Professional Documents

Culture Documents

AISC (MM) Properties

Uploaded by

Ebert Joel Paico AmayaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISC (MM) Properties

Uploaded by

Ebert Joel Paico AmayaCopyright:

Available Formats

AISC MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single Angles Double Angles Square & Rectangular HSS

Y Y Y

k1=15.875 Y Y Y

k=16.764 tf=9.144 tf=9.906 b=88.9 t = 8.9 k1=15.875

bf=146.05 t=9.525

y=27.178 x=26.67

x(bar)=14.5288 tf=9.144 d=88.9 t=12.7 X

d=259.08 T X d=203.2 X X d=127 d=203.2 X

d=129.286 X y=26.67

tw=6.096 tw=5.588 tw=6.096 b=88.9

(0, 3/8, or 3/4

bf=146.05 bf=57.404 gap) b=152.4

W10x22 C8x11.5 WT5x11 L3-1/2x3-1/2x1/2 2L5x3-1/2x3/8LLBB HSS8x6x3/8

A = 41.9 cm

2

A = 21.7 cm

2

A = 20.9 cm

2

d = 88.9 mm d = 127.0 mm d = 203.2 mm

d = 259.1 mm d = 203 mm d = 129.3 mm b = 88.9 mm b = 88.9 mm b = 152.4 mm

tw = 6.1 mm tw = 5.6 mm tw = 6.1 mm t = 12.7 mm t = 9.5 mm t = 8.9 mm

bf = 146.1 mm bf = 57 mm bf = 146.1 mm k = 22.2 mm k = 20.6 mm wt. = 17.9 kg/ml

tf = 9.1 mm tf = 9.9 mm tf = 9.1 mm wt. = 16.6 kg/ml wt. = 30.9 kg/ml A = 22.8 cm

2

T = 8-1/4 in. T = 1005840.0 mm k = 16.8 mm A = 21.1 cm

2

A = 39.4 cm

2

Ix = 3292.4 cm

4

k = 16.8 mm k = 23.8 mm d/tw = 21.2 Ix = 151.1 cm

4

Ix = 645.2 cm

4

Sx = 324.5 cm

3

k1 = 15.9 mm gage = 1-3/8 in. Ix = 286 cm

4

Sx = 24.3 cm

3

Sx = 74.7 cm

3

rx = 7.54 cm

gage = 2-3/4 in. x(bar) = 14.5 mm Sx = 28.2 cm

3

rx = 2.7 cm rx = 4.0 cm Zx = 394.9 cm

3

rt = 3.8 cm eo = 17.7 mm rx = 3.7 cm y = 26.7 mm y = 40.6 mm Iy = 2106.1 cm

4

d/Af = 4.91 d/Af = 9.08 y = 27.2 mm Iy = 151.1 cm

4

ry(0) = 33.8 mm Sy = 276.9 cm

3

Ix = 4912 cm

4

Ix = 1353 cm

4

Iy = 238 cm

4

Sy = 24.3 cm

3

ry(3/8) = 37.1 mm ry = 6.0 cm

Sx = 380 cm

3

Sx = 133 cm

3

Sy = 32.6 cm

3

ry = 2.7 cm ry(3/4) = 40.4 mm Zy = 324.5 cm

3

rx = 10.8 cm rx = 7.9 cm ry = 3.4 cm x = 26.7 mm ro(bar) = 63.8 mm J = 4162 cm

4

Iy = 475 cm

4

Iy = 55 cm

4

J = 5.0 cm

4

rz = 1.7 cm H = 0.683

Sy = 65 cm

3

Sy = 12.7 cm

3

Cw = 28.7 cm

6

TAN(a) = 1.0 Round HSS & Pipes

ry = 3.4 cm ry = 1.6 cm a = 9.8 cm J = 11.7 cm

4

Y

Zx = 426.1 cm

3

J = 5.4 cm

4

ro(bar) = 5.5 cm Cw = 63.9 cm

6

t= 4.5

Zy = 100.0 cm

3

Cw = 4430.8 cm

6

H = 0.830 a = 9.6 cm

J = 9.95 cm

4

a = 117.0 cm wt. = 16.4 kg/ml ro(bar) = 4.7 cm

Cw = 73579 cm

6

ro(bar) = 8.7 cm H = 0.634 O.D.= 33.5 X

a = 351.5 cm H = 0.862

Wno = 91.0 cm

2

wt. = 17.1 kg/ml I.D.=24.3078

Sw = 303.8 cm

4

Qf = 79.6 cm

3

PIPE1XS

Qw = 209.8 cm

3

O.D. = 33.5 mm.

wt. = 32.9 kg/ml I.D. = 24.3 mm.

t = 4.5 mm.

wt. = 3.2 kg/ml

A = 4.1 cm

2

I = 1 cm

4

S = 3 cm

3

r = 1.0 cm.

J = 9 cm

4

Reference:

The shapes contained in this database are a

compilation of those listed in the current AISC

"Shapes Database" CD-ROM Version 3.0 (June,

2001), as well as those listed in the AISC 9th

Edition Manual of Steel Construction (1989)

AISC MEMBER DIMENSIONS AND PROPERTIES VIEWER

W, S, M, HP Shapes C, MC Shapes WT, ST, MT Shapes Single Angles Double Angles Square & Rectangular HSS

Y Y Y

k1=0.625 Y Y Y

k=0.66 tf=0.36 tf=0.436 b=3.5 t=0.349

bf=5.75 t=0.375

y=1.07 x=0.854

x(bar)=0.634 tf=0.36 d=5 t=0.375 X

d=10.2 T X d=10 X X d=5 d=8 X

d=5.09 X y=1.6

tw=0.24 tw=0.24 tw=0.24 b=3.5

(0, 3/8, or 3/4

bf=5.75 bf=2.6 gap) b=6

W10x22 C10x15.3 WT5x11 L5x3-1/2x3/8 2L5x3-1/2x3/8LLBB HSS8x6x3/8

A = 6.49 in.^2 A = 4.48 in.^2 A = 3.24 in.^2 d = 5 in. d = 5 in. d = 8 in.

d = 10.200 in. d = 10.000 in. d = 5.090 in. b = 3.5 in. b = 3.5 in. b = 6 in.

tw = 0.240 in. tw = 0.240 in. tw = 0.240 in. t = 0.375 in. t = 0.375 in. t = 0.349 in.

bf = 5.750 in. bf = 2.600 in. bf = 5.750 in. k = 0.8125 in. k = 0.8125 in. wt./ft. = 32.50 plf.

tf = 0.360 in. tf = 0.436 in. tf = 0.360 in. wt./ft. = 10.40 plf. wt./ft. = 20.80 plf. A = 8.97 in.^2

T = 8-1/4 in. T = 8 in. k = 0.6600 in. A = 3.05 in.^2 A = 6.10 in.^2 Ix = 79.10 in.^4

k = 0.6600 in. k = 1.0000 in. d/tw = 21.20 Ix = 7.75 in.^4 Ix = 15.50 in.^4 Sx = 19.80 in.^3

k1 = 0.6250 in. gage = 1-1/2 in. Ix = 6.88 in.^4 Sx = 2.28 in.^3 Sx = 4.56 in.^3 rx = 2.970 in.

gage = 2-3/4 in. x(bar) = 0.634 in. Sx = 1.72 in.^3 rx = 1.590 in. rx = 1.590 in. Zx = 24.10 in.^3

rt = 1.510 in. eo = 0.796 in. rx = 1.460 in. y = 1.600 in. y = 1.600 in. Iy = 50.60 in.^4

d/Af = 4.91 d/Af = 8.81 y = 1.070 in. Iy = 3.15 in.^4 ry(0) = 1.330 in. Sy = 16.90 in.^3

Ix = 118.00 in.^4 Ix = 67.30 in.^4 Iy = 5.71 in.^4 Sy = 1.19 in.^3 ry(3/8) = 1.460 in. ry = 2.380 in.

Sx = 23.20 in.^3 Sx = 13.50 in.^3 Sy = 1.99 in.^3 ry = 1.020 in. ry(3/4) = 1.590 in. Zy = 19.80 in.^3

rx = 4.270 in. rx = 3.870 in. ry = 1.330 in. x = 0.854 in. ro(bar) = 2.51 in. J = 100.00 in.^4

Iy = 11.40 in.^4 Iy = 2.27 in.^4 J = 0.119 in.^4 rz = 0.755 in. H = 0.683

Sy = 3.97 in.^3 Sy = 1.15 in.^3 Cw = 0.107 in.^6 TAN(a) = 0.486 Round HSS & Pipes

ry = 1.330 in. ry = 0.711 in. a = 1.53 in. J = 0.15 in.^4 Y

Zx = 26.00 in.^3 J = 0.21 in.^4 ro(bar) = 2.16 in. Cw = 0.217 in.^6 t=0.365

Zy = 6.10 in.^3 Cw = 45.5 in.^6 H = 0.830 a = 1.94 in.

J = 0.24 in.^4 a = 23.74 in. ro(bar) = 2.45 in.

Cw = 274 in.^6 ro(bar) = 4.19 in. H = --- O.D.=10.8 X

a = 54.48 in. H = 0.884

Wno = 14.10 in.^2 I.D.=10

Sw = 7.30 in.^4

Qf = 4.86 in.^3 PIPE10STD

Qw = 12.80 in.^3 O.D. = 10.8 in.

I.D. = 10 in.

t = 0.365 in.

wt./ft. = 40.50 plf.

A = 11.90 in.^2

I = 161.00 in.^4

S = 29.90 in.^3

r = 3.670 in.

J = 321.00 in.^4

Reference:

The shapes contained in this database are a

compilation of those listed in the current AISC

"Shapes Database" CD-ROM Version 3.0 (June,

2001), as well as those listed in the AISC 9th

Edition Manual of Steel Construction (1989)

NOMENCLATURE FOR MEMBER PROPERTIES AND DIMENSIONS:

A = Cross-sectional area of member (in.^2)

d = Overall depth of member, parallel to X-axis (in.)

tw = Thickness of web of member (in.)

bf = Width of flange of member (in.)

tf = Thickness of flange of member (in.)

T = Distance between fillets for wide-flange or channel shape (in.) = d-2*k

k = Distance from outer face of flange to web toe of fillet (in.)

k1 = Distance from web centerline to flange toe of fillet (in.)

gage = Standard gage (bolt spacing) for member (in.)

rt = Radius of gyration of compression flange plus 1/3 of compression web area, taken about an axis in plane of web (in.)

d/Af = Ratio of of total depth of member to area of compression flange of member = d/(bf*tf)

Ix = Moment of inertia of member taken about X-axis (in.^4)

Sx = Elastic section modulus of member taken about X-axis (in.^3)

rx = Radius of gyration of member taken about X-axis (in.) = SQRT(Ix/A)

Iy = Moment of inertia of member taken about Y-axis (in.^4)

Sy = Elastic section modulus of member taken about Y-axis (in.^3)

ry = Radius of gyration of member taken about Y-axis (in.) = SQRT(Iy/A)

Zx = Plastic section modulus of member taken about X-axis (in.^3)

Zy = Plastic section modulus of member taken about Y-axis (in.^3)

J = Torsional constant of member (in.^4)

Cw = Warping constant (in.^6)

a = Torsional property, a = SQRT(E*Cw/G*J)

E = Modulus of elasticity of steel = 29,000 ksi

G = Shear modulus of elasticity of steel = 11,200 ksi

Wno = Normalized warping function at a point at the flange edge (in.^2)

Sw = Warping statical moment at a point on the cross section (in.^4)

Qf = Statical moment for a point in the flange directly above the vertical edge of the web (in.^3)

Qw = Statical moment at the mid-depth of the section (in.^3)

x(bar) = Distance from outside face of web of channel shape to Y-axis (in.)

eo = Horizontal distance from the outer edge of a channel web to its shear center (in.) = (approx.) tf*(d-tf)^2*(bf-tw/2)^2/(4*Ix)-tw/2

xo = x-coordinate of shear center with respect to the centroid of the section (in.)

yo = y-coordinate of shear center with respect to the centroid of the section (in.)

ro(bar) = Polar radius of gyration about the shear center (in.) = SQRT(xo^2+yo^2+(Ix+Iy)/A)

H = Flexural constant, H = 1-(xo^2+yo^2)/ro(bar)^2)

LLBB = Long legs back-to-back for double angles

SLBB = Short legs back-to-back for double angles

STD = Standard weight (Schedule 40) pipe section

XS = Extra strong (Schedule 80) pipe section

XXS = Double-extra strong pipe section

You might also like

- Wind RoseDocument49 pagesWind RoseIzzy StardlinNo ratings yet

- Earthquake Safety Assessment of Buildings Through Rapid Visual ScreeningDocument14 pagesEarthquake Safety Assessment of Buildings Through Rapid Visual ScreeningMerwin Andrew UyNo ratings yet

- Analisa PedestalDocument22 pagesAnalisa PedestalAnisha MayaNo ratings yet

- Steel Frame Design ManualDocument80 pagesSteel Frame Design ManualHaytham ZaghloulNo ratings yet

- Seismic Design Practice For Eccentrically Braced Frames Based On The 1994 UBCDocument32 pagesSeismic Design Practice For Eccentrically Braced Frames Based On The 1994 UBCkalikid20No ratings yet

- Base Reactions Table AnalysisDocument12 pagesBase Reactions Table AnalysisGema Mahardika YogatamaNo ratings yet

- Staad (1) .Pro 2006 Technical Reference (Halid)Document702 pagesStaad (1) .Pro 2006 Technical Reference (Halid)Victoria WU MengqianNo ratings yet

- AISC member dimensions and properties viewerDocument23 pagesAISC member dimensions and properties viewerMadara Uchija100% (1)

- Analytical Approach of Anchor Rod Stiffness and Steel Base-Plate Calculation under TensionDocument24 pagesAnalytical Approach of Anchor Rod Stiffness and Steel Base-Plate Calculation under TensionVladimir GuamanNo ratings yet

- Diseño Sismico Usando EtabsDocument83 pagesDiseño Sismico Usando EtabsBilly GsmNo ratings yet

- Evaluasi Gedung MNC Tower MENGGUNAKAN SNI 03-1726-2012 DENGAN Metode Pushover AnalysisDocument81 pagesEvaluasi Gedung MNC Tower MENGGUNAKAN SNI 03-1726-2012 DENGAN Metode Pushover AnalysisantokNo ratings yet

- Calculation Sheet For Power House Structure Due To Load Test OHCDocument6 pagesCalculation Sheet For Power House Structure Due To Load Test OHCnofrinaldo ratmanNo ratings yet

- Welcome To The Presentation On "One Way Slab Design: Md. Asif Rahman 10.01.03.108 Dept. of CeDocument29 pagesWelcome To The Presentation On "One Way Slab Design: Md. Asif Rahman 10.01.03.108 Dept. of CeAmit GuptaNo ratings yet

- Wind Tunnel Methods2Document21 pagesWind Tunnel Methods2mdkml2100% (1)

- Peru NDTDocument50 pagesPeru NDTGabrielNo ratings yet

- 3-3 Working With SpreadsheetsDocument34 pages3-3 Working With Spreadsheetscrystal macababbadNo ratings yet

- Lpile Group ModuleDocument2 pagesLpile Group ModuleMUHAMMAD ALINo ratings yet

- Pushover AnalysisDocument12 pagesPushover Analysisrobby guntaraNo ratings yet

- Anchor ReinforcementDocument6 pagesAnchor Reinforcementmr.KramNo ratings yet

- Pipe Schedule and WeightDocument1 pagePipe Schedule and WeightAffendiNo ratings yet

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNo ratings yet

- Construction Methods for Wharf StructuresDocument43 pagesConstruction Methods for Wharf Structuresruli100% (1)

- Pushover Prusinski PDFDocument116 pagesPushover Prusinski PDFJesus Chavez SolanoNo ratings yet

- One Liberty Place - MSC PDFDocument40 pagesOne Liberty Place - MSC PDFpaninzynier100% (1)

- Anchor Design HILTIDocument14 pagesAnchor Design HILTIRohit GadekarNo ratings yet

- 1992 - 04 Designing For Cost Efficient FabricationDocument8 pages1992 - 04 Designing For Cost Efficient FabricationHenry HoyosNo ratings yet

- ASCE 7-95 Seismic CoefficientDocument1 pageASCE 7-95 Seismic Coefficientrina2369No ratings yet

- Bab IV - Perhitungan Floor Deck (Ok)Document6 pagesBab IV - Perhitungan Floor Deck (Ok)Aditia Maulana ANo ratings yet

- DNV OS-C502 (2004) Offshore Concrete StructuresDocument100 pagesDNV OS-C502 (2004) Offshore Concrete StructuresnimitNo ratings yet

- Design of Composite Member Part 3 PDFDocument30 pagesDesign of Composite Member Part 3 PDFBaskara HutahaeanNo ratings yet

- Imp Design GuideDocument32 pagesImp Design GuideRahulNo ratings yet

- Structural Steel Design: Plate GirdersDocument20 pagesStructural Steel Design: Plate GirdersumerumerumerNo ratings yet

- Bridge RulesDocument21 pagesBridge Rulesraghuveer11No ratings yet

- Analisa PedestalDocument22 pagesAnalisa PedestalAnisha MayaNo ratings yet

- Analysis of Tank 1Document20 pagesAnalysis of Tank 1BALRAJNo ratings yet

- Steel JoistDocument2 pagesSteel JoistWilliam Greco100% (1)

- Elastic-Plastic Analysis of Simply Supported Rectangular Plates U PDFDocument178 pagesElastic-Plastic Analysis of Simply Supported Rectangular Plates U PDFTawsif AhmedNo ratings yet

- Bab III Gording FixDocument11 pagesBab III Gording FixSatria IstanaNo ratings yet

- Effect of Extreme Climate On Topology of RailwayDocument30 pagesEffect of Extreme Climate On Topology of RailwayKimNo ratings yet

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurNo ratings yet

- Rarhu Reservoir Scheme stability analysis and design of non-overflow dam maximum sectionDocument26 pagesRarhu Reservoir Scheme stability analysis and design of non-overflow dam maximum sectionp_ignatiusNo ratings yet

- PRISM For Earthquake Engineering A Program For Seismic Response Analysis of SDOF SystemDocument13 pagesPRISM For Earthquake Engineering A Program For Seismic Response Analysis of SDOF SystemPrabhat KumarNo ratings yet

- Hinge PropertiesDocument2 pagesHinge PropertiesSantiago Felix Mota Paez100% (1)

- BridgeDocument15 pagesBridgeKutti ManiNo ratings yet

- Genetic Algorithm Optimizes Cost of Prestressed Concrete BridgesDocument8 pagesGenetic Algorithm Optimizes Cost of Prestressed Concrete BridgesParth TrivediNo ratings yet

- Building and Design CodesDocument15 pagesBuilding and Design CodesKeangsinh TaingNo ratings yet

- İsrail Deprem Yönetmeliği EkiDocument18 pagesİsrail Deprem Yönetmeliği EkiErol Eylemci KaplanNo ratings yet

- Structural Calculation For Skid - 08.02.2024 CommentedDocument104 pagesStructural Calculation For Skid - 08.02.2024 Commentedkehape8723No ratings yet

- Design - Concept - JAPANESE DEVELOPMENT OF EARTHQUAKE RESISTANT BUILDING DESIGN PDFDocument15 pagesDesign - Concept - JAPANESE DEVELOPMENT OF EARTHQUAKE RESISTANT BUILDING DESIGN PDFCem TuraNo ratings yet

- Base Plate Verification ExampleDocument10 pagesBase Plate Verification ExampleKarthikeyan VediNo ratings yet

- 2 PDFDocument15 pages2 PDFEman AhmedNo ratings yet

- Pondasi Tang Pancang Spun PileDocument22 pagesPondasi Tang Pancang Spun PileMochammad ShokehNo ratings yet

- Penjelasan Sni 1726 2012Document37 pagesPenjelasan Sni 1726 2012Gunaedy UtomoNo ratings yet

- Chapter 3 TorsionDocument41 pagesChapter 3 TorsionDave WundererNo ratings yet

- The Comparison of Manual Calculation Vs Tekla Structural DesignerDocument1 pageThe Comparison of Manual Calculation Vs Tekla Structural DesignerrajakNo ratings yet

- AISC member properties viewer dimensions guideDocument2 pagesAISC member properties viewer dimensions guideNoeBongaNo ratings yet

- CALCULOSDocument227 pagesCALCULOSLuisHuamanQuilicheNo ratings yet

- Bases de Diseño AiscDocument127 pagesBases de Diseño AiscZain AndabloNo ratings yet

- Per FilesDocument144 pagesPer FilesPaúl A Vasquez GonzalezNo ratings yet

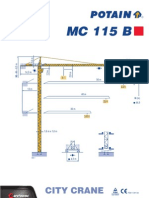

- City Crane: Above. Beyond. EverywhereDocument4 pagesCity Crane: Above. Beyond. EverywhereEbert Joel Paico AmayaNo ratings yet

- Beam CalculatorDocument113 pagesBeam CalculatorEbert Joel Paico AmayaNo ratings yet

- AISC 13th Edition Member Dimensions and Properties Viewer DatabaseDocument3 pagesAISC 13th Edition Member Dimensions and Properties Viewer DatabaseFlorencio SandovalNo ratings yet

- Heat-Treated Steel Structural Bolts, 150 Ksi Minimum Tensile StrengthDocument7 pagesHeat-Treated Steel Structural Bolts, 150 Ksi Minimum Tensile StrengthJosé Ramón GutierrezNo ratings yet

- Tramo D (M) L (M) L/S M3/S AB BC CD DA RA QDocument2 pagesTramo D (M) L (M) L/S M3/S AB BC CD DA RA QEbert Joel Paico AmayaNo ratings yet

- Formulario Suelos 1 y 2 PDFDocument5 pagesFormulario Suelos 1 y 2 PDFMelrukia Huanacuni ContrerasNo ratings yet

- Introduction To Electro Magnetism PDFDocument97 pagesIntroduction To Electro Magnetism PDFDebi Prasad SenNo ratings yet

- Module II Lecture 4Document19 pagesModule II Lecture 4Prateek NayakNo ratings yet

- The critical state behaviour of barodesy compared with the Matsuoka–Nakai failure criterionDocument15 pagesThe critical state behaviour of barodesy compared with the Matsuoka–Nakai failure criterionAgámez MarlonNo ratings yet

- General Manager UIP Nusra SRM Operasi Dan Konstruksi UIP NUSRA PT. PLN (Persero) UPP Timor ArsipDocument31 pagesGeneral Manager UIP Nusra SRM Operasi Dan Konstruksi UIP NUSRA PT. PLN (Persero) UPP Timor Arsiphastaria mannaNo ratings yet

- KOM Lesson PlanDocument2 pagesKOM Lesson PlanFarhan Shah Sarani100% (1)

- ME-EM 5210 Advanced Fluid Engineering: Course Goals, Policies Textbooks GradesDocument16 pagesME-EM 5210 Advanced Fluid Engineering: Course Goals, Policies Textbooks GradesashNo ratings yet

- BeerVM11e PPT Ch16Document67 pagesBeerVM11e PPT Ch16brayanNo ratings yet

- EE2202 ELECTROMAGNETIC THEORYDocument2 pagesEE2202 ELECTROMAGNETIC THEORYBenish CmNo ratings yet

- Stopping Sight DistanceDocument20 pagesStopping Sight DistanceDushan SenarathneNo ratings yet

- Maths and Physics Equations GuideDocument6 pagesMaths and Physics Equations GuideJan Noszczyk100% (1)

- FEM-quiz Bank-Mid-2Document2 pagesFEM-quiz Bank-Mid-2DarbhalaPavanKumarNo ratings yet

- Simple Stresses and Strains of Statically Indeterminate StructuresDocument12 pagesSimple Stresses and Strains of Statically Indeterminate Structuresnacot58559No ratings yet

- LPile 2015 Technical ManualDocument238 pagesLPile 2015 Technical ManualMahesh HanmawaleNo ratings yet

- C 2Document11 pagesC 2RushmoreNo ratings yet

- Wave Optics (QB)Document12 pagesWave Optics (QB)Raju SinghNo ratings yet

- Scott & Whittle 2005 Moment Redistribution Effects in BeamsDocument13 pagesScott & Whittle 2005 Moment Redistribution Effects in BeamsRm1262No ratings yet

- Transport and Dispersion of Air Pollutants by DR NormahDocument24 pagesTransport and Dispersion of Air Pollutants by DR NormahNabilah BeylaNo ratings yet

- Fan Application Manual 180629054956 PDFDocument290 pagesFan Application Manual 180629054956 PDFMin ZayarNo ratings yet

- Phase Identifier Trough Partial DerivativesDocument9 pagesPhase Identifier Trough Partial DerivativesrelojucaNo ratings yet

- Final-Problems BPO5 ENGDocument3 pagesFinal-Problems BPO5 ENGPool Giancarlo Pujay GasparNo ratings yet

- Physics HelpDocument4 pagesPhysics HelpEiko RiskerNo ratings yet

- Multi Leaf SpringDocument10 pagesMulti Leaf SpringShehzad AhmadNo ratings yet

- Antecedente Investigativo 7Document13 pagesAntecedente Investigativo 7Jonathan Triveño HuamaniNo ratings yet

- Ra 07a31001 Electromagnetic Waves and Transmission LinesDocument1 pageRa 07a31001 Electromagnetic Waves and Transmission LinessivabharathamurthyNo ratings yet

- Chap 11Document96 pagesChap 11noscribdyoucantNo ratings yet

- Development of A Low-Friction Radial Shaft Seal UsDocument15 pagesDevelopment of A Low-Friction Radial Shaft Seal UsAnissa LamraniNo ratings yet

- FWEFJLNIY4QKLQXDocument13 pagesFWEFJLNIY4QKLQXSoldan MihaiNo ratings yet

- Kinematics of Machines Notes Tutorials MDocument46 pagesKinematics of Machines Notes Tutorials Minayat rasoolNo ratings yet

- Structural stress calculation methods for welded jointsDocument11 pagesStructural stress calculation methods for welded jointsBob LoblawNo ratings yet

- Tutorial 1,2,3Document8 pagesTutorial 1,2,3RameshNo ratings yet