Professional Documents

Culture Documents

Absorption and Sorptivity Tests

Uploaded by

ourebooksCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Absorption and Sorptivity Tests

Uploaded by

ourebooksCopyright:

Available Formats

TN 001 ABSORPTION & SORPTIVITY.

DOC

BCRC

Building & Construction

Research & Consultancy

Sydney Perth

PO Box 10, Brookton BC PO Box 2357, Clarkson,

NSW 2100, Australia WA 6030, Australia

Tel: 02 9939 7533 Tel: 08 9407 5363

Fax: 02 9939 7544 Fax: 08 9407 4031

1. INTRODUCTION

Tests that measure concretes propensity to suck in

water are generally termed absorption or sorptivity

tests. The difference between the two terms is

generally considered to be that absorption is the

capacity of a sample to hold water while sorptivity is

the rate at which the sample fills the sample.

2. PRINCIPLE

There are two ways of measuring

absorption/sorptivity. In one the concrete is immersed

under a small head of water (20-30mm) while in the

other less common method the sample is held in

contact but above the water. The difference is that

gravity adds to the driving force in the immersion

method and detracts from the driving force in the

suspension method. The gravitational component has

been found to be insignificant compared to the

suction force and in essence the two methods

measure the same thing i.e. water drawn in under

capillary suction.

Research has shown:

a) the penetration is dependent on initial water

content

b) drying to a constant rate of moisture loss provides

more accurate results than drying for a set time

as it provides a more consistent moisture content

c) the depth of penetration can be calculated

from:

d= (r

2

P

u

T/4)

where

r = nominal pore radius

Pu = atmospheric pressure

= viscosity

T = time

From this the nominal pore radius can be calculated

for any depth of penetration if time and temperature

are known

The many tests fall into three categories:

I) Sample is immersed for a set time that does not

lead to saturation. If immersion time and

temperature(absorption) are constant the

weight gain is a function of average pore

diameter. The depth of penetration will vary and

no estimate of voids van be made without this.

II) Sample is immersed such that it becomes

saturated. The result measure the volume of

permeable voids (VPV). As the sample is

saturated only voids can be measured.

III) Sample is immersed and measurements of height

rise and/or weight gain are measured. In some

tests measurements are made at various time

increments (normally root time based) while in

others the depth is measured at a standard time.

If depth in a given time is measured the result

relates only to nominal pore radius. If depth and

weight gain are measured then voids and

nominal pore radius can be estimated assuming

that capillaries are all full. Measurements at

various times improve the accuracy of the

method.

While there are many tests around the world for

measuring absorption/sorptivity only those commonly

recognised in Australia are discussed here.

3. TESTS METHODS

3.1 AS4058

The principle concrete quality test for pipes in AS 4058

is the absorption test undertaken in accordance with

AS4058 Appendix F. This requires that cores of

approximately 120mm diameter be taken through the

pipe thickness for pipes 14-28days after casting.

Cores are kept damp until tested. They are then oven

dried, weighed, immersed, boiled, cooled and

reweighed. Absorption is calculated as the weight of

water absorbed during immersion, boiling and

cooling divided by the weight of dry sample. It can

be assumed that the procedure will saturate all voids.

Although not mentioned in the standard the

absorption can be converted to voids percentage by

multiplying the absorption by the specific gravity of

the concrete, i.e. approximately 2.3. AS4058

requirements are shown in Table 1

Table 1 - AS 4058 Requirements for Absorption

A

b

s

o

r

p

t

i

o

n

m

u

s

t

n

o

t

e

x

c

e

e

d

E

q

u

i

v

a

l

e

n

t

v

o

i

d

s

V

i

c

R

o

a

d

s

V

P

V

C

l

a

s

s

pressure, sewage or

marine or other

aggressive

environments

6.5% 15% 2.

Good

for drainage pipes

8.0% 18.4% 4.

Marginal

Specialist Concrete Consultants For Engineers & Contractors

Page 2 of 5

TN 001 Absorption & Sorptivity.Doc

Specialist Concrete Consultants For Engineers & Contractors

BCRC

Building & Construction

Research & Consultancy

In considering revision to AS4058 one must consider

whether the absorption test prescribed continues to

be valid in light of developments since the last

standard was published in regards test methods,

acceptance criteria and durability criteria.

3.2 RTA T362

The NSW RTA T362 sorptivity test dries sample slowly to

avoid thermal shock. After drying at a RH of 50% for

the prescribed drying time the samples are immersed

at 23C for different times. The sorptivity is then

measured as the depth of penetration except that the

depth is doubled for class A and B1 concretes. The

method is specified in RTA B80 specification as a test

for curing. Criteria and testing intervals specified are

shown in Table 2 together with the mix requirements

for each exposure category.

The test method has been specifically developed by

RTA to provide a check on the adequacy of curing for

different grades of concrete. In developing the

criteria a number of variables are introduced

between different grades eg drying time, immersion

time and result calculation method. This means that

there may be no relationship between RTA sorptivity

and different grades of concrete.

The test requires that samples are stored at constant

50% humidity and are broken in a beam test rig.

These requirements for special facilities limits seriously

limits where the test can be undertaken. The breaking

of the sample to obtain a result means a result can

only be obtained at one time interval for each

sample.

Table 2 - RTA B80 Sorptivity Requirements

RTA T362 Sorptivity Test

E

x

p

o

s

u

r

e

C

l

a

s

s

i

f

i

c

a

t

i

o

n

M

i

n

i

m

u

m

C

e

m

e

n

t

C

o

n

t

e

n

t

(

k

g

/

m

3

)

M

a

x

i

m

u

m

w

/

b

r

a

t

i

o

D

r

y

i

n

g

T

i

m

e

a

t

2

3

C

(

d

a

y

s

)

I

m

m

e

r

s

i

o

n

T

i

m

e

A

t

2

3

C

(

h

r

s

)

M

a

x

S

o

r

p

.

G

P

C

e

m

e

n

t

(

m

m

)

M

a

x

S

o

r

p

.

b

l

e

n

d

e

d

C

e

m

e

n

t

(

m

m

)

A 320 0.56 21 6 35 35

B1 320 0.5 21 6 25 25

B2 370 0.46 28 24 17 20

C 420 0.4 35 24 N/A 8

U Project Specific

This method is similar in many respect to the CSIRO

test developed by Ho and Lewis but which has

seldom been used commercially because of the

large number of samples required due to their being

broken open for each test.

3.3 AS4056, ASTM C642 &AS1012.21

AS 4056, ASTM C642 & AS1012.21 tests require that

samples are immersed and boiled such the

permeable voids are saturated. Procedures are

shown in Table 3.

Table 3 - Comparison of Absorption Test Methods

AS4056 AS1012.21 ASTM C642

Weigh sample Weigh sample Weigh sample

Dry at 105

o

C to

constant wt

Dry at 105

o

C for

24hrs

Dry at 105

o

C to

constant wt

Cool sample Cool sample Cool sample

Weigh sample

in air, M1

Weigh sample in

air, M1

Weigh sample,

M1

Immerse sample

for 48hrs

Immerse

sample to

constant wt

Weigh sample in

air, M2

Weigh sample

in air, M2

Immerse

sample and

boil for 5hrs

Immerse sample

and boil for 5-

6hrs

Immerse

sample and

boil for 5hrs

Cool sample in

2 hrs

Cool naturally Cool naturally

Weigh sample

in air, M2

Weigh sample in

air, M3

Weigh sample

in air, M3

Weigh sample in

water M4

Weigh sample

in water M4

AS4056 gives the absorption as (M2-M1)/M1. Result is

weight of water absorbed as a percentage of sample

weight but can easily be calculated as VPV

ASTM C642 & AS1012.21 gives the VPV as (M3-M1)/

(M3-M4). Result (VPV) is volume of continuous voids

as a percentage of the sample volume.

Concern is sometimes expressed about thermal

shock causing cracking and the test methods

discounted on that basis.

Phaedonos

(1)

of Vic Roads reviews the ASTM C642

absorption test. This is similar to the absorption test in

AS 4058 and AS1012.21 in that the samples are dried

in the oven at 105C. The paper states results indicate

that the oven drying temperature of 100-110C has a

negligible effect on the pore system or microstructure

of concrete. The excellent correlation between oven

drying at 50C and 105C indicates there is very little

mass loss when the temperature increases from 50-

105C, thereby confirming that no combined water is

lost. He goes on to discuss other results ie that oven

drying temperature and the overall treatment of the

sample during the test procedure have no

detrimental effects on the microstructure. He

provides reference to various authors that conclude

the same. In view of this there is no concerned about

microcracking when curing at 105C.

Page 3 of 5

TN 001 Absorption & Sorptivity.Doc

Specialist Concrete Consultants For Engineers & Contractors

BCRC

Building & Construction

Research & Consultancy

Phaedonas also states Whereas the ASTM C642

method requires oven dried samples to cool naturally

followed by a two day water immersion where 99% of

the water absorption is achieved, the AS 4058 method

requires oven dried samples to be cooled and rapidly

heated to 100C for the 5 hour boiling period, The

ASTM C642 method is therefore considered as

subjecting test specimens to more sever testing due

to an induced thermal shock and the possibility of

macro cracking. The AS 4058 test produces 0.5% to

2% higher volume of permeable voids.

The ASTM C642 test (with refinements) has been made

an Australian Standard (AS1012.21-1999) and in a

phone conversation with Phaedonos he

recommended that the AS1012.21 test should be

adopted in place of AS 4058 testing.

Vic roads criteria for VPV using the ASTMC642 method

are given (Table 4). These criteria could also apply to

AS1012.21.

Table 4 - Criteria For VPV

D

u

r

a

b

i

l

i

t

y

C

l

a

s

s

i

f

i

c

a

t

i

o

n

V

o

l

u

m

e

o

f

P

e

r

m

e

a

b

l

e

V

o

i

d

s

(

V

P

V

)

(

%

b

y

v

o

l

u

m

e

I

m

m

e

r

s

e

d

a

n

d

B

o

i

l

e

d

A

b

s

o

r

p

t

i

o

n

(

%

b

y

w

t

)

S

o

r

p

t

i

v

i

t

y

(

m

m

/

s

e

c

0

.

5

)

1. Excellent <14 <6 <0.08

2. Good 14-16 6-7 0.08-0.10

3. Normal 16-17 7-7.5 0.10-0.15

4. Marginal 17-19 7.5-8.5 0.15-0.20

5. Bad >19 >8 >0.20

A major shortcoming of these tests is that they waste

the opportunity to plot weight gain with time. This is

particularly true of the AS1012.21 test where the

sample is immersed for 48hrs without boiling in any

event. Given a large enough sample the flow will

approximate to uniaxial

3.4 ASTM C1585 SORPTIVITY TEST

In this test an oven dried sample is suspended above

water and the height rise and weight gain measured

at time intervals. The sorptivity is calculated as the

weight gain per unit cross section against the square

root of time. It provides a relative measure that

combines pore size diameter and number of pores.

The test was originally developed for use on bricks

and introduced to Taywood Engineering in the early

1980s by Ken Baker of Halpern Glick as a potential

method of measuring concrete pore characteristics.

Taywood used the test extensively and were one of

the first companies to use Sorptivity as a performance

requirement. Only recently has the test become and

ASTM method.

Oven drying is not seen as an issue for the reasons

discussed in section 3.3.

The test method plots weight gain (absorption) at

several time increments for the same sample thereby

increasing accuracy by enabling initial surface effect

to be discarded and results to be based on the

statistical fit of a number of measurements. Hence, it

gives more reliable absorptions than simple weight

gain at a set interval. The test can also be set up to

measure absorption by placing the surface of interest

in touch with the water. The performance of the

exposed (surface can be assessed and the effect of

distance form the surface can also be determined.

The height rise measurement is comparable to the

RTA test method but unlike the RTA test the ASTM test

is simple to undertake.

Converting the height rise and weight gain to a pore

volume does not provide a reliable VPV in the same

fashion as the boiled absorption type tests. However

the test method lends itself to establishing this at the

end of the sorptivity test as an additional procedure.

The test method is not unique and was originally

developed by Fagerlund

(6)

. Similar tests are

commonly used for absorption tests on bricks eg

Reda

(5)

and it is the brick test, with an extended

measurement time, that has become the ASTM C

Sorptivity test method.

4. PREVIOUS RESEARCH

4.1 VPV VS OTHER TESTMETHODS &W/B RATIO

Whiting compared VPV results with results from water

permeability and air permeability on mixes with

different w/c ratio and a mix with silica fume (Table

5). The results show that VPV differentiated better than

air permeability between the concretes at w/c ratios

less than O.4 but neither method differentiated

between concretes at w/c ratios over 0.4. By

comparison water permeability differentiates the high

w/c ratio concretes but measurements at low w/c

ratios could not be made.

Phaedonos

(3)

reports on the relationship between VPV

and various concrete properties as follows:

Relationship to strength is poor reflecting that

strength is a poor indicator of durability

VPV detect the improved performance of slag, fly

ash and silica fume in a similar fashion to other

durability tests

Hydrophobic admixtures reduce VPV very

significantly while water-proofers did not reduce

VPV significantly

4.2 SORPTIVITY

V.Sirivivatnanon

(4)

tested fly ash, slag and silica fume

concrete using the RTA sorptivity test and ASTM VPV

Page 4 of 5

TN 001 Absorption & Sorptivity.Doc

Specialist Concrete Consultants For Engineers & Contractors

BCRC

Building & Construction

Research & Consultancy

test. The results for GP, FA and slag cement systems

indicated that the two tests gave similar results in the

w/c range 0.34-0.6 except for one anomaly with the

slag cement at a w/c ratio of 0.43. For silica fume one

high w/c mix (0.87) indicate VPV was less sensitive

than RTA sorptivity in this high w/c range.

Table 5 - Results of VPV and Other Penetrability Tests

w/b SCF

(wt %

binder)

VPV

(%)

Air

Permeability

(Darcy)

Water

Permeability

(Darcy)

0.26 12% 6.2 29 *

0.29 - 8.0 33 *

0.40 - 12.2 120 0.03

0.50 - 12.7 170 0.20

0.60 - 12.5 150 0.23

0.75 - 13.3 150 0.86

0

20

40

60

80

100

0.3 0.4 0.5 0.6 0.7 0.8 0.9

w/c r at io

R

T

A

S

(

s

o

l

i

d

l

i

n

e

)

12

13

14

15

16

17

V

P

V

%

(

d

o

t

t

e

d

l

i

n

e

)

GP - RTAS

FA - RTAS

SF - RTAS

HS - RTAS

GP - VPV

FA - VPV

SF - VPV

HS - VPV

Figure 1 - Sirivivatnanon Test Results for VPV and RTA

4.3 SORPTIVITY TESTING VS VPV

As noted above VPV is a measure of voids and

sorptivity (whether my mass gain or depth of

penetration) is a measure of nominal pore radius and

number of pores. While there may be some

relationship between these two parameters its not

likely that the relationship would be constant across

all concrete types.

Reda

(5)

measured total absorption and sorptivity on a

range of samples. The results for each tests method

gave a low standard deviation however a plot of total

voids vs sorptivity gave a very poor correlation

suggesting that the two properties are not related.

5. MECHANISMS OF DETERIORATION

Pipes deep below the ground water table will be

attacked by substances (acids, sulphate, chl;oride)

dissolved in water penetrating by permeability. In

pipes just below the water table and above it the

attacking substances will be taken in by water

penetrating by sorptivity. Classical formulae for

permeability and sorptivity suggest that the rate of

penetration to a given depth is controlled by the pore

radius while the volume of water delivered is related

to the pore volume. For diffusion pore volume may be

more significant.

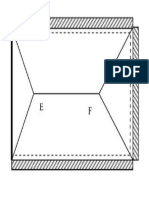

Figure 2 - Six Notional Concretes

1. 5% voids, no capillaries

4. 2% voids, few large capillaries

3. 3% voids, few fine capillaries

5. 1% voids, few fine capillaries 6. 2% voids, many fine capillaries

2. 10% voids, few fine capillaries 1. 5% voids, no capillaries

4. 2% voids, few large capillaries

3. 3% voids, few fine capillaries

5. 1% voids, few fine capillaries 6. 2% voids, many fine capillaries

2. 10% voids, few fine capillaries

Figure 2 depicts six concretes. The variable are

discrete void percentage, capillary void number and

capillary void size. The discrete voids have little effect

on performance. For example the performance of

concrete 1 would be little different to a concrete with

0% voids. Similarly the effect of discrete void

percentage in concrete 2 and 3 makes little

difference to performance. The difference in

concretes 4,5 and 6 however would be marked. The

early depth of penetration will be highest in concrete

4 although ultimately the depth of penetration in

concrete 5 and 6 is likely to catch up, particularly at

the low depths of significance in most deterioration

mechanisms.

The objective of a sorptivity/absorption test is to be

able to differentiate these concrete in respect to

durability. In making concrete pipe voids, as denoted

in Figure 2, would most likely be caused by poor

compaction while the capillaries are most likely to be

a function of the concrete mix and curing. It would

seem that discrete voids are not so significant and

one issue with just measuring VPV is that such discrete

voids could make a durable concrete appear of poor

quality. Conversely a test that only measures pore

radius (eg RTA sorptivity) gives no idea of the volume

of flow, a key durability factor.

Table 6 shows the likely grade testing the concretes

by the various absorption./sorptivity methods would

provide. This is a broad assessment where grade 1 is

excellent and grade 5 is very poor.

Page 5 of 5

TN 001 Absorption & Sorptivity.Doc

Specialist Concrete Consultants For Engineers & Contractors

BCRC

Building & Construction

Research & Consultancy

Table 6 - Test Methods Result (Grade) for Six Notional

Concretes

Type 1 as Figure 2 1 2 3 4 5 6

Test

method

Measuremen

t function of

Grade Expected Using

Test Method Shown

AS 1012.21

VPV

Voids 1 5 3 2 1 2

AS 4056

Absorption

Voids 1 5 3 2 1 2

TE Sorptivity

No of pores

and radius

1 1 1 5 1 3

RTA

Sorptivity

Pore radius 1 2 2 5 2 2

6. RECOMMENDATIONS

Measurement of the rate of absorption with root time

up to the point of saturation is gaining acceptance as

a test method and ASTM and Canadian standards are

being developed. The accuracy, measurement of

nominal pore radius and number of pores, ability to

measure VPV simplicity of tests all make it a clear

leader in terms of durability assessment.

The Taywood Sorptivity Tests is not well accepted and

is unlikely to find favour at this stage as and Australian

Standard tests are too far removed. The RTA sorptivity

test carries some authority but it is considered far too

limited, has too many variables and requires too

much specialist equipment to be considered as it is

for general use in quality.

Of the boiled absorption tests the AS1012.12 is the

most suitable for adoption. It currently allows for a

48hr immersion time without boiling. During this period

the weight gain with time can be measured to

establish a sorptivity.

The Papworth Modified AS1012.21 includes an

allowance for measurements of the sorptivity rate and

is able to be undertaken as a standard test at BRC.

You might also like

- Concrete Lab ReportDocument8 pagesConcrete Lab ReportJun Kang100% (2)

- A Water Absorption Test For ConcreteDocument5 pagesA Water Absorption Test For Concretekhoagle0% (1)

- ASTM C1403-13 Standard Test Method For Rate of Water AbsorptionDocument4 pagesASTM C1403-13 Standard Test Method For Rate of Water AbsorptionEdwin R Ruiz100% (1)

- ASTM D2842 06 Water Absorption Test MethodDocument10 pagesASTM D2842 06 Water Absorption Test MethodAnonymous BXmahb50% (1)

- Laboratory Worksheet: Center For Diploma StudiesDocument6 pagesLaboratory Worksheet: Center For Diploma StudiesSyihabuddin Yusoff0% (1)

- Astm C87 (2005)Document4 pagesAstm C87 (2005)Stuar TencioNo ratings yet

- Flexural TestDocument13 pagesFlexural TestAliaNo ratings yet

- Sorptivity Test 01Document5 pagesSorptivity Test 01Shaheer Ahmed KhanNo ratings yet

- CHAPTER 1 FINAL YEAR ProjectDocument5 pagesCHAPTER 1 FINAL YEAR ProjectdejayzNo ratings yet

- Experiment Title: Aggregate Impact Value TestDocument9 pagesExperiment Title: Aggregate Impact Value TestNaim Rous100% (1)

- ASTMC39Document5 pagesASTMC39Isaac NuñezNo ratings yet

- Aashto T307Document27 pagesAashto T307Viviana CruzNo ratings yet

- Concrete Slump TestDocument3 pagesConcrete Slump TestShaan LalwaniNo ratings yet

- Shotcrete Boiled Water AbsorptionDocument6 pagesShotcrete Boiled Water AbsorptiondjajadjajaNo ratings yet

- Concrete Mix DesignDocument7 pagesConcrete Mix Designadil271No ratings yet

- CBR TestDocument4 pagesCBR TestAtish Kumar100% (1)

- Self-Compacting Concrete SeminarDocument16 pagesSelf-Compacting Concrete SeminarAnubhab GhoshNo ratings yet

- Determination of The International Roughness Index (IRI) Using ARRB TR Walking ProfilerDocument9 pagesDetermination of The International Roughness Index (IRI) Using ARRB TR Walking Profilerतिप्लोकाची तिरुनचिपल्ली केरकेट्टा100% (1)

- Pervious Concrete As A Sustainable Pavement Material-Research Findings and Future Prospects A State-Of-The-Art-reviewDocument13 pagesPervious Concrete As A Sustainable Pavement Material-Research Findings and Future Prospects A State-Of-The-Art-reviewNoéMestas100% (1)

- Astm C 215Document7 pagesAstm C 215mickyfelixNo ratings yet

- Concrete masonry testing standardsDocument4 pagesConcrete masonry testing standardsHaniAminNo ratings yet

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocument12 pagesQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- Compressive Strength Test On Concrete CoreDocument4 pagesCompressive Strength Test On Concrete CoreSyed Mohd MehdiNo ratings yet

- Chemical Analysis Test (ASTM C114)Document8 pagesChemical Analysis Test (ASTM C114)Ayaz AhmadNo ratings yet

- Hyper CreteDocument2 pagesHyper CretedjgiumixNo ratings yet

- Soil testing methods guideDocument2 pagesSoil testing methods guideDr Wong Kim YuenNo ratings yet

- Ibs Company ProfileDocument52 pagesIbs Company ProfileFaeez ZainNo ratings yet

- ACI 116R Admixture Effects Setting TimeDocument3 pagesACI 116R Admixture Effects Setting TimeRavi Ayyavu100% (1)

- Determination of Aggregate CrushingDocument8 pagesDetermination of Aggregate CrushingPoovan Rajaratnam100% (2)

- Specific Gravity of Cement TestDocument9 pagesSpecific Gravity of Cement TestSyed Mohd MehdiNo ratings yet

- Lab 7 - Triaxial - UuDocument11 pagesLab 7 - Triaxial - Uudixn__No ratings yet

- Asphalt ExtractionDocument4 pagesAsphalt ExtractionOsikur RahamanNo ratings yet

- Lab Tests On AggregatesDocument15 pagesLab Tests On AggregatesYohan NyirendaNo ratings yet

- BS 812-109 1990 (Moisture Content)Document12 pagesBS 812-109 1990 (Moisture Content)Kartika Setia RiniNo ratings yet

- ASTM C40C40M. Obsoleta2019Document2 pagesASTM C40C40M. Obsoleta2019JAIME CARDONA DIAZ DIAZ100% (1)

- Standard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Document5 pagesStandard Test Method For Splitting Tensile Strength of Cylindrical Concrete Specimens1Lupita RamirezNo ratings yet

- Oedometer Test: Soil Mechanics 2 CE PC 504Document26 pagesOedometer Test: Soil Mechanics 2 CE PC 504SumanHaldarNo ratings yet

- Aichouni - Basic Quality Tools in Mixed ConcreteDocument8 pagesAichouni - Basic Quality Tools in Mixed ConcreteEdwin Lucio CcuchoNo ratings yet

- Fineness Test On CementDocument13 pagesFineness Test On CementTvsp Sekhar50% (2)

- Viscosity Penetration Test ReportDocument7 pagesViscosity Penetration Test ReportMoganraj100% (3)

- Fly Ash Cement Replacement Tds PDFDocument2 pagesFly Ash Cement Replacement Tds PDFabualamalNo ratings yet

- Los Angeles Abrasion Test PDFDocument6 pagesLos Angeles Abrasion Test PDFFathimaNo ratings yet

- Determination of PenetrationDocument57 pagesDetermination of Penetrationtunlaji0% (2)

- Department of Civil Engineering Diploma of Civil EngineeringDocument6 pagesDepartment of Civil Engineering Diploma of Civil Engineeringyuya_saraNo ratings yet

- Astm C185Document4 pagesAstm C185MuhammadRomadonNo ratings yet

- Concret CementDocument29 pagesConcret CementKamal Hameed Al-taiy100% (1)

- Concrete Quality Non-Destructive TestsDocument5 pagesConcrete Quality Non-Destructive TestsNadhirah LnfNo ratings yet

- As 2350.14-2006 Methods of Testing Portland Blended and Masonry Cements Length Change of Cement Mortars ExposDocument2 pagesAs 2350.14-2006 Methods of Testing Portland Blended and Masonry Cements Length Change of Cement Mortars ExposSAI Global - APAC100% (1)

- AIVDocument4 pagesAIVAfiq SafwanNo ratings yet

- DiscussionDocument4 pagesDiscussionmaizansofiaNo ratings yet

- Marshall Mix Design Test ProcedureDocument3 pagesMarshall Mix Design Test Procedureshafiqz_4No ratings yet

- C685C685M 14Document9 pagesC685C685M 14Alvin BaraNo ratings yet

- Clay Bricks BS 3921Document2 pagesClay Bricks BS 3921balgit100% (3)

- Astm C 40-2020Document3 pagesAstm C 40-2020Mohammed AliNo ratings yet

- Standard ASTM E96 Cup Method Water Vapor Permeability TestingDocument6 pagesStandard ASTM E96 Cup Method Water Vapor Permeability TestingSUPATTRA KLAYYANo ratings yet

- C 830 - 93 R98 - Qzgzmc1sruqDocument6 pagesC 830 - 93 R98 - Qzgzmc1sruqPrakash MakadiaNo ratings yet

- ASTM D 870 - 02 Testing Water Resistance of Coatings Using Water ImmersionDocument3 pagesASTM D 870 - 02 Testing Water Resistance of Coatings Using Water Immersionalin2005100% (1)

- Comparison of Hydraulic Conductivity Test Methods For Landfill Clay Liners 5084Document10 pagesComparison of Hydraulic Conductivity Test Methods For Landfill Clay Liners 5084Geovanny HerediaNo ratings yet

- ASTM-D-2247 Standard Practice Testing Coatings100Document5 pagesASTM-D-2247 Standard Practice Testing Coatings100chinocatNo ratings yet

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984From EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984No ratings yet

- History of The Development of Cement and Concrete (Non-HydraulicDocument2 pagesHistory of The Development of Cement and Concrete (Non-HydraulicourebooksNo ratings yet

- Introduction To FRCDocument3 pagesIntroduction To FRCourebooksNo ratings yet

- Equivalent Load ConceptDocument1 pageEquivalent Load ConceptourebooksNo ratings yet

- Early Age Cracking Tests PDFDocument15 pagesEarly Age Cracking Tests PDFourebooksNo ratings yet

- IRC Publications Page 3Document1 pageIRC Publications Page 3ourebooksNo ratings yet

- Sky ScapperDocument1 pageSky ScapperourebooksNo ratings yet

- IRC Publications Page 2Document1 pageIRC Publications Page 2ourebooksNo ratings yet

- Astm C 1581Document1 pageAstm C 1581ourebooks0% (1)

- Reinforced Concrete Text BookDocument1 pageReinforced Concrete Text BookourebooksNo ratings yet

- IRC PublicationsDocument1 pageIRC PublicationsourebooksNo ratings yet

- Guyed ChimneyDocument1 pageGuyed ChimneyourebooksNo ratings yet

- Yield Line PatternDocument1 pageYield Line PatternourebooksNo ratings yet

- First Floor DisplacementsDocument1 pageFirst Floor DisplacementsourebooksNo ratings yet

- Rectilinear MotionDocument1 pageRectilinear MotionourebooksNo ratings yet

- Engineering VibrationsDocument1 pageEngineering VibrationsourebooksNo ratings yet

- Mechanical VibrationsDocument1 pageMechanical VibrationsourebooksNo ratings yet

- Ring TestDocument1 pageRing TestourebooksNo ratings yet

- Mathematical Model of Human BeingDocument1 pageMathematical Model of Human BeingourebooksNo ratings yet

- Tall Structure PDFDocument1 pageTall Structure PDFourebooksNo ratings yet

- Tall StructureDocument1 pageTall StructureourebooksNo ratings yet

- Characterization of The Toughness of FRC Using Load CMOD ResponseDocument14 pagesCharacterization of The Toughness of FRC Using Load CMOD ResponseourebooksNo ratings yet

- Mode ShapesDocument1 pageMode ShapesourebooksNo ratings yet

- Full Page PhotoDocument1 pageFull Page PhotoourebooksNo ratings yet

- MDOFDocument1 pageMDOFourebooksNo ratings yet

- FTMDocument1 pageFTMourebooksNo ratings yet

- Ground Floor Slab and BeamsDocument1 pageGround Floor Slab and BeamsourebooksNo ratings yet

- Influence of Bending Test Configuration On Cracking Behavior of FRC FullDocument9 pagesInfluence of Bending Test Configuration On Cracking Behavior of FRC FullourebooksNo ratings yet

- Frame AnalysisDocument1 pageFrame AnalysisourebooksNo ratings yet

- 48 M ChomneyDocument1 page48 M ChomneyourebooksNo ratings yet

- 99 M Chimney GermanyDocument1 page99 M Chimney GermanyourebooksNo ratings yet

- Alimentando La Palma, Revisión de La Nutrición de La PalmaDocument97 pagesAlimentando La Palma, Revisión de La Nutrición de La Palmadarwin ortegaNo ratings yet

- Designs CatalogDocument77 pagesDesigns CatalogGen MendozaNo ratings yet

- NACE-MR0274 Mat Req For Polyolefin Cold-AppliedDocument7 pagesNACE-MR0274 Mat Req For Polyolefin Cold-Appliedluis fernando beltran balderasNo ratings yet

- NAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsDocument8 pagesNAF-Check Tilting Disc Check Valves FK 30.70 (11) GB: CharacteristicsRobovenNo ratings yet

- MT12550FTDocument1 pageMT12550FTJuan carlosNo ratings yet

- Safely Purging Air from Pipelines and VesselsDocument7 pagesSafely Purging Air from Pipelines and Vesselsgan_raoNo ratings yet

- Microplastic Communities in Different Environments Differenc - 2021 - Water R PDFDocument11 pagesMicroplastic Communities in Different Environments Differenc - 2021 - Water R PDFSunita ChayalNo ratings yet

- Application of Nanoparticles in AgricultureDocument11 pagesApplication of Nanoparticles in AgricultureShetti Swamy PatelNo ratings yet

- Role of pancreatic lipase and bile in fat digestionDocument15 pagesRole of pancreatic lipase and bile in fat digestionTom Anthony Tonguia100% (2)

- Technical Data Sheet: Ptfe + 20% PeekDocument1 pageTechnical Data Sheet: Ptfe + 20% PeekRohan KulkarniNo ratings yet

- Purpose of Master Batch PPA in PEDocument49 pagesPurpose of Master Batch PPA in PEin_abhay2706No ratings yet

- Uniz Resin Spec PDFDocument11 pagesUniz Resin Spec PDFYerayNo ratings yet

- Noble Gases 20 Aug 2022Document2 pagesNoble Gases 20 Aug 2022PLABAN DASNo ratings yet

- Carbomer 940: Information SheetDocument3 pagesCarbomer 940: Information SheetrendyNo ratings yet

- Mysore Road Plastic Industry ListDocument6 pagesMysore Road Plastic Industry ListjafarptrNo ratings yet

- Using Pumps As Power Recovery TurbinesDocument4 pagesUsing Pumps As Power Recovery TurbinesKali CharanNo ratings yet

- Stress HomographsDocument3 pagesStress HomographsMagali MadariagaNo ratings yet

- CBSE Class 12 Chemistry Previous Year Question Paper 2019 Set-3 QuestionDocument6 pagesCBSE Class 12 Chemistry Previous Year Question Paper 2019 Set-3 QuestionVikram tomarNo ratings yet

- USP <1115> Impact on Bioburden ControlDocument65 pagesUSP <1115> Impact on Bioburden ControlBlank Backtobasic100% (1)

- Dynamic model of offshore water treatmentDocument114 pagesDynamic model of offshore water treatmentferchosb12No ratings yet

- Soils of Karnataka-361Document10 pagesSoils of Karnataka-361naturewisdom100% (3)

- Cell Organelles and Their Functions - RS' ScienceDocument1 pageCell Organelles and Their Functions - RS' ScienceMishaNo ratings yet

- Atmospheric Water GeneratorDocument3 pagesAtmospheric Water GeneratorKhusnil MujibNo ratings yet

- Electro Chemistry AssignmentDocument2 pagesElectro Chemistry AssignmentDeepak PradhanNo ratings yet

- Basic Mechanical Engineering MCQ PDF Part 3Document10 pagesBasic Mechanical Engineering MCQ PDF Part 3kibrom atsbhaNo ratings yet

- Using psychrometric charts to analyze HVAC systemsDocument18 pagesUsing psychrometric charts to analyze HVAC systemsRockydel MontesNo ratings yet

- 07 10 2021 Bio AssignmentDocument4 pages07 10 2021 Bio AssignmentSuneel ReddyNo ratings yet

- Lecture 2 MassMicroDocument25 pagesLecture 2 MassMicroPelin KınıkNo ratings yet

- Physiology Exam 1Document16 pagesPhysiology Exam 1sa'di OsmanNo ratings yet