Professional Documents

Culture Documents

Feci. Spec - Cq.A-Z50/@ CH 77, 1967: Fedesal Specification

Uploaded by

Ozan SümenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Feci. Spec - Cq.A-Z50/@ CH 77, 1967: Fedesal Specification

Uploaded by

Ozan SümenCopyright:

Available Formats

QQ-A-250/@

~

LPIIiSEOING

FecI.Spec.CQ.A-Z50/@

~ch 77,1967

FEDESAL SPECIFICATION

M01n7WM ALLoY 2024,PIATEAND SHEWI

This specificationwae appzuvedby the

Commissioner,Federd SuPplyService,

(lenemlSexVicesAdmlniatmtion, for .

the use of till. FeAe@. agencies.

(lhis specification fomw a part

of the latest issue of Federal L@ci.

f ication GQ-A-250. )

1. LzJOPE AND CLASSIFICATION

1.1 2c0 e. This speclfioation covers the specific requirements for aluminum

e alloy 202 plate and sheet;the generalXeqnlrements are coveredin QQ-A-250.

1.2 classification.

ers. The plate and sheet shell be classifiedas O, T3, Tk, T36,

T42 ;%; ~-, T%, T3Z, T361, ?2651,T%l, ... F temper,M SPeC~i$ (see

6.2~. Tne definitionsof these tempersshall be ae specifie&in AmericanNational

StandardANS H35.1.

2. APPLICABLEIxXXM@TS

Latest issue of FederalSpecification:

QQ-A.250- Aluminumand AluminumAI.1oYPlate and Sheet;Geneml Specificationfor.

(Activitiesoutsidethe FederalGovernmentmay obtaincopiesof Fe&ml SPeui-

ficationsand Standar%, as outlinedunderGenexalInfommtion in the Indexof

Fedeml SpecificationsandStandardsand at the prices indicatedin the Index. The

Index,which includescuuwlativemonthlySUppleUIentS as issued,is for 8tie on a

subscrlptiopbasis by the Su erlntendentof Documents,U. S. Governmentprftiins

1

d Cffice,Washington,D. c. 2 02.

Fsa 9535

1:

,.

Source: http://www.assistdocs.com -- Downloaded: 2014-04-11T11:53Z

Check the source to verify that this is the current version before use.

IW-A-250/4W

(Simglecopiesof tlxM$peoMicati.on and otherFederalSpeo@.oation$required

by aotititieenuteidetheWderel Oovermnen

t for bidctl.ng purpoeeeere avell.able

tithoutohargefromEmeine#eServiceOent.ers at the GeneralSer%l.oes Administration

RegionalOffioesin Soston,New York,Weehinston,DO, Atlante,Cbbeso, SensesCity,

Mo.,FortWorth$De$rnm,SanFrnnoLeoo,Les Angelesd Seattle,We-n.

(Federel. Governmetiaotititiesw obta.in oopiesofFederalSpecMicatlon$,

Stexdards$endlIaudbQoks and the Imdexof FederelSpeoifioablcmS endSt@xlardsfrem

theestab~ehed d.tetdmtim Petite in their egmmies.)

(Copiesof MilitarySpeeifieati- and Stdesd.s reqtied by oontraetis in

aonneotd,on with epeoifioprocurementflmotion$ekeuldbe obtdned i%m the preour-

* aotititgor 2s direotedbp the eentraotd.ng offioer.)

Ameriaan NationalSt.dxde Inetitute:

ANS H35,1 - Alloyand TemperDesignationSystemsforAlumlnum.

(Applfoat.ion for aopieeshouldbe addressedto theAmericanNationalSten&+nis :.,,

Inetitute,1430Breadway,NewYork,New York10018.) ,~.:

3. F@UII@WSWIW

3.1 ChetiaL cowmsition.

3.1.1 me ehern$cal aOwsttiOn shallconfoneto the requirements speeified

in tableI.

J !CAIW I. Ch~ical composition1

Percent

Minimum Msximim

Copper

3.8

49

MgneOium 1.2 1:8

Mengane6e 0.30 0.9

Silioon .

Iron

.50

Zino

.50

.

.25

Chromlwil

.

.Lo

Othere, eaoh -

Othere, total

.05

-

.15

Aluminum Remeinder

J in thie table X, If, hwever, the preeenceof other elementsis Indiaatedin

the oonrae of nxtine aaelyeis,further enelysieshell be rade to determine

confome.nceto the limitespeeifiedfor other elements.

3.2 Meehanioalpropertied.

3.2.1 Meohanloalptmpertlesof materialas snpplied. The meohenicalProperties

perpenflloular. to t e ~for meterielIese then 9

Inahea in width,shalloonfoneto the requirements of tebleII.for the twer aPeoi-

fied. For meteriallees than 9 inches in width, the meehenlcalprepertieepamllel

to the elireetionof fiaal rollingehall conformto the requirementsof table II for

the temper speoified.

2

. .

Source: http://www.assistdocs.com -- Downloaded: 2014-04-11T11:53Z

Check the source to verify that this is the current version before use.

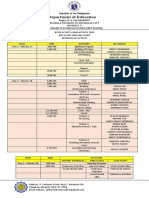

Temper

o

!!ia

T

TABLE II. MechanicalPIVPC

1

wi dth Thickness Tensile

Btrength,

minimum

I I

Inches Inches F.s.i.

All

All

An

All

30 sad under

30 and under

30 and wider

wer 30 thru 48

wer 30 thru 48

wer 30 thru 48

wer 48 thaw 60

wer 48 thru 60

wer 48 thru 60

over 60

over 60

All 0.010 thru 0.499@2,0cM

All 5C0 #l-u 1.750 3/32,000

All I 0L20LI

.010%: ::: $~

O%J ~: O:y *

.M3 mm -g * o.a20 thru 0,

.500

.G20tllm .062 %%

.063thru .2kg 69,000

.250thti .50Q 69,0c0

.020thru .062 67,0cm

.063thru .249 68,.ooo

.250iim .5c0 67,000

.c63tam .249 67,000

.250thru .499 66.000

All 0,010 thna 0.020

All

L

62,000

.021 thtu .2kg 62,060

All .250thxu .499 62,000

.5oiIthru 1.000 61,0ea

All 1.cO1 thm 1.500 60,0iIo

Au 1.501 thm 2.000 60,0@

xl 80GQ

All I .500 thru l.@% 63$%

All I2.001 thra 3.a

All I0.250 thru 0.4!

All l.bolthru 1.500 62;003

All 1.501 thnl 2.m 62,000

All 2.001 thm 3.00Q 60,000

All 3,601 thru 4.OGQ 57.000

All 0.010 thm 0,499

.500thw 3.000 63$%

All

All 0.010 thru 0.249 6J3.OCO

All. 0.010 thru 0.249 7,000

QQ-A.250~E

es

Yield stren@h at

0.2 percentoffset

or at extension

-

ted

Extension

rider load

~

0.0033

O.cf%o

.0070

.Oqo

.0070

.0070

.0070

.C068

.0069

.0068

a

.0059

.W67

_#@&_

:0056

,cQ56

.0056

.cc56

.ce56

-#x!&_

:O@3

.0050

.0060

-$&_

_+fJf_

0.0075

Longat ion

in 2 in.

~ 4 times1)~

. minimum

Percent

12

K

10

-

+

9

10

8

9

10

8

9-

10

8

+_

9

+_

15

12

8

!

+__

8

z

+

5

5

~

3

. . ..

Source: http://www.assistdocs.com -- Downloaded: 2014-04-11T11:53Z

Check the source to verify that this is the current version before use.

QQ.A.250/4E

9!empe

TABI J 3II. Mechani cal

r

merties

!lenelle

mlnhnn

P.6.i.

72,0C0

72,006

72,CQ0

Ts!,cco

72,CC0

71,000

70,0ca

7L,GQ0

70,000

71.,000

*

*

& 1

:ontInued

eld streI@h at

).2percentoffset

30 and uudem 0.020 thru O.@

30 and under

.063thru .249

30 an~ under

.250 thaw .500

over 30 thruh8 .020thlu .C62

ever30 thm 46 .C63thru .249

2

over o thiw48 .250thrd .5@3

over 8 thru60 .020thrn .*

over48 thra60 .063tbru .249

over48 thru60 .250tiru .500

over60 .c63thru .249

over64 ,250thau .500

~

~

All .063thru .249

All .250thru .500

m5v ~ -- 0.250

.500thruL.OCO

F. All

1 t rlel1/2 inchor

~Fikfo??e;~

~%~%~ % %&h%e~u%&e only.

i

Materialin the!!42,T62,or T72 temperti not availablefma the msterialsproduoero.

~ No requtreaeuts,

or- at e

Indici

iinimom

Pos.i.

66,CCQ

68,CO0

61,000

66,0Q0

67,0cQ

66,000

62,cC0

67,000

65,0GQ

%%

*

%%%

E

1.

,ension

ed

kteusion

ndw load

=m==

o:g3

.mek

.0083

:3

.0082

.o#3

.0081

mL&--

.0081

mtg--

6/

Iongation

in 2 in.

r 4 times D~

/, minimvm

Percent

~. .,,,

4.

+

3.2.2 MeelmniealP2vperble8 after heat treatment. In additionto conformingto

the requirementof 3,2.1,ns.terialin the annealed(0) end the as-fabricated(F) tempere

ehall,aften plmper eolutionheat treatmeat,eleo confozmte the requirementsof table

11 for the 2$2 temper. Materielas receivedin the T3, T4, T35L, 3!81,and T851 tempein

ehall,@ten proper resolution heat-treatment,be capableof coufoami

qulre!nent.s speeifiedin table II for the Tk2 temper. Materialin the %)?$er%all.,

after proper aging, be oapableof ooofonnlugto the requirementsHpeotiiedlo table II

forthe T62 or w&2 temper. Materiel in the T3, !c36,T.351,and T36~ t~e~ s~lj

after pro es aging,be capableof confona.ingte the requirementsspecifiedin table II

8 for theT 1, l@6,l?851,andT&l tempers,re6peetivel.Y.

4

Source: http://www.assistdocs.com -- Downloaded: 2014-04-11T11:53Z

Check the source to verify that this is the current version before use.

3.2.3 Bend test. Bend-testspecimenstaken fmm materialshall be capable

of withst8n~0ut cmctiw, the bend test sp%ified in QQ-A-250. me ~les

for bend factorN are given in table III.

TABLE III. Bend test factorN

Thicknccsof

~

*=D ----

MEIterial

o

I

??3

I

. J . - u . . . .

r

- - . . . . - . ..

Inch

0.008 thru 0.009

.010thr+i . CX20

.021 thru . 032

; g : : : ?;

. 129 thru : 2k9

. 250 thm . 499

0

0

4

4

-

G

5

5

6

6

8

3.3 Internaldefects. !ihenspecified(see6.2), p~te shallbe ~t~sO~@llY

Inspected(seeQQ-A-E50). Acceptancelimitschall be as specifiedin table IV.

TAB13 IV. 01.tr+onicdiscontinuityeaceptanoelimits

Y

Maximumweight

Thickness per piece Discontinuity C@3S d

i I

Inches

I

POunas

I

0.500 thru 1.499 2,000 B

1.500 thru 3.000 2,000 A

3.001 +hm 4.000 2,000 B

1 Discontinuities in excessof those li8ted in tsbl

e IV ray be allowed eub$eotto

the apprrwalof the p~uring activity,if it is establishedthat they will be

removed by machining or that they are in non-critical areas.

2J TM aimmtinuity cM.. IititsaIW defim.ain MIL-I-8950.

In additionto the mcbrkingrequiredin Fed. Std. No. l@t,aaterlal

in t!$!cW9?851, and 9!861tempersshall be Identifiesby a lot number_@

in at l.smt one locationon e3cb piece. Plate ana sheet in the T36 and T% teapers

shallalso be marked immealately after the temper ae6ig~tion with the orxinal width

of the nmterial, as f Ou~e:

5

Source: http://www.assistdocs.com -- Downloaded: 2014-04-11T11:53Z

Check the source to verify that this is the current version before use.

QQ-A-250/kE

Originalwidth 1

Identiticationtmwking

3mhe8 I

up thru30 .==30

Over30 thfu48

= 48

overb8 thru60 = 60

over60 760

4. QUALI TY A2sURAWE PRW1210N2

(SeeQQ-A-250.)

4.1 Wet treatment.

4. 1. 1 Agi ng peri od bef ore testi ~. spacl mans i n the T3, Tk, T36, T42, T351

and T361 temperawill xmt be raquiradto be testedwithink daysafter completion

of the haat traatment. ~ the manufacturerso elects,samplesmay be .testadafter

leas thdn 4 days aging;but if they fail to ehovthe specifiedproptiies, tie

teat maples shallbe diecti and additionalsamplesshallbe testadaftar h

days*132+n g.

k.2 Machanic.1testafterheat treatment.

4. 2. 1 Number of testafterheat traatmamt. Prom materialin the annealed(0)

8tIdas-fabrlcatad(F) tampa?6,an additionalnumberof 8paaimensequl w those

fequiredby QQ-A-250@all be taken and testadaftersolutionha8t-tfaatmentto

detezmlnecamgd.+.uce viti 3.2.2.

5. PNEPAIL9TION POR DELIVEW

(2aeQQ-A-250.)

6. NOl?E2

6.1 Inten&eduse. TIIiSalloy is intendedfor use wherehigh stran2tbIs ra-

quiredand no weldingis involved. TempersT351 and T4 shouldnot be wad whera

optimumcorrosionresistance1s raqulti. TemperaT62, T72, and 9!851shouldbe

spacifiedwhen optimumresietenceto stress 6ormsion is raquirad. The T351 and T851

temperaara intendedpriimrilyto prevldematerialwith low rasidualstressesand

consequentmlnlnwmdlatorbionduringmachining.

6.2 orderingdata. Purchasersshouldselectthe preferredoptionspemltted

hereinand Includetbe following informationin pmmfement docmments!

(a)

(b)

Title,number,anddate of this specification.

FOmCandtamperraqvlrad(see1.2.1).

6

t

Source: http://www.assistdocs.com -- Downloaded: 2014-04-11T11:53Z

Check the source to verify that this is the current version before use.

(c)

(d)

(e)

(r)

Dimensionsrequired.

Requirements for sizes

QQ-A-250/4E

not specifioally covered (see QQ-A-250).

Whetherultrasonic inspection of plate is required (see 3.3).

Selectionof appli.sblelevelsof prueerwation,packaging,and packins

required,If other *ban level C (seeQQ-A.250).

6.3 =. TempersT351 and T851 are a~ihble in pkte O@Y.

6UUTASY CLE71UDL4NS:

preuariw activity:

ArnqJ-flR

Navy - AS ~~J%9535-0192-4 )

Air Force -.11

851Yi~ac

tivitiee:

-- MS, MI, f6U, WC

.,

Navy - RR, As, m, FZ

Air Force . 85

w =t

ivitles:

Army -EL, ME

Navy - 342,0s

*U. S. Government Printing Office r 1971 0 .436-361 (2337)

Cindersfor tbls publicationare to be placedtith -al ServicesAdminis-

tration,acting 8s an agentfor the Superintendentof DOcumenta.See Section2

of ~ apeoifioationto obtain copiesand otherdooumentsrefemnoed heawin.

PriOe10 cent6eaah.

7

Source: http://www.assistdocs.com -- Downloaded: 2014-04-11T11:53Z

Check the source to verify that this is the current version before use.

You might also like

- Mil C 9084CDocument20 pagesMil C 9084CNick AlanenNo ratings yet

- ARMOR SPECDocument22 pagesARMOR SPECpradellesNo ratings yet

- Feci - Spec.Cq.A-Z50/@ CH 77, 1967: LpiiiseoingDocument7 pagesFeci - Spec.Cq.A-Z50/@ CH 77, 1967: LpiiiseoingHòa NguyễnNo ratings yet

- Distribution Transformers G210-12-1Document14 pagesDistribution Transformers G210-12-1boopelectraNo ratings yet

- Increasing ECM RatesDocument124 pagesIncreasing ECM Ratesdavid2404No ratings yet

- MIL-H-19886, 1988 Helmet, Ground Troops, Parachutists, Steel, M-1Document23 pagesMIL-H-19886, 1988 Helmet, Ground Troops, Parachutists, Steel, M-1cjnjr1No ratings yet

- MIL-A-2550C Ammunition General SpecDocument17 pagesMIL-A-2550C Ammunition General Speccpt_suzukiNo ratings yet

- Plymetal SpecificationsDocument10 pagesPlymetal SpecificationsGiuseppe GoriNo ratings yet

- Mfaf BK: ScopeDocument23 pagesMfaf BK: ScopesbalajimNo ratings yet

- Thermal Power Station Equipment GuideDocument178 pagesThermal Power Station Equipment GuideJay LawsonNo ratings yet

- Alumunium For BodyplaneDocument7 pagesAlumunium For Bodyplaneikhsan alfinusNo ratings yet

- Iuli IiaaDocument20 pagesIuli Iiaaawesome_600No ratings yet

- Aluminum Alloy Tube Specification GuideDocument7 pagesAluminum Alloy Tube Specification GuideBryan MartinezNo ratings yet

- AED Design Requirements - Electrical Design Requirements - Jul - 11Document30 pagesAED Design Requirements - Electrical Design Requirements - Jul - 11Krishna ManandharNo ratings yet

- SIL-35-111 - AVOX Systems, Inc.Document7 pagesSIL-35-111 - AVOX Systems, Inc.reginaldo11No ratings yet

- Hvac Boq - R0Document17 pagesHvac Boq - R0Avik Biswas67% (3)

- Mil R 24537Document10 pagesMil R 24537巫錦福No ratings yet

- SmartTank Master SpecDocument13 pagesSmartTank Master Speccarlos030476No ratings yet

- Electric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Document3 pagesElectric-Resistance-Welded and Carbonamanganere Boiler Tuôes'Joao Osmar CorreaNo ratings yet

- SIEMENS 10KV AIS Commissioning ReportDocument41 pagesSIEMENS 10KV AIS Commissioning ReportDamia QistinaNo ratings yet

- Wapda P 46 2008Document81 pagesWapda P 46 2008Engr Awais Khan100% (7)

- MIL-A-22771D - Aluminum Forgings, Heat TreatedDocument24 pagesMIL-A-22771D - Aluminum Forgings, Heat TreatedklinedavidklineNo ratings yet

- Review of Orifice Plate Steam TrapsDocument35 pagesReview of Orifice Plate Steam TrapsOmar Ezzat100% (1)

- Mil DTL 7990cDocument10 pagesMil DTL 7990cDavid Esteban Pinzon GiraldoNo ratings yet

- PVC 300DataSheetDocument3 pagesPVC 300DataSheetarnella_hNo ratings yet

- Retrofitting Existing Wind Turbines for Increased Power and LifetimeDocument8 pagesRetrofitting Existing Wind Turbines for Increased Power and LifetimemannoqamarNo ratings yet

- ./Fi'Ttmtfef: &Pmtuu:Ra of Idnnmpartlition-Ll1Ulerni I/Uintiun NlminimrntinnDocument2 pages./Fi'Ttmtfef: &Pmtuu:Ra of Idnnmpartlition-Ll1Ulerni I/Uintiun NlminimrntinnMajved Ariel HassanNo ratings yet

- Mil STD 1344aDocument129 pagesMil STD 1344aBillTrager100% (1)

- AS 2853-1986 - Enclousure - Temperature Controlled - Perfomance Testing and Grading PDFDocument15 pagesAS 2853-1986 - Enclousure - Temperature Controlled - Perfomance Testing and Grading PDFDini AprianiNo ratings yet

- SAE StandardDocument9 pagesSAE StandardAzizol Wahab50% (4)

- FED-STD-228 Cable Wire Testing (Flex) PDFDocument222 pagesFED-STD-228 Cable Wire Testing (Flex) PDFnoman888No ratings yet

- Design of Rope Drum and Chain HoistsDocument19 pagesDesign of Rope Drum and Chain Hoistssuresh_501100% (1)

- Mil W 13855D PDFDocument20 pagesMil W 13855D PDFjimr6590No ratings yet

- Bid Bulletin No. 4 Bid No. 23 004 02 Bukidnon Airport Development Project CY 2022 - CompressedDocument6 pagesBid Bulletin No. 4 Bid No. 23 004 02 Bukidnon Airport Development Project CY 2022 - CompressedAlbert Conrad II LopezNo ratings yet

- SHIZUKI Capacitors and ReactorsDocument6 pagesSHIZUKI Capacitors and ReactorsUrsula JohnsonNo ratings yet

- SECTION 15510 PIPES AND PIPE FITTINGSDocument8 pagesSECTION 15510 PIPES AND PIPE FITTINGSSanthu MeprathuNo ratings yet

- 510 Open ExamDocument17 pages510 Open Examariyamanjula2914100% (1)

- Sae Ams 2417e PDFDocument8 pagesSae Ams 2417e PDFunknown17110% (1)

- Technical SpecificationsDocument10 pagesTechnical SpecificationsRamos Vicher HutajuluNo ratings yet

- TS - 400kVA Earthing TransformerDocument8 pagesTS - 400kVA Earthing TransformerViswanathan VNo ratings yet

- Mil C 39029DDocument83 pagesMil C 39029Demawz21No ratings yet

- Project Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Document32 pagesProject Report: On Analyze Submerged Arc Welding (SAW) With Respect To MIG Welding (GMAW)Rama Krishna Reddy DonthireddyNo ratings yet

- O&M Manual For FCUDocument30 pagesO&M Manual For FCUBeatrice Li50% (2)

- Mil F 5509Document18 pagesMil F 5509RwilcoNo ratings yet

- MIL-G-10944 Rev B PDFDocument14 pagesMIL-G-10944 Rev B PDFffincher4203No ratings yet

- Electrical Bonding Materials and SpecificationsDocument28 pagesElectrical Bonding Materials and SpecificationsDaniel GarciaNo ratings yet

- Mil DTL 48623Document18 pagesMil DTL 48623David ByronNo ratings yet

- Mil F 25173a DzusDocument19 pagesMil F 25173a DzusacparaujoNo ratings yet

- BasrahDocument19 pagesBasrahDurban Chamber of Commerce and IndustryNo ratings yet

- Havc Underground Piping MosDocument5 pagesHavc Underground Piping MosYusuf Ziya DilbazNo ratings yet

- Deck Crane EL Control Box Mainetanance & Spare PartsDocument5 pagesDeck Crane EL Control Box Mainetanance & Spare PartsJayant AradwadNo ratings yet

- 1.1 A. B. C. D. E. F. G. H. 1.2 A. B. C. D. E. 1.3 A.: Click HereDocument5 pages1.1 A. B. C. D. E. F. G. H. 1.2 A. B. C. D. E. 1.3 A.: Click Heretkm2004No ratings yet

- Sys A CDocument40 pagesSys A Cdnageshm4n244No ratings yet

- Cussons Boiler Instructon ManualDocument32 pagesCussons Boiler Instructon Manualjakakolenk100% (1)

- Online TS 3.02.04 I5Document31 pagesOnline TS 3.02.04 I5akmezimNo ratings yet

- OIL/SD/06: Cluster Isolation Draining and Water Flushing ProcedureDocument26 pagesOIL/SD/06: Cluster Isolation Draining and Water Flushing ProcedureHosseinNo ratings yet

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Spline DIN 5480Document27 pagesSpline DIN 5480ewillia13100% (3)

- ASTM D3951 Packaging Rules PDFDocument42 pagesASTM D3951 Packaging Rules PDFOzan SümenNo ratings yet

- Double Enveloping Worm Gear Sets PDFDocument36 pagesDouble Enveloping Worm Gear Sets PDFOzan SümenNo ratings yet

- PMP Mock Exam 200 Q ADocument31 pagesPMP Mock Exam 200 Q ALuis Olavarrieta100% (5)

- PMP Formulas: Earned ValueDocument3 pagesPMP Formulas: Earned ValuefraspaNo ratings yet

- NASA 2001 tm209857Document46 pagesNASA 2001 tm209857Ozan SümenNo ratings yet

- PMP Formulas: Earned ValueDocument3 pagesPMP Formulas: Earned ValuefraspaNo ratings yet

- Gear Technical FundamentalsDocument176 pagesGear Technical Fundamentalsjoe9000No ratings yet

- TM 9-2330-246-24P M348a2/xm1007Document376 pagesTM 9-2330-246-24P M348a2/xm1007AdvocateNo ratings yet

- Gear Engineering DataDocument18 pagesGear Engineering DataOzan SümenNo ratings yet

- Solidworks K-Factors Sheet for Bending CalculationsDocument9 pagesSolidworks K-Factors Sheet for Bending CalculationsashkansoheylNo ratings yet

- TM 9-2330-392-14&PDocument354 pagesTM 9-2330-392-14&POzan SümenNo ratings yet

- Gear Engineering DataDocument18 pagesGear Engineering DataOzan SümenNo ratings yet

- TM 9 6650 221 35Document82 pagesTM 9 6650 221 35Ozan SümenNo ratings yet

- Lo 5 2410 237 12Document14 pagesLo 5 2410 237 12Ozan SümenNo ratings yet

- Long Addendum Gears 1946Document15 pagesLong Addendum Gears 1946Marco ViniciusNo ratings yet

- 7-21 Isuzu Despiece 721Document57 pages7-21 Isuzu Despiece 721Dani Serrano SanchezNo ratings yet

- TM-ZX1500 B GDocument6 pagesTM-ZX1500 B GDadung PrakosoNo ratings yet

- Mayhem Entry 2015Document1 pageMayhem Entry 2015thedietdocNo ratings yet

- 12-Animal Continuous Fist of Xingyiquan in Picture SeriesDocument15 pages12-Animal Continuous Fist of Xingyiquan in Picture Seriesfofofofo100% (1)

- Apelco Fishfinder 365Document83 pagesApelco Fishfinder 365Ivan Campione100% (1)

- Betting Data 2020 21 - Ver 7.0Document192 pagesBetting Data 2020 21 - Ver 7.0Kaung MyatNo ratings yet

- Super Mario Galaxy 2 Walkthrough PDFDocument11 pagesSuper Mario Galaxy 2 Walkthrough PDFStephen FoleyNo ratings yet

- GYM Glow Up Fitness PlanDocument71 pagesGYM Glow Up Fitness PlanGailGNo ratings yet

- Yamaha Wr125 Service Manual PDFDocument372 pagesYamaha Wr125 Service Manual PDFTudor Miclăuș67% (6)

- Imagine Dragons - DemonsDocument2 pagesImagine Dragons - DemonsIgorNo ratings yet

- F1 2011 Manual PS3Document11 pagesF1 2011 Manual PS3arturoasperoNo ratings yet

- MISSION WS 600 Pump Spec SheetDocument2 pagesMISSION WS 600 Pump Spec SheetFaroukNo ratings yet

- RFP 28 Day Pilates Challenge 2024Document1 pageRFP 28 Day Pilates Challenge 2024Carol ChanNo ratings yet

- Possessive Pronouns: Possessive Pronouns Show Ownership. They Tell The Reader That SomethingDocument8 pagesPossessive Pronouns: Possessive Pronouns Show Ownership. They Tell The Reader That SomethingGan Zi XiNo ratings yet

- Aion Account - Buy Cheap Aion Accounts - PlayerAuctionsDocument8 pagesAion Account - Buy Cheap Aion Accounts - PlayerAuctionsAbraham RenaudNo ratings yet

- Chess Tournament Guidelines and Nicknames for Phoenix LegionDocument7 pagesChess Tournament Guidelines and Nicknames for Phoenix LegionCora MonicaNo ratings yet

- Danh Sach Anh Cư NG G IDocument46 pagesDanh Sach Anh Cư NG G IPhạm QuyếtNo ratings yet

- Assignment 2.2 ForcesDocument4 pagesAssignment 2.2 Forcespanghua tanNo ratings yet

- Nutrition 3Document2 pagesNutrition 3azszahNo ratings yet

- 3v3 Basketball Rules GuideDocument3 pages3v3 Basketball Rules GuideMark Anthony AnaretaNo ratings yet

- Get Free Spins Get Free Coins Coin Master GeneratorDocument3 pagesGet Free Spins Get Free Coins Coin Master GeneratorNathaniel YukihiroNo ratings yet

- Monthly ItineraryDocument1 pageMonthly ItineraryErwindelaCruzNo ratings yet

- Scouts Camp Activity 2023Document4 pagesScouts Camp Activity 2023Mhel PerezNo ratings yet

- tkr305p 20201101Document1 pagetkr305p 20201101Nicolas, Charles Franz ConradNo ratings yet

- ProbDocument38 pagesProbmcaviimsNo ratings yet

- 1-Mar Guys/Gals Combo Guys: Gals: Dim SumDocument3 pages1-Mar Guys/Gals Combo Guys: Gals: Dim SumposerNo ratings yet

- Halo Fleet Battles FAQ Errata and Clarifications PDFDocument4 pagesHalo Fleet Battles FAQ Errata and Clarifications PDFSam VeeversNo ratings yet

- PE 8 - Q2 - Mod 3 - Introductio To Team Sports Volleyball - v2Document37 pagesPE 8 - Q2 - Mod 3 - Introductio To Team Sports Volleyball - v2Eloisa BrailleNo ratings yet

- 303 ProjectDocument4 pages303 ProjectChristian SawayaNo ratings yet

- 2019 Vulcan® Motorcycles PDFDocument44 pages2019 Vulcan® Motorcycles PDFOlgerdNo ratings yet