Professional Documents

Culture Documents

Agitation and Mixing of Fluid

Uploaded by

Anonymous METdvGewCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Agitation and Mixing of Fluid

Uploaded by

Anonymous METdvGewCopyright:

Available Formats

AGITATION AND MIXING OF

FLUIDS

Purpose of agitation:

- intensification of transport processes in agitated batch (heat and mass transfer)

- preparation of materials of required properties (suspension, emulsion)

Examples of industrial applications:

- blending of two miscible liquids as ethyl alcohol and water

- dissolving solids in liquids, such as salt in water

- dispersing a gas in a liquid as fine bubbles, such as oxygen from

air in a suspension of microorganisms for fermentation or for the

activated sludge process in waste treatment

- liquid-liquid dispersion, such as dispersion of pigment in solvents

- suspending of fine solid particles in a liquid, as in catalytic

hydrogenation of a liquid

- agitation of the fluid to increase heat tranfer between the fluid and

a coil or jacket in the vessel wall

- mechanical mixing (rotating, vibrating)

- hydraulic mixing

- pneumatic mixing

- pipeline mixing (turbulent flow, static mixer)

Method of mixing fluids

A mechanical mixing using

turbines

B mechanical mixing using

blade impellers

C hydraulic mixing

D pneumatic mixing with

stationary inputs

E pneumatic mixing with

automatic regulation

F hydraulic mixing with

antifoaming shower

Pipeline mixing Reynolds experiments

Paul, E. L., Atiemo-Obeng, V. A., Kresta, S. M.:

Handbook of industrial mixing: science and

practice. Canada: Wiley-Interscience, 2003,

1377 p. ISBN 0-471-26919-0

a axial-flow pattern, baffled vessel, b radial-flow pattern, baffled vessel,

c tangential-flow pattern, unbaffled vessel

Flow in agitated batch

Equipment for mechanical mixing

Design layout of mixing equipments

A B C

A Centrally placed impeller in bafled vessel, B Side-entring propeller, C Agitator

with draught tube

A B

A Equipment with a drive at the top, B Equipment with a drive at the bottom

Mechanical seal

Close clearance agitator High-speed impeller

Design layout of agitators

Maine type of close clearance agitators

No. Layout of agitator Name T/d

Geometrical

parameters

1

Anchor (paddle)

agitator

CVS 69 1014

1,11

8 , 0 / = d h

v

12 , 0 / = d h

055 , 0 /

2

= d H

2

Helical-screw agitator

with draught tube

CVS 69 1028

2

5 , 1 / = d h

v

1 / = d s

1 , 1 / = d D

15 , 1 / = ' D H

3

Eccentrically placed

helical-screw agitator

2

5 , 1 / = d h

v

25 , 0 /

2

= d H

1 / = d s

02 , 0 / = T c

No. Layout of agitator Name T/d

Geometrical

parameters

4

Helical-ribbon

agitator

CVS 69 1029

1,05

1 / = d h

v

1 / = d s

1 , 0 / = d h

5

Leaf agitator

CVS 69 1016

2 1 / = d h

6

Multi-stage agitator 2

2 , 0 / = d h

65 , 1 / = d h

v

= 45 o

= 45 |

02 , 0 / = T c

175 , 0 /

2

= d H

Main type of high-speed impellers

No. Layout of impeller Name T/d

Geometrical

parameters

1

Six-blade turbine

with disk (Ruschton

turbine)

CVS 69 1021

3 4

2 , 0 / = d h

25 , 0 / 1 = d

75 , 0 /

1

= d d

6 blades

2

Six-blade open

turbine

3 4

2 , 0 / = d h

6 blades

3

Pitched six-blade

turbine with pitch

angle 45

CVS 69 1020

3 4

20 , 0 / = d h

= 45 o

No. Layout of impeller Name T/d

Geometrical

parameters

4

Pitched three-blade

turbine with pitch

angle 45

CVS 69 1025.3

3 4

2 , 0 / = d h

= 45 o

5

Propeller

CVS 69 1019

3 4

1 / = d s

22 , 0 / = d h

4 , 0 / = d R

16 , 0 /

1

= R R

6

High shear stress

impeller

CVS 69 1038.1, .2

2 4

1

st

variant

1 , 0 / = d h

8 , 0 /

2

= d d

2

nd

variant

075 , 0 / = d h

85 , 0 /

2

= d d

Power consumption of agitator

Characteristics of mixing system

( ) Re f Po =

5 3

d n

P

Po

2

nd

Re =

Re

A

Po =

creeping

flow

turbulent

flow

transition

zone of flow

baffled

vessel

unbaffled

vessel

. const B Po = =

Power characteristics of close clearance agitators

1 anchor agitator (CVS 69 1014), 2 helical-screw agitator with draught tube (CVS

69 1028), 3 eccentrically placed helical-screw agitator, 4 helical-ribbon agitator

(CVS 69 1029), 5 leaf agitator (CVS 60 1016), 6 multi-stage agitator

Power characteristics of high-speed impellers operated in baffled vessel

1 six-blade turbine with disk (Ruschton turbine) (CVS 69 1021), 2 six-blade open

turbine, 3 pitched six-blade turbine with pitch angle 45 (CVS 69 1020),

4 Pitched three-blade turbine with pitch angle 45 (CVS 69 1025.3), 5 propeller

(CVS 60 1019), 6a,b high shear stress impeller (CVS 69 1038.1.2)

Blending effect of agitator

Homogenization of miscible liquids: - due to recirculation flow (convective diffusion)

- due to turbulent flow (turbulent diffusion)

- due to molecular diffusion

( ) Re f t n t

m

= =

-

. konst t n t

m

= =

-

. konst t n t

m

= =

-

During homogenization (or blending) of miscible liquids are compensated temperature and

concentration differences in agitated batch.

Homogenization characteristics of agitators

1 helical-screw agitator with draught tub (CVS 69 1028), 2 eccentrically placed

helical-screw agitator, 3 helical-ribbon agitator (CVS 69 1029), 4 eccentrically

placed multi-stage agitator, 5 anchor agitator (CVS 69 1014), 6 six-blade turbine

with disk (Ruschton turbine) (CVS 69 1021)

( ) Re f t n t

m

= =

-

1 roubov mchadlo (CVS 69 1028), 2 roubov mchadlo umstn excentricky,

3 psov mchadlo (CVS 69 1029), 4 tynsobn lopatkov mchadlo umstn

excentricky, 5 kotvov mchadlo (CVS 69 1014), 6 turbnov mchadlo (CVS 69

1021), 7 estilopatkov mchadlo (CVS 69 1020), 8 tlopatkov mchadlo (CVS

69 1025.3)

m

t P E =

Impellers for dispersing of gas in liquid

Impeller power consumption for gas liquid dispersing

|

|

.

|

\

|

=

3

nd

V

f

P

P

g g

Mixing of suspension

Impeller power consumption for mixing of suspension

( ) Re f Po =

5 3

d n

P

Po

su

su

nd

Re

2

=

( )

l v s v su

c c + = 1

J ust-suspended impeller speed

0,1

1

10

0,0001 0,001 0,01 0,1

D/T

F

r

'

0,025

0,05

0,1

0,15

0,2

c

v

c

T

D

C r F

|

.

|

\

|

=

'

A

=

'

g

d n

r F

2

( )

v

c B A C exp =

v

c c | o + =

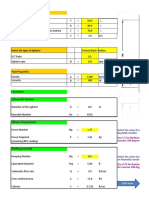

EXAMPLE: Blending efficiency of impellers

Select type of high-speed impeller with minimum energetic requirements

for continual blending (homogenization) of two miscible liquids A + B ( = 5

mPas, = 1100 kgm

-3

) with flow rate of mixture 10 ls

-1

. For suitable degree

of homogenization must be residence time of liquids in equipment 5 x longer

than blending time. Mixing equipment has standard geometrical configuration

(baffled cylindrical vessel with diameter T = 1200 mm, T/d = 3.3; H

2

/d = 1, H/T

= 1 ).

Dimensionless blending time of high-speed impellers in turbulent flow regime

Type of impeller T/d H

2

/d nt

m

Six-blade turbine with disk (Ruschton

turbine), CVS 69 1021

3.3 1 51.8

Pitched six-blade turbine with pitch

angle 45, CVS 69 1020

3.3 1 53.1

Pitched three-blade turbine with pitch

angle 45, CVS 69 1025.3

3.3 1 60.5

You might also like

- Boiling: Research and AdvancesFrom EverandBoiling: Research and AdvancesYasuo KoizumiNo ratings yet

- Chapter 6-Agitated LiquidDocument48 pagesChapter 6-Agitated LiquidAhmad SiddiqNo ratings yet

- Agitaionandmixing 160117143824 PDFDocument30 pagesAgitaionandmixing 160117143824 PDFMESCIA EngineersNo ratings yet

- B635 Tank Mixing Eductors PDFDocument12 pagesB635 Tank Mixing Eductors PDFivanmatijevicNo ratings yet

- Agitator Power Requirement and Mixing Intensity CalculationDocument26 pagesAgitator Power Requirement and Mixing Intensity CalculationChemical Engineering100% (2)

- Agitator and MixerDocument6 pagesAgitator and MixerCik MinnNo ratings yet

- Stirred Tank CFD SimulationDocument49 pagesStirred Tank CFD SimulationAdhe ParamitaNo ratings yet

- MixingDocument20 pagesMixingadityafortranNo ratings yet

- CHE 503 Agitation LiquidsDocument33 pagesCHE 503 Agitation LiquidsNurtasha Atikah100% (1)

- Mixing With Helical Ribbon AgitatorsDocument9 pagesMixing With Helical Ribbon AgitatorsWilson Agudelo CatañoNo ratings yet

- MixingandAgitation93851 10Document18 pagesMixingandAgitation93851 10Eugenio Díaz HenríquezNo ratings yet

- ServiceKitsForSPAndAgitators E10046 PDFDocument8 pagesServiceKitsForSPAndAgitators E10046 PDFgilbertogatoNo ratings yet

- Rheology: Dairy Processing Handbook/chapter 3Document8 pagesRheology: Dairy Processing Handbook/chapter 3Margo SmithNo ratings yet

- WCB Waukesha U1 Instruction Manual PDFDocument106 pagesWCB Waukesha U1 Instruction Manual PDFJojaca Xencillo CaqueNo ratings yet

- Assignment Fermentation (Agitator)Document8 pagesAssignment Fermentation (Agitator)izzat ezmanNo ratings yet

- How To Scale-Up: M Miix Xiin NG G P Prro Occe Es Ss Se Es S Iin NDocument9 pagesHow To Scale-Up: M Miix Xiin NG G P Prro Occe Es Ss Se Es S Iin NOdst Ovac100% (1)

- More Solutions PDFDocument59 pagesMore Solutions PDFleopardo7No ratings yet

- Froude Number in Mixing PDFDocument4 pagesFroude Number in Mixing PDFrinuakNo ratings yet

- Impeller Design For Mixing of SuspensionsDocument16 pagesImpeller Design For Mixing of SuspensionsFaycel OuerdienNo ratings yet

- Reactors Ppt4Document55 pagesReactors Ppt4DanishNo ratings yet

- Reactor DesignDocument27 pagesReactor Designcheckmeout803100% (3)

- Agitation and MixingDocument9 pagesAgitation and MixingFaraj Al-Taher100% (3)

- Flow Characteristics in Mixers Agitated by Helical Ribbon Blade ImpellerDocument15 pagesFlow Characteristics in Mixers Agitated by Helical Ribbon Blade Impellerkalyan555No ratings yet

- Review of The Main Mathematical ModelsDocument37 pagesReview of The Main Mathematical Modelsgrincheu70No ratings yet

- MixingDocument9 pagesMixingDiana M P100% (1)

- Agitation and Mixing of Liquids: Unit IVDocument54 pagesAgitation and Mixing of Liquids: Unit IVmehtab hussain100% (3)

- Mixing Studies of Non-Newtonian Uids in An Anchor Agitated VesselDocument10 pagesMixing Studies of Non-Newtonian Uids in An Anchor Agitated VesselJose Davi Rodrigues Silva UFC100% (1)

- SpargerDocument14 pagesSpargerNishevitha GangatharanNo ratings yet

- 2015-Tackling Difficult Mixing ProblemsDocument8 pages2015-Tackling Difficult Mixing Problemsjuan sepulvedaNo ratings yet

- Inquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteDocument5 pagesInquiry - Sitemap - E-Mail: Dispersing, Suspending, Emulsifying & Homogenizing Technik For Liquid and PasteCik MinnNo ratings yet

- Silverson Lab MixerDocument6 pagesSilverson Lab MixerSandip MehtaNo ratings yet

- PMPa006 A Comparison of Extenders in Semi-Gloss Emulsion Paints June 2009Document2 pagesPMPa006 A Comparison of Extenders in Semi-Gloss Emulsion Paints June 2009Dian Pires100% (2)

- Membrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngasDocument10 pagesMembrane Gas-Solvent Contactor Trials of CO2 Absorption From SyngascurlychemNo ratings yet

- Process Mixer SelectionDocument5 pagesProcess Mixer Selectionhyde2520015754No ratings yet

- 6 Crystallizer Design and Operation1Document22 pages6 Crystallizer Design and Operation1Shweta ChaudhariNo ratings yet

- Mixing-And-Processing-Of-Liquids-And-Solids 18.1Document43 pagesMixing-And-Processing-Of-Liquids-And-Solids 18.1vane-16100% (2)

- Calculate Outside Heat Transfr Coeff. For JacketDocument6 pagesCalculate Outside Heat Transfr Coeff. For JacketSuryakant RanderiNo ratings yet

- Pages From Chapter 10 Mixing and AgitationDocument4 pagesPages From Chapter 10 Mixing and AgitationDaniel PadillaNo ratings yet

- Agitation of Non-Newtonian FluidsDocument8 pagesAgitation of Non-Newtonian FluidsandresjypNo ratings yet

- Thermascrew: Advanced FeaturesDocument3 pagesThermascrew: Advanced FeaturesFLIRIDIR1678No ratings yet

- Heat Transfer in Agitated VesselsDocument33 pagesHeat Transfer in Agitated VesselsGanesh.Mahendra100% (1)

- Crystallizer Design PDFDocument20 pagesCrystallizer Design PDFMelwyn FranciscoNo ratings yet

- Agitiation and Mixing Liquids To StudentsDocument30 pagesAgitiation and Mixing Liquids To StudentsAkshay dev100% (1)

- Agitator Design: HP CalculationDocument32 pagesAgitator Design: HP CalculationJose Heli Vallejos CoronadoNo ratings yet

- Fi-103 Agitator PDFDocument18 pagesFi-103 Agitator PDFuttam prabhuNo ratings yet

- Mastering Mixing FundamentalsDocument82 pagesMastering Mixing FundamentalsArturo K. Cabras Jr.No ratings yet

- The Effect of Particle Size Distributions On The Microstructural Evolution During SinteringDocument12 pagesThe Effect of Particle Size Distributions On The Microstructural Evolution During SinteringGusti EricsandraNo ratings yet

- Agitating VesselDocument37 pagesAgitating VesseldigecaNo ratings yet

- Pack RYTDocument41 pagesPack RYTGonzalo Alonso QuintanaNo ratings yet

- Lightnin Impeller Technology PDFDocument8 pagesLightnin Impeller Technology PDFNaila TheExplore HorisonNo ratings yet

- KCA T19 Centrifuge SurveyDocument8 pagesKCA T19 Centrifuge SurveyБен ГазиNo ratings yet

- Perancangan Alat PengadukDocument29 pagesPerancangan Alat PengadukIrpan RomadonaNo ratings yet

- Performance of Radial Piston Type Reciprocating Expander For CO2 Refrigeration CycleDocument9 pagesPerformance of Radial Piston Type Reciprocating Expander For CO2 Refrigeration CycleAbe WaNo ratings yet

- KSB Centrifugal Pump DesignDocument47 pagesKSB Centrifugal Pump Designggrapsas100% (3)

- 750HP DW PDFDocument6 pages750HP DW PDFilkerkozturkNo ratings yet

- Producción de BombaDocument7 pagesProducción de BombacaroNo ratings yet

- Francis Turbine Test 1. TurbinesDocument5 pagesFrancis Turbine Test 1. TurbinesSerhat GüvenNo ratings yet

- Taller Gestiondecostosenplantasparteiiidiap101 126Document13 pagesTaller Gestiondecostosenplantasparteiiidiap101 126NolandNo ratings yet

- Swirl Decay in The Gas-Liquid Two-Phase Swirling Flow Inside A CircularDocument28 pagesSwirl Decay in The Gas-Liquid Two-Phase Swirling Flow Inside A CircularMuhammad RonaldoNo ratings yet

- KSB B: Deep Well Turbine Pump BDocument36 pagesKSB B: Deep Well Turbine Pump BKishore Krishna0% (1)