Professional Documents

Culture Documents

6RA24 Englisch

Uploaded by

Raja ShannmugamOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6RA24 Englisch

Uploaded by

Raja ShannmugamCopyright:

Available Formats

SIMOREG K

6RA24

Instruction Manual

SIMOREG

SIEMENS

Edition: G Order-No.: 6RX1240-0AD76

03.94

0/1

s

SIMOREG K

6RA24 converters with microprocessor,

from 6kW to 774kW in a B6C fully-controlled

tree-phase bridge circuit and

circulating current-free, anti-parallel circuit

(B6)A(B6)C for DC variable-speed drives

Instruction Manual

Order-No.: 6RX1240-0AD76

Converter software release: starting with 2.00

March 1994 Edition

03.94

2/6

03.94

5/24

03.94

6/42

03.94

7/30

03.94

9/140

03.94

12/2

03.94

13/2

06.96

16/1

16 Installation instructions for EMC-correct

installation of Drives

NOTE

These Installation Instructions do not purport to handle or take into account all of the equipment

details or versions or to cover every conceivable operating situation or application.

If you require more detailed information, or if special problems occur, which are not handled in

enough detail in this document, please contact your local Siemens office.

The contents of these Installation Instructions are not part of an earlier or existing agreement or legal

contract and neither do they change it. The actual purchase contract represents the complete liability

of the ASI 1 Variable-Speed Drives Group of Siemens AG. The warranty conditions, specified in the

contract between the two parties is the only warranty which will be accepted by the ASI 1 Variable-

Speed Drives Group. The warranty conditions specified in the contract are neither expanded nor

changed by the information provided in these Installation Instructions.

WARNING

These converters have components and parts at hazardous potentials, have

dangerous rotating machine components (fans) and control rotating mechanical

equipment (drives). Death, severe bodily injury or significant material damage

could occur if the instructions in the associated Instruction Manuals are not

followed.

Only qualified personnel who are knowledgeable about all of the safety informa-

tion and instructions specified in the Instruction Manual as well as installation-,

operating- and maintenance information may work on these converters.

Perfect and safe operation of the converters assumes that they have been

professionally transported, stored, installed and mounted as well as careful

operator control and maintenance.

16.1 EMC basics

16.1.1 What is EMC

EMC stands for electromagnetic compatibility and defines the capability of a piece of equipment to

operate satisfactorily in an electromagnetic environment without itself causing electromagnetic

disturbances which would be unacceptable for other electrical equipment in this environment.

Thus, the electrical equipment should not mutually disturb each other.

16.1.2 Noise radiation and noise immunity

EMC is dependent on two characteristics of the equipment/units involved - the radiated noise and

noise immunity. Electrical equipment can either be fault sources (transmitters) and/or noise receivers.

Electromagnetic compatibility exists, if the fault sources do not negatively influence the function of the

noise receivers.

A piece of electrical equipment/unit can also be both a fault source and fault receiver at the same time.

For example, the power section of a converter can be considered as noise source, and the control

section (gating unit, etc.), as noise receiver.

06.96

16/2

16.1.3 Maximum values

The Product Standard E DIN IEC 22G/21/CDV is available as draft for electric drives. According to this

product standard, all EMC measures are not necessarily required for industrial supply networks, and a

solution should be defined, adapted to the actual environment. Thus, it may be more cost-effective to

increase the noise immunity of a sensitive piece of equipment than implementing noise suppression

measures for the converter. Thus, a solution is selected dependent on its cost-effectivness.

The basic EN 50081 and EN 50082 Standards are valid until the Product Standard comes into force.

These specify that EN 55011 must be maintained. These define max. values for noise radiation in

industrial- and domestic environments. Cable-borne noise at the supply connection point is measured

under standardized conditions as radio interference noise voltage, electromagnetically radiated noise

as radio interference (radiated noise). The standard defines max. values A1 and B1, which are valid

for the radio interference voltage in the range between 150kHz and 30MHz and for radio interference

radiation between 30MHz and 2GHz. As SIMOREG K converters are used in industrial applications, in

this case, limit value A1 is valid. To achieve value A1, SIMOREG K converters must be provided

with external radio interference suppression filters.

The noise immunity defines the behavior of a piece of equipment subject to electromagnetic noise. For

industrial applications, the EN50082-2 Standard defines the demands and evaluation criteria for the

behavior of the unit/equipment. This standard is fulfilled by the converters listed in Section 16.2.3.

16.1.4 SIMOREG K converters in industrial applications

In an industrial environment, equipment must have a high level of noise immunity whereas lower

demands are placed on noise radiation.

SIMOREG K converters are components of an electric drive system, along with contactors and

switches etc. Professionally trained personnel must integrate them to form a complete drive system,

which comprises, as a minimum, the converter itself, motor feeder cables and motor. Generally,

commutating reactors and fuses are also required. Limiting (max.) values can only be maintained if

these components are installed and mounted in the correct way. In order to limit the radiated noise

according to limit value A1, in addition to the converter, a radio interference suppression filter and a

commutating reactor are required. If SIMOREG K converters are not equipped with radio interference

suppression filters, the radiated noise exceeds limit value A1, specified in EN55011.

If the drive is part of an overall system, initially it does not have to fulfill any requirements regarding

radiated noise. However, the EMC Law specifies that the system as a whole must be electromagneti-

cally compatible with its environment.

If all of the system control components (e.g. PLCs) have noise immunity for industrial environments,

then it is not necessary that each drive maintains limit value A1 for itself.

16.1.5 Non-grounded supplies

Non-grounded supplies (IT-supplies) are used in several industrial sectors, in order to increase the

availability of the plant. If a ground fault occurs, a fault current does not flow, and the plant can still

produce. However, when a radio interference suppression filter is used, when a ground fault occurs, a

fault current does flow, which can result in the drive being shutdown or even the radio interference

suppression filter being destroyed. Thus, the Product Standard does not define limit values for these

supplies. From a cost standpoint, if radio interference suppression is required, this should be realized

at the grounded primary of the supply transformer.

06.96

16/3

16.1.6 EMC planning

If two units are not electromagnetically compatible, you can either reduce the noise radiated by the

noise source, or increase the noise immunity of the noise receiver. Noise sources are generally power

electronic units with a high current requirement. In order to reduce the radiated noise from these units,

complex, costly filters are required. Noise receivers especially involve control units and sensors,

including their evaluation circuitry. It is less complex and costly to increase the noise immunity of low-

power equipment. Thus, in an industrial environment it is often more cost-effective to increase the

noise immunity rather than reduce the radiated noise. For example, in order to maintain limit value

Class A1 of EN 55011, the radio interference voltage at the supply connection point at 150kHz and

500kHz, may not exceed 79dB(V) and between 500kHz and 30Mhz, 73dB(V) (9mV or 4.5mV).

In industrial environments, the EMC of the equipment used must be based on a well-balanced mixture

of noise radiation (low level) and noise immunity.

The most favorably priced interference measure is to spatially isolate noise sources and noise

receivers, assuming that it is already taken into account when designing the machine/plant. The first

step is to define whether each unit is a potential noise source (noise radiator) or noise receiver. Noise

sources are, for example, converters, contactors. Noise receivers are, for example, PLCs, transmitters

and sensors.

The components must be spatially separated in the cabinet (noise sources and noise receivers), using

metal partitions or by mounting the components in metal enclosures. A possible component layout

configuration in a cabinet is illustrated in Fig. 1.

16.2 EMC-correct installation/mounting of converters

(installation instructions)

16.2.1 General information

As drives can be operated in a wide range of differing environments, and as the electrical components

used (controls, switched-mode power supplies etc.) can widely differ regarding noise immunity and

noise radiation, any mounting/installation guideline can only be represent a practical compromise.

Thus, deviations can be made from the EMC regulations, under the assumption that they are checked-

out on a case-for-case basis.

In order to guarantee electromagnetic compatibiity (EMC) in your cabinets in rugged electrical

environments, and alsofulfill the standards specified by the relevant legal bodies, the following EMC

regulations must be observed when designing and manufacturing the drive cabinets.

Rules 1 to 10 are generally valid. Rules 11 to 15 are necessary, in order to fulfill the noise radiating

standards.

16.2.2 Rules for EMC-correct installation

Rule 1

All of the metal cabinet components must be electrically connected with one another through the

largest possible surface area (not paint on paint!). If required, use serrated washers. The cabinet door

should be connected to the cabinet through grounding straps (top, center, bottom) which should be

kept as short as possible.

Rule 2

Contactors, relays, solonoid valves, electro-magnetic operating hours counters etc. in the cabinet, and

if required, in adjacent cabinets, should be provided with quenching elements, for example, RC

elements, varistors, diodes etc. These devices must be connected directly at the coil.

06.96

16/4

Rule 3

Signal cables

1)

should enter the cabinet, if possible, at only one level.

Rule 4

Non-shielded cables belonging to the same circuit (incoming and outgoing conductor) should be

twisted, or the surface between the two conductors kept as low as possible in order to prevent

unnecessary coupling effects.

Rule 5

Connect reserve conductors to the cabinet ground at both ends. This offers an additional shielding

effect.

Rule 6

Unnecessary cable/conductor lengths should be avoided. Thus, coupling capacitances and

inductances are kept low.

Rule 7

Crosstalk is kept low if cables are routed close to the cabinet ground. Thus, wiring shouldnt be routed

freely in the cabinet, but as close as possible to the cabinet frame and mounting panels. This is also

true for reserve cables.

Rule 8

Signal- and power cables should be routed separately from one another (to avoid noise being coupled-

in!). A minimum 20cm clearance should be maintained.

If it is not possible to spatially separate encoder- and motor cables, then the encoder cable must be

laid either using a metal partition or in a metal pipe or duct. The partition or metal pipe must be

grounded at several locations along this length.

Rule 9

The shields of digital signal cables must be connected to ground at both ends (source and destination)

through the largest possible surface area. If there is poor potential bonding between the shield

connections, to reduce the shield current, an additional potential bonding cable of at least 10mm must

be connected in parallel to the shield. The shields can be connected to the cabinet frame at several

positions (ground). The shields can also be connected to ground at several locations, even outside the

cabinet.

Foil-type shields should be avoided if possible. They do not shield as well as braided shields; they are

poorer by a factor at least 5.

Rule 10

The shields of analog signal cables can be connected to ground at both ends if potential bonding is

good (through the largest possible surface area). Good potential bonding can be assumed, if all metal

parts are well connected and all of the electronic components involved are supplied from one source.

The single-ended shield connection prevents low-frequency, capactive noise from being coupled-in

(e.g. 50Hz hum). The shield should be connected in the cabinet, whereby the shield can also be

connected up through a connecting wire.

Rule 11

Always locate the radio interference suppression filter close to the assumed noise source. The filter

must be mounted through the largest possible surface area at the cabinet housing, mounting panel etc.

The input and output cables must be spatially separated.

Rule 12

Radio interference suppression filters must be used in order to maintain limit value class A1. Additional

loads must be connected in front of the filter (line supply side).

Ob ein zustzliches Netzfilter installiert werden mu, ist abhngig von der verwendeten Steuerung und

wie der restliche Schaltschrank verdrahtet ist.

06.96

16/5

Rule 13

A commutating reactor is required in the field circuit for controlled field supplies.

Rule 14

A commutating reactor is required in the converter armature circuit.

Rule 15

For SIMOREG drives, the motor cables can be unshielded. The line supply cable must be a minimum

of 20cm away from the motor cables (field, armature).

If required, use a metal partition.

Footnotes:

1) Signal cables are defined as:

Digital signal cables.: or analog signal cables.:

Pulse encoder cables (e.g. + 10V setpoint cable)

Serial interfaces, e.g. PROFIBUS-DP

2) Generally, all metallic conductive parts, which can be connected to a protective conductor, e.g.

cabinet housing, motor frame, foundation grounder, etc., are considered as ground.

Cabinet design and shielding

The cabinet design illustrated in Figure 1 is intended to make the user sensitive and aware of EMC-

critical components and parts. The example does not claim to handle all possible cabinet components

and their respective mounting possibilities.

Details, which influence the noise immunity/noise radiation of the cabinet and which arent absolutely

clear in the overview diagram, are described in Figures 1a - 1d.

Different shield connecting techniques with reference source information are illustrated in detail in

Figures 2a - 2d.

Mounting radio interference suppression filters and commutating reactors:

Radio interference suppression filter and commutating reactor mounting for SIMOREG K drives is

described in Section 16.2.3. The sequence when installing the reactor and filter must be maintained.

The semiconductor protection fuses are selected according to the Instruction Manual of the converters.

06.96

16/6

SIMOREG K

Converter

Main conductor

Cable rataining bar

Shield rail

Terminals

Commutating reactor

Cable duct

Line filter

SIMOREG K

Shield rail

Terminals Main switch

Circuit-breaker

Field

Field commutating

reactor

Fuse links/m.c.b.

Converter filter

Fuse links

Control transformer

fan

Protective conductor

(location is non-critical) DC customer connection

3-ph. AC customer connection

Field customer connection

Pulse encoder

Figure 1b

Figure 1c

Figure 1a

Figure 1d

Shield rail

Circuit-breaker

Figure 1: Example of a cabinet design with a SIMOREG K converter (with

microprocessor) 30A - 600A

06.96

16/7

Cable retaining bar

Shield connection corresponding to

the following versions 1, 2, 3 and 4.

Connect to the cabinet housing

at both endstrough the largest

possible surface area!

Also shield on the plant side

(e.g. at the pulse encoder).

Cable duct

Shield rail must not be

used as strain relief

Cable retaining bar

Figure 1a: Shielding where the cable enters the cabinet

Terminals

Analog signal line

Data line

(e.g. PROFIBUS-DP)

Data line

(e.g. Pulse encoder)

Connect to the cabinet housing

at both endstrough the largest

possible surface area!

Also shield on the plant side

(e.g. at the pulse encoder).

Figure 1b: Shielding in the cabinet

06.96

16/8

Cables to the

ext. terminal block

Interfaces

RS 485, RS 232

Cables to the external

operator control panel

Connect the board to the

SIMOREG housing

Internal shield rail

Electronics board

C98043-A1600

XA XB X501 X500

X300

Figure 1c: Connecting the shields at the SIMOREG K 6RA24

06.96

16/9

L

I

N

E

Filtered cable Non-filtered cable

Connect the filter to the cabinet

housing through the largest

possible surface area!

Seperate the filtered and

non-filtered cables

Connect the

protective conductor

S

i

e

m

e

n

s

Figure 1d: Line filter for the SIMOREG K 6RA24 electronics power supply

06.96

16/10

Shield connection:

Version 1: Version 2:

Figure 2a: Connecting terminal mounted

on a copper busbar, max.

cable/cable diameter 15mm

Figure 2b: Terminal mounted on a

copper busbar, max.

cable/cable diameter 10mm.

Caution!

The conductor could be damaged if the terminal

screw is over-tightened

Note:

Terminals:

5mm busbar thickness,

Order No. 8US1921-2AC00

10 mm busbar thickness,

Order No. 8US1921-2BC00

Note:

Terminals:

Order No. 8HS7104,

8HS7104, 8HS7174, 8HS7164

06.96

16/11

Version 3: Version 4:

Figure 2c: Metalized tubing or cable ties

on a bare metal serrated rail

Figure 2d: Clamp and metalic mating

piece on a cable support rail.

Note:

Serrated rail:

Item No. J48028

Note:

Siemens 5VC55... cable clamps;

Various size mounting rails:

Item No. K48001 to 48005

Can be ordered from:

SIEMENS AG ANL A443 KA

Gnther-Scharowsky-Str. 2

Betriebe Sd

91058 Erlangen

Can be ordered from:

SIEMENS AG ANL A443 KA

Gnther-Scharowsky-Str. 2

Betriebe Sd

91058 Erlangen

06.96

16/12

16.2.3 Converter component arrangement

Reactor and filter arrangement

Supply voltage

1U1 1V1 1W1 3U1 3W1 5U1 5W1

Field Armature Power supply

SIMOREG-Converter

1C1 1D1

M

3C 3D

1) 2)

4)

3)

1) The commutating reactor in the field circuit is dimensioned for the nominal motor field current.

2) The commutating reactor in the armature circuit is dimensioned for the nominal motor armature

current. The line supply current is the DC current x 0.82.

3) The field circuit filter and the electronics power supply are dimensioned for the nominal motor field

current plus 0.5A.

4) The armature circuit filter is dimensioned for the nominal motor armature current. The line supply

current is the DC current x 0.82.

Note:

When filters are used, commutating reactors are always required at the converter input to decouple the

snubber circuitry.

The commutating reactors are selected according to the information provided in Catalog DA93.1.

06.96

16/13

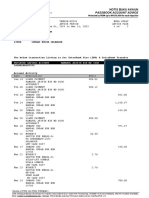

16.2.4 List of the recommended radio interference suppression filters

Rated current

radio

interference

suppression

filter (A)

Radio interference

suppression filter

Order No.

Terminal

cross-

section

(mm)

Weight

(kg)

Dimensions

HxWxD

(mm)

12 6SE7021-0ES87-0FB0 10*) 2,2 215x90x81

18 6SE7021-8ES87-0FB0 10*) 2,2 215x90x81

36 6SE7023-4ES87-0FB0 25 3,7 245x101x86

80 6SE7027-2ES87-0FB0 50 9,5 308x141x141

120 6SE7031-0ES87-0FA0 50 10 348x171x141

180 6SE7031-8ES87-0FA0 95 13 404x171x141

500 6SE7033-7ES87-0FA0 Connecting

lug

49 590x305x154

1000 6SE7041-0ES87-0FA0 Connecting

lug

90 840x465x204

1600 6SE7041-6ES87-0FA0 Connecting

lug

130 870x465x204

*) The filters generate discharge currents. VDE 0160 specifies a protective conductor connection with

10 mm.

For converter units for 3-phase supplies, the line current (filter current) is equal to the

DC current x 0.82.

For converters for two-phase supplies, two phases are connected to the three-phase filter. In this case,

the line supply current is the same as the DC current.

Important technical data of the radio interference protection filter:

Rated supply voltage 3-ph 380-460 V (+/- 15%)

Rated frequency 50/60 Hz (+/- 6%)

Operating temperature 0 C to +40 C

Degree of protection IP20 (EN60529)

IP00 500 A

Refer to the Instruction Manual for further technical data on the filters:

SIMOVERT Master Drives radio interference suppression filter, EMC filter,

Order No.: 6SE7087-6CX87-0FB0.

06.96

16/14

16.3 Information on line-side harmonics generated by converters in a fully-

controlled three-phase bridge circuit configuration B6C and (B6)A(B6)C

Converter for the medium power range usually consists of fully-controlled three-phase bridge circuit

configurations. An example of the harmonics generated by a typical system configuration for two firing

angles ( = 20 and = 60) is subsequently shown.

The values have been taken from an earlier publication, and more specifically from Harmonics in the

line-side current of six-pulse line-commutated converters from H. Arremann and G. Mltgen, Siemens

Forsch.- u. Entwickl.-Ber. Bd. 7 (1978) Nr. 2, Springer-Verlag 1978.

Formulas and equations were specified with which the short-circuit rating S

K

and the armature

inductance L

a

could be determined dependent on the specific operating data (line supply voltage (no-

load voltageV

v0

), line frequency f

N

and DC current I

d

]; this would then be valid for the specified

harmonic spectrum. A dedicated calculation is required if the actual system fault level and/or the actual

armature inductance deviate from the calculated values.

The specified harmonic spectrum is obtained, if the values for the system fault level S

K

at the

converter supply point and armature inductance L

a

of the motor, calculated using the following

formulas, are the same as the actual plant values. The harmonics must be separately calculated if the

values differ.

a.) = 20 b.) = 60

Basic fundamental g = 0,962 Basic fundamental g = 0,953

I

/I

1

I

/I

1

I

/I

1

I

/I

1

5 0,235 29 0,018 5 0,283 29 0,026

7 0,100 31 0,016 7 0,050 31 0,019

11 0,083 35 0,011 11 0,089 35 0,020

13 0,056 37 0,010 13 0,038 37 0,016

17 0,046 41 0,006 17 0,050 41 0,016

19 0,035 43 0,006 19 0,029 43 0,013

23 0,028 47 0,003 23 0,034 47 0,013

25 0,024 49 0,003 25 0,023 49 0,011

The basic fundamental current I

1

is calculated using the following formula as reference quantity

I I

1 d

0,817 = g

with I

d

DC current at the operating point being investigated

with g Harmonic content (refer above)

The harmonic currents calculated from the above tables, are only valid for

I.) System fault level S

K

at the converter supply connection point

( )

S

U

X

K

v 0

2

N

VA =

06.96

16/15

with

( ) X X X

U

f L

N K D

v 0

d

N D

, = = 003536 2

I

and

U

v0

No-load voltage at the converter supply connection point in V

I

d

DC current in A at the operating point to be investigated

f

N

Line frequency in Hz

L

D

Inductance of the commutating reactor in H

II.) Armature inductance L

a

( ) L

U

f

a

v0

N

, H =

00488

I

d

A separate calculation is required if the actual system fault level S

K

and/or the armature

inductance L

a

deviate from the values calculated using the above formula.

Example

A drive has the following data:

U

v0

= 400 V

I

d

= 150 A

f

N

= 50 Hz

L

D

= 0,169 mH (4EU2421-7AA10 with I

Ln

= 125 A)

With

X

N

, , , = =

003536

400

150

2 50 0169 10 00412

3

provides the following system fault level at the converter connecting point

S

K

,

, MVA = =

400

00412

388

2

and the following motor armature inductance which is required.

L

a

, , mH =

= 00488

400

50 150

260

The harmonic currents I

, which can be taken from the tables (with I

1

= g x 0.817 x I

d

for firing angles

= 20 and = 60) are only valid for the calculated values S

K

and L

a

. A separate calculation is

required if the values differ.

When dimensioning/designing filters and compensation circuits with reactors, the thus determined

harmonic values can only be used if the calculated values for S

K

and L

a

are the same as the actual

drive values. For all other case, a separate calculation must be made (this is especially true when

using compensated motors, as these motors have a very low armature inductance).

06.96

16/16

SIMOVIS

Disk 1

SIMOVIS

Disk 2

03.97

Equipment Plant Vienna

P.O. Box 83, A-1211 Vienna

Drives and Standard

Products from Siemens

Siemens Aktiengesellschaft

Subject to change without notice Order-No.: 6RX1240-0AD76

Printed in Austria

The following versions have appeared so far: Version Internal Part number

04 C98130-A1196-A1-04-7647

05 C98130-A1196-A1-05-7647

F C98130-A1196-A1-06-7647

G C98130-A1196-A1-07-7647

Version G consists of the following chapters

Chapter Pages Date of Edition

0 Contents 12 03.94

1 Safety information 2 03.94

2 Type spectrum 6 03.94

3 Description 10 03.94

4 Transport, unpacking 2 03.94

5 Installation 24 03.94

6 Connecting-up 42 03.94

7 Start-up 30 03.94

8 Operation 48 03.94

9 Parameter list 140 03.94

10 Functions 122 03.94

11 Maintenance 2 03.94

12 Service 2 03.94

13 Spare parts 2 03.94

14 Appendix 2 03.94

15 SIMOVIS 10 03.94

16 Installation instructions for EMC-correct installation of Drives 16 06.96

You might also like

- 6RA24 EnglischDocument496 pages6RA24 EnglischokebNo ratings yet

- vc34 Kompend Kap03 eDocument24 pagesvc34 Kompend Kap03 eSafetyjoe2No ratings yet

- DRV MasterDrives DriveMonitorDocument26 pagesDRV MasterDrives DriveMonitorWhite TigerNo ratings yet

- Earthing Bonding Variable Speed DrivesDocument26 pagesEarthing Bonding Variable Speed Drivesmitesh.rivonkarNo ratings yet

- Technical Information: Recommendations For EMC-compliant Wiring of Servo Drivers and MotorsDocument10 pagesTechnical Information: Recommendations For EMC-compliant Wiring of Servo Drivers and MotorsMaria TzagarakiNo ratings yet

- B4304Document9 pagesB4304jamesearl_cubillasNo ratings yet

- General Wiring and Installation Guidelines: Protecting Signals From Radiated and Conducted NoiseDocument2 pagesGeneral Wiring and Installation Guidelines: Protecting Signals From Radiated and Conducted NoiseMahmoud AlaaNo ratings yet

- EMC Fact FileDocument2 pagesEMC Fact FilewjscoNo ratings yet

- Tips On Shielding and Grounding in Industrial Automation - Technical Article PDFDocument20 pagesTips On Shielding and Grounding in Industrial Automation - Technical Article PDFTim BirloivNo ratings yet

- Shielding and GroundingDocument4 pagesShielding and GroundingSaibuOluwaseyiNo ratings yet

- Broschuere EMV Kabelverschraubungen enDocument16 pagesBroschuere EMV Kabelverschraubungen enLang AwNo ratings yet

- Electromagnetic Interference EMIDocument16 pagesElectromagnetic Interference EMIErnesto Vergara Jr.No ratings yet

- Technical Data SheetDocument14 pagesTechnical Data SheetRavi Ranjan VermaNo ratings yet

- Services and Solutions For Photovoltaic SystemsDocument4 pagesServices and Solutions For Photovoltaic SystemsMarijana IlicNo ratings yet

- YASKAWA L7 Manual PDFDocument242 pagesYASKAWA L7 Manual PDFangustiohNo ratings yet

- Operators & Service ManualDocument18 pagesOperators & Service ManualdocumentshitNo ratings yet

- CSR-CSFT438 Product Description and User's Manual Rev F 20-JUNE-2011Document62 pagesCSR-CSFT438 Product Description and User's Manual Rev F 20-JUNE-2011معاذ أحمدNo ratings yet

- Customization To Suppress Emi in DC MotorsDocument1 pageCustomization To Suppress Emi in DC MotorsgrsobhaNo ratings yet

- A Guide To Electromagnetic Compatibility For Variable Speed Drives-EmersonDocument28 pagesA Guide To Electromagnetic Compatibility For Variable Speed Drives-EmersonDelfinshNo ratings yet

- An-42007 AN42007 Safety, EMI and RFI ConsiderationsDocument6 pagesAn-42007 AN42007 Safety, EMI and RFI ConsiderationsSunu PradanaNo ratings yet

- Oi Variair Frequency Inverter 4-3 English 05.12.2012Document42 pagesOi Variair Frequency Inverter 4-3 English 05.12.2012jhurtado2kNo ratings yet

- A Review of EMI Standards, Part 2Document5 pagesA Review of EMI Standards, Part 2lcisnydeksdtaujutlNo ratings yet

- Schneider EMC-EMI GuideDocument26 pagesSchneider EMC-EMI Guideeurasoglu100% (1)

- Electromagnetic Compatibility (EMC) and Variable Speed DrivesDocument2 pagesElectromagnetic Compatibility (EMC) and Variable Speed Drivessopan saNo ratings yet

- Surge Protection Technical TrainingDocument52 pagesSurge Protection Technical TrainingAndrewcaesarNo ratings yet

- Residual Current Devices Basic Understanding and TutorialsDocument7 pagesResidual Current Devices Basic Understanding and TutorialsKrishna JashaNo ratings yet

- Selection Guide For Transformer-Primary Fuses in Mediumand High-Voltage Utility and Industrial SubstationDocument124 pagesSelection Guide For Transformer-Primary Fuses in Mediumand High-Voltage Utility and Industrial SubstationNicol Belén EscobarNo ratings yet

- Bu6010 GB 0300Document44 pagesBu6010 GB 0300Kadirou BigstarNo ratings yet

- Video Copy Processor: Operation ManualDocument42 pagesVideo Copy Processor: Operation ManualZahid MubeenNo ratings yet

- CPU928B CPU948 Communication (E) OCRDocument353 pagesCPU928B CPU948 Communication (E) OCROscar LealNo ratings yet

- EMI in Power SuppliesDocument16 pagesEMI in Power SuppliesHansraj AkilNo ratings yet

- HA IFC300 en 061121Document72 pagesHA IFC300 en 061121magolelNo ratings yet

- Avr EsdDocument18 pagesAvr EsdAlex PatelNo ratings yet

- Tech Note 26Document6 pagesTech Note 26Srinivas PentapatiNo ratings yet

- Some General Rules Concerning Control Panels GroundingDocument4 pagesSome General Rules Concerning Control Panels Groundingwaqas_a_shaikh4348No ratings yet

- CG Controlgear Catalogue 7.7Document258 pagesCG Controlgear Catalogue 7.7nagarajanNo ratings yet

- Atmel Avr3000: Qtouch Conducted ImmunityDocument11 pagesAtmel Avr3000: Qtouch Conducted ImmunityVictor CamposNo ratings yet

- Infrared RaysDocument7 pagesInfrared RaysShree RaiNo ratings yet

- Danfoss RFIDocument1 pageDanfoss RFIASM_213No ratings yet

- UFS Brake Units - Data Sheet NT348E-05 (12.01)Document21 pagesUFS Brake Units - Data Sheet NT348E-05 (12.01)ahmed alahmedNo ratings yet

- Improving Electro-Magnetic Noise Immunity in Serial Communications SystemsDocument6 pagesImproving Electro-Magnetic Noise Immunity in Serial Communications SystemsrijaseNo ratings yet

- J1939 Gateway™: Installation and Operation GuideDocument27 pagesJ1939 Gateway™: Installation and Operation GuideEmrol2No ratings yet

- Dc400 Selfs Pour Variateurs CCDocument28 pagesDc400 Selfs Pour Variateurs CCJesus UrrietaNo ratings yet

- Ect 160Document20 pagesEct 160Emailsuman ExbiiNo ratings yet

- UFS 15-22-40-110 UFS15J-22J-40J: Braking UnitDocument21 pagesUFS 15-22-40-110 UFS15J-22J-40J: Braking UnitnayanNo ratings yet

- Installation of Vibration SensorsDocument8 pagesInstallation of Vibration SensorsnmguravNo ratings yet

- Technical Comparison of Harmonic Mitigation PDFDocument9 pagesTechnical Comparison of Harmonic Mitigation PDFGurmeet SinghNo ratings yet

- RF Controlled Starting of Induction MotorDocument28 pagesRF Controlled Starting of Induction MotorCR AthiraNo ratings yet

- Multiple Earthed NeutralDocument6 pagesMultiple Earthed Neutralrajpre1213No ratings yet

- MEN System of EarthningDocument6 pagesMEN System of EarthningstarykltNo ratings yet

- AVR040: EMC Design Considerations: 8-Bit Microcontroller Application NoteDocument17 pagesAVR040: EMC Design Considerations: 8-Bit Microcontroller Application Noteattanasio89No ratings yet

- Pm100usb ManualDocument62 pagesPm100usb ManualbabshuagNo ratings yet

- ABB Application Guide For Surge ArrestersDocument88 pagesABB Application Guide For Surge ArrestersNader Tahan0% (1)

- Supresor ElectricoDocument12 pagesSupresor ElectricoJuan QuezadaNo ratings yet

- Danfoss Active Harmonic Filter Design GuideDocument59 pagesDanfoss Active Harmonic Filter Design GuidenaveedfndNo ratings yet

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- High-Performance D/A-Converters: Application to Digital TransceiversFrom EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- 411PROFIBUSENGDocument74 pages411PROFIBUSENGRaja Shannmugam0% (1)

- 7SJ62-64 Manual AA V046401 UsDocument715 pages7SJ62-64 Manual AA V046401 UsstunnchuckNo ratings yet

- Configuration Tool Manual R2Document176 pagesConfiguration Tool Manual R2Bassem MostafaNo ratings yet

- Hmi Mp377 Mp377pro Operating Instructions en-US en-USDocument340 pagesHmi Mp377 Mp377pro Operating Instructions en-US en-USroypearsonNo ratings yet

- 7UT6x Manual A4 V040300 enDocument694 pages7UT6x Manual A4 V040300 enAnonymous m65TTcfOTNo ratings yet

- LOGO! 0BA8 Reserved VM AddressesDocument3 pagesLOGO! 0BA8 Reserved VM AddressesRaja Shannmugam100% (1)

- Hmi MP 277 Operating Instructions en-US en-US PDFDocument214 pagesHmi MP 277 Operating Instructions en-US en-US PDFRaja ShannmugamNo ratings yet

- Com Profibus 7sj6x 6md63 UsDocument90 pagesCom Profibus 7sj6x 6md63 UshelveciolopesNo ratings yet

- C-Userschard2DocumentsPLCspdp 7sj6263 e PDFDocument36 pagesC-Userschard2DocumentsPLCspdp 7sj6263 e PDFRaja ShannmugamNo ratings yet

- PGH FC FB Fuer s7cp 76Document191 pagesPGH FC FB Fuer s7cp 76Surit ApiwanNo ratings yet

- Conditions of Contract enDocument3 pagesConditions of Contract enmikeadrianNo ratings yet

- Com Profibus 7sj6x 6md63 UsDocument90 pagesCom Profibus 7sj6x 6md63 UshelveciolopesNo ratings yet

- Lafarge Cement Optimization SolutionDocument2 pagesLafarge Cement Optimization SolutionRaja Shannmugam100% (1)

- Roles and Responsibilities of A Project Manager PDFDocument5 pagesRoles and Responsibilities of A Project Manager PDFRaja Shannmugam80% (5)

- 7sj62 - Katalog - PDF (1.227kb)Document35 pages7sj62 - Katalog - PDF (1.227kb)vetsasNo ratings yet

- Premature Stator FailureDocument9 pagesPremature Stator FailurePugalenthi.SNo ratings yet

- Vsds Manual AbbDocument446 pagesVsds Manual AbbRaja ShannmugamNo ratings yet

- V3i5 Ijertv3is051014 PDFDocument5 pagesV3i5 Ijertv3is051014 PDFRaja ShannmugamNo ratings yet

- Comprehensive Electrical System Maintenance ChecklistsDocument6 pagesComprehensive Electrical System Maintenance ChecklistsRaja ShannmugamNo ratings yet

- Mm440 Cat enDocument33 pagesMm440 Cat enÖnder ÇiftçiNo ratings yet

- Mm440 Cat enDocument33 pagesMm440 Cat enÖnder ÇiftçiNo ratings yet

- Siemens MM 440 Quick Start GuideDocument68 pagesSiemens MM 440 Quick Start GuideGritz JohnNo ratings yet

- Premature Stator FailureDocument9 pagesPremature Stator FailurePugalenthi.SNo ratings yet

- MBA (PM) - Dec-2011Document23 pagesMBA (PM) - Dec-2011Raja ShannmugamNo ratings yet

- Installation Troubleshooting Capacitors APFCSystemDocument23 pagesInstallation Troubleshooting Capacitors APFCSystemAshish ParasharNo ratings yet

- Micromaster Mm4 Profibus enDocument76 pagesMicromaster Mm4 Profibus enMarcelino Martín PérezNo ratings yet

- A Guide To Battery ChargingDocument7 pagesA Guide To Battery Chargingsenkum812002No ratings yet

- Hunger Games Mini Socratic Seminar2012Document4 pagesHunger Games Mini Socratic Seminar2012Cary L. TylerNo ratings yet

- Distillation Column DesignDocument42 pagesDistillation Column DesignAakanksha Raul100% (1)

- Demonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BeDocument4 pagesDemonstration of Preprocessing On Dataset Student - Arff Aim: This Experiment Illustrates Some of The Basic Data Preprocessing Operations That Can BePavan Sankar KNo ratings yet

- Aerated Concrete Production Using Various Raw MaterialsDocument5 pagesAerated Concrete Production Using Various Raw Materialskinley dorjee100% (1)

- 2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessDocument11 pages2014 Abidetal. TheoreticalPerspectiveofCorporateGovernance BulletinofBusinessOne PlusNo ratings yet

- 09-11-2016 University Exam PaperDocument34 pages09-11-2016 University Exam PaperSirisha AsadiNo ratings yet

- Rules and Fallacies For Categorical SyllogismsDocument5 pagesRules and Fallacies For Categorical SyllogismsFatima Ismael PortacioNo ratings yet

- Tensile Strength of Ferro Cement With Respect To Specific SurfaceDocument3 pagesTensile Strength of Ferro Cement With Respect To Specific SurfaceheminNo ratings yet

- Thesis StoryboardDocument5 pagesThesis StoryboardJill Brown100% (2)

- DC Motor: F Bli NewtonDocument35 pagesDC Motor: F Bli NewtonMuhammad TausiqueNo ratings yet

- Relay G30 ManualDocument42 pagesRelay G30 ManualLeon KhiuNo ratings yet

- Handbook+for+Participants+ +GCC+TeenDocument59 pagesHandbook+for+Participants+ +GCC+Teenchloe.2021164No ratings yet

- Business Logic Module 1Document5 pagesBusiness Logic Module 1Cassandra VenecarioNo ratings yet

- Review Rachna WasteDocument9 pagesReview Rachna WasteSanjeet DuhanNo ratings yet

- 01 IntroductionDocument15 pages01 IntroductionAli FarhatNo ratings yet

- Assistant Bookkeeper Resume Sample - Best Format - Great Sample ResumeDocument4 pagesAssistant Bookkeeper Resume Sample - Best Format - Great Sample ResumedrustagiNo ratings yet

- RHB Islamic Bank BerhadDocument2 pagesRHB Islamic Bank BerhadVape Hut KlangNo ratings yet

- Riveted JointsDocument28 pagesRiveted Jointsgnbabuiitg0% (1)

- Citroen CX Manual Series 2 PDFDocument646 pagesCitroen CX Manual Series 2 PDFFilipe Alberto Magalhaes0% (1)

- 1974 - Roncaglia - The Reduction of Complex LabourDocument12 pages1974 - Roncaglia - The Reduction of Complex LabourRichardNo ratings yet

- ER288 090714 5082 CV OKP (089) Method Statement For Plate Baring TestDocument3 pagesER288 090714 5082 CV OKP (089) Method Statement For Plate Baring TestWr ArNo ratings yet

- FmatterDocument12 pagesFmatterNabilAlshawish0% (2)

- Eurocode Conference 2023 Seters Van Eurocode 7Document33 pagesEurocode Conference 2023 Seters Van Eurocode 7Rodolfo BlanchiettiNo ratings yet

- Pre Intermediate Talking ShopDocument4 pagesPre Intermediate Talking ShopSindy LiNo ratings yet

- Excavation Trench Permit Ex 1 F0206Document5 pagesExcavation Trench Permit Ex 1 F0206emeka2012No ratings yet

- Introducing Eventstorming-4Document1 pageIntroducing Eventstorming-4Alex TrujilloNo ratings yet

- Astn/Ason and Gmpls Overview and Comparison: By, Kishore Kasi Udayashankar Kaveriappa Muddiyada KDocument44 pagesAstn/Ason and Gmpls Overview and Comparison: By, Kishore Kasi Udayashankar Kaveriappa Muddiyada Ksrotenstein3114No ratings yet

- 3.1 MuazuDocument8 pages3.1 MuazuMon CastrNo ratings yet

- Each Life Raft Must Contain A Few ItemsDocument2 pagesEach Life Raft Must Contain A Few ItemsMar SundayNo ratings yet

- Yumemiru Danshi Wa Genjitsushugisha Volume 2Document213 pagesYumemiru Danshi Wa Genjitsushugisha Volume 2carldamb138No ratings yet