Professional Documents

Culture Documents

High Tech Tool Catalog

Uploaded by

Madirley PimentaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Tech Tool Catalog

Uploaded by

Madirley PimentaCopyright:

Available Formats

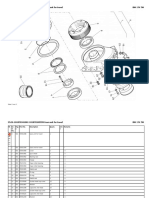

Carbide inserts

Tool holders

Boring/Threading bars

Quick-Change bars and chuck jaws

High Tech Tool, Inc.

High Tech Tool, Inc. - Online Catalog

Metal Cutting Tools

To Order Call: 713-641-2303 Page 2

Standard Products:

A) Carbide Inserts

High Tech stocks finished, and semi-

finished blanks, to allow prompt deliv-

ery of all types of threading and groov-

ing inserts, either coated or uncoated.

A substantial stock of API threading

and grooving inserts is also maintained.

B) Toolholders

High Tech maintains one of the most

modern and complete toolholder manu-

facturing facilities in the region.

Our toolholders are designed and

manufactured utilizing the Carboly NL

lock pin* along with a low profile clamp

as standard features.

Holders and bars are made of medium

carbon alloy steel and heat treated to

42 Rockwell C hardness.

C) Replaceable heads & bars

High Tech replaceable boring, thread-

ing and grooving heads provide the

maximum in flexibility and economy

without sacrificing rigidity.

Bars will accept right or left hand heads

and either is available with coolant pro-

vision internally.

Carbide and heavy metal bars are also

available.

D) Quick Change tooling

Share tooling among different ma-

chines and improve rigidity and reduce

setup times with High Tech Quick

Change bars and adapters. Improve

your part holding capabilities and re-

duce setup times with High Tech Quick

Change chuck jaws and jaw inserts.

Catalog I.D. Numbers

Standard Inserts API Threading &

Grooving Inserts

CNGA SNMP API *

CNMA SNU ANMA- * P BUT

CNMG SPG TNMA- * P PITT

CNMP SPU TNMA- * P X-LINE

CPG TNG TNMA- * RD

DNGA TNMA TNMA H90

DNMG TNMG TNMA NT

DNMP TNMP TNMA NV

DCMT TCMT

RNMA TNU TNMA SL H90

RNMG TPG TNMA V *

SNG TPU TPMA NG

SNMA VNGA LT V *

SNG TPU TPMANG

SNMA VNGA LT V *

SNMG VNMA LT 43 * RD

SCMT VNMP LT 43 NV

V- 84

V- 85

Toolholders

APISMR-L

MDJNR-L

MDPNN

MTHLR-L

MTHOR-L

MTJNRS-LS

MTVOR-L

MTVORO-LO

MTZOL

MVINN

MVJNR-L

MVLNR-L Toolholders can be furnished

Qualified for N/C applications

MVTNR-L

Replaceable Heads & Bars

Threading & Grooving

HTHLR

HTHOR

HTHPR

HTNER Tech Loc threader

Style DG Face groover

Style G ID/OD groover

Boring & Turning

HTENR

HTFNR

HTJNR

HDQNR

HSKNR

HSDNR

HDRNR

HCLNR

Style DP Double pocket f/CNMG

HCKNR

Profiling

HDJNR

HVJNR

HDPNR

High Tech Tool, Inc.

High Tech Tool, Inc. Page 3 CONTENTS

Catalog Number Page

Grades 4

TNMA-NG 5

TPMA-NG 5

TNMA-NV 6

TNMA-NT 6

TNMA-8RD 6

TNMA-10RD 6

LT-43 8RD 7

LT-43 10RD 7

LT-43 5P BUT 7

Catalog Number Page

LT-43 8P BUT 7

LT-43 NV 7

LT-54 V-0.038R 7

LT-54 V-0.040R 7

LT-54 V-0.050R 7

TNMA-V-0.038R 7

TNMA-V-0.040R 7

TNMA-V-0.050R 7

TNMA-H90 8

TNMA-5P BUT 8

Catalog Number Page

TNMA-8P BUT 8

TNMA-5P VAM 9

TNMA-6P VAM 9

TNMA-8P VAM 9

TNMA-5P X-LINE 9

TNMA-6P X-LINE 9

TNMA-8P/6P/5P FOX-K 9

TNMA-8P/5P NKK 9

APIP 10

A.P.I. Groove Details 10

INSERTS - Page 4

TOOL HOLDERS - Page 11

Catalog Number Page

MTVORO-LO 12

MTVOR-L 13

MTHOR-L 14

MTZOL 15

REPLACEABLE HEADS - Page 23

Catalog Number Page

RHB 24

RHBT 24

HTHLR-L 25

HTHOR-L 26

HTHPR-L 27

STYLE TN f/Tech Loc 27

STYLE DG V-Bottom Anvil 28

STYLE G V-Bottom Anvil 28

HTENR-L 29

Catalog Number Page

HTFNR-L 29

HTJNR-L 30

HDQNR-L 30

HSKNR-L 31

HSDNR-L 31

HDRNR-L 32

HCLNR-L 32

HCKNR-L 33

Style DP double pocket 33

Catalog Number Page

HDQCR-L 34

HDJNR-L 34

HVJNR-L 35

HDPNR-L 35

Catalog Number Page

MTHLR-L 16

APIHPR-L 17

APIHPR-L AH Heavy Duty 18

APISMR 19

Catalog Number Page

RGH 20

MVQNRO 21

MVQNR 21

MVTNR-L 22

HIGH TECH QUICK CHANGE TURRET TOOLING - Page 36

HIGH TECH QUICK CHANGE CHUCK JAWS - Page 38

To Order Call: 713-641-2303 Page 4 INSERTS

High Tech Tool Carbide Grades

High Tech Tool offers many different grades of carbides

and coatings. We solicit your inquiries for any grade de-

sired but offer the following as standard (and generally

in stock);

Grade Machining Applications

15 A high strength carbide for low speed machining non-ferrous and high

temperature alloys.

16 For semi-finishing, non-ferrous alloys at high temperature and moder-

ate speeds and chip loads.

18 A general purpose grade for machining cast iron non-ferrous and high

temperature alloys.

50 A general purpose grade used for machining at lower surface speeds

and for interrupted cuts on steel.

55 A general purpose steel cutting grade designed for semi-finishing and

finishing at moderate speeds.

65 A high titanium grade carbide used where edge buildup is a problem

and good cosmetics is required. Can be used at moderate to high

speeds on carbon and alloy steels.

70 A finishing grade for steel designed for high cutting temperatures at

higher speeds.

Uncoated Grades

High Tech Tool also offers coated grades for applica-

tions where edge wear is a factor;

Grade Machining Applications

TN-16 Titanium nitride coated grades for turning applications on steel at

higher speeds.

TN-50 Titanium nitride coated general purpose grade for machining steel

at moderate to high speeds.

TN-55 Titanium nitride coated finishing grade for steel

CVD Coated Grades

Grade Machining Applications

TPN-100 Superior tough grade for threading where chip interference is a

problem in steel.

TPN-102 Finishing grade for threading steel. Less resistant to chipping but

superior wear resistance.

TPN-115 General purpose coated grade for threading steel.

PVD Coated Grades

TPN-120 Similar to TPN-115 but more wear resistant.

Grade Machining Applications

ALN-200 Our toughest threading grade with superior edge strength. Suit-

able for plain steel as well as chrome and high temperature al-

loys.

ALN-202 Similar to ALN-200 except more abrasion resistance.

ALN-205 Finishing grade for high temperature alloys.

Aluminum Nitride Coated Grades

ALN-215 General purpose grade for steel.

ALN-220 Finishing grade for steel.

High Tech Tool, Inc.

High Tech Tool, Inc. Page 5

GROOVING

STYLE TNMA

0 RAKE, RIGHT HAND AND LEFT HAND

INSERTS

Catalog Number Dimensions

Right Hand Left Hand I.C.

W*

Min. Max.

TNMA 32NG-R TNMA 32NG-L 3/8 .125 1/16 1/8

TNMA 43NG-R TNMA 43NG-L 1/2 .187 1/8 3/16

TNMA 54NG-R TNMA 54NG-L 5/8 .250 3/16 1/4

TNMA 64NG-R TNMA 64NG-L 3/4 .250 3/16 1/4

TNMA 66NG-R TNMA 66NG-L 3/4 .375 3/16 3/8

Thk.

GROOVING

STYLE TPMA

5 & 10 POSITIVE RAKE, RIGHT HAND

AND LEFT HAND.

* W Dimension must be specified when ordering.

Style TNMC (inserts with corner radii), or full radius inserts are available.

Inserts with W min. less than shown available on a quotation basis only.

Catalog Number Dimensions

Right Hand Left Hand I.C. Thk.

W*

Min. Max.

TPMA 32NG-R TPMA 32NG-L 3/8 .125 5 1/16 1/8

TPMA 43NG-R TPMA 43NG-L 1/2 .187 5 1/8 3/16

TPMA 54NG-R TPMA 54NG-L 5/8 .250 5 3/16 1/4

TPMA 64NG-R TPMA 64NG-L 3/4 .250 5 3/16 1/4

TPMA 66NG-R TPMA 66NG-L 3/4 .375 5 3/16 3/8

R

TPMA 32NG-R 10 TPMA 32NG-L 10 3/8 .125 10 1/16 1/8

TPMA 43NG-R 10 TPMA 43NG-L 10 1/2 .187 10 1/8 3/16

TPMA 54NG-R 10 TPMA 54NG-L 10 5/8 .250 10 3/16 1/4

TPMA 64NG-R 10 TPMA 64NG-L 10 3/4 .250 10 3/16 1/4

TPMA 66NG-R 10 TPMA 66NG-L 10 3/4 .375 10 3/16 3/8

* W Dimension must be specified when ordering.

Style TPMC (inserts with corner radii), or full radius inserts are available.

Inserts with W min. less than shown available on a quotation basis only

Style TPMA NG 10 inserts are for use only with style HTHPR heads. See

page 27.

To Order Call: 713-641-2303 Page 6

60 V THREADING

STYLE TNMA

Catalog Number

Dimensions

I.C. Thk.

TNMA 32NV 3/8 .125

TNMA 43NV 1/2 .187

TNMA 54NV 5/8 .250

TNMA 64NV 3/4 .250

TNMA 66NV 3/4 .375

Styles TNMC, TPMA & TPMC available upon request.

ACME THREADING

STYLE TNMA

Catalog Number

Dimensions

I.C. Thk.

TNMA 32NT 3/8 .125

TNMA 43NT 1/2 .187

TNMA 54NT 5/8 .250

TNMA 64NT 3/4 .250

TNMA 66NT 3/4 .375

Pitch *

6P thru 16P

4P thru 16P

3P

3P

2P

*Must specify general purpose or stub, and pitch.

Styles TNMC, TPMA, TPMC & inserts with modified

pitch acme available upon request.

API 8RD. AND 10RD. THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

Catalog Number *

Dimensions

I.C. Thk.

TNMA 43 8RD 1/2 .187

TNMA 43 10RD 1/2 .187

TNMA 54 8RD 5/8 .250

TNMA 54 10RD 5/8 .250

*Specify internal or external when ordering.

INSERTS

High Tech Tool, Inc.

High Tech Tool, Inc. Page 7

API THREADING

STYLE LT

INTERNAL AND EXTERNAL

*Catalog Number

Dimensions

I.C. Thk.

LT 43 8RD. 1/2 3/16

LT 43 10RD. 1/2 3/16

LT 43 5P. BUT 3/4 TPF 1/2 3/16

LT 43 5P BUT 1 TPF 1/2 3/16

LT 43 8P BUT 3/4 TPF 1/2 3/16

API Connection Size Pitch

8RD. CASING & TUBING 8

10RD. CASING & TUBING 10

4-1/2 - 13-3/8 BUT CASING 5

16 AND LARGER BUT CASING 5

2-3/8 - 4-1/2 BUT TUBING 8

LT 43 NV 60 V-THD 8P & FINER 8 1/2 3/16

LT 54 V-0.038R 2 TPF NC-23 - NC-50 4 5/8 1/4

LT 54 V-0.038R 3 TPF NC-56 - NC-77 4 5/8 1/4

LT 54 V-0.040R 3 TPF 2-3/8 - 4-1/2 REG. 5 5/8 1/4

LT 54 V-0.050R 2 TPF 6-5/8 REG. 4 5/8 1/4

LT 54 V-0.050R 3 TPF 5-1/2, 7-5/8, 8-5/8 REG. 4 5/8 1/4

H-90 and other special thread forms available on request..

Internal, full topping form shown.

API THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

*Catalog Number API Connection Size Pitch

Dimensions

I.C. Thk.

TNMA 55 V-0.038R 2 TPF NC-23 - NC-50 4 5/8 .312

TNMA 55 V-0.038R 3 TPF NC-56 - NC-77 4 5/8 .312

TNMA 55 V-0.040R 3 TPF 2-3/8 - 4-1/2 REG. 5 5/8 .250

TNMA 55 V-0.040R 3 TPF 2-3/8 - 4-1/2 REG. 5 5/8 .312

TNMA 55 V-0.050R 2 TPF 6-5/8 REG. 4 5/8 .312

TNMA 55 V-0.050R 3 TPF 5-1/2, 7-5/8 & 8-5/8 REG. 4 5/8 .312

*Specify internal or external when ordering.

*Catalog Number API Connection Size Pitch

Dimensions

I.C. Thk.

TNMA 54 V-0.038R NC-23 - NC-77 4 5/8 .250

TNMA 54 V-0.040 2-3/8 - 4-1/2 REG. 5 5/8 .250

TNMA 54 V-0.050 5-1/2 - 8-5/8 REG. 4 5/8 .250

The following API connections having obsolete thread form V-0.065 are

interchangeable with the V-0.038 2 TPF thread form per API specifica-

tion 7; 2-3/8 IF, 2-7/8 IF, 3-1/2 IF, 4 FH, 41F and 4-1/2 IF.

For API thread forms other than shown please inquire.

Certain API connections are interchangeable as follows; NC-26 and 2-

3/8 IF, NC-31 and 2-7/8 IF, NC-38 and 3-1/2 IF, NC-40 and 4 FH, NC-46

and 4 IF, NC-50 and 4-1/2 IF. See API specification 7; pp. 23-25.

Non-topping form for internal or external;

Full-topping form;

INSERTS

To Order Call: 713-641-2303 Page 8

H-90 THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

*Catalog Number Connection Size Pitch

Dimensions

I.C. Thk.

TNMA 55 H90 2 TPF 3-1/2 - 6-5/8 H-90 3-1/2 5/8 .312

TNMA 55 H90 3 TPF 7 - 8-5/8 H-90 3-1/2 5/8 .312

*Specify internal or external when ordering.

Full-topping form.

*Catalog Number Connection Size Pitch

Dimensions

I.C. Thk.

TNMA 54 H90 3-1/2 - 8-5/8 H-90 3-1/2 5/8 .250

TNMA 55 SL H90 2-5/8 - 3-1/2 Slim Line H-90 3 5/8 .312

Non-topping form for internal or external.

API 5P, BUTTRESS THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

*Catalog Number Casing Size

Dimensions

I.C. Thk.

TNMA 54 5P BUTT 3/4 TPF 4-1/2 - 13-3/8 5/8 .250

TNMA 54 5P BUTT 1 TPF 16 & Larger 5/8 .250

*Specify internal or external when ordering.

8P, BUTTRESS THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

*Catalog Number

Dimensions

I.C. Thk.

TNMA 43 8P BUTT 1/2 .187

*Specify internal or external when ordering.

INSERTS

High Tech Tool, Inc.

High Tech Tool, Inc. Page 9

VAM 5P, 6P & 8P THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

*Catalog Number Casing Size

Dimensions

I.C. Thk.

TNMA 54 5P VAM 5 5/8 .250

TNMA 54 6P VAM 6 5/8 .250

TNMA 43 8P VAM 8 1/2 .187

*Specify internal or external when ordering.

X-LINE 5P & 6P THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

*Catalog Number Casing Size

Dimensions

I.C. Thk.

TNMA 43 6P X-LINE 3/4 TPF 6 1/2 .187

TNMA 43 6P X-LINE 1-1/2 TPF 6 1/2 .187

TNMA 54 5P X-LINE 1-1/4 TPF 5 5/8 .250

*Specify internal or external when ordering.

INSERTS

FOX-K BUTTRESS THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

Catalog Number

Dimensions

I.C. Thk.

TNMA 43 8P FOX-K INT. 1/2 .187

TNMA 43 8P FOX-K EXT. 1/2 .187

TNMA 43 6P FOX-K INT. 1/2 .187

TNMA 43 6P FOX-K EXT. 1/2 .187

TNMA 54 5P FOX-K INT. 5/8 .250

TNMA 54 5P FOX-K EXT. 5/8 .250

Catalog Number

Dimensions

I.C. Thk.

TNMA 43 8P NKK INT. NK3SB 1/2 .187

TNMA 54 5P NKK INT. NK3SB 5/8 .250

TNMA 54 5P NKK EXT. NK3SB 5/8 .250

TNMA 43 8P NKK EXT. NK3SB 1/2 .187

NKK BUTTRESS THREADING

STYLE TNMA

INTERNAL AND EXTERNAL

To Order Call: 713-641-2303 Page 10

API RING GROOVING

STYLE APIP

PRECISION GROUND, POSITIVE RAKE

*Catalog

Number

A T B C Ref D R

APIP 086-3 .079 .187 .372 3/4 .015

APIP 131-3 .125 .187 .414 3/4 .031

APIP 162-3 .156 .187 .437 3/4 .031

APIP 203-3 .197 .187 .574 1 .031

APIP 203-3H .197 .187 .574 1 .203 .031

APIP 213-3 .206 .187 .574 1 .062

APIP 265-3 .260 .187 .630 1 .031

APIP 281-3 .277 .187 .646 1 ..031

APIP 300-3 .295 .187 .662 1 .031

APIP 329-3 .324 .187 .688 1 .031

APIP 355-3 .350 .187 .712 1 .031

APIP 420-3 .415 .187 .772 1 .031

APIP 284-3 .278 .187 .718 1-3/16 .250 .062

APIP 162-4 .156 .250 .730 1-1/2 .250 .031

APIP 203-4 .197 .250 .773 1-1/2 .250 .031

APIP 213-4 .206 .250 .773 1-1/2 .250 .062

APIP 265-4 .260 .250 .773 1-3/8 .250 .031

APIP 281-4 .277 .250 .773 1-5/16 .250 .031

APIP 300-4 .295 .250 .773 1-9/32 .250 .031

APIP 329-4 .324 .250 .773 1-7/32 .250 .031

APIP 355-4 .350 .250 .773 1-5/32 .250 .031

APIP 420-4 .415 .250 .773 1 .250 .031

HEAVY DUTY

APIP 061-3H .061 .187 .500 1.136 .150 .031

APIP 061-3 .061 .187 .349 3/4 .031

A B C* D A.P.I. Groove Number

7/32 5/32 .079 1/64 RX-201, 205

11/32 1/4 .125 1/32

R-19, 20, 22, 25, 29, 33, 36,

40, 43, 48, 52, 56, 59, 64, 68,

72, 76

3/8 1/4 .156 1/32 RX-210

15/32 5/16 .197 1/32

R-21, 23, 24, 26, 27, 30, 31,

34, 35, 37, 39, 41, 44, 45, 49,

53, 57, 61, 65, 69, 84, 92, 99;

RX-215

17/32 3/8 .206 1/16 R-28, 32, 46, 73, 85

21/32 7/16 .278 1/16

R-38, 50, 54, 62, 66, 77, 86,

87

25/32 1/2 .350 1/16

R-42, 47, 70, 74, 83, 88, 89,

93

29/32 9/16 .422 1/16 R-51, 58, 90

1-1/16 5/8 .525 3/32 R-63, 78

1-3/16 11/16 .597 3/32 R-55, 67, 71

1-5/16 11/16 .722 3/32 R-60, 75, 91

1-7/16 13/16 .741 3/32 R-79

.452 7/32 .260 1/32 BX-150

.468 7/32 .273 1/32 BX-151

.498 15/64 .295 1/32 BX-152

.554 17/64 .318 1/32 BX-153

.606 19/64 .345 1/32 BX-154

.698 21/64 .415 1/32 BX-155

GROOVE DETAILS FOR A.P.I. FLANGES

*Calculated at sharp corner with A, B & 23 at their means.

INSERTS

High Tech Tool, Inc.

High Tech Toolholders

Our toolholders are designed and manufactured in Houston utilizing the Carboloy NL lock pin. A low profile

clamp is a standard feature. Holders are made of medium carbon alloy steel and heat-treated to 40 Rockwell

C.

Our toolholders are available at standard prices and can be qualified for N/C applications at an additional

charge.

High Tech Tool, Inc. Page 11 TOOLHOLDERS

Catalog Number Dimensions Insert Size Parts

Right Hand Left Hand A B C D E F

V

Max.

I.C. Thk. Lock Pin Clamp

Clamp

Screw

(B.H.C.S)

MTVORO 8-3 MTVOLO 8-3 1/2 1/2 4-1/2 1-1/16 1-1/16 5/8 5/32 3/8 1/8 NL-33 C-1 10-32 x 5/8

MTVORO 10-3 MTVOLO 10-3 5/8 5/8 4-1/2 1-1/16 3/4

MTVORO 12-3 MTVOLO 12-3 3/4 3/4 6 1-1/16 7/8

MTVORO 16-3 MTVOLO 16-3 1 1 6 1-1/16 1-1/8

MTVORO 85-3 MTVOLO 85-3 1 1-1/4 7 1-1/16 1-1/4

MTVORO 12-4 MTVOLO 12-4 3/4 3/4 6 1-3/8 7/8 7/32 1/2 3/16 NL-44

MTVORO 16-4 MTVOLO 16-4 1 1 6 1-3/8 1-1/4 C-2 1/4-28 x 3/4

MTVORO 85-4 MTVOLO 85-4 1 1-1/4 7 1-3/8 1-1/4

MTVORO 86-4 MTVOLO 86-4 1 1-1/2 8 1-3/8 1-1/4

MTVORO 20-4 MTVOLO 20-4 1-1/4 1-1/4 7 1-3/8 1-1/2

MTVORO 24-4 MTVOLO 24-4 1-1/2 1-1/2 8 1-3/8 2

MTVORO 16-5 MTVOLO 16-5 1 1 6 1-9/16 1-1/4 9/32 5/8 1/4 NL-56

MTVORO 85-5 MTVOLO 85-5 1 1-1/4 7 1-9/16 1-1/4

MTVORO 86-5 MTVOLO 86-5 1 1-1/2 8 1-9/16 1-1/4

MTVORO 20-5 MTVOLO 20-5 1-1/4 1-1/4 7 1-9/16 1-1/2

MTVORO 24-5 MTVOLO 24-5 1-1/2 1-1/2 8 1-9/16 2

MTVORO 16-55 MTVOLO 16-55 1 1 6 1-9/16 1-1/4 9/32 5/8 NL-56

MTVORO 85-55 MTVOLO 85-55 1 1-1/4 7 1-9/16 1-1/4

MTVORO 86-55 MTVORO 86-55 1 1-1/2 8 1-9/16 1-1/4

MTVORO 20-55 MTVOLO 20-55 1-1/4 1-1/4 7 1-9/16 1-1/2

MTVORO 24-55 MTVOLO 24-55 1-1/2 1-1/2 8 1-9/16 2

MTVORO 20-56 MTVOLO 20-56 1-1/4 1-1/4 7 1-9/16 1-1/2 5/16 3/8

MTVORO 24-69 MTVOLO 24-69 1-1/2 1-1/2 7 1-9/16 1-1/2 9/32 1/2 NL-58L

MTVORO 16-66 MTVOLO 16-66 1 1 6 1-15/16 1-15/16 1-1/4 3/8 3/4 3/8 NL-66L C-3 5/16-24 x 1

MTVORO 85-66 MTVOLO 85-66 1 1-1/4 7 1-15/16 1-1/4

MTVORO 86-66 MTVOLO 86-66 1 1-1/2 8 1-15/16 1-1/4

MTVORO 20-66 MTVOLO 20-66 1-1/4 1-1/4 7 1-15/16 1-1/2

MTVORO 24-66 MTVOLO 24-66 1-1/2 1-1/2 8 1-15/16 2

MTVORO 20-69 MTVOLO 20-69 1-1/4 1-1/4 7 1-15/16 1-1/2 9/32

MTVORO 24-69 MTVOLO 24-69 1-1/2 1-1/2 8 1-15/16 2

5/16

STYLE V - TRIANGLE OFFSET SHANK

THREADING INSERTS: TNMA-NV, TPMA-NV, TNMA-NT AND TPMA-NT

GROOVING INSERTS: TNMA-NG AND TPMA-NG

To Order Call: 713-641-2303 Page 12 TOOLHOLDERS

High Tech Tool, Inc.

STYLE V - TRIANGLE

THREADING INSERTS: TNMA-NV, TPMA-NV, TNMA-NT AND TPMA-NT

GROOVING INSERTS: TNMA-NG AND TPMA-NG

Catalog Number Dimensions Insert Size Parts

Right Hand Left Hand A B C D E F

V

Max.

I.C. Thk. Lock Pin Clamp

Clamp

Screw

(B.H.C.S)

MTVOR 8-3 MTVOL 8-3 1/2 1/2 4-1/2 3/4 1/2 5/32 3/8 1/8 NL-33 C-1 10-32 x 5/8

MTVOR 10-3 MTVOL 10-3 5/8 5/8 4-1/2 3/4 13/16 5/8

MTVOR 12-3 MTVOL 12-3 3/4 3/4 6 3/4 13/16 3/4

MTVOR 16-3 MTVOL 16-3 1 1 6 13/16 1

MTVOR 85-3 MTVOL 85-3 1 1-1/4 7 13/16 1

MTVOR 12-4 MTVOL 12-4 3/4 3/4 6 1 15/16 3/4 7/32 1/2 3/16 NL-44

MTVOR 16-4 MTVOL 16-4 1 1 6 15/16 1 C-2 1/4-28 x 3/4

MTVOR 85-4 MTVOL 85-4 1 1-1/4 7 15/16 1

MTVOR 86-4 MTVOL 86-4 1 1-1/2 8 15/16 1

MTVOR 20-4 MTVOL 20-4 1-1/4 1-1/4 7 15/16 1-1/4

MTVOR 24-4 MTVOL 24-4 1-1/2 1-1/2 8 15/16 1-1/2

MTVOR 16-5 MTVOL 16-5 1 1 6 1-1/8 1-3/16 1 9/32 5/8 1/4 NL-56

MTVOR 85-5 MTVOL 85-5 1 1-1/4 7 1-3/16 1

MTVOR 86-5 MTVOL 86-5 1 1-1/2 8 1-3/16 1

MTVOR 20-5 MTVOL 20-5 1-1/4 1-1/4 7 1-3/16 1-1/4

MTVOR 24-5 MTVOL 24-5 1-1/2 1-1/2 8 1-3/16 1-1/2

MTVOR 16-55 MTVOL 16-55 1 1 6 1-1/8 1-3/16 1 9/32 5/8 5/16

MTVOR 85-55 MTVOL 85-55 1 1-1/4 7 1-3/16 1

MTVOR 86-55 MTVOR 86-55 1 1-1/2 8 1-3/16 1

MTVOR 20-55 MTVOL 20-55 1-1/4 1-1/4 7 1-3/16 1-1/4

MTVOR 24-55 MTVOL 24-55 1-1/2 1-1/2 8 1-3/16 1-1/2

MTVOR 20-56 MTVOL 20-56 1-1/4 1-1/4 7 1-1/4 3/8

MTVOR 20-58 MTVOL 20-58 1-1/4 1-1/4 7 1-1/4 1/2 NL-58L

MTVOR 16-66 MTVOL 16-66 1 1 6 1-3/16 1-5/16 1 3/8 3/4 3/8 NL-66L

MTVOR 85-66 MTVOL 85-66 1 1-1/4 7 1-3/16 1-5/16 1

MTVOR 86-66 MTVOL 86-66 1 1-1/2 8 1-5/16 1

MTVOR 20-66 MTVOL 20-66 1-1/4 1-1/4 7 1-3/16 1-5/16 1-1/4

MTVOR 24-66 MTVOL 24-66 1-1/2 1-1/2 8 1-5/16 1-1/2

MTVOR 20-69 MTVOL 20-69 1-1/4 1-1/4 7 1-3/16 1-1/4 9/16

MTVOR 24-69 MTVOL 24-69 1-1/2 1-1/2 8 1-1/4

NL-56

High Tech Tool, Inc. Page 13 TOOLHOLDERS

Standard alternate clamp

location for threading to

shoulder.

Catalog Number Dimensions Insert Size Parts

Right Hand Left Hand A B C E F G

*Min.

Bore

Depth

K

I.C. Thk. Lock Pin Clamp

Clamp

Screw

(B.H.C.S)

MTHOR 8-3 MTHOL 8-3 1/2 1/2 5-1/2 3/4 7/8 3/8 1-7/8 .100 3/8 1/8 NL-33 C-1 10-32 x 3/4

MTHOR 10-3 MTHOL 10-3 5/8 5/8 5-1/2 3/4 1 3/8 1-7/8

MTHOR 12-3 MTHOL 12-3 3/4 3/4 7 3/4 1-1/8 3/8 2-1/4

MTHOR 16-3 MTHOL 16-3 1 1 7 3/4 1-1/2 1/2 2-3/4

MTHOR 85-3 MTHOL 85-3 1 1-1/4 8 3/4 1-1/2 1/2 3-1/4

MTHOR 12-4 MTHOL 12-4 3/4 3/4 7 1 1-1/4 1/2 2-3/4 .140 1/2 3/16 NL-44

MTHOR 16-4 MTHOL 16-4 1 1 7 1 1-1/2 1/2 3 C-2 1/4-28 x 3/4

MTHOR 85-4 MTHOL 85-4 1 1-1/4 8 1 1-1/2 1/2 3-1/2

MTHOR 86-4 MTHOL 86-4 1 1-1/2 8 1 1-1/2 1/2 4

MTHOR 20-4 MTHOL 20-4 1-1/4 1-1/4 8 1 1-3/4 1/2 3-1/2

MTHOR 24-4 MTHOL 24-4 1-1/2 1-1/2 8 1 2 1/2 4

MTHOR 16-5 MTHOL 16-5 1 1 7 1 1-1/2 1/2 3-1/4 .180 5/8 1/4 NL-56

MTHOR 85-5 MTHOL 85-5 1 1-1/4 8 1 1-1/2 1/2 3-3/4

MTHOR 86-5 MTHOL 86-5 1 1-1/2 8 1 1-1/2 1/2 4-1/4

MTHOR 20-5 MTHOL 20-5 1-1/4 1-1/4 8 1 1-3/4 1/2 3-3/4

MTHOR 24-5 MTHOL 24-5 1-1/2 1-1/2 8 1 2 1/2 4-1/4

MTHOR 20-66 MTHOL 20-66 1-1/4 1-1/4 8 1-1/4 1-3/4 1/2 4 .230 3/4 3/8

MTHOR 24-66 MTHOL 24-66 1-1/2 1-1/2 8 1-1/4 2 1/2 4-1/2

NL-66L

STYLE H - TRIANGLE

THREADING INSERTS: TNMA-NV, TPMA-NV, TNMA-NT AND TPMA-NT

GROOVING INSERTS: TNMA-NG AND TPMA-NG

*Min bore is at K depth

Right hand holders require NGL style grooving inserts.

Left hand holders require NGR style grooving inserts.

Right hand shown

Left hand opposite

To Order Call: 713-641-2303 Page 14 TOOLHOLDERS

High Tech Tool, Inc.

STYLE Z - TRIANGLE

THREADING INSERTS: TNMA-NV, TPMA-NV, TNMA-NT AND TPMA-NT

GROOVING INSERTS: TNMA-NG AND TPMA-NG

Catalog Number Dimensions Insert Size Parts

Left Hand A B C E F G V Max I.C. Thk. Lock Pin Clamp

Clamp

Screw

(B.H.C.S)

MTZOL 16-3 1 1 6 1 1-1/4 1/4 .150 3/8 1/8 NL-33 C-1 10-32 x 3/4

MTZOL 85-3 1 1-1/4 6 1 1-1/4 1/4

MTZOL 86-3 1 1-1/2 7 1 1-1/4 1/4

MTZOL 20-3 1-1/4 1-1/4 7 1 1-1/2 1/4

MTZOL 16-4 1 1 6 1-3/8 1-1/4 1/4 .230 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

MTZOL 85-4 1 1-1/4 6 1-3/8 1-1/4 1/4

MTZOL 86-4 1 1-1/2 7 1-3/8 1-1/4 1/4

MTZOL 20-4 1-1/4 1-1/4 7 1-3/8 1-1/2 1/4

MTZOL 24-4 1-1/2 1-1/2 7 1-3/8 1-3/4 1/4

MTZOL 16-5 1 1 6 1-1/2 1-1/4 1/4 .292 5/8 1/4

MTZOL 85-5 1 1-1/4 6 1-1/2 1-1/4 1/4

MTZOL 86-5 1 1-1/2 7 1-1/2 1-1/4 1/4

MTZOL 20-5 1-1/4 1-1/4 7 1-1/2 1-1/2 1/4

MTZOL 24-5 1-1/2 1-1/2 7 1-1/2 1-3/4 1/4

NL-56

Standard alternate clamp

location for threading to

shoulder.

High Tech Tool, Inc. Page 15 TOOLHOLDERS

STYLE H - LAYDOWN

THREADING INSERTS: LT-54

FOR A.P.I. ROTARY SHOULDER CONNECTIONS

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C E F I.C. Thk. Lock Pin Seat Clamp

Clamp

Screw

(B.H.C.S)

MTHLR 16-4 MTHLL 16-4 1 1 6 1-1/4 1-1/4 1/2 3/16 NL-46 APIS-4T C-1 10-32 x 5/8

MTHLR 85-4 MTHLL 85-4 1 1-1/4 7 1-1/4 1-1/4

MTHLR 86-4 MTHLL 86-4 1 1-1/2 7 1-1/4 1-1/4

MTHLR 20-4 MTHLL 20-4 1-1/4 1-1/4 6 1-1/4 1-1/2

MTHLR 24-4 MTHLL 24-4 1-1/2 1-1/2 7 1-1/4 1-3/4

MTHLR 16-5 MTHLL 16-5 1 1 6 1-1/2 1-1/4 5/8 1/4 NL-58 APIS-5T C-2

MTHLR 85-5 MTHLL 85-5 1 1-1/4 7 1-1/2 1-1/4

MTHLR 86-5 MTHLL 86-5 1 1-1/2 7 1-1/2 1-1/4

MTHLR 20-5 MTHLL 20-5 1-1/4 1-1/4 6 1-1/2 1-1/2

MTHLR 24-5 MTHLL 24-5 1-1/2 1-1/2 7 1-1/2 1-3/4

1/4-28 x 3/4

These items are available on request only and are subject to quote.

Left hand holders require internal inserts.

To Order Call: 713-641-2303 Page 16 TOOLHOLDERS

High Tech Tool, Inc.

NEUTRAL RAKE

STYLE API

INSERTS: APIP

Catalog Number Dimensions Insert No. Parts

API Groove

Number

Group

No. Right Hand *Left Hand A B C E F W Ref.

Lock

Pin

Seat Clamp

Clamp

Screw

(B.H.C.S)

APIHPR 061-16A APIHPL 061-16A 1 1 7 1-1/2 1/2 .061

APIP 061-3 APIS 061-2 C-2 1/4-28 x 1 BONNET

FACE

GROOVE

A

APIHPR 086-12A APIHPL 086-12A 3/4 3/4 6 1-3/8 3/8 .079 APIP 086-3 APIS 086-2 CC-1 RX-201, 205 A

APIHPR 086-16A APIHPL 086-16A 1 1 6 1-3/8 1/2 .079

APIHPR 131-12A APIHPL 131-12A 3/4 3/4 6 1-3/8 3/8 .125 APIP 131-3 APIS 131-2 R-19, 20, 22,

25, 29

A

APIHPR 131-16A APIHPL 131-16A 1 1 6 1-3/8 1/2 .125

APIHPR 131-12B APIHPL 131-12B 3/4 3/4 6 1-3/8 3/8 .125 R-33, 36, 40,

43, 48

B

APIHPR 131-16B APIHPL 131-16B 1 1 6 1-3/8 1/2 .125

APIHPR 131-12C APIHPL 131-12C 3/4 3/4 6 1-3/8 3/8 .125 R-52, 56, 59,

64, 68, 72, 76

C

APIHPR 131-16C APIHPL 131-16C 1 1 6 1-3/8 1/2 .125

APIHPR 162-16A APIHPL 162-16A 1 1 6 1-3/8 1/2 .156 APIP 162-3 APIS 162-2 RX-210 A

APIHPR 162-85A APIHPL 162-85A 1 1-1/4 6 1-3/8 1/2 .156

APIHPR 162-86A APIHPL 162-86A 1 1-1/2 6 1-3/8 1/2 .156

APIHPR 203-16A APIHPL 203-16A 1 1 6 1-5/8 1/2 .197 APIP 203-3 S-46 or

NL-46

APIS 213-2H R-21, 23, 24,

27, 30, 31

A

APIHPR 203-85A APIHPL 203-85A 1 1-1/4 6 1-5/8 1/2 .197

APIHPR 203-86A APIHPL 203-86A 1 1-1/2 6 1-5/8 1/2 .197

APIHPR 203-16B APIHPL 203-16B 1 1 6 1-5/8 1/2 .197 R-34, 35, 37,

39, 41, 44, 45,

49, 53, 57, 61,

65, 69, 84, 92,

99, RX-215

B

APIHPR 203-85B APIHPL 203-85B 1 1-1/4 6 1-5/8 1/2 .197

APIHPR 203-86B APIHPL 203-86B 1 1-1/2 6 1-5/8 1/2 .197

APIHPR 213-16A APIHPL 213-16A 1 1 6 1-5/8 1/2 .206 APIP 213-3 S-46 or

NL-46

APIS 213-2H R-28, 32, 46,

73, 85

A

APIHPR 213-85A APIHPL 213-85A 1 1-1/4 6 1-5/8 1/2 .206

APIHPR 213-86A APIHPL 213-86A 1 1-1/2 6 1-5/8 1/2 .206

APHIPR 265-16A APIHPL 265-16A 1 1 6 1-5/8 1/2 .260 APIP 265-3 APIS 265-2 BX-150 A

APIHPR 265-85A APIHPL 265-85A 1 1-1/4 6 1-5/8 1/2 .260

APIHPR 265-86A APIHPL 265-86A 1 1-1/2 6 1-5/8 1/2 .260

APIHPR 281-16A APIHPL 281-16A 1 1 6 1-5/8 1/2 .277 APIP 281-3 APIS 281-2 BX-151 A

APIHPR 281-85A APIHPL 281-85A 1 1-1/4 6 1-5/8 1/2 .277

APIHPR 281-86A APIHPL 281-86A 1 1-1/2 6 1-5/8 1/2 .277

APIHPR 300-16A APIHPL 300-16A 1 1 6 1-5/8 1/2 .295 APIP 300-3 APIS 300-2 BX-152 A

APIHPR 300-85A APIHPL 300-85A 1 1-1/4 6 1-5/8 1/2 .295

APIHPR 300-86A APIHPL 300-86A 1 1-1/2 6 1-5/8 1/2 .295

APIHPR 329-16A APIHPL 329-16A 1 1 6 1-5/8 1/2 .324 APIP 329-3 APIS 329-2 BX-153 A

APIHPR 329-85A APIHPL 329-85A 1 1-1/4 6 1-5/8 1/2 .324

APIHPR 329-86A APIHPL 329-86A 1 1-1/2 6 1-5/8 1/2 .324

APIHPR 355-16A APIHPL 355-16A 1 1 6 1-5/8 1/2 .350 APIP 355-3 APIS 355-2 BX-154 A

APIHPR 355-85A APIHPL 355-85A 1 1-1/4 6 1-5/8 1/2 .350

APIHPR 355-86A APIHPL 355-86A 1 1-1/2 6 1-5/8 1/2 .350

APIHPR 420-16A APHIPL 420-16A 1 1 6 1-5/8 1/2 .415 APIP 420-3 APIS 420-2 BX-155 A

APIHPR 420-85A APIHPL 420-85A 1 1-1/4 6 1-5/8 1/2 .415

APIHPR 420-86A APIHPL 420-86A 1 1-1/2 6 1-5/8 1/2 .415

*These items are available on request only and are subject to quote.

See chart on page 10 for API groove details.

High Tech Tool, Inc. Page 17 TOOLHOLDERS

NEUTRAL RAKE

STYLE API - HEAVY DUTY

INSERTS: APIP

Catalog Number Dimensions Insert No. Parts

API Groove

Number

Group

No.

Right Hand *Left Hand A B C E F W Ref. Lock Pin Seat Clamp

Clamp Screw

(B.H.C.S)

APIHPR 061-16AH APIHPL 061-16AH

1 1 6 1-11/16 1/2 .061 APIP 061-3H NL-34L APIS 061-2H CC-1 1/4-28 x 1 BONNET

FACE

GROOVE

AH

APIHPR 284-16AH APIHPL 284-16AH 1 7 1-13/16 .278 APIP 284-3 NL-58 APIS 284-4 CC-2 5/16-24 x 1-1/4

APIHPR 284-85AH APIHPL 284-84AH 1-1/4

APIHPR 284-86AH APIHPL 284-86AH 1-1/2

APIHPR 162-16AH APIHPL 162-16AH 1 2-1/8 .156 APIP 162-4 APIS 162-3 RX-210

APIHPR 162-85AH APIHPL 162-85AH 1-1/4

APIHPR 162-86AH APIHPL 162-86AH 1-1/2

APIHPR 203-16AH APIHPL 203-16AH 1 .197 APIP 203-4 APIS 213-3 R-21, 23, 24,

27, 30, 31

APIHPR 203-85AH APIHPL 203-85AH 1-1/4

APIHPR 203-86AH APIHPL 203-86AH 1-1/2

APIHPR 203-16BH APIHPL 203-16BH 1 R-34, 35, 37,

39, 41, 44, 45,

49, 53, 57, 61,

65, 69, 84, 92,

99; RX-215

BH

APIHPR 203-85BH APIHPL 203-85BH 1-1/4

APIHPR 203-86BH APIHPL 203-86BH 1-1/2

APIHPR 213-16AH APIHPL 213-16AH 1 .206 APIP 213-4 APIS 213-3 R-28, 32, 46,

73, 85

AH

APIHPR 213-85AH APIHPL 213-85AH 1-1/4

APIHPR 213-86AH APIHPL 213-86AH 1-1/2

APIHPR 265-16AH APIHPL 265-16AH 1 .260

.

APIP 265-4 APIS 265-3 BX-150

APIHPR 265-85AH APIHPL 265-85AH 1-1/4

APIHPR 265-86AH APIHPL 265-86AH 1-1/2

APIHPR 281-16AH APIHPL 281-16AH 1 .277 APIP 281-4 APIS 281-3 BX-151

APIHPR 281-85AH APIHPL 281-85AH 1-1/4

APIHPR 281-86AH APIHPL 281-86AH 1-1/2

APIHPR 300-16AH APIHPL 300-16AH 1 .295 APIP 300-4 APIS 300-3 BX-152

APIHPR 300-85AH APIHPL 300-85AH 1-1/4

APIHPR 300-86AH APIHPL 300-86AH 1-1/2

APIHPR 329-16AH APIHPL 329-16AH 1 .324 APIP 329-4 APIS 329-3 BX-153

APIHPR 329-85AH APIHPL 329-85AH 1-1/4

APIHPR 329-86AH APIHPL 329-86AH 1-1/2

APIHPR 355-16AH APIHPL 355-16AH 1 .350 APIP 355-4 APIS 355-3 BX-154

APIHPR 355-85AH APIHPL 355-85AH 1-1/4

APIHPR 355-86AH APIHPL 355-86AH 1-1/2

APIHPR 420-16AH APIHPL 420-16AH 1 2 .415 APIP 420-4 APIS 420-3 BX-155

APIHPR 420-85AH APIHPL 420-85AH 1-1/4

APIHPR 420-86AH APIHPL 420-86AH 1-1/2

R-38,50,54, 62,

66, 77, 86, 87

*These items are available on request only and are subject to quote.

See chart on page 10 for API groove details.

To Order Call: 713-641-2303 Page 18 TOOLHOLDERS

High Tech Tool, Inc.

NEUTRAL RAKE

STYLE API - SIDE MOUNT

INSERTS: APIP

Catalog Number Dimensions Insert No. Parts

API Groove

Number

Group

No.

Right Hand A B C E F Ref. Lock Pin Seat Clamp

Clamp Screw

(B.H.C.S)

APISMR 086-16 1 1 4 1-3/8 3.687 APIP 086-3 APIS 086-2 CC-1 1/4-28 x 1 RX-201, 205 A

APISMR 131-16A 4 1-3/8 3.656 APIP 131-3 APIS 131-2 R-19, 20, 22,

25, 29

APISMR 131-16B 5 1-3/8 4.656 R-33, 36, 40,

43, 48

B

APISMR 131-16C 6 1-3/8 5.656 R-52, 56, 59,

64, 68, 72, 76

C

APISMR 162-16A 4 1-3/8 3.625 APIP 162-3 APIS 162-2 RX-210 A

APISMR 203-16A 4 1-5/8 3.562 APIP 203-3 S-46,

NL-46

APIS 213-2H R-21, 23, 24,

27, 30, 31

APISMR 203-16B 6 1-5/8 5.562 R-34, 35, 37,

39, 41, 44, 45,

49, 53, 57, 61,

65, 69, 84, 92,

99; RX-215

APISMR 213-16A 6 1-5/8 5.562 APIP 213-3 R-28, 32, 46,

73, 85

APISMR 265-16A 3-1/2 1-5/8 2.970 APIP 265-3 APIS 265-2 BX-150

APISMR 281-16A 3-9/16 1-5/8 3.050 APIP 281-3 APIS 281-2 BX-151

APISMR 300-16A 3-3/4 1-5/8 3.200 APIP 300-3 APIS 300-2 BX-152

APISMR 329-16A 4 1-5/8 3.500 APIP 329-3 APIS 329-3 BX-153

APISMR 355-16A 4-15/16 1-5/8 4.300 APIP 355-3 APIS 355-2 BX-154

APISMR 420-16A 5-1/2 1-5/8 4.875 APIP 420-3 APIS 420-2 BX-155

HEAVY DUTY

APISMR 162-16AH 1-1/4 1 6 2-1/4 5.437 APIP 162-4 NL-58 APIS 162-3 CC-2 5/16-24 x 1 RX-210 A

APISMR 265-16AH 3-1/2 2-1/8 2.970 APIP 265-4 APIS 265-3 BX-150

APISMR 281-16AH 3-9/16 2-1/8 3.050 APIP 281-4 APIS 281-3 BX-151

APISMR 300-16AH 3-3/4 2-1/8 3.200 APIP 300-4 APIS 300-3 BX-152

APISMR 329-16AH 4 2-1/8 3.500 APIP 329-4 APIS 329-3 BX-153

APISMR 355-16AH 4-15/16 2-1/8 4.300 APIP 355-4 APIS 355-3 BX-154

APISMR 420-16AH 5-1/2 2 4.875 APIP 420-4 APIS 420-3 BX-155

5/16-24 x 1-1/4

Left hand available on request and are subject to quote.

See chart on page 10 for API groove details.

High Tech Tool, Inc. Page 19 TOOLHOLDERS

RING GROOVING HEADS

FOR FLYCUTTING API RING GROOVES

USES STYLE APISMR QUALIFIED HOLDERS

Catalog Number

Ptich Dia.

Range

Dimensions

Toolholder

Length - Qual.

Parts

A B Set Screws (4) BoltsFurnished w/shank

RGH-1 2-1/2 - 3-1/2 4-1/2 3-1/2 2-11/16 3/8-24 x 3/4 3/8-16 x 1-1/4

RGH-2 3-1/2 - 4-1/2 5-1/2 3-3/8

RGH-3 4-1/2 - 5-1/2 6-1/2

RGH-4 5-1/2 - 6-1/2 7-1/2

4

Shank and toolholder must be ordered separately

Retention knob not furnished w/50 CV shank

Special shanks available on request

* Refer to page 19 for APISMR style holders

Refer to page 10 for API ring groove details

To Order Call: 713-641-2303 Page 20 TOOLHOLDERS

High Tech Tool, Inc.

NEGATIVE RAKE

STYLE Q - OFFSET 35 DIAMOND

VNMA, VNMG, VNMP, VNGA AND VNGP

Catalog Number Dimensions Insert Parts

Right Hand Left Hand A B C E F I.C. Thk. Rad. Lock Pin Seat Clamp

Clamp Screw

(B.H.C.S)

MVQNRO 16-3 MVQNLO 16-3 1 1 5-5/8 3/4 2-1/4 3/8 .188 1/32 NL-34L IVSN-323 C-1 #10-32 x 5/8

MVQNRO 20-3 MVQNLO 20-3 1-1/4 1-1/4 5-5/8 3/4 2-1/2

MVQNRO 24-3 MVQNLO 24-3 1-1/2 1-1/2 5-5/8 3/4 2-3/4

MVQNRO 20-4 MVQNLO 20-4 1-1/4 1-1/4 5-1/2 1 2-11/16 1/2 .188 1/32 NL-46

MVQNRO 24-4 MVQNLO 24-4 1-1/2 1-1/2 5-1/2 1 2-15/16

MVQNRO 85-4 MVQNLO 85-4 1 1-1/4 5-1/2 1 2-7/16

MVQNRO 86-4 MVQNLO 86-4 1 1-1/2 5-1/2 1 2-7/16

IVSN-433

NEGATIVE RAKE

STYLE Q - 35 DIAMOND

VNMA, VNMG, VNMP, VNGA AND VNGP

High Tech Tool, Inc. Page 21 TOOLHOLDERS

Catalog Number Dimensions Insert Parts

Right Hand Left Hand A B C F G I.C. Thk. Rad. Lock Pin Seat Clamp

Clamp Screw

(B.H.C.S)

MVQNR 16-3 MVQNL 16-3 1 1 6 1-5/8 5/8 3/8 .188 1/32 NL-34L IVSN-323 C-1 #10-32 x 5/8

MVQNR 20-3 MVQNL 20-3 1-1/4 1-1/4 1-7/8

MVQNR 24-3 MVQNL 24-3 1-1/2 1-1/2 2-1/8

MVQNR 20-4 MVQNL 20-4 1-1/4 1-1/4 1-7/8 1/2 .188 1/32 NL-46 IVSN-433

MVQNR 24-4 MVQNL 24-4 1-1/2 1-1/2 2-1/8

NEGATIVE RAKE

STYLE T - 35 DIAMOND

VNMA, VNMG, VNMP, VNGA AND VNGP

Catalog Number Dimensions Insert Size Parts

Right Hand Left Hand A B C E F G I.C.. Thk. Lock Pin Shim Clamp

Clamp Screw

(B.H.C.S)

MVTNR 12-3 MVTNL 12-3 3/4 3/4 6 1-1/2 1 3/8 3/16 NL-34L IVSN-324 C-2 1/4-28 x 3/4

MVTNR 16-3 MVTNL 16-3 1 1 6 1-1/2 1-1/4

MVTNR 85-3 MVTNL 85-3 1 1-1/4 6 1-1/2 1-1/4

MVTNR 86-3 MVTNL 86-3 1 1-1/2 7 1-1/2 1-1/4

MVTNR 20-3 MVTNL 20-3 1-1/4 1-1/4 7 1-1/2 1-1/2

MVTNR 24-3 MVTNL 24-3 1-1/2 1-1/2 7 1-1/2 1-3/4

MVTNR 16-4 MVTNL 16-4 1 1 6 1-5/8 1-1/2 1/2 1/2 3/16 NL-46 IVSN-433

MVTNR 85-4 MVTNL 85-4 1 1-1/4 6 1-5/8 1-1/2

MVTNR 86-4 MVTNR 86-4 1 1-1/2 7 1-5/8 1-1/2

MVTNR 20-4 MVTNL 20-4 1-1/4 1-1/4 7 1-5/8 1-3/4

MVTNR 24-4 MVTNL 24-4 1-1/2 1-1/2 7 1-5/8 2

1/4

To Order Call: 713-641-2303 Page 22 TOOLHOLDERS

High Tech Tool, Inc.

High Tech Tool, Inc. Page 23 REPLACEABLE HEADS

High Tech Tool Replaceable Heads and Bars

High Techs replaceable boring, threading and grooving heads provide the maximum in flexibility and economy for your internal operations

without sacrificing rigidity. The simple drive key and locating dowel pin design assures positive location of the head and provides the

strength required by heavier cuts which was not previously available in a replaceable head bar.

Some of the advantages of the High Tech replaceable head bars are as follows;

Less expensive than solid bars

You will find that the head cost is approximately 10% - 25% less than the cost of a comparable solid bar, with even more savings on

coolant hole bars and specially designed shanks.

Minimize stock space

Many long bars may now be replaced by a simple 1-1/2 - 2 long replaceable head.

Reduced setup time

Instead of changing out a complete bar, you replace only the head.

Allows for special design shanks

Due to the economy of having only a head to replace you may now have specially designed shanks or heavy metal or carbide shanks

which are more suitable to your operation. These were previously not practical due to the cost of having to replace an entire bar.

Lock pin and clamp

All heads except positive rake are provided with lock pin and clamp for maximum holding power on insert.

Suitable for R.H. or L.H. applications

Bars will accept right or left hand heads and either is available with coolant provision internally.

Please consult the following pages for styles and sizes available from stock. We solicit your inquiries for specials or sizes not shown.

Available with High Techs Quick Change bar mounting.

See page 36 to see how you may benefit even more from a rigid, Quick Change bar-to-machine connection.

To Order Call: 713-641-2303 Page 24 REPLACEABLE HEAD BARS

REPLACEABLE HEAD BARS

A L

Parts

Screws*

(S.H.C.S.)

Key Dowel

RHB-16 1 10 8-32 x 1/2 K-16 3/16 x 3/4

RHB-20 1-1/4 12 10-24 x 3/4 K-20 1/4 x 1

RHB-24 1-1/2 13 10-32 x 3/4 K-24 5/16 x 1

RHB-28 1-3/4 13 1/4-20 x 1 K-28 5/16 x 1

RHB-32 2 15 1/4-20 x 1 K-32 5/16 x 1

Catalog Number

RHB-36 2-1/4 15 5/16-18 x 1 K-36 5/16 x 1

RHB-40 2-1/2 16 5/16-18 x 1 K-40 5/16 x 1

TAPERED REPLACEABLE HEAD BARS

Catalog Number A B C D

Parts

Screws*

(S.H.C.S.)

Key Dowel

RHBT-28-24 1-3/4 7-3/4 1-1/2 3-1/2 1/4-20 x 1 K-28 5/16 x 1

RHBT-28-32 1-3/4 12 2 1/4-20 x 1 K-28 5/16 x 1

RHBT-32-40 2 13 2-1/2 1/4-20 x 1 K-32 5/16 x 1

E

1-1/2

Parts are supplied with bar.

*2 Reqd.

Bars also available in heavy metal or carbide for special applications

See Quick Change bars on page 36 for faster setups.

For coolant provision, add suffix C to bar number (ex; RHB-16C)

Parts are supplied with bar.

*2 Reqd.

Bars also available in heavy metal or carbide for special applications.

See Quick Change bars on page 36 for faster setups.

For coolant provision, add suffix C to bar number (ex; RHB-16C)

Bars will accept right or left hand heads.

Bars will accept right or left hand heads.

High Tech Tool, Inc.

High Tech Tool, Inc. Page 25

REPLACEABLE HEADS

FOR THREADING & GROOVING

STYLE H LAYDOWN TRIANGLE

THREADING INSERTS - LT43, LT-54

Right hand shown

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Shim Clamp

Clamp

Screw

(S.H.C.S)

HTHLR 20-4 HTHLL 20-4 1-1/4 .920 1-5/8 1-5/8 1/2 3/16 NL-44 C-1 10-32 x

5/8

HTHLR 24-4 HTHLL 24-4 1-1/2 1.000 1-3/4 1-7/8 NL-46 APIS-4H

HTHLR 28-4 HTHLL 28-4 1-3/4 1.125 2 2-1/8

HTHLR 32-4 HTHLL 32-4 2 1.250 2 2-3/8

HTHLR 36-4 HTHLL 36-4 2-1/4 1.375 2 2-5/8

HTHLR 40-4 HTHLL 40-4 2-1/2 1.500 2 2-7/8

HTHLR 20-5 HTHLL 20-5 1-1/4 5/8 1/4 NL-56 APIS-5H C-2

HTHLR 24-5 HTHLL 24-5 1-1/2 1.045 1-3/4

HTHLR 28-5 HTHLL 28-5 1-3/4 .937 1-3/4

HTHLR 32-5 HTHLL 32-5 2 1.031 2

HTHLR 36-5 HTHLL 36-5 2-1/4

HTHLR 40-5 HTHLL 40-5 2-1/2 1.281 2

1/4-28 x

3/4

For coolant provision add suffix C to catalog number (ex; HTHLR 28-4C)

*These items available on request only and are subject to quote. Left hand

heads require external inserts.

STYLE H LAYDOWN TRIANGLE

THREADING INSERTS - LT-54

FOR A.P.I. ROTARY SHOULDER CONNECTIONS

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Clamp Shim

Clamp

Screw

(S.H.C.S)

HTHLR 28-5T HTHLL 28-5T 1-3/4 .937 1-3/4 1-13/16 5/8 1/4 NL-58 C-2 APIS-5H

HTHLR 32-5T HTHLL 32-5T 2 .1.031 2 2-1/8

HTHLR 40-5T HTHLL 40-5T 2-1/2 1.282 2 2-5/8

1/4-28 x 3/4

For coolant provision add suffix C to catalog number (ex; HTHLR 28-5TC)

*Left hand available on request only and are subject to quote. Left hand heads require

external inserts.

To Order Call: 713-641-2303 Page 26

STYLE H TRIANGLE

THREADING INSERTS - TNMA-NV, TPMA-NV, TNMA-NT AND TPMA-NT

GROOVING INSERTS - TNMA-NG AND TPMA-NG

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D E I.C. Thk.

Lock

Pin

Clamp

Clamp

Screw

(S.H.C.S)

HTHOR 20-3 HTHOL 20-3 1-1/4 .775 1-1/2 1-7/8 .100 3/8 1/8 NL-33 C-1 10-32 x 5/8

HTHOR 20-4 HTHOL 20-4 1-1/4 .800 1-1/2 2-1/2 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHOR 24-3 HTHOL 24-3 1-1/2 .906 1-1/2 1-15/16 .100 3/8 1/8 NL-33 C-1 10-32 x 5/8

HTHOR 24-4 HTHOL 24-4 1-1/2 .980 1-1/2 2-3/4 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHOR 24-5 HTHOL 24-5 1-1/2 1.032 1-1/2 3-1/4 .187 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHOR 24-55 HTHOL 24-55 1-1/2 1.032 1-1/2 3-1/4 .187 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHOR 28-4 HTHOL 28-4 1-3/4 1.100 1-3/4 2-13/16 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHOR 28-5 HTHOL 28-5 1-3/4 1.156 1-3/4 3-3/8 .190 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHOR 28-55 HTHOL 28-55 1-3/4 1.156 1-3/4 3-3/8 .190 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHOR 32-4 HTHOL 32-4 2 1.225 2 2-7/8 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHOR 32-5 HTHOL 32-5 2 1.281 2 3-1/2 .190 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHOR 32-55 HTHOL 32-55 2 1.281 2 3-1/2 .190 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHOR 32-66 HTHOL 32-66 2 1.350 2 3-9/16 .218 3/4 3/8 NL-66L C-3 5/16-24 x 3/4

HTHOR 36-4 HTHOL 36-4 2-1/4 1.350 2 2-15/16 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHOR 36-5 HTHOL 36-5 2-1/4 1.406 2 3-5/8 .195 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHOR 36-55 HTHOL 36-55 2-1/4 1.406 2 3-5/8 .195 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHOR 36-66 HTHOL 36-66 2-1/4 1.475 2 4 .234 3/4 3/8 NL-66L C-3 5/16-24 x 3/4

HTHOR 40-4 HTHOL 40-4 2-1/2 1.480 2 3 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHOR 40-5 HTHOL 40-5 2-1/2 1.540 2 3-1/2 .200 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHOR 40-55 HTHOL 40-55 2-1/2 1.540 2 3-1/2 .200 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHOR 40-66 HTHOL 40-66 2-1/2 1..600 2 4-5/8 .250 3/4 3/8 NL-66L C-3 5/16-24 x 3/4

HTHOR 40-69 HTHOL 40-69 2-1/2 1.600 2 4-5/8 .250 3/4 9/32 NL-66L C-3 5/16-24 x 3/4

REPLACEABLE HEADS

FOR THREADING & GROOVING

*Min. bore is at max depth E. Consult High Tech for depths greater than and/or less than shown.

Right hand heads require NGL style grooving inserts.

Left hand heads require NGR style grooving inserts.

High Tech Tool, Inc.

STYLE T - TECH LOC

Catalog Number Dimensions Parts

Right Hand Left Hand A B C W

Clamp Clamp

Screw

(S.H.C.S)

RH LH

HTNER 20-3 HTNEL 20-3 1-1/4 .875 1.625 .195 CM-72 CM-73 10-32 x 3/4

HTNER 24-3 HTNEL 24-3 1-1/2 1.000

HTNER 28-3 HTNEL 28-3 1-3/4 1.125

HTNER 32-3 HTNEL 32-3 2 1.250

HTNER 40-3 HTNEL 40-3 2-1/2 1.500

HTNER 28-4 HTNEL 28-4 1-3/4 1.250 .255

HTNER 32-4 HTNEL 32-4 2 1.375

HTNER 36-4 HTNEL 36-4 2-1/4 1.500

HTNER 40-4 HTNEL 40-4 2-1/2 1.625

HTNER 28-6 HTNEL 28-6 1-3/4 1.250 .383 CM-120

HTNER 32-6 HTNEL 32-6 2 1.375

HTNER 40-6 HTNEL 40-6 2-1/2 1.625

CM-121

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D E I.C. Thk.

Lock

Pin

Clamp

Clamp

Screw

(S.H.C.S)

HTHPR 20-3 HTHPL 20-3 1-1/4 .780 1-1/2 1-9/16 .100 3/8 1/8 NL-33 C-1 10-32 x 5/8

HTHPR 20-4 HTHPL 20-4 1-1/4 .800 1-1/2 1-5/8 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHPR 24-3 HTHPL 24-3 1-1/2 .906 1-1/2 1-13/16 .100 3/8 1/8 NL-33 C-1 10-32 x 5/8

HTHPR 24-4 HTHPL 24-4 1-1/2 .980 1-1/2 1-7/8 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHPR 24-5 HTHPL 24-5 1-1/2 1.032 1-1/2 2 .187 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHPR 24-55 HTHPL 24-55 1-1/2 1.032 1-1/2 2 .187 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHPR 28-4 HTHPL 28-4 1-3/4 1.100 1-3/4 2-1/8 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHPR 28-5 HTHPL 28-5 1-3/4 1.156 1-3/4 2-1/4 .190 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHPR 28-55 HTHPL 28-55 1-3/4 1.156 1-3/4 2-1/4 .190 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHPR 32-4 HTHPL 32-4 2 1.225 2 2-3/8 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHPR 32-5 HTHPL 32-5 2 1.281 2 2-1/2 .190 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHPR 32-55 HTHPL 32-55 2 1.281 2 2-1/2 .190 5/8 5/16 Nl-56 C-2 1/4-28 x 3/4

HTHPR 32-66 HTHPL 32-66 2 1.350 2 2-5/8 .218 3/4 3/8 NL-66L C-3 5/16-24 x 3/4

HTHPR 36-4 HTHPL 36-4 2-1/4 1.350 2 2-5/8 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHPR 36-5 HTHPL 36-5 2-1/4 1.406 2 2-3/4 .195 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHPR 36-55 HTHPL 36-55 2-1/4 1.406 2 2-3/4 .195 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHPR 36-66 HTHPL 36-66 2-1/4 1.480 2 2-7/8 .234 3/4 3/8 NL-66L C-3 5/16-24 x 3/4

HTHPR 40-4 HTHPL 40-4 2-1/2 1.480 2 2-7/8 .156 1/2 3/16 NL-44 C-2 1/4-28 x 3/4

HTHPR 40-5 HTHPL 40-5 2-1/2 1.540 2 3 .200 5/8 1/4 NL-56 C-2 1/4-28 x 3/4

HTHPR 40-55 HTHPL 40-55 2-1/2 1.540 2 3 .200 5/8 5/16 NL-56 C-2 1/4-28 x 3/4

HTHPR 40-66 HTHPL 40-66 2-1/2 1.600 2 3-1/8 .250 3/4 3/8 NL-66L C-3 5/16-24 x 3/4

High Tech Tool, Inc. Page 27

REPLACEABLE HEADS

FOR THREADING & GROOVING

STYLE H TRIANGLE - 10 POSITIVE RAKE

THREADING INSERTS - TPMA-NV-10 AND TPMA-NT-10

GROOVING INSERTS - TPMA - NG

For coolant provision add suffix C to catalog number (ex; HTHPR 28-4C)

For threading

and grooving,

with coolant port.

STYLE DG - V-BOTTOM

FOR DEEP FACE GROOVING OPERATIONS

STYLE G - V-BOTTOM

FOR DEEP GROOVING OPERATIONS

To Order Call: 713-641-2303 Page 28

REPLACEABLE HEADS

FOR THREADING & GROOVING

Catalog Number Groove Diameter

825408-3 4-1/2 - 5-1/2

825408-4 5-1/2 - 7-1/2

825408-5 7-1/2 - 9

825408-6 9 - 10-1/2

825408-7 10-1/2 - 13-1/2

825408-8 13-1/2 +

Replaceable Anvils

Head 825408-1

Clamp 825408-2

Clamp Screw 1/4-20 x 1 S.H.C.S.

Item Catalog Number

Insert VDB250-B015

Head 825099-1

Clamp 821262-1

Insert

824618 (Carbide)

824619 (Ceramic)

VDB-250-B-015

Item Catalog Number

Anvil 825099-2

High Tech Tool, Inc.

High Tech Tool, Inc. Page 29

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HTENR 16-3 HTENL 16-3 1 .750 1-3/8 1-1/2 3/8 3/16 NL-33L C-1 10-32 x 5/8

HTENR 20-3 HTENL 20-3 1-1/4 .875 1-5/8 1-3/4 3/8 3/16 NL-34L ITSN-323 C-1 10-32 x 5/8

HTENR 24-4 HTENL 24-4 1-1/2 1.125 1-3/4 2-1/4 1/2 3/16 NL-46 ITSN-433 C-2 1/4-28 x 3/4

HTENR 28-4 HTENL 28-4 1-3/4 1.250 2 2-1/2

HTENR 32-4 HTENL 32-4 2 1.375 2 2-3/4

HTENR 36-5 HTENL 36-5 2-1/4 1.625 2 3-1/4 5/8 1/4 NL-58

HTENR 40-5 HTENL 40-5 2-1/2 1.750 2 3-1/2

ITSN-533

STYLE E TRIANGLE

TNMA, TNMG AND TNMP

For coolant provision add suffix C to catalog number (ex; HTENR 28-4C)

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D R I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HTFNR 16-3 HTFNL 16-3 1 .640 1-3/8 1-9/32 12 3/8 3/16 NL-33L C-1 10-32 x 5/8

HTFNR 20-3 HTFNL 20-3 1-1/4 .765 1-5/8 1-17/32 12 NL-34L ITSN-323

HTFNR 24-4 HTFNL 24-4 1-1/2 1.031 1-3/4 2-1/16 10 1/2 3/16 NL-46 ITSN-433 C-2 1/4-28 x 3/4

HTFNR 28-4 HTFNL 28-4 1-3/4 1.156 2 2-5/16 8

HTFNR 32-4 HTFNL 32-4 2 1.281 2 2-9/16 8

HTFNR 36-4 HTFNL 36-4 2-1/4 1.406 2 2-13/16 8

HTFNR 40-4 HTFNL 40-4 2-1/2 1.531 2 3-1/16 8

HTFNR 32-5 HTFNL 32-5 2 1.281 2 2-9/16 8 5/8 1/4 NL-58

HTFNR 36-5 HTFNL 36-5 2-1/4 1.406 2 2-13/16 8

HTFNR 40-5 HTFNL 40-5 2-1/2 1.531 2 3-1/16 8

HTFNR 40-6 HTFNL 40-6 2-1/2 1.531 2 3-1/16 8 3/4 3/8 NL-68L TSN-637 C-3 5/16-24 x 1

ITSN-533

STYLE F TRIANGLE

TNMA, TNMG AND TNMP

For coolant provision add suffix C to catalog number (ex; HTFNR 16-3C)

REPLACEABLE HEADS

FOR BORING & TURNING

For coolant provision add suffix C to catalog number (ex; HTFNR 16-3C)

To Order Call: 713-641-2303 Page 30

STYLE J TRIANGLE

TNMA, TNMG AND TNMP

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D R I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HTJNR 16-3 HTJNL 16-3 1 .640 1-3/8 1-9/32 12 3/8 3/16 NL-33L C-1 10-32 x 5/8

HTJNR 20-3 HTJNL 20-3 1-1/4 .765 1-5/8 1-17/32 12 NL-34L ITSN-323

HTJNR 24-4 HTJNL 24-4 1-1/2 1.031 1-3/4 2-1/16 10 1/2 3/16 NL-46 ITSN-433 C-2 1/4-28 x 3/4

HTJNR 28-4 HTJNL 28-4 1-3/4 1.156 2 2-5/16 8

HTJNR 32-4 HTJNL 32-4 2 1.281 2 2-9/16 8

HTJNR 36-4 HTJNL 36-4 2-1/4 1.406 2 2-13/16 8

HTJNR 40-4 HTJNL 40-4 2-1/2 1.531 2 3-1/16 8

HTJNR 32-5 HTJNL 32-5 2 1.281 2 2-9/16 8 5/8 1/4 NL-58

HTJNR 36-5 HTJNL 36-5 2-1/4 1.406 2 2-13/16 8

HTJNR 40-5 HTJNL 40-5 2-1/2 1.531 2 3-1/16 8

HTJNR 40-6 HTJNL 40-6 2-1/2 1.531 2 3-1/16 8 3/4 3/8 NL-68L TSN-637 C-3 5/16-24 x 1

ITSN-533

REPLACEABLE HEADS

FOR BORING & TURNING

NEGATIVE RAKE

STYLE Q 55 DIAMOND

DNMG, DNMP AND DNGA

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D R I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HDQNR 24-4 HDQNL 24-4 1-1/2 0.690 2.000 1-3/8 12 1/2 3/16 NL-46 DSN-433 C-2 1/4-28 x 3/4

HDQNR 28-4 HDQNL 28-4 1-3/4 1.250 2.000 2-1/2 12 1/2 3/16 NL-46 DSN-433 C-2 1/4-28 x 3/4

HDQNR 40-4 HDQNL 40-4 2-1/2 1.750 2.250 3-1/2 10 1/2 *3/16 NL-46 *DSN-423 C-2 1/4-28 x 3/4

HDQNR 40-5 HDQNL 40-5 2-1/2 1.625 2.250 3-1/4 10 5/8 1/4 NL-58 DSN-533 C-2 1/4-28 x 3/4

For coolant provision add suffix C to catalog number (ex; HDQNR 24-4C)

*This item available in 1/4 thickness with DSN-433 seat

High Tech Tool, Inc.

High Tech Tool, Inc. Page 31

REPLACEABLE HEADS

FOR BORING & TURNING

NEGATIVE RAKE

STYLE K SQUARE

SNMA, SNMG AND SNMP

Catalog Number Dimensions

Insert

Size

Parts

Right Hand *Left Hand A B C D R I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HSKNR 20-4 HSKNL 20-4 1-1/4 .765 1-5/8 1-17/32 12 1/2 3/16 NL-46 ISSN-433 C-1 10-32 x 5/8

HSKNR 24-4 HSKNL 24-4 1-1/2 .890 1-3/4 1-25/32 12 C-2 1/4-28 x 3/4

HSKNR 28-4 HSKNL 28-4 1-3/4 1.015 2 2-1/32 12

HSKNR 32-5 HSKNL 32-5 2 1.281 2 2-9/16 12 5/8 1/4 NL-58

HSKNR 36-5 HSKNL 36-5 2-1/4 1.406 2 2-13/16 10

HSKNR 40-5 HSKNL 40-5 2-1/2 1.531 2 3-1/16 10

HSKNR 40-6 HSKNL 40-6 2-1/2 1.531 2 3-1/16 10 3/4 1/4 NL-68 ISSN-634

HSKNR 40-8 HSKNL 40-8 2-1/2 1.656 2-1/4 3-5/16 10 1 3/8 NL-810 ISSN-844 C-3 5/16-24 x 1

SSN-533

For coolant provision add suffix C to catalog number (ex; HSKNR 20-4C)

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HSDNR 16-3 HSDNL 16-3 1 .750 1-3/8 1-1/2 3/8 3/16 NL-33L C-1 10-32 X 5/8

HSDNR 20-4 HSDNL 20-4 1-1/4 .937 1-5/8 1-7/8 1/2 3/16 NL-46 ISSN-433 C-2 1/4-28 x 3/4

HSDNR 24-4 HSDNL 24-4 1-1/2 1.062 1-3/4 2-1/8

HSDNR 28-5 HSDNL 28-5 1-3/4 1.312 2 2-5/8 5/8 1/4 NL-58 SSN-533

HSDNR 32-5 HSDNL 32-5 2 1.437 2 2-7/8

HSDNR 36-6 HSDNL 36-6 2-1/4 1.625 2 3-1/4 3/4 1/4 NL-68

HSDNR 40-6 HSDNL 40-6 2-1/2 1.750 2 3-1/2

ISSN-633

NEGATIVE RAKE

STYLE D SQUARE

SNMA, SNMG AND SNMP

For coolant provision add suffix C to catalog number (ex; HSDNR 20-4C)

To Order Call: 713-641-2303 Page 32

REPLACEABLE HEADS

FOR BORING & TURNING

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HDRNR 20-4 HDRNL 20-4 1-1/4 1-1/4 1/2 2-1/2 1/2 3/16 NL-46 DSN-433 C-2 1/4-28 x 3/4

HDRNR 24-4 HDRNL 24-4 1-1/2 1-3/8 1/2 2-3/4

HDRNR 28-4 HDRNL 28-4 1-3/4 1-1/2 1/2 3

HDRNR 32-5 HDRNL 32-5 2 1-3/4 5/8 3-1/2 5/8 1/4 NL-58

HDRNR 36-5 HDRNL 36-5 2-1/4 1-7/8 5/8 3-3/4

HDRNR 40-5 HDRNL 40-5 2-1/2 2 5/8 4

DSN-533-S

NEGATIVE RAKE

STYLE R 55 DIAMOND

DNMG, DNMP AND DNGA

For coolant provision add suffix C to catalog number (ex; HDRNR 20-4C)

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HCLNR 20-4 HCLNL 20-4 1-1/4 .765 1-5/8 1-17/32 1/2 3/16 NL-46 CSN-433-S C-1 10-32 x 5/8

HCLNR 24-4 HCLNL 24-4 1-1/2 .890 1-3/4 1-25/32 C-2 1/4-28 x 3/4

HCLNR 28-4 HCLNL 28-4 1-3/4 1.015 2 2-1/32

HCLNR 32-4 HCLNL 32-4 2 1.281 2 2-9/16

HCLNR 36-4 HCLNL 36-4 2-1/4 1.406 2 2-13/16

HCLNR 40-4 HCLNL 40-4 2-1/2 1.531 2 3-1/16

HCLNR 32-6 HCLNL 32-6 2 1.281 2 2-9/16 3/4 1/4 NL-68 CSN-633

HCLNR 36-6 HCLNL 36-6 2-1/4 1.406 2 2-13/16

HCLNR 40-6 HCLNL 40-6 2-1/2 1.531 2 3-1/16

NEGATIVE RAKE

STYLE L 80 DIAMOND

CNMA, CNMG, CNMP AND CNGA

For coolant provision add suffix C to catalog number (ex; HCLNR 20-4C)

High Tech Tool, Inc.

High Tech Tool, Inc. Page 33

REPLACEABLE HEADS

FOR BORING & TURNING

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HCKNR 20-4 HCKNL 20-4 1-1/4 .765 1-5/8 1-17/32 1/2 3/16 NL-46 CSN 433-S C-1 10-24 x 5/8

HCKNR 24-4 HCKNL 24-4 1-1/2 .890 1-3/4 1-25/32 C-2 1/4-28 x 3/4

HCKNR 28-4 HCKNL 28-4 1-3/4 1.015 2 2-1/32

HCKNR 32-4 HCKNL 32-4 2 1.281 2 2-9/16

HCKNR 36-4 HCKNL 36-4 2-1/4 1.406 2 2-13/16

HCKNR 40-4 HCKNL 40-4 2-1/2 1.531 2 3-1/16

HCKNR 32-6 HCKNL 32-6 2 1.281 2 2-9/16 3/4 1/4 NL-68 CSN-633

HCKNR 36-6 HCKNL 36-6 2-1/4 1.406 2 2-13/16

HCKNR 40-6 HCKNL 40-6 2-1/2 1.531 2 3-1/16

NEGATIVE RAKE

STYLE K 100 DIAMOND

CNMA, CNMG, CNMP AND CNGA

For coolant provision add suffix C to catalog number (ex; HCKNR 20-4C)

Catalog

Number

Dimensions Insert Size Parts

A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HTD-06714 1-3/4 .920 2 2-1/4 1/2 3/16 NL-46 CSN-433 C-1 10-24 x 5/8

HTD-13242 2 1.281 2 3 5/8

1/4

NL-58 CSN-533

C-2 1/4-28 x 3/4 HTD-08517 2-1/2 1.531 2 3-1/2

NL-68 CSN-633

HTD-10523 3 1.781 2.5 4

3/4

NEGATIVE RAKE

STYLE DP 80 DIAMOND

INSERTS: CNMG

Coolant is standard on this style

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk. Rad.

Insert

Screw

Seat

Seat

Screw

Clamp

Screw

(S.H.C.S)

HDQCR 16-3 HDQCL 16-3 1 .750 1-3/8 1-1/2 3/8 .156 1/32 S-3 10-32 x 5/8

HDQCR 20-3 HDQCL 20-3 1-1/4 .875 1-5/8 1-3/4

HDQCR 24-3 HDQCL 24-3 1-1/2 1.000 1-3/4 2 DSP-3 SS-3

HDQCR 28-3 HDQCL 28-3 1-3/4 1.125 2 2-1/4

HDQCR 32-3 HDQCL 32-3 2 1.250 2 2-1/2

HDQCR 36-3 HDQCL 36-3 2-1/4 1.375 2 2-3/4

HDQCR 40-3 HDQCL 40-3 2-1/2 1..500 2 3

E CLR.

5

5

4

3

3

3

3

For coolant provision add suffix C to catalog number (ex; HDQCR 20-3C)

POSITIVE RAKE

STYLE Q - 55 DIAMOND

DCMT

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HDJNR 20-4 HDJNL 20-4 1-1/4 1.000 1-5/8 2 1/2 3/16 NL-46 DSN-433 C-1 10-32 x 5/8

HDJNR 24-4 HDJNL 24-4 1-1/2 1.125 1-3/4 2-1/4 C-2 1/4-28 x 3/4

HDJNR 28-4 HDJNL 28-4 1-3/4 1.250 2 2-1/2

HDJNR 28-5 HDJNL 28-5 1-3/4 1.375 2 2-3/4 5/8 1/4 NL-58

HDJNR 32-5 HDJNL 32-5 2 1.500 2 3

HDJNR 36-5 HDJNL 36-5 2-1/4 1.625 2 3-1/4

HDJNR 40-5 HDJNL 40-5 2-1/2 1.750 2 3-1/2

DSN-533-S

NEGATIVE RAKE

STYLE J 55 DIAMOND

DNMG, DNMP AND DNGA

For coolant provision add suffix C to catalog number (ex; HDJNR 20-4C)

To Order Call: 713-641-2303 Page 34

REPLACEABLE HEADS

FOR BORING & TURNING

High Tech Tool, Inc.

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HVJNR 20-3 HVJNL 20-3 1-1/4 1.125 1-5/8 2-1/4 3/8 3/16 NL-34L IVSN-324 C-1 10-32 x 5/8

HVJNR 24-3 HVJNL 24-3 1-1/2 1.250 1-3/4 2-1/2 C-2 1/4-28 x 3/4

HVJNR 28-4 HVJNL 28-4 1-3/4 1.500 2 3 1/2 3/16 NL-46 IVSN-433

HVJNR 32-4 HVJNL 32-4 2 1.625 2 3-1/4

HVJNR 36-4 HVJNL 36-4 2-1/4 1.750 2 3-1/2

HVJNR 40-4 HVJNL 40-4 2-1/2 1.875 2 3-3/4

NEGATIVE RAKE

STYLE J 35 DIAMOND

VNMA, VNMG, VNMP, VNGA AND VNGP

For coolant provision add suffix C to catalog number (ex; HVJNR 20-3C)

Catalog Number Dimensions Insert Size Parts

Right Hand *Left Hand A B C D I.C. Thk.

Lock

Pin

Seat Clamp

Clamp

Screw

(S.H.C.S)

HDPNR 20-4 HDPNL 20-4 1-1/4 1.125 1-3/8 2-1/4 1/2 3/16 NL-46 DSN-433 C-2 1/4-28 x 3/4

HDPNR 24-4 HDPNL 24-4 1-1/2 1.250 1-1/2 2-1/2

HDPNR 28-4 HDPNL 28-4 1-3/4 1.375 1-3/4 2-3/4

HDPNR 32-5 HDPNL 32-5 2 1.625 1-3/4 3-1/4 5/8 1/4 NL-58

HDPNR 36-5 HDPNL 36-5 2-1/4 1.750 1-3/4 3-1/2

HDPNR 40-5 HDPNL 40-5 2-1/2 1.875 1-3/4 3-3/4

DSN-533

NEGATIVE RAKE

STYLE P 55 DIAMOND

DNMG, DNMP AND DNGA

For coolant provision add suffix C to catalog number (ex; HDPNR 20-4C)

High Tech Tool, Inc. Page 35

REPLACEABLE HEADS

FOR BORING & TURNING

Adapter designed

for your machine. See

below.

High Tech Tool developed the Quick Change connection to provide several productivity-enhancing features

such as;

Low-cost, ultra-rigid large diameter steel bars to virtually eliminate chatter, allowing higher speeds and

feeds.

Shorter setup times. A bar change can be performed in a couple of minutes.

A moment-resisting 5-inch diameter adapter face.

Easily adaptable to virtually any make of machine turret or tool changer, allowing bars to be shared across

different machines in your shop.

Cost less than carbide/devibe bars.

Internal coolant port suitable for high-pressure coolant applications.

How it works:

The bars 2-1/2 inch shank stabs into a turret adapter. The 5-inch diameter shoulder on the bar makes up to the

adapter face, and two 1-inch cone-point allen set screws in the adapter make up on offset-machined conical-

bottomed holes in the bar shank, pulling the bar tight against the adapter face. A keyway provides for positive

indexing at 0 and 180 for right hand and left hand applications.

Introducing the High Tech Tool line of Quick Change boring/turning/threading bars.

The turret or tool changer adapter is unique to the machine, but the bars are universal. We can build an adapter

for virtually any machine turret or tool changer. Here is a short list of a few machines we have built adapters for;

Okuma Horizontal & VTL Bullard Cincinnati Cinturn 18U, 24U

Dainichi Heligenstat Homma

J&L Mazak Slant Turn 60N, Powermaster Monarch

Mori Seiki SL-600, SL-403B, SL-8 Motch Okuma

Olympia Sunstrand W&S 5A

Cincinnati 24U turret loaded with

High Tech Quick Change Tooling

To Order Call: 713-641-2303 Page 36 QUICK-CHANGE TURRET TOOLING

High Tech Tool, Inc.

Please call with your particular application.

QUICK CHANGE BARS FOR BORING, THREADING AND TURNING

QUICK CHANGE BARS FOR BORING, THREADING AND TURNING

HEAVY DUTY W/OFFSET HEAD MOUNT

Catalog Number

Dimensions

D *L

G125 24-4 1-1/2 4

G125 24-6 1-1/2 6

G125 28-5 1-3/4 5

G125 28-7 1-3/4 7

G125 32-6 2 6

G125 32-8 2 8

G125 36-7 2-1/4 7

G125 36-9 2-1/4 9

G125 40-8 2-1/2 8

G125 40-10 2-1/2 10

Catalog Number

Dimensions

D *L

G125F 48-8 3 8

G125F 48-10 3 10

G125F 64-10 4 10

G125F 64-12 4 12

G125F 80-4.5 5 4.5

G125F 80-6 5 6

G125F 80-8 5 8

G125F 80-10 5 10

G125F 80-12 5 12

G125F 80-15 5 15

- As with all quick change bars, this bar may

be indexed 180. On these offset-style bars,

this allows you to obtain a right or left hand

offset.

* Special lengths are available upon request.

High Tech Tool, Inc. Page 37

Quick-Change bars

FOR BORING/THREADING/TURNING

- Available in Heavy Metal

* Special lengths and diameters

available upon request.

Introducing the High Tech Tool line of Quick Change chuck jaws.

To Order Call: 713-641-2303 Page 38 QUICK-CHANGE CHUCK JAWS

With the same goals in mind as the Quick-Change turret tooling, High Tech Tool developed the Quick Change

chuck jaw design;

Shorter setup times. A single jaw insert change can be performed in about a minute.

Jaws and inserts are hardened, providing excellent wear resistance. Soft jaws are available.

Repeatability within .002

Adaptable to virtually any make of machine chuck, allowing jaw inserts to be shared across different ma-

chines in your shop.

How it works:

A tongue and groove connection featuring ground surfaces and a diamond-dowel for positive location. The jaw

insert is clamped in place with a cone-point screw that makes up in a conical relief in the tongue of the jaw in-

sert, pulling the insert against the top jaw. The ground surfaces of the jaw and top jaw ensure a rock-solid con-

nection.

Top jaw designed

for your machine. See

below.

The top jaw is unique to the machine, but the jaws inserts are universal. We can build top jaws for virtually any

machine turret or tool changer. Here is a short list of a few machines we have built top jaws for;

Okuma Horizontal & VTL Bullard Cincinnati Cinturn 18U, 24U

Dainichi Heligenstat Homma

J&L Mazak Slant Turn 60N, Powermaster Monarch

Mori Seiki SL-600, SL-403B, SL-8 Motch Okuma

Olympia Sunstrand W&S 5A

High Tech Tool, Inc.

Jaws are available in a variety of configurations, including but not limited to;

Wrap-around (see inside rear cover)

Jaws with carbide gripper pads

Soft jaws

Please call us with your particular application.

Special and custom products:

Carbide Inserts

Special threading and grooving

inserts ground on all popular style

blanks. Some examples are

shown in a, b, c, d and e.

Other styles are available on re-

quest. Send us your drawings or

let us design inserts for y our

needs.

Tooling combinations

f) Specially built tool packages to

meet specific customer needs.

g) Ring grooving heads for flycut-

ting API ring grooves. Uses style

APISMR qualified holders in this

catalog.

Chuck jaws

g) Various types of chuck jaws for

pipe and tubing with or without car-

bide gripper pads.

Designed tooling packages

h) Efficient turning, boring, thread-

ing and grooving with specially de-

signed gang tool blocks, tool hold-

ers, boring bars and heads, de-

signed to meet your specific

needs.

From chuck face to turret and eve-

rything in between, you can de-

pend on High Tech Tool for all

your tooling and accessories.

Technical Capabilities

Using our CAD/CAM systems and

manufacturing skills, we can pro-

duce specially designed jigs, fix-

tures and tooling to meet your

needs.

If you have not worked with us be-

fore, give us a call! You will appre-

ciate our prompt deliveries and the

consistently high quality of our

products.

a b

h

h

f

c

d e

g

High Tech Tool, Inc. Page 39 HIGH TECH TOOL, INC.

High Tech Tool, Inc. High Tech Tool, Inc. High Tech Tool, Inc. High Tech Tool, Inc.

7803 S. Loop East

Houston, TX 77012

Phone: 713.641.2303

Fax: 713.641.6664

Email: sales@hightechtool.com

Web & Online Catalog: www.hightechtool.com

High Tech Tool: The Company -

High Tech Tool, located in Houston, Texas, is a major pro-

ducer of tooling and accessories in the southwest. We

service domestic and international markets serving all ma-

jor industries such as oil field, aerospace, defense, and

automotive.

High Tech Tool: Manufacturing -

High Tech Tools spacious 32,000 sq. ft. manufacturing

facility, in Houston, Texas is centrally located for easy cus-

tomer access or service requirements.

Equipment at this facility includes standard and specially

built machinery for grinding, threading and grooving, bor-

ing, drilling, 3 and 5-axis NC milling and turning, conven-

tional milling and turning, as well as other specialized ma-

chine operations.

High Tech Tool: Design Engineering -

Discuss your tooling and accessories needs with our ex-

perienced tool design engineers and professionals.

We understand your problems, and by using our advanced

CAD/CAM systems, we can work closely with you to solve

them.

High Tech Tool: Customer Service -

With over 100 years of tooling and manufacturing experi-

ence, plus design and manufacturing capabilities, High

Tech Tool offers a product and problem solving combina-

tion that customers have come to depend on. Also pro-

vided are:

Quality products

Prompt deliveries

Quick response time

Competitive prices

Let us consult with you regarding your manufacturing and

tooling requirements.

We look forward to working with you

You might also like

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- High Tech Tool Catalog PDFDocument40 pagesHigh Tech Tool Catalog PDFMakmur Hasan100% (1)

- TurboTorch CatalogDocument32 pagesTurboTorch CatalogZiad Al HussainNo ratings yet

- TTM/TTK/TTC TIG torch technical specifications and ordering codesDocument4 pagesTTM/TTK/TTC TIG torch technical specifications and ordering codescocoNo ratings yet

- Accessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsDocument32 pagesAccessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsPartsGopher.comNo ratings yet

- KX TG9341BX Service ManualDocument115 pagesKX TG9341BX Service ManualroyapriportNo ratings yet

- TTA11 BrocDocument42 pagesTTA11 BrocMáy cầm tay Hoàng TrungNo ratings yet

- TurboTorch 1423-0024 CatalogDocument40 pagesTurboTorch 1423-0024 CatalogMáy cầm tay Hoàng TrungNo ratings yet

- Debitarea Oxi GazDocument24 pagesDebitarea Oxi GazRogo CatalinNo ratings yet

- 1 SW Tig 175 PDFDocument6 pages1 SW Tig 175 PDFCarlos Padilla100% (1)

- Каталог адаптеров ParkerDocument26 pagesКаталог адаптеров ParkergeomashsnabNo ratings yet

- CB-8391 CBND Technical Data - SpecificationsDocument43 pagesCB-8391 CBND Technical Data - SpecificationsRodrigo Lagos EscobarNo ratings yet

- Air Mite CatalogDocument56 pagesAir Mite Catalogtemoc128No ratings yet

- Catalog Materiale de Adaos FileurDocument193 pagesCatalog Materiale de Adaos FileurRogo CatalinNo ratings yet

- Roberts Oxygen Welding Industrial Catalog 2011Document104 pagesRoberts Oxygen Welding Industrial Catalog 2011sanjibkrjanaNo ratings yet

- Bernard Q - Gun Parts Break DownDocument13 pagesBernard Q - Gun Parts Break DownullwnNo ratings yet

- Gatescorporationhydraulichosecouplingsequipment 2015 ProductscatalogDocument626 pagesGatescorporationhydraulichosecouplingsequipment 2015 ProductscatalogAhmed Metin RashidNo ratings yet

- Counter TigDocument8 pagesCounter TigMichael SchreiberNo ratings yet

- ThyssenKrupp Drilling CatálogoDocument16 pagesThyssenKrupp Drilling Catálogoflasher_for_nokiaNo ratings yet

- Linde q1 Feb1march31Document12 pagesLinde q1 Feb1march31KiukStaksNo ratings yet

- 14R013FC Watts Air RegulatorDocument24 pages14R013FC Watts Air RegulatorMROstop.comNo ratings yet

- EquipmentDocument58 pagesEquipmentPartsGopher.com100% (1)

- BTC Gate ValvesDocument26 pagesBTC Gate ValvesCamilo Sanchez VanegasNo ratings yet

- Data Sheet Tag 180-Pu-011eDocument8 pagesData Sheet Tag 180-Pu-011eSarah PerezNo ratings yet

- Honda / AcuraDocument7 pagesHonda / Acuracrower_scribdNo ratings yet

- Royal Catalog MedDocument32 pagesRoyal Catalog MedGerardo Miranda IIINo ratings yet

- CS310ADocument4 pagesCS310Arabacet2923No ratings yet

- BAP Choke CatalogDocument26 pagesBAP Choke Catalogkutts76No ratings yet

- Anchor Rods: ManufacturingDocument22 pagesAnchor Rods: Manufacturingjacopap100% (1)

- Hanla Vol1Document40 pagesHanla Vol1jasleenchhabraNo ratings yet

- MBD Annular SectionDocument4 pagesMBD Annular SectionCompra Venta De Maquinaria IndustrialNo ratings yet

- Low Cost Quartz Crystal OptionsDocument6 pagesLow Cost Quartz Crystal Optionselectrocla86No ratings yet

- Hydraulic Fluid Warmers: Hydra Liner SeriesDocument2 pagesHydraulic Fluid Warmers: Hydra Liner Seriesfrancis_15inNo ratings yet

- Hydraulic: Hose & FittingsDocument40 pagesHydraulic: Hose & FittingsBoedi Syafiq100% (1)

- Unj Roscas InsertosDocument6 pagesUnj Roscas InsertosCreativo2013No ratings yet

- Pressure and Vacuum Switches - 216Document32 pagesPressure and Vacuum Switches - 216Nirav GandhiNo ratings yet

- Catalogo WT FerramentasDocument8 pagesCatalogo WT FerramentasMaria OrtegaNo ratings yet

- 3/4" - 2" Cartridge Style Liquid Turbine Meter: Features/BenefitsDocument2 pages3/4" - 2" Cartridge Style Liquid Turbine Meter: Features/Benefitssrmedinac2122No ratings yet

- Condensadora TTB TraneDocument24 pagesCondensadora TTB TraneRoberto Reyes Lara100% (1)

- IAI Mini Robo Cylinder CatalogDocument167 pagesIAI Mini Robo Cylinder CatalogElectromateNo ratings yet

- Gates CatalogDocument72 pagesGates CatalogAldo B Aldo BNo ratings yet

- Burndy CatalogDocument79 pagesBurndy CatalogRoger Carlos100% (1)

- Welding& Inspection WPS& WelderDocument112 pagesWelding& Inspection WPS& WelderNitesh Garg100% (7)

- Siamesa Recto Y Siamesa GiacominiDocument8 pagesSiamesa Recto Y Siamesa GiacominieselcosacNo ratings yet

- High Tensile Industrial Fasteners and Precision ComponentsDocument12 pagesHigh Tensile Industrial Fasteners and Precision ComponentsSandeep KaundinyaNo ratings yet

- Ordering Information: Text Text DIP Switch (Rotary Type) - A6R/A6RV DIP Switch (Rotary Type) - A6C/A6CVDocument4 pagesOrdering Information: Text Text DIP Switch (Rotary Type) - A6R/A6RV DIP Switch (Rotary Type) - A6C/A6CVNiklasNo ratings yet

- Canalta Parts Catalogue PDFDocument25 pagesCanalta Parts Catalogue PDFZohaib MaqboolNo ratings yet

- 160S 1Document51 pages160S 1Ahmad Mustaghfiri AsrarNo ratings yet

- Fil+Reg+Lub: D A E D A EDocument14 pagesFil+Reg+Lub: D A E D A EIrwin ParedesNo ratings yet

- Aeroquip Part IndexDocument9 pagesAeroquip Part IndexSetyohdWNo ratings yet

- Products Presentation MajorDocument47 pagesProducts Presentation MajorJuanita AndrewsNo ratings yet

- Kollmorgen Powermax II CatalogDocument4 pagesKollmorgen Powermax II CatalogElectromateNo ratings yet

- Lsis Miniature Circuit BreakersDocument5 pagesLsis Miniature Circuit BreakersECATOnlineNo ratings yet

- Vircap Profile NewDocument12 pagesVircap Profile Newtgohiakri2006No ratings yet

- Ed5 5Document8 pagesEd5 5Anonymous 4e7GNjzGWNo ratings yet

- Portable welding and gas/plasma cutting machineDocument4 pagesPortable welding and gas/plasma cutting machineCarlos PadillaNo ratings yet

- Aurora A 03 201Document36 pagesAurora A 03 201macsosaNo ratings yet

- HazMaxPinnacle AlDocument6 pagesHazMaxPinnacle AlCasadotab TolentinoNo ratings yet

- 8 Perguntas Sobre Alienação Parental - A Construção Do Desamor - Geledés PDFDocument3 pages8 Perguntas Sobre Alienação Parental - A Construção Do Desamor - Geledés PDFMadirley PimentaNo ratings yet

- Book Partituras - Richard Clayderman 3 - Piano Solo Best Collection PDFDocument49 pagesBook Partituras - Richard Clayderman 3 - Piano Solo Best Collection PDFMadirley Pimenta100% (1)

- Carbodur Komplett Uk 1 PDFDocument13 pagesCarbodur Komplett Uk 1 PDFMadirley PimentaNo ratings yet

- SAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFDocument5 pagesSAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFMadirley PimentaNo ratings yet

- BOP Catalog vFEB20152 PDFDocument36 pagesBOP Catalog vFEB20152 PDFMadirley Pimenta100% (1)

- Material Data Sheets and Element Data Sheets For PipingDocument133 pagesMaterial Data Sheets and Element Data Sheets For PipingJorge Durão100% (1)

- 6252 8377 1 PB PDFDocument5 pages6252 8377 1 PB PDFMadirley PimentaNo ratings yet

- Did You Think To Pray: Arranged by Amber L. Tilley and Naloni LovellDocument6 pagesDid You Think To Pray: Arranged by Amber L. Tilley and Naloni LovellMadirley PimentaNo ratings yet

- Chapter-1: Well ControlDocument25 pagesChapter-1: Well ControlRama KrishnaNo ratings yet

- 4362 en PDFDocument6 pages4362 en PDFMadirley PimentaNo ratings yet

- 1 CR Mo-ARCELORMITTAL - PRESSURE - VESSELDocument12 pages1 CR Mo-ARCELORMITTAL - PRESSURE - VESSELRocky ThomasNo ratings yet

- SAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFDocument5 pagesSAE J404 2000 Chemical Compositions of SAE Alloy Steels PDFMadirley PimentaNo ratings yet

- Bop HydrilDocument1 pageBop HydrilMadirley PimentaNo ratings yet

- M CR 601r1Document14 pagesM CR 601r1nazari123No ratings yet

- Catalogo General BOPs (Hydril - GE)Document46 pagesCatalogo General BOPs (Hydril - GE)Ronal Borrero100% (2)

- BopDocument37 pagesBopBrahim Letaief100% (1)

- BOP Operations MaintenanceDocument54 pagesBOP Operations MaintenanceSean Murphy100% (2)

- API CatalogueDocument20 pagesAPI CatalogueMadirley Pimenta100% (1)

- Austinitic WeldDocument43 pagesAustinitic WeldJim GrayNo ratings yet

- General Welding Fabrication and TestingDocument24 pagesGeneral Welding Fabrication and TestingAhmed FathyNo ratings yet

- ECFR - Code of Federal RegulationsDocument8 pagesECFR - Code of Federal RegulationsMadirley PimentaNo ratings yet

- 3Document4 pages3Madirley PimentaNo ratings yet

- API FlangesDocument2 pagesAPI FlangesandresaroNo ratings yet

- Cameron LoadKing Drilling Riser 3.5 ManualDocument277 pagesCameron LoadKing Drilling Riser 3.5 ManualMadirley Pimenta83% (6)

- RTJDocument5 pagesRTJkdvc18No ratings yet

- dataStyleBX 0 0Document2 pagesdataStyleBX 0 0Madirley PimentaNo ratings yet

- Agenda: of The ASME Boiler and Pressure VesselDocument240 pagesAgenda: of The ASME Boiler and Pressure VesselMadirley PimentaNo ratings yet

- Flange Api6a Api6b Api6bx BlindDocument4 pagesFlange Api6a Api6b Api6bx BlindMadirley PimentaNo ratings yet

- DOUBLE STUDDED ADAPTER FLANGE SPECSDocument1 pageDOUBLE STUDDED ADAPTER FLANGE SPECSMadirley PimentaNo ratings yet

- Klopp: AlloysDocument10 pagesKlopp: AlloyssunsirNo ratings yet

- 14 Oktobar PrezentacijaDocument56 pages14 Oktobar PrezentacijaJovan VukovicNo ratings yet

- Qatar Building Engineering Company Site Work Procedure for Building PaintingDocument5 pagesQatar Building Engineering Company Site Work Procedure for Building PaintingTATATAHERNo ratings yet