Professional Documents

Culture Documents

Chilled Beams 022409

Uploaded by

almig200Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chilled Beams 022409

Uploaded by

almig200Copyright:

Available Formats

Chilled Chilled Beams Beams

The Energy Efficient Solution For Schools The Energy Efficient Solution For Schools

Clint Schwartz, PE

Controlled Air, Inc. Controlled Air, Inc.

clint@controlled-air.com

Wh t A Chill d B ? Wh t A Chill d B ? What Are Chilled Beams? What Are Chilled Beams?

Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams

Airflow Pattern Airflow Pattern

Concrete soffit Concrete soffit

Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams

Air Distribution Pattern w/ UFAD Air Distribution Pattern w/ UFAD

Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams

Typical Installation Above Ceiling Typical Installation Above Ceiling

Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams Passive Chilled Beams

Typical Installation Typical Installation Fidelity Investments Fidelity Investments

Active Chilled Active Chilled Beams Beams Active Chilled Active Chilled Beams Beams

How They Work How They Work

Sl b ffit

Primary

Slab or soffit air supply

Suspended Ceiling p g

Active Chilled Beams Active Chilled Beams Active Chilled Beams Active Chilled Beams

Two Two--Way Way Distribution Pattern Distribution Pattern

Active Chilled Beams Active Chilled Beams Active Chilled Beams Active Chilled Beams

Typical Installation Typical Installation

Design Design

C id ti C id ti Considerations Considerations

Design Considerations Design Considerations Design Considerations Design Considerations

Thermal Output Test Thermal Output Test Standards Standards

Design Design Considerations Considerations Design Design Considerations Considerations

Water Water Supply Supply vs. Room vs. Room Dewpoint Dewpoint Temperature Temperature

Extract From Extract From

Independent Independent Energie Energie

Climatic Ceilings Climatic Ceilings

Passive

Climatic Ceilings Climatic Ceilings

+ 0.5 C ( + 0.9 F )

Active

- 1.5 C ( - 2.7 F)

R l ti t i d i t Relative to room air dew point

Design Considerations Design Considerations

S D i t V til ti Ai

Design Considerations Design Considerations

OA OA Dewpoint Dewpoint vs. Room vs. Room Dewpoint Dewpoint 200 BTU/hr/person 200 BTU/hr/person

Space Dewpoint vs. Ventilation Air

80.00

70.00

o

F

)

40 DP

Supply DP

60.00

S

p

a

c

e

D

e

w

p

o

i

n

t

(

o

40 DP

45 DP

50 DP

55 DP

60 DP

Max DP

50.00

40.00

5 10 15 20 25 30

Ventilation Air (cfm/person)

Design Considerations Design Considerations Design Considerations Design Considerations

Primary/Secondary Chilled Water Loops Primary/Secondary Chilled Water Loops

Primary Chilled

Water Supply

HEAT

EXCHANGER

Primary Chilled

Water Return

Supply

Temperature

Controller

Chill d

3-way

Modulating

Valve

T

Chilled

Water

Pump

Return Water Bypass

Secondary

(Tempered)

Chilled Water

Supply to

B

2-way Chilled Water

Valves (one per

Beams

Secondary

Chilled Water

Return

To Chilled Beam

Zones

Valves (one per

zone)

Design Considerations Design Considerations Design Considerations Design Considerations

Dedicated Chiller Dedicated Chiller

3-way

Dedicated

Chiller

T

Supply

Temperature

Controller

Chilled

Water

y

Modulating

Valve

Return Water Bypass

Storage

Vessel

Pump

yp

Chilled Water

Supply to Beams

Chilled

Water

Return

To Chilled Beam

Zones

Design Considerations Design Considerations Design Considerations Design Considerations

Thermal Zoning Thermal Zoning

Chilled

water

supply

Chilled

water

return

Isolation

valve

Isolation

valve

2 way

control

valve

Chill d b ithi i l th l

T Zone

thermostat

Chilled beams within a single thermal

zone

Design Considerations Design Considerations Design Considerations Design Considerations

Water Piping Condensation Sensor Water Piping Condensation Sensor

Design Considerations Design Considerations Design Considerations Design Considerations

Thermal Comfort Thermal Comfort -- Diffuser Diffuser

What does a diffuser do?

Delivers fast cold (or hot) air to the space

It directs the discharge

M k f th C d ff t

What does a diffuser do?

Delivers fast cold (or hot) air to the space

It directs the discharge

M k f th C d ff t

The primary air

Provides fresh air requirement

C t l t t Makes use of the Coand effect

Reduced velocity by mixing

Changes temperature by mixing

Makes use of the Coand effect

Reduced velocity by mixing

Changes temperature by mixing

Controls temperature

Controls humidity

Design Considerations Design Considerations Design Considerations Design Considerations

Thermal Comfort Thermal Comfort -- Chilled Beam Chilled Beam

Beam vs. diffuser

Increases volume, Example: assume 60% water 40% air

Beam vs. diffuser

Increases volume, Example: assume 60% water 40% air

100 cfm by diffuser, 40 cfm @ beam but with

induction ratio of say 5:1, = total air discharged is 40 x

5 = 200 cfm

If we work on 1cfm/SF and room Height of 10

100 cfm by diffuser, 40 cfm @ beam but with

induction ratio of say 5:1, = total air discharged is 40 x

5 = 200 cfm

If we work on 1cfm/SF and room Height of 10 If we work on 1cfm/SF and room Height of 10

100 cfm = 6 ac/hr, 200 cfm = 12 ac/hr (room air movement)

The increased discharge temperature helps but the higher

volume throws further

If we work on 1cfm/SF and room Height of 10

100 cfm = 6 ac/hr, 200 cfm = 12 ac/hr (room air movement)

The increased discharge temperature helps but the higher

volume throws further

Where Does The Energy Where Does The Energy

S i C F ? S i C F ? Savings Come From? Savings Come From?

Energy Savings Energy Savings Energy Savings Energy Savings

Water vs. Air Water vs. Air

Water weighs 800 times more than water

1 lb. of CHW (6T) transports 25% more

cooling energy than 1 lb. of air (20T)

On a volumetric basis:

1 FT of CHW (6T) transfers 1000 times

more cooling energy vs. 1 FT of air (20T)

Space Savings Space Savings Space Savings Space Savings

Water vs. Air Water vs. Air

Flo Cross Section Ratio

1 : 327

Flow Cross Section Ratio

18 x 18

Air Duct

1 diameter

Water Pipe

Energy Savings Energy Savings Energy Savings Energy Savings

Chilled Beams Chilled Beams

Airflow requirement

reduced by 60 to 70%

Airflow requirement

reduced by 60 to 70%

60 to 70% of sensible heat 60 to 70% of sensible heat

removed by chilled water

Energy Savings Energy Savings Energy Savings Energy Savings

DOE Report DOE Report Energy Savings Potential Energy Savings Potential

Energy Savings Energy Savings Energy Savings Energy Savings

DOE Report DOE Report 15 Technologies Investigated 15 Technologies Investigated

Energy Savings Energy Savings Energy Savings Energy Savings

DOE Report DOE Report Simple Payback Simple Payback

Energy Savings Energy Savings Energy Savings Energy Savings

LEED Analysis LEED Analysis Constitution Center, Washington DC Constitution Center, Washington DC

22.4%

Cost

Baseline Building

Constitution Center

E U

Cost

Savings

Energy Usage

Energy Usage

Energy Savings Energy Savings Energy Savings Energy Savings

No motor to cool

Reduced airflow

Transportation of a ton Transportation of a ton

of cooling by air requires

7 to 10 times more

energy than by chilled energy than by chilled

water.

Elevated CHWS

Hi h hill COP Higher chiller COP

Longer free cooling

(water-cooled chiller)

Energy Savings Energy Savings Energy Savings Energy Savings

Compressor Efficiency Compressor Efficiency -- Chillers Chillers

Energy Savings Energy Savings Energy Savings Energy Savings

Lower Humidity, Raise Temperature Lower Humidity, Raise Temperature

Save energy by having

higher db, lower rh

Higher comfort perceived Higher comfort perceived

at 78/45% vs. 75/50%

Less temp difference

between inside and outside between inside and outside

3 To 5% energy cost

reduction for each F

thermostat is raised thermostat is raised

Energy Savings Energy Savings Energy Savings Energy Savings

Reduced Outdoor Air vs. VAV Reduced Outdoor Air vs. VAV

Multiple space equation in ASHRAE 62.1 can

add up to 70%

7

to required outdoor air in VAV

DOAS vs. DOAS

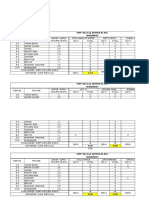

Project: Reynolds and Reynolds- 4th Floor

Zone Box Max. Cfm Min Pos Min. Cfm OA Reg. % OA Room Nos. Zone Type

1 7045 30% 2114 620 29% n/a Exterior Office Space

2 21240 30% 6372 4620 73% n/a Interior Office Space ASHRAE 62 METHOD MULTIPLE SPACES 2 21240 30% 6372 4620 73% n/a Interior Office Space ASHRAE 62 METHOD, MULTIPLE SPACES

3 220 100% 220 0 0% 402,404 Restrooms

4 455 30% 137 100 73% n/a Round Stairwell Y = X/(1+X-Z)

5 1765 30% 530 275 52% 406,420 Copy/Coffee/Corr X = OA rate for all branches on system / Tot al supply airf low

6 1455 30% 437 325 74% 408 Break Rm/Stairwell Z = OA rate for critical space / Tot al supply air in critical space

7 350 100% 350 0 0% 414,416 Electrical/SER Y = Correct ed fraction of OA / Total suppy airf low

8 285 50% 143 120 84% 422,424 Huddle Rooms

9 935 70% 655 520 79% 426 Staff Team Room X = 0.63

10 C f 10 515 80% 412 340 83% 428 Conference Z = 0.87

11 650 50% 325 260 80% 432,434,436,438 Huddle Rooms Zone No. 12

12 415 100% 415 360 87% 480 Conference Y = 0.83

13 505 50% 253 205 81% 460,464,468,470 Huddle/Storage

14 895 40% 358 260 73% 472 Diagnostics Lab Corrected Fraction of Outdoor air = Y (Tot al supply airf low)

15 485 100% 485 420 87% 474 Conference

16 445 100% 445 380 85% 482 War Room OA = 13125 cfm

17 2680 30% 804 600 75% 484 Break/Coffee Rm 17 2680 30% 804 600 75% 484 Break/Coffee Rm

18 1100 30% 330 180 55% 486,488 Mail/Corr/Copy/Stairwell

19 350 100% 350 0 0% 490,492 SER/Electrical

20 255 100% 255 0 0% 496,498 SW Rest

21 845 60% 507 400 79% 476, 478 Video Conf/AV

Totals 42890 15894 9985

Oth A f S i Oth A f S i Other Areas of Savings Other Areas of Savings

Chilled Beam Benefits Chilled Beam Benefits Chilled Beam Benefits Chilled Beam Benefits

Structural Height Savings Structural Height Savings

600mm

26

126

11

96

96

f.f.l.

8

6

Active Chilled Beams Active Chilled Beams Active Chilled Beams Active Chilled Beams

Structural Height Savings Structural Height Savings - - Constitution Center Constitution Center

12 Ceiling Plenum

-

0

-

0

12 Ceiling Plenum

2

Chilled Beam Benefits Chilled Beam Benefits Chilled Beam Benefits Chilled Beam Benefits

Maintenance Savings Maintenance Savings

No Moving Parts

No Fans

No Motors No Motors

No Power Requirements

No Filter

No Condensate

Pump/Drain

4 Year Inspection & 4 Year Inspection &

Vacuum

Simple Controls

Active Chilled Beams Active Chilled Beams Active Chilled Beams Active Chilled Beams

AstraZeneca AstraZeneca Waltham, Massachusetts Waltham, Massachusetts

Our first Waltham building using chilled beams was opened in

2000 Wh l d f ilit i 2003 i t ith 2000. When we enlarged our facility in 2003, we again went with

chilled beams. Our new buildings under construction will also be

using chilled beam technology.

The beams at our facility have not required any maintenance or cleaning. The facility

does not have rugs, and the chilled beams are supplied by the same air handlers that

serve laboratories.

The three principal advantages that I see for chilled beams over a VAV system are (i)

the level of quiet operations, (ii) the energy efficiency, and (iii) the virtual freedom from

maintenance.

Bruce MacGregor

System Specialist

S i lt Chill d B S i lt Chill d B Specialty Chilled Beams Specialty Chilled Beams

Four Four Way Blow Way Blow Four Four--Way Blow Way Blow

Available in 2 x 2 and

2 x 4 sizes

Primarily for

partitioned office

applications pp

Displacement Ventilation Displacement Ventilation Displacement Ventilation Displacement Ventilation

Trox Trox QLCI QLCI

Induction Nozzles

Primary air delivered at 50 to 55F

Mixing within terminal elevates supply

air to appropriate temperature

Integral Heat Transfer Coil Integral Heat Transfer Coil

Room air induced through coil

Supplements space cooling

Eliminates separate heating system Eliminates separate heating system

Displacement Ventilation Displacement Ventilation Displacement Ventilation Displacement Ventilation

How Does it Work? How Does it Work?

Return @ 80 Return @ 80--85 85

oo

FF

Convective Heat Source Convective Heat Source

Displacement Ventilation Displacement Ventilation Displacement Ventilation Displacement Ventilation

Displacement Ventilation Displacement Ventilation Displacement Ventilation Displacement Ventilation

Ventilation Effectiveness Ventilation Effectiveness

Displacement System Displacement System Mixed Air System Mixed Air System

V

EFF

=

C

RETURN

- C

SUPPLY

C

ROOM

- C

SUPPLY

1 V

EFF

=

C

RETURN

- C

SUPPLY

C

ROOM

- C

SUPPLY

1

Displacement System Displacement System Mixed Air System Mixed Air System

C

ROOM

C

RETURN

C

FLOOR

C

ROOM

C

CEILING

E

l

e

v

a

t

i

o

n

Occupied

Z

T

50

Occupied

Zone

E

l

e

v

a

t

i

o

n

Local CO Concentration

Zone

Local CO Concentration Local CO

2

Concentration Local CO

2

Concentration

Trox QLCI Trox QLCI Trox QLCI Trox QLCI

CO CO

22

Comparison with Unit Vent Comparison with Unit Vent

1600

Identical classrooms

Tests conducted over two

eek period

Minnesota Elementary School

t

i

o

n

(

P

P

M

)

1000

1200

1400

Mixed Air System (UV)

week period

CO

2

concentration at six foot

level monitored

2

C

o

n

c

e

n

t

r

a

t

600

800

1000

level monitored

Mixed system: 1100 PPM

DV System: 400 PPM

20% reduction in CO

2

levels

C

O

2

400

Displacement System

20% reduction in CO

2

levels

produced 15% improvement

in student performance

Time

Source: Technical University of Denmark

(Indoor Air 2005)

Active Chilled Beams Active Chilled Beams Active Chilled Beams Active Chilled Beams

Displacement Conditioning Displacement Conditioning Cooling Operation Cooling Operation

Return Air

450 CFM

(82 to 85F)

100% Exhausted

450 CFM

Primary Airflow

450 CFM

(50 to 55F)

Room Air

900 CFM

(75 to 78F)

Chilled Water

Supply Airflow

1350 CFM

(62 to 68F)

Active Chilled Beams Active Chilled Beams Active Chilled Beams Active Chilled Beams

Displacement Conditioning Displacement Conditioning Heating Operation Heating Operation

Return Air

450 CFM

100% Exhausted

450 CFM

Optional Heat

Recovery

Primary Airflow

450 CFM

(50 to 60F)

Room Air

900 CFM

Hot Water

(50 to 60F)

Supply Airflow

(70 to 72F)

y

1350 CFM

(82 to 85F)

Active Chilled Beams Active Chilled Beams Active Chilled Beams Active Chilled Beams

Displacement Conditioning Displacement Conditioning Staggered Operation Staggered Operation

68F 68F 90F 90F 68 F 68 F 90 F 90 F

Trox Trox QLCI QLCI Trox Trox QLCI QLCI

Installation Example Installation Example Ocean City Community College, NJ Ocean City Community College, NJ

Multi Multi Sevice Chilled Beams Sevice Chilled Beams Multi Multi--Sevice Chilled Beams Sevice Chilled Beams

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Customized Design Customized Design

B C t Beam Costs

Cooling &

Heating 40%

Other services 10%

Lighting 30% Aesthetics 20 % Aesthetics 20 %

~ + 25% of aesthetics = + 5% of total price

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Royal Bank of Scotland Royal Bank of Scotland

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Airbus, UK: Pearce, Carillion Airbus, UK: Pearce, Carillion

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Bow Call Center Bow Call Center

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Chamber of Commerce, Luxembourg Chamber of Commerce, Luxembourg

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Indirect Lighting Indirect Lighting

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Innovative Lighting Innovative Lighting

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Innovative Lighting Innovative Lighting

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Innovative Lighting Innovative Lighting

Multi Multi--Service Chilled Beams Service Chilled Beams

Multi Purpose Chilled Beams are

Multi Multi Service Chilled Beams Service Chilled Beams

Capital Cost Capital Cost

Multi-Purpose Chilled Beams are

delivered to the job ready to install

as one unit.

All ti i k l

$ Cost Neutral

All connections are quick couple

type.

Pre-assemble units average up to g p

12 ft in length.

Cost data courtesy

of

Multi Multi--Service Chilled Beams Service Chilled Beams Multi Multi Service Chilled Beams Service Chilled Beams

Accelerated Construction Schedule Accelerated Construction Schedule MSCB vs. FCU MSCB vs. FCU

AHU L t O ti AHU L t O ti AHU Layout Options AHU Layout Options

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Traditional Traditional -- DX Cooling w/ Hot Gas Reheat DX Cooling w/ Hot Gas Reheat

R d d ffi i Reduced efficiency

Requires multiple

compressor stages

Compressor cycling issues

require capacity modulation

at part load

Recommend at least four, Recommend at least four,

but preferably six

Requires modulating hot-

gas reheat to maintain g

space comfort

Limited at part load as

reheat requirements can

exceed cooling exceed cooling

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Cooling w/ Reheat Cooling w/ Reheat Psychrometrics Psychrometrics

1 2 3

1

22

3

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Energy Recovery Energy Recovery Heatpipe (Plate HX Alternative) Heatpipe (Plate HX Alternative)

Sensible only energy

transfer

More beneficial in

heating

Still need HGRH Still need HGRH

Need frost prevention

strategy strategy

Preheat frost control

Face and bypass yp

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Heatpipe Heatpipe Psychrometrics Psychrometrics -- Cooling Cooling

1 3 5

6

1

2

4

3

2 4

5 6 5 6

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Energy Recovery Energy Recovery Passive Desiccant (Enthalpy) Wheel Passive Desiccant (Enthalpy) Wheel

S ibl d l Sensible and latent

energy recovered

Wheel must be

maintained

Motor and bearings

Potential for clogging gg g

Still need HGRH

Need frost prevention

strategy strategy

Modulating wheel

Preheat frost control

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Passive Wheel Passive Wheel Psychrometrics Psychrometrics - - Cooling Cooling

6

5 3 1

1

4

4

2

2

3

5 6 5 6

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Wringer Wringer

E i h Energy recovery with

no exhaust air

Provides free pre-cool p

and reheat based on

the temperature

difference between

td i d i outdoor air and air

leaving the cooling coil

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Wringer Psychrometrics Wringer Psychrometrics

4

5

3

2 1

1

2

3 4 3 4

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Active Desiccant Wheel (Condenser Heat Regeneration) Active Desiccant Wheel (Condenser Heat Regeneration)

Reduced mechanical

cooling requirement

Wheel converts latent Wheel converts latent

to sensible energy

Slow rotational speed p

As low as 1/10 RPM

Increased COP

Active Desiccant Process Active Desiccant Process Active Desiccant Process Active Desiccant Process

How It Works How It Works

Moisture transfer based on difference in RH

Moisture transfers from high RH to low

The greater the difference in RH, the greater the

mechanism for moisture transfer

Conversion of latent heat to sensible

Evaporative cooling in regeneration airstream and

it i l ( ) i t opposite in supply (process) airstream

Heat increase is heat of vaporization of water

1050 BTU per lb of water 1050 BTU per lb of water

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Active Wheel Psychrometrics Active Wheel Psychrometrics

A

C

B

C

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Which System Uses Least Which System Uses Least Dehumidification Dehumidification Energy? Energy?

HCU

SingleHXEnergyUseComparison

Wringer

HCU

Heatpipe

EnthalpyWheel

$0 $2,000 $4,000 $6,000 $8,000 $10,000 $12,000 $14,000 $16,000 $18,000

BruteForce

Dehumidification Heating FrostControl FanPenalty g y

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Hybrid System Hybrid System -- Two Two Heatpipes Heatpipes or Plates or Plates

Increases recovered

energy while utilizing

maintenance friendly maintenance friendly

heat exchangers

Provides free reheat Provides free reheat

Need to have frost

prevention strategy prevention strategy

Preheat coil in OA or

EA positions

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Two Two Heatpipe Heatpipe Psychrometrics Psychrometrics

1 3 5 1 3 5

7

1

2

4

6

3

2

6

5

4

6

5

7

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Hybrid System Hybrid System Passive Wheel and Passive Wheel and Heatpipe Heatpipe or Plate or Plate

Increases energy

recovered

Provides free

reheat

Need to have frost

prevention strategy

Preheat coil in OA

or EA

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Passive Wheel and Passive Wheel and Heatpipe Heatpipe

1 3 5 1 3 5

7

2

4

6

1

6

6

2

5

4

3

6

5

7

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Passive Wheel and Wringer Cycle Passive Wheel and Wringer Cycle

Combines energy recovery with

dehumidification

Need frost prevention strategy

Prefer modulating wheel with vfd

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Passive Wheel and Wringer Cycle Passive Wheel and Wringer Cycle

1 3

2 4 5

6

7

1 3

6

1

4

2

3 5

6

7

6

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Passive Wheel and Active Wheel Passive Wheel and Active Wheel

C bi h Combines heat recovery

and dehumidification

Exhaust air stream is the

P C l

Supply Side Gas F

Side Return Air

condensing air stream

No separate condensing

unit

Pre -Cool

DX Coil

Supply

Fan

Side

Supply

Gas

Af terheat

E

D

F

B C

Side Return Air

Bottom Deck

W

h

e

e

l

Need frost prevention for

enthalpy wheel

Modulating enthalpy

h l / VFD

R t C il SideMakup Air

G

TopExhaust

H

I

Enthalpy Wheel

D

H

W

C d C il

J

C

o

n

t

r

o

l

-

C

a

n

C

o

m

p

r

e

s

s

o

r

s

wheel w/ VFD

React Coil SideMakup Air

Top Deck A

TopExhaust

Cond Coil

DOAS System Design DOAS System Design DOAS System Design DOAS System Design

Passive Wheel and Active Wheel Passive Wheel and Active Wheel

A

G

F

B

C

D

DOAS Options DOAS Options DOAS Options DOAS Options

Energy Usage Comparison Energy Usage Comparison

DrycoolERV

DOAUOperationalCostComparison

Enthalp Wheel

TwoSensHX

EnthalpyWheel/SensHX

EnthalpyWheel/Wringer

Heatpipe

Wringer

HCU

EnthalpyWheel

$0 $2,000 $4,000 $6,000 $8,000 $10,000 $12,000 $14,000 $16,000 $18,000

BruteForce

Dehumidification Heating FrostControl FanPenalty g y

Th k F Li t i ! Th k F Li t i ! Thanks For Listening! Thanks For Listening!

You might also like

- 11Document1 page11almig200No ratings yet

- Fully Extended: (CD11-2) Straight Duct, Flexible (Abushakra 2004 and Culp 2011Document1 pageFully Extended: (CD11-2) Straight Duct, Flexible (Abushakra 2004 and Culp 2011almig200No ratings yet

- Vvip Villa at Almina Place BasementDocument8 pagesVvip Villa at Almina Place Basementalmig200No ratings yet

- Ligends: West Yas - Residential 1017 VILLASDocument1 pageLigends: West Yas - Residential 1017 VILLASalmig200No ratings yet

- Table E103Document3 pagesTable E103almig200No ratings yet

- (CR11-1) Straight Duct, Rectangular (Huebscher 1948) : Tel: FaxDocument1 page(CR11-1) Straight Duct, Rectangular (Huebscher 1948) : Tel: Faxalmig200No ratings yet

- (CR3-1) Elbow, Smooth Radius Without Vanes (Idelchik 1986, Diagram 6-1)Document1 page(CR3-1) Elbow, Smooth Radius Without Vanes (Idelchik 1986, Diagram 6-1)almig200No ratings yet

- ASHRAE Duct DesignDocument13 pagesASHRAE Duct DesignJose Darwin Margate100% (2)

- The Hazren Williams FormulaDocument3 pagesThe Hazren Williams Formulaalmig200No ratings yet

- Design Options For HVAC Distribution SystemsDocument68 pagesDesign Options For HVAC Distribution Systemscathybravo100% (3)

- 5 7 Sidewall Standard Spray SprinklersDocument7 pages5 7 Sidewall Standard Spray Sprinklersalmig200No ratings yet

- Integration of HVAC System Design With Simplified Duct DistributionDocument2 pagesIntegration of HVAC System Design With Simplified Duct Distributionalmig200No ratings yet

- Chilled Water Pipe Insulation Method StatementDocument2 pagesChilled Water Pipe Insulation Method StatementGündoğdu Akın75% (4)

- Expansion Tank Sizing Calculation Hydronic SystemDocument16 pagesExpansion Tank Sizing Calculation Hydronic SystemNay Myo OoNo ratings yet

- Chiller Vs VRFDocument26 pagesChiller Vs VRFalmig20080% (15)

- Leed Hvac Design Leed Commissioning Jorge Mbo SmriDocument39 pagesLeed Hvac Design Leed Commissioning Jorge Mbo Smrialmig200No ratings yet

- Specifications and FormulasDocument1 pageSpecifications and Formulasalmig200No ratings yet

- Input Required Data in Yellow Field OnlyDocument7 pagesInput Required Data in Yellow Field Onlyalmig200No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- I. Objective III. Problem Solving. Show Your SolutionsDocument1 pageI. Objective III. Problem Solving. Show Your SolutionsYsmael Alongan B. MangorsiNo ratings yet

- 4.system ChecksumsDocument1 page4.system Checksumshvacvn1984No ratings yet

- Book No. 121, Page. 330 (The Physical Basis of Thermodynamics: With Applications To Chemistry by Pascal Richet)Document1 pageBook No. 121, Page. 330 (The Physical Basis of Thermodynamics: With Applications To Chemistry by Pascal Richet)DarrenLovelockNo ratings yet

- HVAC - Equipment ScheduleDocument1 pageHVAC - Equipment ScheduleRommel Dela SernaNo ratings yet

- ReviewerDocument30 pagesReviewerAriel Mark PilotinNo ratings yet

- Select Aire Heat Recovery System: Technical Bulletin 6Document4 pagesSelect Aire Heat Recovery System: Technical Bulletin 6Việt Đặng XuânNo ratings yet

- New Voltas AC - Tech - SpecsDocument1 pageNew Voltas AC - Tech - Specsmohamad chaudhariNo ratings yet

- Temperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGDocument104 pagesTemperature Enthalpy (HG) KJ/KG Enthalpy (HF) KJ/KGUzair BukhariNo ratings yet

- HVAC 101 by AircondloungeDocument32 pagesHVAC 101 by AircondloungeNigel AngNo ratings yet

- Lapres PendinginDocument60 pagesLapres PendinginGiantcanaNo ratings yet

- Property Data: 4.1 Unit SystemDocument60 pagesProperty Data: 4.1 Unit SystemAnonymous N3LpAXNo ratings yet

- Heat P1P2Document4 pagesHeat P1P2Sharvinder SinghNo ratings yet

- Watson - 1931 - Prediction of Critical Temperatures and Heats of VDocument5 pagesWatson - 1931 - Prediction of Critical Temperatures and Heats of VMartinNo ratings yet

- MEC 4205 Exam - May - 2016 - FinalDocument5 pagesMEC 4205 Exam - May - 2016 - FinalBirimumaso DavidNo ratings yet

- Different Parameters To Define SpontaneityDocument26 pagesDifferent Parameters To Define SpontaneityPayalNo ratings yet

- RAC Assignment 1Document9 pagesRAC Assignment 1basantNo ratings yet

- Reversible and Irreversible ProcesesDocument12 pagesReversible and Irreversible ProcesesFarouk BassaNo ratings yet

- Carnot CycleDocument3 pagesCarnot CyclealexontingNo ratings yet

- Entropy: Thermodynamics: An Engineering ApproachDocument45 pagesEntropy: Thermodynamics: An Engineering ApproachAdolfo Carlos Almendares ÁlvarezNo ratings yet

- Senamhi - HuantaDocument247 pagesSenamhi - HuantaAnonymous rocmFmAnNo ratings yet

- Thermodynamics ANSWER KEYDocument4 pagesThermodynamics ANSWER KEYLeah Mae CalangNo ratings yet

- FST 209 - CHAPTER 1 Part Temprature ConversionDocument7 pagesFST 209 - CHAPTER 1 Part Temprature ConversionNur Ayu Nadhirah Bt YahyaNo ratings yet

- Lecture 03 First Law of Themodynamics - Closed SystemsDocument34 pagesLecture 03 First Law of Themodynamics - Closed SystemsdinurjNo ratings yet

- Entregable 1 InglesDocument8 pagesEntregable 1 InglesMoisés NouNo ratings yet

- Heat Lecture 1 Handouts KunalDocument4 pagesHeat Lecture 1 Handouts KunalVikram KumarNo ratings yet

- Molier Diagram ConceptDocument37 pagesMolier Diagram ConceptMONER MANUSNo ratings yet

- Assignment Of: Thermodynamics: Group MembersDocument12 pagesAssignment Of: Thermodynamics: Group MembersUsama Jahangir KhanNo ratings yet

- TCE301T MEMO Test 1 Thermodynamics IIIDocument4 pagesTCE301T MEMO Test 1 Thermodynamics IIIRamolwetsi Kamogelo67% (3)

- 3 Hours / 100 Marks: Seat NoDocument4 pages3 Hours / 100 Marks: Seat NoAkshay KhangreNo ratings yet

- EWAD-TZ D-EIMAC00904-14 IOM Installation Manuals EnglishDocument229 pagesEWAD-TZ D-EIMAC00904-14 IOM Installation Manuals EnglishAmir ShamshiriNo ratings yet