Professional Documents

Culture Documents

Fuel Ethanol From Sugar Cane Bagasse

Uploaded by

oscariq0 ratings0% found this document useful (0 votes)

29 views42 pagesAlfredo / Puente de ixtla, morelos, Mexico. BioEthanol Outline Motivation and the Mexican perspective. New fuels are needed to substitute oil derivatives and fossil fuels.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAlfredo / Puente de ixtla, morelos, Mexico. BioEthanol Outline Motivation and the Mexican perspective. New fuels are needed to substitute oil derivatives and fossil fuels.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

29 views42 pagesFuel Ethanol From Sugar Cane Bagasse

Uploaded by

oscariqAlfredo / Puente de ixtla, morelos, Mexico. BioEthanol Outline Motivation and the Mexican perspective. New fuels are needed to substitute oil derivatives and fossil fuels.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 42

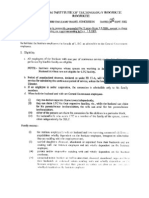

Fuel Ethanol from Sugar Cane Bagasse

Alfredo Martnez Jimnez

Dpto. Ingeniera Celular y Biocatlisis

Instituto de Biotecnologa UNAM

alfredo@ibt.unam.mx

http://pbr322.ibt.unam.mx/~alfredo/

Puente de Ixtla, Morelos.

Wednesday 4, 2009

Competence Platform on Energy Crop

and Agroforestry Systems for Arid

And Semi-Arid Ecosystems

BioEthanol

Outline of the Presentation

Motivation and the Mexican perspective

Lignocellulose Biomass

2ng Generation Fuel Ethanol

Carbon metabolism studies in ethanologenic

Escherichia coli

Biomass Sources and Potential

Final Remarks

Acknowledgements

Questions

New fuels are needed to substitute oil

derivatives and fossil fuels

CO

2

Accumulation

Climatic Change

Global Warming

Oil, natural gas and carbon: Industrial

activities, electricity generation, transport, etc.

Oil

Depletion (Mexico ~2020)

Price Increase

Contamination-Spills

Emissions

Economic National Support

Alternative Renewable E

Wind

Hydro

Waves

Geothermic

Solar

Electricity

Biomass: Solid Bio-fuel

Liquid Bio-fuels

For Transportation

Fuel Ethanol

Sun Biomass Fossil Fuels

~ 100 Million Years

Sun Biomass Bio-Fuels

!~ or < 1 Year!

BioEtanol

Energy Consumption

~30%

Mexico 2004: 8%

Sugar Cane Bagasse

Timber

~35%

Fuel Ethanol Production

Sucrose syrups from Sugar Cane + Yeast Ethanol

40% car use E95. Others E22. Ford, GM, WV, Honda, etc.

Brazil, expertise 30 years

More than 15,000 million L/year (41 million L/day)

Saccharomyces cerevisiae

Mature Technology

Fuel Ethanol Production

USA: expertise 20 years

2006: More than 41 million L/day (more than Brazil)

Corn Starch + Amylases Glucose

Glucose + Yeast Ethanol

E10 any car: 2% gasoline consumption EUA

Mature Technology

1st Generation Fuel Ethanol

USA and Brazil

0

2

4

6

8

10

12

14

Jul 06 Ene 07

m

i

l

e

s

d

e

m

i

l

l

o

n

e

s

d

e

g

a

l

o

n

e

s

Production In Construction

Year Area

(Mha)

Alcohol

(Mm

3

)

2005 5.50 15.60

2015 7.92 45.00

2025 8.64 78.00

Colombia

~2 years expertise

1 million liters/day

What about Mexico?

Sucrose syrups from Sugar Cane + Yeast Ethanol

Mexican Scenario: Fuel Ethanol

Substrate Bulk Price Et-OH Prod. Cost

in Mexico Substrate

(pesos/kg) (pesos/L)

Glucose 8-11

Sucrose 8-11

Gasoline Price

8 - 10 pesos/L

Glucose 2 Ethanol + 2 CO

2

Sucrose 4 Ethanol + 4 CO

2

Theoretical Yield: 0.51

g

ETHANOL

/ g

(GLC or SUC)

0.64 L

EtOH

/kg

Glucose, Corn Imports: 8 x 10

6

metric tons

& Corn Yield: 2-4 ton/ha vs 12-14 ton/ha

Sucrose, small surplus small market &

high sugar cane price (3 times the price of Brazil)

- Mexican demonstrated oil reserves

will be depleted in 9 years

- 33% of the Mexican federal income

is based in oil commercialization.

Vision 20 years

Given that in 20 years the main form of

transportation fuel will still be liquid fuel, the

technological vision for 2020-30 is that bio-fuels

will evolve to those that will integrate seamlessly

into current transportation refining to end use

fuel systems: Bio-ethanol, bio-diesel and other

liquid and gaseous bio-fuels need to be

produced

Look for solutions: Biotechnology

Bio-Ethanol Market

Schubert. Nature: 2006

Second Generation Fuel Ethanol

Purpose:

Purpose:

Design microorganism

Design microorganism

and process

and process

to transform

to transform

Lignocellulose (cellulose & hemicellulose:

Lignocellulose (cellulose & hemicellulose:

pentoses,

pentoses,

hexoses, disaccharides

hexoses, disaccharides

)

)

to ethanol

to ethanol

ETHANOL

Lignocellulose Biomass

Agricultural Residues

Sugar Cane Bagasse

Fermentation

Hydrolysis

CO

CO

2 2

Xylose,

Cellobiose

Glucose,

etc.

Cellulose,

Hemicellulose

C5 & C6

Artificial

CO

2

cycle

Sun

Martinez et al. 2006

Lignocellulose

Sugar Cane Bagasse

Pectin

(Poligalacturonate)

2-20%

Others

(8%)

Lignin

(aromatics)

10-20%

Cellulose

(glucose)

20-50%

Hemicellulose

(xil, ara,

man, glc, gal)

20-40%

Pentoses 85% + Hexoses 15%

(Xil + Ara) + (Gluc+Man+Gal)

+ Acetate + Glucuronic Acid

Ingram et al., 1998

Martinez et al. 2000

Sugars in Sugar Cane Bagasse

Hemicellulose Hydrolysates

(g/L)

Xylose: 80

Arabinose: 5

Glucose: 15

Biomass Lignocellulose

Future Raw Material

Hemicellulose

Hydrolysis

Products

CH

2

OH

OH

OH

O

OH

OH

Glucose

6-carbons

OH

OH

OH

OH

O

Xilose

5-carbons

OH

OH

OH

OH

O

Arabinose

5-carbons

Yeast: Do not Ferment Pentose Sugars

Two main strategies: Pentoses Ethanol

Metabolic Pathway Engineering

Pentoses

Hexoses

E

t

h

a

n

o

l

E

t

h

a

n

o

l

B: NO Ethanol producer

Pathway complementation. Engineer to produce only ethanol

Escherichia coli

A: Ethanol producer

Increase substrate range. Engineer to use pentoses

Saccharomyces cerevisiae and Zymomonas mobilis

H

e

x

o

s

e

s

Ethanol

Pentoses

P

e

n

t

o

s

e

s

Escherichia coli: Uses a wide range of sugars

Embden-Meyerhof-Parnas Entner-Doudoroff Pentose Pathway

PYRUVATE

Succinate

Lactate

Acetate

Acetyl-CoA +

CO

2

H

2

Ethanol

LDH

PDH

Formate

HEXOSES (Glc, Fru, Gal, Man etc.) + PENTOSES (Xyl, Ara, Rib, Xylu, etc.)

PFL

and make fermentation products, but little ethanol

Construction of ethanologenic E. coli: KO11

Embden-Meyerhof-Parnas Entner-Doudoroff Pentose Patway

PYRUVATE

Succinate

Lactate

Acetate

Acetyl-CoA +

CO

2

H

2

Ethanol

LDH

(Km = 7 mM)

PFL

(Km = 2 mM)

Formate

HEXOSES (Glc, Fru, Gal, Man etc.) + PENTOSES (Xyl, Ara, Rib, Xylu, etc.)

KO11 (E. coli W)

frd, pfl::pdc adhB cat

Metabolic Engineering

pfl: strong promoter

X

Otha et al., 1991

FRD

Ethanol

Pyruvate Decarboxylase

(PDC) (Km = 0.4mM)

Acetaldehyde

Alcohol

Dehydrogenase II

(ADHII) (Km = 0.012mM )

CO

2

Ingram et al., 1998

Xylose (10%) fermentation

Yield 94.0%

Theoretical Yield =

0.51 g

Et-OH

/g

Glc or Xyl

Luria Broth, 35

o

C, 100 rpm, pH 7.0

Cell mass: KO11 > Ec

W

(34%)

: KO11 > Ec

W

(30%)

q

S

: (g

Xyl

/g

DCW

h) KO11 > Ec

W

(30%)

Q

EtOH

(g

Et-OH

/l h) KO11 = 1.0

Tao et al., 2001, Martnez et al., 1999

0 12 24 36 48 60 72 84 96

0

20

40

60

80

100

Xylose (g/l)

Acids (g/l)

0

1

2

3

4

Ec W

Cell mass (g/l)

Time (h)

Ethanol (g/l)

0 12 24 36 48 60 72 84 96

0

20

40

60

80

100

Xylose (g/l)

Ethanol (g/l)

Acids (g/l)

0

1

2

3

4

KO11

Cell mass (g/l)

Time (h)

Metabolic Engineering

(Genetic Engineering Tools)

DNA

Gene 1 Gene 2 Gene 3

Enzima 1 Enzima 2 Enzima 3

A B C D

A

DNA

D

DNA

Gene 1 Gene 2 Gene 3

Enzima 1 Enzima 2 Enzima 3

A B C D

A

Delete Interrupt Genes

DNA

X

X

X

New genes

DNA

Gene 1 Gene 2 Gene 3

Enzima 1 Enzima 2 Enzima 3

A B C D

A

DNA

New (add foreign) genes

DNA

Gene 1 Gene 2 Gene 3

Enzima 1 Enzima 2 Enzima 3

A B C D

A

Gene 4

E

n

z

i

m

a

4

E

Strain evaluation

Fermentor setup: 6-Mini-fermentors (Fleakers)

Working volume 200 ml

Mineral media (some with Rich Media) & Sugars (Xyl, Glc)

Temperature: 37C; Speed: 100 rpm; pH: 7.0

Without aeration

0 12 24 36 48

0

10

20

30

40

0.0

0.5

1.0

1.5

2.0

KO11

Time (h)

G

l

u

c

o

s

e

(

g

/

l

)

E

t

h

a

n

o

l

(

g

/

l

)

C

e

l

l

m

a

s

s

(

g

D

C

W

/

l

)

KO11: Glc or Xyl (4%): Mineral Media

Sugar Cane Hemicellulose Hydrolyzates

In comparison with rich media, in mineral media there are reductions by:

57

Glc

& 63

Xyl

% in cell mass formation; 25% in the specific growth rate

70

Glc

& 60

Xyl

% in the specific sugar consumption rate

Q

EtOH

is reduced to 0.42

Glc

& 0.33

Xyl

g

Et-OH

/l h, for glucose and xylose

0 12 24 36 48

0

10

20

30

40

0.0

0.5

1.0

1.5

2.0

KO11

Time (h)

X

y

l

o

s

e

(

g

/

l

)

E

t

h

a

n

o

l

(

g

/

l

)

C

e

l

l

m

a

s

s

(

g

/

l

)

Yield 70%

Yield 60%

Main Conclusion

The study provides the basis for the

implementation of appropriate genetic

modifications to increase the ethanol yield

when mineral media or sugar from

hemicellulose syrups containing a large

amount of pentoses are used, for instance,

the disruption of succinate and lactate

pathways that compete for ethanol

production.

Ethanologenic E. coli 2nd Generation

Embden-Meyerhof-Parnas Entner-Doudoroff Pentoses Pathway

PIRUVATE

Lactate

Acetate

Acetil-CoA

Ethanol

Pyruvate Decarboxylase

(0.4mM)

Acetaldehyde +CO

2

Alcohol Dehydrogenase

(0.012mM)

Formate

ETHANOL

HEXOSES (Glucose) + PENTOSES (Xylose)

PEP

ADH

Succinate

Block Organic Acids

Increase PDCZm & ADH

Zm

X

X

X

X

Martnez et al., 2007

ldh

-

, frd

-

,pta-ack

-

, pfl

-

No Growth

pdc-adh

+

Only way

to Grow Up

X

Ethanol Production in Mineral Media-Xyl-Glc

Or Hemicellulose Syrups

0.0

0.8

1.6

2.4

3.2

C

e

l

l

m

a

s

s

(

g

D

C

W

/

L

)

0 24 48 72 96

0

10

20

30

40

50

0.0

0.2

0.4

0.6

0.8

1.0

Time (h)

E

t

h

a

n

o

l

(

g

/

L

)

E

t

h

a

n

o

l

(

m

o

l

e

s

/

L

)

Martinez et al., 2007

2nd Generation

Homo-ethanologenic strains

Capable to ferment glc, xyl or mixtures (100

g/L total sugars) in 48 h

Yield above 90% of the theoretical

Some metabolic evolution work was

performed to contend with the effects of pfl

interruption.

Generalized Process

Lignocellulose Milling

Hemicellulose Hydrolysis

Diluted Acid Treatment

Enzymatic Hydrolysis

& Glc Fermentation

Fermentation

(pentoses)

Distillation

Water Elimination

Organic Fuel

(Steam)

Recombinant

Microorganisms

Ethanol Producers

Hemicellulose

Syrup

CO

2

CO

2

Solids

Lignin

Cellulose &

Lignin

Cellulases

Diluted Ethanol (>40 g/L)

Ethanol 95%

Etanol 100%

Detoxification

Generate a

Mature Technology

Martnez et al. 2006

SCB

Production Potential with Sugar Cane

Base 100 Ton/Ha

Cane syrups: 7,500 L/Ha

Bagasse (300 kg/Ton, 50% humidity)

5,500 L/Ha

Syrups + Bagasse

13,000 L/Ha

+ Stover

300 kg/Ton, ~20% humidity

+ 7,000 L/ha

~ 20,000 L/Ha

Wood

Corn Stover

Bagasse

- Sugar Cane

- Agave

Lumber

Paper

Any lignocellulosic material, biomass from semi-arid areas

Sources

Fast Growth Grasses

Bio-Ethanol Activities at the IBt - UNAM

The Biotechnology Institute has been

involved in the research project since

1999.

It has a fermentation pilot plant based in

100 and 350 liters fermentors.

We had demonstrated the generation of

fermentable sugars using thermohemical

and enzymatic hydrolysis at laboratory

and pilot plant scale.

We have develop (and patented) bacterial

strains with the capacity to ferment all

sugars present in hydrolyzates with

conversions yields above 90% of the

theoretical and with volumetric

productivities reaching 1 g/L/h.

Actual research focus in:

Other raw materials

Improve and integrate a process

Cost reduction

0 24 48 72 96

0

10

20

30

40

50

0.0

0.2

0.4

0.6

0.8

1.0

Time (h)

E

t

h

a

n

o

l

(

g

/

L

)

E

t

h

a

n

o

l

(

m

o

l

e

s

/

L

)

Technological goals

1. Many opportunities remains to optimize ethanologenic biocatalyst

2. Raw materials (lignocellulose) is different for each country or

region. So process development is case specific.

3. Thermochemical (pre-treatments and distillation) need to be

energy efficient

4. Enzymatic hydrolysis of cellulose needs to be optimized

Wyman. Trends in Biotechnol. 2007.

My vision:

Politics are very important. Biomass production is

fundamental. We need to avoid competence with food

and feed, and take care of land usage. Sustainable

methodologies are essential for all the chain process.

BUT DEVELOPING COUNTRIES ALSO CAN DEVELOP

THEIR OWN TECHNOLOGIES, WE DO NOT NEED TO

WAIT FOR THE BIG COMPANIES TO DEVELOP THEM

AND LATER DEPEND ON THEM. BIOTECHNOLOGY IS

FUNDAMENTAL FOR THIS TECHNOLOGIES.

Alfredo Martnez 2006

!!Thanks!!

Acknowledgments

CONACyT Grants

SAGARPA 2004-C01-224

Estado de Morelos 2004-C02-48

PAPIIT DGAPA - UNAM

I N220908-3

Collaborations

Instituto de Biotecnologa

University of Florida

Students

Questions

Production Cost and Energy Balance

Science 2007

Fuel Ethanol (dol/gal) Pesos/Liter

NREL-DOE Corn Stover: 1.44 4.20

NREL-California Lumber: 1.07 3.10

Estimated Production Costs

Brazil Prices March 2005

($/ L) (R/ L)

Alcohol: 5.9 1.3

Gasoline: 10.4 2.3

Sugar Cane Bagasse Mexico

Production Cost $3.7 / Liter

From Molasses (2001)

Production Cost $2.3 /Liter

Cabrera, Gmez & Quintero 2001

Bio-ethanol: Mexico

Sugar Cane

Planta Sn. Juan Bautista

Tuxtepec (Tuxtepec, Oaxaca)

Planta Tecnol del Sureste S.A

de C.V (Huehuetan, Chiapas)

Ingenio La Gloria (Veracruz)

Corn

Planta Mex-Starch (Sinaloa)

Planta Destilmex (Navolato,

Sinaloa)

Sorgum

Bioenergticos Mexicanos

S.A.P.I. de C.V (Valle Hermoso,

Tamaulipas)

Cianobacterias

BioFields (Sonora

Lignocellulose

Planta Piloto IBt UNAM

BioEthanol

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Achieving Excellence Guide 3 - Project Procurement LifecycleDocument27 pagesAchieving Excellence Guide 3 - Project Procurement LifecycleMoath AlhajiriNo ratings yet

- Civil Service Commission upholds invalidation of 96 appointmentsDocument20 pagesCivil Service Commission upholds invalidation of 96 appointmentsKriszanFrancoManiponNo ratings yet

- University of Education: FreemasonryDocument41 pagesUniversity of Education: FreemasonryWaqar KhanNo ratings yet

- Appeal of Murder Conviction in Stabbing IncidentDocument2 pagesAppeal of Murder Conviction in Stabbing IncidentJona Carmeli CalibusoNo ratings yet

- English - Vocabulary - in - Use - Pre - Intermediate - and - Intermediate - Book 2Document2 pagesEnglish - Vocabulary - in - Use - Pre - Intermediate - and - Intermediate - Book 2Наталия БруслинецNo ratings yet

- Politics and Culture Essay PDFDocument6 pagesPolitics and Culture Essay PDFapi-267695090No ratings yet

- Yalit - Beowulf AnnotatedDocument6 pagesYalit - Beowulf Annotatedapi-25329773450% (2)

- Leave Travel Concession PDFDocument7 pagesLeave Travel Concession PDFMagesssNo ratings yet

- Build - Companion - HarrimiDocument3 pagesBuild - Companion - HarrimiandrechapettaNo ratings yet

- The Canterbury Tales Is A Collection of Stories Written in Middle English byDocument25 pagesThe Canterbury Tales Is A Collection of Stories Written in Middle English byyoonglespianoNo ratings yet

- EXAMENUL DE BACALAUREAT 2008 Proba Orală La Limba EnglezăDocument2 pagesEXAMENUL DE BACALAUREAT 2008 Proba Orală La Limba EnglezăMar ConsNo ratings yet

- MkgandhiDocument220 pagesMkgandhiDebarpit TripathyNo ratings yet

- Lec 2 IS - LMDocument42 pagesLec 2 IS - LMDương ThùyNo ratings yet

- Logistics AssignmentDocument15 pagesLogistics AssignmentYashasvi ParsaiNo ratings yet

- Dunn, David Christopher vs. Methodist Hospital (Court 189)Document1 pageDunn, David Christopher vs. Methodist Hospital (Court 189)kassi_marksNo ratings yet

- Föreställningar Om Klass Och Kön I Arbetsförmedlingens Yrkesbeskrivningar?Document28 pagesFöreställningar Om Klass Och Kön I Arbetsförmedlingens Yrkesbeskrivningar?Filozófus ÖnjelöltNo ratings yet

- Gantt Chart TemplateDocument3 pagesGantt Chart TemplateAamir SirohiNo ratings yet

- DONGAH GEOLOGICAL Company BrochureDocument64 pagesDONGAH GEOLOGICAL Company Brochuredongah_geologicalNo ratings yet

- Clinical Risk Factor For Preterm BirthDocument22 pagesClinical Risk Factor For Preterm BirthGabyBffNo ratings yet

- Universiti Kuala Lumpur Intra Management System: Unikl-ImsDocument16 pagesUniversiti Kuala Lumpur Intra Management System: Unikl-ImsAfnanFadlanBinAzmiNo ratings yet

- People vs. Aruta Case DigestDocument3 pagesPeople vs. Aruta Case DigestRhea Razo-Samuel100% (1)

- Fruits and Vegetables Coloring Book PDFDocument20 pagesFruits and Vegetables Coloring Book PDFsadabahmadNo ratings yet

- Annex D Initial Evaluation Results IER 2Document6 pagesAnnex D Initial Evaluation Results IER 2ruffaNo ratings yet

- Apg-Deck-2022-50 - Nautical Charts & PublicationsDocument1 pageApg-Deck-2022-50 - Nautical Charts & PublicationsruchirrathoreNo ratings yet

- UntitledDocument12 pagesUntitledSolomon JoysonNo ratings yet

- Location - : Manhattan, NyDocument15 pagesLocation - : Manhattan, NyMageshwarNo ratings yet

- Preventive MaintenanceDocument2 pagesPreventive Maintenancedoctor_mumairkNo ratings yet

- Toward Plurality in American Acupuncture 7Document10 pagesToward Plurality in American Acupuncture 7mamun31No ratings yet

- Procter &gamble: Our PurposeDocument39 pagesProcter &gamble: Our Purposemubasharabdali5373No ratings yet

- B2B AssignmentDocument7 pagesB2B AssignmentKumar SimantNo ratings yet