Professional Documents

Culture Documents

Written Pole

Uploaded by

BaneeIshaqueK0 ratings0% found this document useful (0 votes)

65 views25 pagesWritten Pole

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentWritten Pole

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

65 views25 pagesWritten Pole

Uploaded by

BaneeIshaqueKWritten Pole

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 25

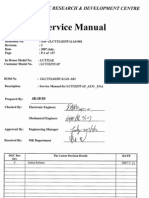

Semi nar Gui de: Pr es ent ed by,

MRS. SHYMA MOHAMMED SAMNA. K

ASST. PROFESSOR S7 EEE

EEE DEPT 07105046

WRITTEN-POLE

ELECTRIC MOTORS

OVERVIEW

y INTRODUCTION

y WRITTEN POLE MOTOR CONSTRUCTION

y WORKING

y BENEFITS

y EXCITER DESIGN

y APPLICATIONS

y CONCLUSION

y REFERENCES

INTRODUCTION

y Rural areas is powering huge loads from rural single

phase electric distribution system.

y Introduced by the Precise Power Corporation of

Bradenton, Florida, in the 1990s.

y The motor dramatically reduced starting current &

are able to drive heavier loads without disrupting

power quality.

Why......?

Large starting current.

Even number of poles.

Dependence of speed on no. of poles of rotor.

speed = 120 X frequency

no. of poles

Conventional Motors Used:

y Squirrel Cage Induction Motor

y Wound Rotor Induction Motor

y Synchronous Motor

CONSTRUCTION

y Stator Construction

1.cast frame construction

2.electrical steel

laminations

3.copper stator winding

with an additional

exciter coil.

y Rotor Construction

1.steel shaft bearings

2.electrical steel

laminations

3.carbon steel rotor cage

4.ferrite magnet layer

WORKING

y There are three modes of operation:-

1.Start Mode

2.Transition Mode

3.Run Mode

Start Mode:

y Induction torque is produced in the machine by the

rotating magnetic field of the stator.

y Hysterisis torque is developed when stator current

slightly magnetize the ferrite material.

y The Hysterisis and Induction torque produced

accelerates the motor to rated speed.

Transition Mode:

y The excitation coil is turned on when the motor reaches

80% - 90% of rated speed.

y The powerful excitation coil starts writing poles to the

ferrite layer as the rotor rotates.

y Magnetic layer magnetized into any desired

configuration using exciter winding.

Figure 1 shows motor is in normal mode of operation.

As the excitation had not been turned on the motor is

running as an induction motor.

Figure 2 & 3 shows the poles are being written into

the magnetic layer in the anticlockwise direction as

the rotor rotates in the clockwise direction.

Contd

y The no: poles produced depends upon the frequency of

signal given to the exciter coil and also speed of the

motor.

y If the exciter has constant frequency o/p then :-

1.Lower speed of rotor results in larger no of poles

with shorter spans.

2.higher speed of rotor results in smaller no of poles

with longer spans.

Run Mode:

y Magnetic interlocking of rotor poles and stator poles

takes place.

y The motor starts run at synchronous speed.

y It excessive torque is applied to the output shaft, causing

the motor to pull out of synchronization, it re-enters the

transition mode and attempts to re- accelerate the load

back to synchronous speed.

BENEFITS

y Low starting current requirements.

y Energy efficient operation.

y Unity power factor operation.

y Low temperature rise.

y High inertia starting.

y Instantaneous restart capability.

y Ride through characteristics.

EXCITER DESIGN

The home appliance requires for a motor to be small,

exciter with a very large magneto-motive force in the

small volume, which is driven by a general voltage

source.

Its divided into:

a) MMF design

b) Pole shape design

Mmf Design:

MMF = Current * coil turns

Voltage equation is given by,

If Seff is the slot area occupied by n turns, then area of

a coil

If Leff is the effective length of a coil side, then

resistance of exciter

Contd

The reactance of coil is proportional to square of

turn number

where R is the magnetic reluctance.

Thus the exciter current is given as,

Thus

Contd

Lesser the turn no:,

larger the exciter

current and mmf.

Maximum MMF is

limited by maximum

allowable current.

Pole Shape Design:

The exciter pole shape is designed with maximising the

magnetic intensity in magnet.

Since the magnetic flux in pole should be concentrated

to increase the magnetic intensity, the width of pole

edge w is selected as variable.

Magneto static analysis is carried out with nImax and

the field intensity according to variation in w.

The edge width corresponding to maximum intensity is

selected.

APPLICATIONS

y Agricultural purpose in rural areas.

y Conveyor belt applications.

y At oil well beam pump.

y To run a 3 phase generator.

CONCLUSION

y WPM shows good value when applied to proper niches

y Technology shows promise where the characteristics

can be benefited for rural and industrial applications.

y For a low Hp WPM, the winding and pole shape of

exciter have to be optimally designed and analyzed.

REFERENCES

y S. Hoffman, B. Banerjee, and M. Samotyj, Written-pole

Revolution, IEEE Power Eng. Rev., pp. 69, 1997.

y A. Hannah, Electrical field measurements on an EPRI two-

pole, 20-HP written pole motor, IEEE Trans. Ind. Applicat.,

vol. 33, no. 2, pp. 408414, Mar./Apr. 1997

y Cyril G. Veinott, Theory and design of small induction

motors, McGraw-Hill pp.447-452, 1959

y R. W. Menzies and L. Ge, Theory investigation of 3-phase

written pole motors, in Proc. 2002 IEEE Can. Conf., 2002,

p. 162165.

THANK YOU

You might also like

- TXG VNB CCTVDocument2 pagesTXG VNB CCTVBaneeIshaqueKNo ratings yet

- Seminar TopicsDocument1 pageSeminar TopicsBaneeIshaqueKNo ratings yet

- Full Report - Blue Brain - 4 - General Technical RequestDocument5 pagesFull Report - Blue Brain - 4 - General Technical RequestBaneeIshaqueKNo ratings yet

- Sun TrackerDocument1 pageSun TrackerBaneeIshaqueKNo ratings yet

- PIC16F628ADocument169 pagesPIC16F628ARimla OtenNo ratings yet

- Pac's Life - Wikipedia, The Free EncyclopediaDocument5 pagesPac's Life - Wikipedia, The Free EncyclopediaBaneeIshaqueKNo ratings yet

- Until The End of Time (Tupac Shakur Album) - Wikipedia, The Free EncyclopediaDocument7 pagesUntil The End of Time (Tupac Shakur Album) - Wikipedia, The Free EncyclopediaBaneeIshaqueKNo ratings yet

- How Can RedTacton Be UsedDocument5 pagesHow Can RedTacton Be UsedBaneeIshaqueKNo ratings yet

- Web Control: The Radio Button ListDocument3 pagesWeb Control: The Radio Button ListBaneeIshaqueKNo ratings yet

- Load MonitoringDocument1 pageLoad MonitoringBaneeIshaqueKNo ratings yet

- History of Microprocessors: From 4-Bit to 64-Bit CPUsDocument32 pagesHistory of Microprocessors: From 4-Bit to 64-Bit CPUsmapua_09No ratings yet

- PIC16F84A DataSheetDocument88 pagesPIC16F84A DataSheetEmanueleNo ratings yet

- Me Against The World - Wikipedia, The Free EncyclopediaDocument9 pagesMe Against The World - Wikipedia, The Free EncyclopediaBaneeIshaqueKNo ratings yet

- Intel 8257 Programmable DMA ControllerDocument17 pagesIntel 8257 Programmable DMA Controllergodfrzero0% (1)

- The Don Killuminati The 7 Day Theory - Wikipedia, The Free EncyclopediaDocument12 pagesThe Don Killuminati The 7 Day Theory - Wikipedia, The Free EncyclopediaBaneeIshaqueKNo ratings yet

- P-N Junction DiodeDocument32 pagesP-N Junction Diodesashi_s2No ratings yet

- 50 Cent DiscographyDocument37 pages50 Cent DiscographyBaneeIshaqueKNo ratings yet

- Qualcomm Snapdragon 800 Product BriefDocument2 pagesQualcomm Snapdragon 800 Product BriefMinh NguyenNo ratings yet

- Tupac Shakur DiscographyDocument18 pagesTupac Shakur DiscographyBaneeIshaqueKNo ratings yet

- Wiki Curtain Call The HitsDocument4 pagesWiki Curtain Call The HitsBaneeIshaqueKNo ratings yet

- Wiki Curtain Call The HitsDocument4 pagesWiki Curtain Call The HitsBaneeIshaqueKNo ratings yet

- Eminem DiscographyDocument45 pagesEminem DiscographyBaneeIshaqueKNo ratings yet

- Wiki The Slim Shady LPDocument8 pagesWiki The Slim Shady LPBaneeIshaqueKNo ratings yet

- 499 Topics For Seminars Electrical and Electronics Engineering - Electrical Engineering PDFDocument11 pages499 Topics For Seminars Electrical and Electronics Engineering - Electrical Engineering PDFBaneeIshaqueKNo ratings yet

- Air PDFDocument16 pagesAir PDFBaneeIshaqueKNo ratings yet

- Problem in Conventoinal Tyre: Portmanteau Tyre French Michelin Polyurethane SpokesDocument12 pagesProblem in Conventoinal Tyre: Portmanteau Tyre French Michelin Polyurethane SpokesBaneeIshaqueKNo ratings yet

- Robot Motors & Sensors Used in Robots: TopicDocument1 pageRobot Motors & Sensors Used in Robots: TopicBaneeIshaqueKNo ratings yet

- A Simple Implementation of Outlook Style Groupbox Control With Transparency SupportDocument3 pagesA Simple Implementation of Outlook Style Groupbox Control With Transparency SupportBaneeIshaqueKNo ratings yet

- 499 Topics For Seminars Electrical and Electronics Engineering - Electrical Engineering PDFDocument11 pages499 Topics For Seminars Electrical and Electronics Engineering - Electrical Engineering PDFBaneeIshaqueKNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Ez Battery ReconditioningDocument5 pagesEz Battery Reconditioningabdou mahfoudNo ratings yet

- 7 Sets PhysicsDocument26 pages7 Sets PhysicsManish GuptaNo ratings yet

- VSE1 W PX200 Batt EngineDocument1 pageVSE1 W PX200 Batt EngineTedy AdhinegoroNo ratings yet

- Icom IC-R5 Instruction ManualDocument80 pagesIcom IC-R5 Instruction ManualYayok S. AnggoroNo ratings yet

- BEEE - Batch 6Document22 pagesBEEE - Batch 6Neo TarunNo ratings yet

- JawDuino talking skull projectDocument6 pagesJawDuino talking skull projectJusteinAlagenioNo ratings yet

- PAD Mounted TRansformersDocument27 pagesPAD Mounted TRansformersMarling Roxsy González ParedesNo ratings yet

- Diode Circuits AnalysisDocument9 pagesDiode Circuits AnalysisLavdim Xhelili100% (1)

- LM1117Document12 pagesLM1117George ArambuloNo ratings yet

- Optelecom 9000 Series Installation and Operation ManualDocument20 pagesOptelecom 9000 Series Installation and Operation ManualfptnamNo ratings yet

- 3410 Lecture Notes v1.0Document226 pages3410 Lecture Notes v1.0MICHAEL K. E. DonkorNo ratings yet

- Split MetersDocument2 pagesSplit Metersrafathnisar100% (1)

- Starter Motor Construction (Automobile)Document8 pagesStarter Motor Construction (Automobile)shalyn matines dabulamanziNo ratings yet

- Ethos Overdrive Amp Spec Sheet RevBDocument2 pagesEthos Overdrive Amp Spec Sheet RevBmikletNo ratings yet

- Rahul Patil Electric Works 123Document12 pagesRahul Patil Electric Works 123Rahul ChitragarNo ratings yet

- Electrical Symbols by Tevin SamuelsDocument3 pagesElectrical Symbols by Tevin SamuelsTevin SamuelsNo ratings yet

- 6823 Datasheet PDFDocument3 pages6823 Datasheet PDFingucvNo ratings yet

- Description of Schematic DiagramDocument18 pagesDescription of Schematic Diagramtest2k3No ratings yet

- SSTC ReportDocument50 pagesSSTC ReportVishal ShahNo ratings yet

- Solar Powered Mobile ChargerDocument33 pagesSolar Powered Mobile ChargerIswarya100% (1)

- 5 - Scalar Control MethodsDocument13 pages5 - Scalar Control MethodsQuynh tranNo ratings yet

- Product Selection Guide: Kabeldon Cable Cabinet, 12-36 KVDocument16 pagesProduct Selection Guide: Kabeldon Cable Cabinet, 12-36 KVQwertyNo ratings yet

- ContextPlus Conventional Brochure 2019 - REV 1aDocument16 pagesContextPlus Conventional Brochure 2019 - REV 1aRasheedNo ratings yet

- 5 KW OFF GRID & Grid Tie Quotation 31-03-2021Document3 pages5 KW OFF GRID & Grid Tie Quotation 31-03-2021ImranFazalNo ratings yet

- Wireless Device SM-J500H Repair GuideDocument99 pagesWireless Device SM-J500H Repair GuideЭдуард ХливнойNo ratings yet

- Ayra Oso 240b Mkii DMX Operator User ManualDocument20 pagesAyra Oso 240b Mkii DMX Operator User Manuallistentomerijn100% (2)

- Simplified Modeling of A PV Panel by Using PSIM and Its Comparison With Laboratory Test ResultsDocument5 pagesSimplified Modeling of A PV Panel by Using PSIM and Its Comparison With Laboratory Test ResultsMuhammadSaeedTahirNo ratings yet

- Akai LCT32Z5TAP LCD TV Service ManualDocument137 pagesAkai LCT32Z5TAP LCD TV Service ManualSantiago SanchezNo ratings yet

- Microphone Sans Fil Akg Wms 450 - CutsheetDocument6 pagesMicrophone Sans Fil Akg Wms 450 - Cutsheetbenblidia.zineddine02No ratings yet

- TS2750J - Similar A Chasis PX20084-2CDocument34 pagesTS2750J - Similar A Chasis PX20084-2CAleksander AlexanderNo ratings yet