Professional Documents

Culture Documents

Parameter Identification of Induction Motors by Using Genetic Algorithms

Uploaded by

Maroof AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Parameter Identification of Induction Motors by Using Genetic Algorithms

Uploaded by

Maroof AhmedCopyright:

Available Formats

PARAMETER IDENTIFICATION OF INDUCTION MOTORS BY USING GENETIC

ALGORITHMS

Marin Janovi, Milan alman, Jn Jovankovi

MicroStep-HDO s r.o.,

Faculty of Electrical Engineering and Information Technology, Slovak University of Technology,

Faculty of Electrical Engineering and Information Technology, Slovak University of Technology

mjancovic@gmail.com, milan.zalman@stuba.sk, jan.jovankovic@stuba.sk

Abstract

This paper aims at demonstrating the possibilities of

genetic algorithms application for parameter

identification of induction motor. The basic procedure to

develop a genetic algorithm is described and the

examples of its application for parameter identification

are introduced. Genetic algorithms (GA) present

universal optimization methods, which can be used to

solve a wide scope of optimization problems. One of

them is the identification of nonlinear systems. For this

ability, we can use GA for parameter identification of

induction motor. We need to know the values of these

parameters for control design, state observer design or

modeling of induction motor. Parameter identification of

induction motor by using genetic algorithm is based on

calculating the values of appropriate quality criterion

which compare input-output data from induction motor

and from simulation model. Minimization of this quality

criterion leads to obtain more precise parameters.

Keywords: induction motor, genetic algorithm,

parameter identification

1. INTRODUCTION

Genetic algorithms (GA) present universal optimization

methods, which use global stochastic search algorithms.

Owing to their universality these algorithms can be used

to solve a wide scope of optimization problems. One of

them is the identification of nonlinear systems. For this

ability, we can use GA for parameter identification of

induction motor. We need to know the values of these

parameters for control design, state observer design or

modeling of induction motor. The accuracy of designed

structures is also dependent on the accuracy of the motor

parameters. As their values can vary from various

reasons so the quality of motor control can be reduced.

Then, for the optimization of control we need to know

the new values of the parameters. Because a direct

measure some of these parameters is very complicated or

impossible, the various researches developed different

techniques for their identification.

Distribution of the identification methods starts from the

measured data set of motor. Under this we can classify

next categories [1]:

with the measurement of voltage, current and

angular speed,

with the measurement of current and angular speed

for the structures with the measurement of angular

speed,

with the measurement of voltage, current for the

structures without direct measurement of angular

speed (sensorless control).

The methods of parameter estimation and identification

for servo-drive with induction motor can be divided also

into the following categories:

Observers that are derived from the dynamic model

of induction motor

o Direct observers that use measured stator

voltages and currents

o Model Reference Adaptive Systems

(MRAS)

o Feedback observers with the adaptation

(Kalman, Luenberger)

Observers with artificial intelligence

o Systems based on fuzzy logic

o Neural networks

o Neuro-fuzzy systems

o Evolution algorithms (genetic algorithms)

Observers that use the properties of motor

construction

o Salient motor poles, motor slots, asymmetry

of the air gap

o The third harmonic of the voltage that are

caused by the saturation of the magnetic

circuit

o Using the superposed signals

Parameter identification of induction motor using genetic

algorithm is based on calculating the values of

appropriate quality criterion which compare input-output

data from induction motor and from simulation model.

Minimization of this quality criterion leads to obtain

more precise parameters. The advantage of GA is that it

provides the identification of parameters with adequate

accuracy also for noised and quantized measured signals.

On the other hand, the system complexity and number of

searched parameters influence the number and time

demands on simulation of dynamical processes. These

properties also causes that genetic algorithms are

significantly time consuming.

2. PARAMETER IDENTIFICATION USING GA

For parameter identification of induction motor, we used

mathematical model of motor in stator coordinate system

described in [2]. The state equations for this model are as

follows:

+ +

+

=

r r r

r

r

s

s

s

k

T

k

u

s L R

i

1

1

(1)

+

+

=

r r r

r

r

s

s

s

k

T

k

u

s L R

i

1

1

(2)

+

=

m

r

r s

r

m

r

L

T

i

sT

L

1

(3)

+

+

=

m

r

r s

r

m

r

L

T

i

sT

L

1

(4)

( )

s r s r

r

m

m

i i

L

L

p T =

2

3

(5)

dt

d

J T T

m

z m

= ,

m

p = (6)

where

2

2

1

r

m

r s

L

L

R R R + = ,

1

1

R

L

T

s

= ,

r

r

r

R

L

T = ,

r

m

r

L

L

k = ,

s s

L L = ,

r s

m

L L

L

2

1 = (7)

i

s

real axis stator current,

i

s

imaginary axis stator current,

u

s

real axis stator voltage,

u

s

imaginary axis stator voltage,

r

real axis rotor flux,

r

imaginary axis rotor flux,

rotor electrical angular speed,

m

mechanical angular speed,

T

m

motor torque,

T

z

load torque,

p number of the pole pairs,

R

s

stator resistance,

R

r

rotor resistance,

L

s

stator self inductance,

L

r

rotor self inductance,

L

m

magnetizing inductance,

J moment of inertia.

For this model we need to identify the values of stator

and rotor resistance, stator and rotor inductance,

magnetizing inductance and moment of inertia. The two

parameters L

s

and L

r

are linearly dependent [3] and the

differences between their values are small. Therefore we

used simplification

s r

L L = , and so reduced the number

of the searched parameters and thereby accelerated the

research process. Searched motor parameters represent

genes of GA and together create the chromosome, which

has a form:

( ) J L L R R r

m s r s

, , , , = (8)

To represent these parameters we choose real number

values. In using real number code in comparison with

binary code the procedure of the respective solution is

more stable, since the values of real numbers change

continuously, proportionally to the required value of

change.

For each gene of the chromosome we must define the

feasible values intervals, i.e. the search space of solution.

The search space must be large enough to contain the

global optimum, but if made too large, the GA might not

be able to find the global optimum at the required

parameter identification accuracy and in a reasonable

period of time (the convergence will be slow). For this,

we can start from catalogue values.

The speed of convergence is also influenced by our

choice of the population size. The population represents

group of chromosomes, i.e. potential solutions in the

time period. The size of it depends on a particular case.

In most cases it is recommended to choose the size

between 10 and 100, most frequently between 20 and 50

[4]. Small population does not provide enough space for

diversity of genetic information, too big population does

not provide better effect and the solution is much longer.

The GA tests each candidate chromosome by an

objective function, which compare a set of measured

values with simulated data. The objective function

consists of two steps. The first one is the implementation

of parameters into simulation model and the following

simulation of the dynamic system with such input data as

for measured system. During the simulation, the system

output is recorded in each sampling period and this

output data are then returned into the quality criterion

with measured output data. The next step is the

calculation of the appropriate criterion. The identification

values of the system parameters approximate to their real

values by the minimalization of this criterion. For the

parameter identification, the integral criterion is used:

( )

=

T

m

dt y y F

0

2

(9)

where y

m

is output of the simulation model and y is

output of the real system.

In our case, the real system is represented by the

induction motor whose input parameters are the

components of the stator voltage u

s

and u

s

and output

parameters are the components of the stator current i

s

a i

s

. Then criterion has a form:

( ) ( )

= =

+ =

N

k

i s i s

N

k

i s i s

i i i i F

1

2

1

2

(10)

where

i s

i

and

i s

i

are currents from real motor,

i s

i

and

i s

i

are estimated currents from model, N is the

number of samples and F is the fitness function value.

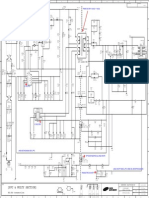

The GA implementation for motor parameter

identification is illustrated in Fig. 1.

us

Frequency

inverter

Simulation

model

Objectives

function

Genetic

algorithm

is

is

F

Induction

motor us

s

u

s

u

r

z

T

~

z

T

i

s

i

~

s

i

~

Fig. 1 Principle of parameter identification of

induction motor using GA

On the basic of fitness values of all candidates, some of

them are selected to the new population and some to the

work group. The operations of crossover and mutations

are applied only to the work group. The copying of the

best individuals into to next population insures the

convergence of solution. The multiple selection of the

best individuals into the work group insures good values

for the crossover and mutation accelerates the

convergence to the optimal values. But it can lead to

local optimum deadlock, therefore we use random

selection of several individuals into the work group for

more diversity during the realization of genetic

operations.

The convergence speed problems can also be at the last

phase of the algorithm, when the differences between

estimated and optimal values are small. For this we used

the multiplicative mutation, which multiplies the value of

the chosen gene by a random number from the defined

range.

The GA procedure can be described as follows:

1. Initially, a population of 50 chromosomes generated

at random in the given interval.

2. Successively, all 50 chromosomes are applied into

the simulation model. The sinusoidal voltages u

s

and u

s

with the same amplitude and frequency are

lead to the model input. After simulation taking 2

second a value of chosen criterion is evaluated. The

GA aims at its minimization.

3. The chromosomes with the smallest and second

smallest fitness value are copied into a new

population.

4. We copy into the working group: three times the

chromosome with the smallest fitness value, twice

the chromosome with the second smallest and once

the chromosome with the third smallest fitness

value.

5. 32 chromosomes are randomly copied into the

working group.

6. The crossover operator is applied to the working

group, where the choice of parents for the crossover

is random. This operator realizes exchange of genes

between parent strings.

7. The multiplicative mutation operator is applied to

the working group, where the value of the chosen

gene is multiplied by a random number from the

range (0, 2), with a mutation probability 0.1.

8. The intermediate crossover operator is applied on

the working group, where the choice of parents for

the crossover is random with parameter 25 , 1 = .

This operator can be used for real number values. It

represents the combination between crossover and

mutation. New string will be created according to

equation:

) (

1 2 1

r r r p + = (11)

where p is a new string, r

1

and r

2

are the parent

strings and is a random value from interval

25 , 1 25 , 0 < < .

9. Then, the work group is moved to the new

generation.

10. The algorithm is repeated with the next generation

population until the 500 generations is reached.

Then the best string is assessed as the best solution.

3. IMPLEMENTATION OF GA AND

SIMULATION RESULT

To verify our proposed genetic algorithm the

Matlab/Simulink environment is used. We used the

simulation model instead of real induction motor because

of checking algorithm. We realized simulations with

sample time 0.25 ms and we defined the space of

solutions by the following intervals:

10 ; 1

s

R , 5 ; 1

r

R , 1 ; 1 . 0

s

L , 1 ; 1 . 0

m

L ,

1 , 0 ; 0001 . 0 J

We tested the application of designed GA for the

different amplitudes and frequencies of the input

voltages. The results of several identifications are

presented in Tab. 1, where the percentage errors of this

results and reference values are calculated. From the

table, you can see that the increase of the frequency

decreases the accuracy of parameter identification.

Tab. 1 Results of identification for the different

amplitudes and frequencies of the input voltages

Rs Rr Ls Lm J

Reference

value

7.608 3.7 0.6015 0.5796 0.0017

Identified

value

7.5954 3.7093 0.60227 0.58047 0.0017059

7.5V, 5Hz

F=1.5062x10

-3

Relative

error

0.166% 0.251% 0.127% 0.150% 0.350%

Identified

value

7.5587 3.7269 0.60204 0.58028 0.0017174

15V, 10Hz

F=1.6439x10

-2

Relative

error

0.648% 0.726% 0.090% 0.117% 1.021%

Identified

value

7.4066 3.8124 0.62926 0.60741 0.0017529

30V, 20Hz

F=1.8171 Relative

error

2.647% 3.039% 4.616% 4.799% 3.111%

Identified

value

7.2382 3.9168 0.70633 0.68436 0.0018073

45V, 30Hz

F=15.3852 Relative

error

4.861% 5.858% 17.43% 18.07% 6.311%

In the case of parameter identification of real motor, the

results are influenced by the noise of the measured

signals and by the quantization of the signals. Therefore

we tested the ability of the parameter identification by

GA also in this case. As the source of the noise we used

white noise with the gain 1.10

-6

. From the result of the

identifications in Tab. 2 you can see that the noise and

quantization didnt have a great effect on the accuracy of

parameter identification compared with the results in

Tab. 1. The Fig. 2 and 3 describe the confrontation

between reference and identified currents for the noised

and quantized signals.

Tab. 2 Results of identification for the different

amplitudes and frequencies of the input voltages for

the noised and quantized reference currents

Rs Rr Ls Lm J

Reference

value

7.608 3.7 0.6015 0.5796 0.0017

Identified

value

7.6558 3.7203 0.59966 0.57804 0.0016947

7.5V, 5Hz

F=65.798 Relative

error

0.628% 0.548% 0.305% 0.270% 0.310%

Identified

value

7.5915 3.7133 0.5987 0.57701 0.0017053

15V, 10Hz

F=66.0976 Relative

error

0.217% 0.359% 0.465% 0.446% 0.312%

Identified

value

7.5184 3.7514 0.61277 0.59093 0.001728

30V, 20Hz

F=66.0636 Relative

error

1.178% 1.389% 1.873% 1.955% 1.644%

Identified

value

8.1683 3.3823 0.49211 0.47021 0.0015378

45V, 30Hz

F=97.9766 Relative

error

7.364% 8.587% 18.19% 18.87% 9.543%

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-1.5

-1

-0.5

0

0.5

1

1.5

2

t [s]

i

s

[

A

]

reference model

identified model

Fig. 2 Stator current i

s

responses for the noised and

quantized reference signals

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-1.5

-1

-0.5

0

0.5

1

1.5

t [s]

i

s

[

A

]

reference model

identified model

Fig. 3 Stator current i

s

responses for the noised and

quantized reference signals

The accuracy of parameter identification can depend on

the sample period. The size of the sample period depends

on the available computing resources. The increase of the

frequency of the input voltage needs the decrease of the

sample period. The results of parameter identification for

different sample periods are presented in the Tab. 3. For

the frequency of the input voltage equal to 5 Hz we

obtained the error less than 1% also with sample period

equal to 2.5 ms. For frequency 10 Hz we needed for this

accuracy the sample period 2 ms and for frequency 20

Hz we need the sample period 0.5 ms. For frequency 30

Hz we obtained the error less than 5% with the sample

period 0.2 ms.

Tab. 3 Results of identification for the different

amplitudes and frequencies of the input voltages

and for the different sample periods

Rs Rr Ls Lm J

Reference

value

7.608 3.7 0.6015 0.5796 0.0017

Identified

value

7.5974 3.684 0.59917 0.5772 0.0016948 7.5V, 5Hz

Tvz=2.5ms

F=1.3542x10

-3

Relative

error

0.139% 0.432% 0.388% 0.414% 0.305%

Identified

value

7.597 3.7073 0.60399 0.58205 0.0017019 15V, 10Hz

Tvz=2ms

F=1.5665x10

-3

Relative

error

0.145% 0.197% 0.414% 0.423% 0.109%

Identified

value

7.628 3.6868 0.59853 0.57663 0.0016941 30V, 20Hz

Tvz=0.5ms

F= 8.2013x10

-3

Relative

error

0.263% 0.356% 0.494% 0.512% 0.344%

Identified

value

7.8813 3.5953 0.59221 0.57026 0.0016332 45V, 30Hz

Tvz=0.2ms

F=2.8285

Relative

error

3.593% 2.829% 1.545% 1.612% 3.932%

4. EXPERIMENTAL RESULTS

After the simulation verification we applied the designed

genetic algorithm to the real system. The real system is

represented by a computer with development software

MATLAB/Simulink/Stateflow from MathWorks,

frequency inverter and induction motor. The computer is

connected with the frequency inverter by interface

DS1104 from company dSPACE. Analogous to the

simulations experiments we realized identification for the

different amplitudes and frequencies of the input

voltages. The results of several identifications are

presented in Tab. 4, where the percentage errors of this

results and values of identification by software for

frequency inverter are calculated. Fig. 4 to Fig. 7 show

the comparison of stator currents i

s

and i

s

responses

from the real system and identified model for the input

voltage with frequency 25 Hz. You can see in Tab. 4.,

that the results of the identification of the stator

resistance are situated at the edge of the interval. The

differences between the values of the other parameters

may be caused by non-linearity of the frequency inverter

and motor structures and also by unknown load torque.

Therefore we repeat the experiments with the addition of

the parameters of Coulomb friction (T

z0

) and viscous

friction (B

) into the motor model:

B T T

z z

+ = sgn

0

(12)

and into the chromosome:

( ) B T J L L R R r

z m s r s

= , , , , , ,

0

(13)

For new parameters we defined the following intervals:

1 . 0 ; 0001 . 0

0

z

T , 1 . 0 ; 0001 . 0 B

Tab. 5 shows the results of identifications of (13) for the

different amplitudes and frequencies of the input

voltages and Fig. 8 to Fig. 11 show the comparison of

stator current i

s

and i

s

responses from the real system

and identified model for the input voltage with frequency

25 Hz. We can see that the results of the identification of

the stator resistance are better than the results of

identifications of (8) and the differences between stator

current i

s

responses are smaller. But the differences

between the results of the identification of Coulomb and

viscous friction are too large.

Tab. 4 Experimental results of identification of (8)

for the different amplitudes and frequencies of the

input voltages

Rs Rr Ls Lm J

Identification

by frequency

inverter

6.3783 3.9558 0.3796 0.3502 0.0068

Identi fied

value

10 2.8509 0.37274 0.31881 0.00325

15V, 5Hz

F=54.8578 Relative

error

56.78% 27.93% 1.81% 8.96% 52.21%

Identi fied

value

10 4.2446 0.42614 0.38074 0.00411

30V, 10Hz

F=313.1876 Relative

error

56.78% 7.30% 12.26% 8.72% 39.56%

Identi fied

value

10 4.4441 0.41365 0.37274 0.00485

35V, 15Hz

F=559.2084 Relative

error

56.78% 12.34% 8.97% 6.44% 28.68%

Identi fied

value

10 4.5360 0.40418 0.36589 0.00474

50V, 20Hz

F=639.4507 Relative

error

56.78% 14.67% 6.47% 4.48% 30.29%

Identi fied

value

9.2844 4.8792 0.38927 0.35272 0.00483

70V, 25Hz

F=647.8662 Relative

error

45.72% 23.34% 2.55% 0.72% 28.97%

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-5

-4

-3

-2

-1

0

1

2

3

4

5

t [s]

i

s

[

A

]

real system

identified model

Fig. 4 Stator current i

s

responses for the input

voltage with frequency 25 Hz

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

t [s]

e

r

r

o

r

i

s

[

A

]

Fig. 5 Error of stator current i

s

responses for the

input voltage with frequency 25 Hz

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-5

-4

-3

-2

-1

0

1

2

3

4

5

t [s]

i

s

[

A

]

real system

identified model

Fig. 6 Stator current i

s

responses for the input

voltage with frequency 25 Hz

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

t [s]

e

r

r

o

r

i

s

[

A

]

Fig. 7 Error of stator current i

s

responses for the

input voltage with frequency 25 Hz

Tab. 5 Experimental results of identification of (13)

for the different amplitudes and frequencies of the

input voltages

Rs Rr Ls Lm J Tz0 B

Identification

by frequency

inverter

6.3783 3.9558 0.3796 0.3502 0.0068 - -

Identified

value

7.7701 4.1915 0.40205 0.36616 0.00569 0.00484 0.02276 15V,

5Hz

F=26,35

Relative

error

21.82% 5.96% 5.91% 4.56% 16.32% - -

Identified

value

8.2009 4.7236 0.44727 0.40803 0.00471 0.02623 0.01077 30V,

10Hz

F=44,17

Relative

error

28.58% 19.41% 17.83% 16.51% 30.74% - -

Identified

value

7.6785 5.011 0.45112 0.4138 0.00521 0.01970 0.00715 35V,

15Hz

F=34,85

Relative

error

20.38% 26.67% 18.84% 18.16% 23.38% - -

Identified

value

7.4173 5.3356 0.43607 0.39994 0.00543 0.03162 0.00559 50V,

20Hz

F=36,99

Relative

error

16.29% 34.88% 14.88% 14.20% 20.15% - -

Identified

value

7.7299 5.276 0.40314 0.36761 0.00504 0.01806 0.00479 70V,

25Hz

F=75,63

Relative

error

21.19 33.37% 6.20% 4.97% 25.88% - -

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-5

-4

-3

-2

-1

0

1

2

3

4

5

t [s]

i

s

[

A

]

real system

identified model

Fig. 8 Stator current i

s

responses for the input

voltage with frequency 25 Hz

5. CONCLUSION

The results of our experiment show that genetic

algorithms can be used for the parameter identification of

induction motor. The GA obtains more accurately values

of searched parameters using serial reproduction of the

new solutions and by using the objective function that

compares the current components from the simulation

and real systems.

The accuracy of identification depends on the frequency

of the input voltage, the sample period, the number of

generations and the accuracy of simulation model. Our

simulation results where very good but the experimental

results were influenced by the differences between

simulation model and real system. Its better if we can

exactly describe the real system by the simulation model.

Its possible for identification by GA. The simulation

model can consider the non-linearity of frequency

inverter and pulse wide modulation and so we can obtain

better parameters of the real system.

The disadvantage of the genetic algorithms is their time

demand that follows mainly from a number of required

simulations.

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

t [s]

e

r

r

o

r

i

s

[

A

]

Fig. 9 Error of stator current i

s

responses for the

input voltage with frequency 25 Hz

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-5

-4

-3

-2

-1

0

1

2

3

4

5

t [s]

i

s

[

A

]

real system

identified model

Fig. 10 Stator current i

s

responses for the input

voltage with frequency 25 Hz

0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

t [s]

e

r

r

o

r

i

s

[

A

]

Fig. 11 Error of stator current i

s

responses for the

input voltage with frequency 25 Hz

ACKNOWLEDGEMENT

This work has been carried out under the financial

support of the KEGA project 3/4196/06 and RLZ VVA

project no. 13120200015 (Europe Social Program).

REFERENCES

[1] Janovi, M., alman, M.: Parameter identification of

induction motor by genetic algorithm. AT&P Journal.

2006, no. 2, pp. 90-96.

[2] alman, M.: Actuating devices. STU Publishing house,

Bratislava, 2003.

[3] Ursem, R. K.: Models for Evolutionary Algorithms and

Their Application in System Identification and Control

Optimization. PhD thesis, EVALife, Department of

Computer Sience, Univerzity of Aarhus, 2003.

[4] Sekaj, I.: Evolution computations and their practice using.

IRIS Publishing house, Bratislava, 2005.

[5] Chrzan, P., J., Klaassen, H.: Parameter identification of

vector-controlled induction machines. Electrical

Engineering, vol. 79 (1996), pp. 39-46.

[6] Chung, P. Y., Dlen, M., Lorenz, R. D.: Parameter

Identification for Induction Machines by Continuous

Genetic Algorithms. ANNIE 2000 Conference, St. Louis,

November 2000.

[7] Huang, K., S., Wu, Q., H.: Effective Identification of

Induction Motor Parameters Based on Fewer

Measurements. IEEE Transaction on Energy Conversion,

vol. 17, no. 1, March 2002, pp. 55-60.

THE AUTHORS

Marin Janovi (Ing) was born in Pieany, in 1976.

He graduated from the Faculty of Electrical Engineering

and Information Technology, Slovak University of

Technology (FEI STU), Bratislava, in 2001. Since 2001

he has been a PhD student in the Department of Control

and Automation FEI STU. His research interests include

neural networks, genetic algorithms and the control of

electrical drive.

Milan alman (Prof, Ing, CSc) was born in Necpaly, in

1945, graduated from the Faculty of Electrical

Engineering of the Slovak University of Technology,

Bratislava, in 1968. At the same university he received

his CSc (PhD), in 1981. Since 1987, appointed Associate

Professor, and from 1999 as a Full Professor, is at the

Department of Control and Automation FEI STU

Bratislava. His research and teaching interests include

the control of electrical drive and motion control

systems.

Jan Jovankovi (Ing, PhD) was born in 1973 in Novi

Sad, Yugoslavia. He received the M.SC and Ph.D.

degrees from Technical University of Bratislava, Slovak

Republic, in 1997 and 2003 respectively. He is author

and co-author of more than 40 journal and conference

papers. His main research interests include modelling,

control and identification of electrical drives using

artificial intelligence.

You might also like

- Mathematical Models and Algorithms for Power System Optimization: Modeling Technology for Practical Engineering ProblemsFrom EverandMathematical Models and Algorithms for Power System Optimization: Modeling Technology for Practical Engineering ProblemsNo ratings yet

- Manual Fcxs500 Eng Rev.0aspa y FlechaDocument62 pagesManual Fcxs500 Eng Rev.0aspa y FlechaMartin Fonseca50% (2)

- Parameter Estimation For Electric Motor Condition MonitoringDocument12 pagesParameter Estimation For Electric Motor Condition MonitoringNatarajNo ratings yet

- IEEE XploreDocument4 pagesIEEE XploreAbhishek SinghNo ratings yet

- AC MachineesreportDocument20 pagesAC Machineesreportaman barnwalNo ratings yet

- Simulation-Based Approach To Application Fitness For An E-BikeDocument6 pagesSimulation-Based Approach To Application Fitness For An E-BikeBatuhan SincanNo ratings yet

- System Identification Algorithm For Systems With Interval CoefficientsDocument8 pagesSystem Identification Algorithm For Systems With Interval Coefficientseetn1100% (1)

- The Squirrel-Cage Induction Motor Model and Its Parameter Identification Via Steady and Dynamic TestsDocument27 pagesThe Squirrel-Cage Induction Motor Model and Its Parameter Identification Via Steady and Dynamic TestsAhmed 7mamNo ratings yet

- Effective Identification of Induction Motor Parameters Based On Fewer MeasurementsDocument6 pagesEffective Identification of Induction Motor Parameters Based On Fewer MeasurementsHichem AbNo ratings yet

- Comparison of The Speedy Estimate Methods of The Induction MotorsDocument12 pagesComparison of The Speedy Estimate Methods of The Induction MotorsTELKOMNIKANo ratings yet

- Mathematics 08 01269Document37 pagesMathematics 08 01269sanatikalaNo ratings yet

- Model-Based Avionic Prognostic Reasoner (MAPR) PDFDocument9 pagesModel-Based Avionic Prognostic Reasoner (MAPR) PDFlalith.shankar7971No ratings yet

- Identification of Model Parameters of Steam Turbine and GovernorDocument15 pagesIdentification of Model Parameters of Steam Turbine and Governorkamranmalik80No ratings yet

- Application of Genetic Algorithms For Determining The Parameters of Induction MotorsDocument5 pagesApplication of Genetic Algorithms For Determining The Parameters of Induction Motorshardik desaiNo ratings yet

- Emcw 2001 Artesis PaperDocument5 pagesEmcw 2001 Artesis Paperವಿಶ್ವನಾಥ ಸಿNo ratings yet

- Identification of Variable Frequency Induction Motor Models From Operating DataDocument8 pagesIdentification of Variable Frequency Induction Motor Models From Operating Datani60No ratings yet

- On - Line Stator Winding Inter - Turn Short - CircuitDocument17 pagesOn - Line Stator Winding Inter - Turn Short - Circuitsaidoune abdelmalekNo ratings yet

- NewNov2016 ModelingandParameterIdentificationofDCMotor PDFDocument12 pagesNewNov2016 ModelingandParameterIdentificationofDCMotor PDFゞ『HaiDerツ98〆No ratings yet

- Uncertainty Analysis of Power System Components Based On Stochastic Response SurfacesDocument8 pagesUncertainty Analysis of Power System Components Based On Stochastic Response SurfacesHassan Ali Al SsadiNo ratings yet

- ISKE2007 Ye ShengyongDocument5 pagesISKE2007 Ye Shengyongrasim_m1146No ratings yet

- Fault Detection of PM Synchronous Motor Via Modulating FunctionsDocument6 pagesFault Detection of PM Synchronous Motor Via Modulating Functionsjithesh87No ratings yet

- Model Reference Adaptive Control Based Parameters Estimation of Permanent Magnet Synchronous Motor DriveDocument9 pagesModel Reference Adaptive Control Based Parameters Estimation of Permanent Magnet Synchronous Motor DriveInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- DC Motor Parameter EstimationDocument10 pagesDC Motor Parameter EstimationElmer HCNo ratings yet

- The Intelligent Fault Diagnosis Frameworks Based On Fuzzy IntegralDocument6 pagesThe Intelligent Fault Diagnosis Frameworks Based On Fuzzy IntegralelmerkhNo ratings yet

- Realtime Parameter Estimation, Calibration and Simulation of A DC MotorDocument10 pagesRealtime Parameter Estimation, Calibration and Simulation of A DC MotorBrasoveanu GheorghitaNo ratings yet

- Identifying Dynamic Model Parameters of A Servo DriveDocument8 pagesIdentifying Dynamic Model Parameters of A Servo DriveBrasoveanu GheorghitaNo ratings yet

- 2009 Parameter Estimationofa DCMotorDocument6 pages2009 Parameter Estimationofa DCMotormohamedNo ratings yet

- Applying Kalman Filtering in Solving SSM Estimation Problem by The Means of EM Algorithm With Considering A Practical ExampleDocument8 pagesApplying Kalman Filtering in Solving SSM Estimation Problem by The Means of EM Algorithm With Considering A Practical ExampleJournal of ComputingNo ratings yet

- Adaptive Theory-Based Improved Linear Sinusoidal Tracer Control Algorithm For DSTATCOMDocument11 pagesAdaptive Theory-Based Improved Linear Sinusoidal Tracer Control Algorithm For DSTATCOMAmmuRaNo ratings yet

- The Use of Genetic Algorithms in Finite Element Model IdentificationDocument8 pagesThe Use of Genetic Algorithms in Finite Element Model IdentificationMilena PopovicNo ratings yet

- Genetic Algorithm Optimized PI and Fuzzy Sliding Mode Speed Control For DTC DrivesDocument6 pagesGenetic Algorithm Optimized PI and Fuzzy Sliding Mode Speed Control For DTC DrivesFrancisco Liszt Nunes JuniorNo ratings yet

- Permanent Magnet Synchronous Motor Parameter Identification Using Particle Swarm OptimizationDocument8 pagesPermanent Magnet Synchronous Motor Parameter Identification Using Particle Swarm OptimizationSrinivas KamarsuNo ratings yet

- Fuzzy Idle Speed ControlDocument6 pagesFuzzy Idle Speed ControlIkhwanul KhairiNo ratings yet

- Fuzzy Flux EstimatorDocument9 pagesFuzzy Flux EstimatorMuhammad Ali Masood CheemaNo ratings yet

- Energies: Research On Improved Auto-Tuning of A PID Controller Based On Phase Angle MarginDocument16 pagesEnergies: Research On Improved Auto-Tuning of A PID Controller Based On Phase Angle MarginLautaro Benjamín IbañezNo ratings yet

- Sine Calafiore 4Document14 pagesSine Calafiore 4Sathish KrishnaNo ratings yet

- 1 s2.0 S0888327014001332 Main PDFDocument15 pages1 s2.0 S0888327014001332 Main PDFbasic joNo ratings yet

- Vector Control System of Induction Motor Based On Fuzzy Control MethodDocument5 pagesVector Control System of Induction Motor Based On Fuzzy Control MethodjhonnydesaNo ratings yet

- 56 DorDocument14 pages56 DorAmy GrayNo ratings yet

- Articulo 1Document8 pagesArticulo 1Jhon Fredy cortesNo ratings yet

- Effective Estimation of Speed and Rotor Position of A PM Synchronous Motor Drive by A Kalman FiltDocument7 pagesEffective Estimation of Speed and Rotor Position of A PM Synchronous Motor Drive by A Kalman FiltAli H. NumanNo ratings yet

- Applsci 08 01073 PDFDocument13 pagesApplsci 08 01073 PDFErsi Ago100% (1)

- Analog Circuit Fault Detection by Impulse Response-Based Signature AnalysisDocument16 pagesAnalog Circuit Fault Detection by Impulse Response-Based Signature Analysisকস্তুরী ঘোষNo ratings yet

- NARMAX Model Identification of A Palm Oil Biodiesel Engine Using Multi-Objective Optimization Differential EvolutionDocument10 pagesNARMAX Model Identification of A Palm Oil Biodiesel Engine Using Multi-Objective Optimization Differential EvolutionYlm PtanaNo ratings yet

- Paper 15-A Review On Parameters Identification Methods For Asynchronous MotorDocument6 pagesPaper 15-A Review On Parameters Identification Methods For Asynchronous MotorAldemar GonzalezNo ratings yet

- System Identification Using Intelligent AlgorithmsDocument13 pagesSystem Identification Using Intelligent AlgorithmsAnonymous gJHAwzENo ratings yet

- Energies 11 01288Document20 pagesEnergies 11 01288Sudarsan Kumar VenkatesanNo ratings yet

- Landau RSTDocument11 pagesLandau RSTpbaculimaNo ratings yet

- Journal - Jpe - 16-3 - 854351307 2Document13 pagesJournal - Jpe - 16-3 - 854351307 2Behrouz MinayiNo ratings yet

- Ijest11 03 07 142Document5 pagesIjest11 03 07 142hoangductuanNo ratings yet

- PerformanceDocument6 pagesPerformanceMoisés Martínez (lesndhem)No ratings yet

- Parameters Identification of Induction Motor Model BasedDocument10 pagesParameters Identification of Induction Motor Model Basedretrueke1170No ratings yet

- Pillay Application GeneticDocument10 pagesPillay Application GenetickfaliNo ratings yet

- Application - of - Structural - Analysis - To - Improve - Fault - Diagnosis - in - A - Gas - TurbineDocument18 pagesApplication - of - Structural - Analysis - To - Improve - Fault - Diagnosis - in - A - Gas - TurbineRafael Garcia IllescasNo ratings yet

- Optimal Signal Selection For Power System Ambient Mode Estimation Using A Prediction Error CriterionDocument13 pagesOptimal Signal Selection For Power System Ambient Mode Estimation Using A Prediction Error Criterionperic_vedranNo ratings yet

- BLDC - GA - SA - ICIAS 2007 - NovDocument5 pagesBLDC - GA - SA - ICIAS 2007 - NovmanasrinuNo ratings yet

- The Econometric Society, Wiley Econometrica: This Content Downloaded From 193.227.1.29 On Sat, 23 Jul 2016 23:17:22 UTCDocument22 pagesThe Econometric Society, Wiley Econometrica: This Content Downloaded From 193.227.1.29 On Sat, 23 Jul 2016 23:17:22 UTCahmed22gouda22No ratings yet

- Paper: New Algorithm ofDocument7 pagesPaper: New Algorithm ofAlexander BuenoNo ratings yet

- Identification of The Machine Parameters IN Vector Controlled Induction Motor DriveDocument6 pagesIdentification of The Machine Parameters IN Vector Controlled Induction Motor DriveBelkacem BerrehailNo ratings yet

- Avr Ieee Dc1Document6 pagesAvr Ieee Dc1Diego J. AlverniaNo ratings yet

- Piezas de Recambio para Los Sistemas de Inyección de Combustible CATERPILLAR, CUMMINS, CAVDocument78 pagesPiezas de Recambio para Los Sistemas de Inyección de Combustible CATERPILLAR, CUMMINS, CAVMiguel Ángel Gil PérezNo ratings yet

- BEEE - Batch 6Document22 pagesBEEE - Batch 6Neo TarunNo ratings yet

- Eee DSP 2 MarksDocument24 pagesEee DSP 2 Marksselvakumargeorg1722No ratings yet

- Networking Deep Dive PDFDocument6 pagesNetworking Deep Dive PDFmbalascaNo ratings yet

- Testbench BookDocument114 pagesTestbench BookPure DecSecNo ratings yet

- Speed Up Demanding Workloads, Save Admin Hassle, and Maximize Storage Capacity With A Dell EMC Isilon All-Flash Storage SystemDocument20 pagesSpeed Up Demanding Workloads, Save Admin Hassle, and Maximize Storage Capacity With A Dell EMC Isilon All-Flash Storage SystemPrincipled TechnologiesNo ratings yet

- Pyro MeterDocument6 pagesPyro Meterseeralan balakrishnanNo ratings yet

- Exercise 11Document36 pagesExercise 11David BamNo ratings yet

- GE Fanuc AutomationDocument847 pagesGE Fanuc AutomationNgọc Phê HồNo ratings yet

- UVLayout Installation GuideDocument11 pagesUVLayout Installation GuideJose de la FuenteNo ratings yet

- Service Manual Audio Car Philips CEM250-55Document32 pagesService Manual Audio Car Philips CEM250-55Alexandre Pereira NunesNo ratings yet

- Flood and Earthquake Detection and Rescue Using IoT TechnologyDocument5 pagesFlood and Earthquake Detection and Rescue Using IoT Technologynama belakang nama depanNo ratings yet

- WL 299CDocument19 pagesWL 299CSorin GhitaNo ratings yet

- Error Solution Canon Tpye 4570Document61 pagesError Solution Canon Tpye 4570Soki LeonardiNo ratings yet

- List of IEC Standards - WikipediaDocument26 pagesList of IEC Standards - WikipediaEngr saqibNo ratings yet

- Instruction Code Instruction Code Instruction Code Instruction Code Instruction CodeDocument4 pagesInstruction Code Instruction Code Instruction Code Instruction Code Instruction Codesm_nictNo ratings yet

- Electric Car Battery Management System (BMS) TrainerDocument3 pagesElectric Car Battery Management System (BMS) Trainermanual imbNo ratings yet

- Homework v.1Document5 pagesHomework v.1RasedulIslam50% (2)

- SMB/4144/R: Strategic Business Plan (SBP)Document5 pagesSMB/4144/R: Strategic Business Plan (SBP)ytumayNo ratings yet

- Mrfud Description: Huawei Technologies Co., LTDDocument14 pagesMrfud Description: Huawei Technologies Co., LTDعلي عباسNo ratings yet

- Edgefx Technologies, A Practical Guide To Build Electronic Projects!.telangana, India, Edgefx, S/a.Document94 pagesEdgefx Technologies, A Practical Guide To Build Electronic Projects!.telangana, India, Edgefx, S/a.JoséArdichotti100% (2)

- Employee Attendance Management SystemDocument15 pagesEmployee Attendance Management SystemJitender KumarNo ratings yet

- Torque Multiplier Catalog MC 14 - 0Document16 pagesTorque Multiplier Catalog MC 14 - 0Jeremy StadtlerNo ratings yet

- (PFC & Multy Section) : Tranf - de Stby 5.3Vcd Y 13VcdDocument2 pages(PFC & Multy Section) : Tranf - de Stby 5.3Vcd Y 13Vcdcentauro2013100% (1)

- Concrete Electrical ResistivityDocument7 pagesConcrete Electrical ResistivityFernando MoitaNo ratings yet

- Ec 501: Advanced Microprocessor and MicrocontrollerDocument2 pagesEc 501: Advanced Microprocessor and Microcontrollersunil kumarNo ratings yet

- Merus A2 Module User Manual 3.1 PDFDocument110 pagesMerus A2 Module User Manual 3.1 PDFFawad NoorNo ratings yet

- Hybrid Nanophotonics: Review of Actual ProblemsDocument68 pagesHybrid Nanophotonics: Review of Actual ProblemsTarun SinghalNo ratings yet

- Feedback Vs FeedforwardDocument27 pagesFeedback Vs FeedforwardjjhenNo ratings yet