManualDocument126 pagesPremium and Atrium Using Unity Pro: Fipway Network User ManualarfeemNo ratings yet

- Memory HistoryDocument11 pagesMemory HistorySayed AsifNo ratings yet

- Transceiver Data SheetDocument19 pagesTransceiver Data Sheethb2938943No ratings yet

- ZXUR 9000 Product DescriptionDocument7 pagesZXUR 9000 Product DescriptionSulman ismailNo ratings yet

- RTU560 Step by StepDocument37 pagesRTU560 Step by StepJoaquim Alves100% (1)

- Acronyms of ComputerDocument179 pagesAcronyms of ComputerDhiman NathNo ratings yet

- Howto Asterisk Voicebluenext3Document9 pagesHowto Asterisk Voicebluenext3Cesar Agustin Colin GuadarramaNo ratings yet

- 1.1 Login Form: User Manual For The Online Exam Registration SystemDocument14 pages1.1 Login Form: User Manual For The Online Exam Registration SystemManeesha PriyangikaNo ratings yet