Professional Documents

Culture Documents

Sika Intraplast Z

Uploaded by

reborn_willyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sika Intraplast Z

Uploaded by

reborn_willyCopyright:

Available Formats

Product Data Sheet

Edition 0608 / 1

Intraplast

-Z

1 1/3

C

o

n

s

t

r

u

c

t

i

o

n

Intraplast

-Z

I nt r apl ast

-Z

Expanding grout admixture

Product

Description

Intraplast

-Z is a ready to use injection aid in powder form. It is non-toxic, non-

flammable and does not contain chlorides or other ingredients of a corrosive nature.

Intraplast

-Z causes the cement mixture to expand before setting. The swelling is

caused by the extremely regular formation of densely distributed tiny gas bubbles

consisting of inert hydrogen. These very tiny pores give the set material a high

degree of frost resistance.

Uses Intraplast

-Z is a patented special product for the grouting of prestressing cables,

loose soil formation and cavities in rocks. The use of Intraplast

-Z in the grouting

mixture has the following effects:

Prolonged workability

Good strength and adherence properties

Protective action against corrosion of the prestressing wires

Durable and dense filing of all cavities

Characteristics /

Advantages

Causes cement mixtures to expand before setting

Reduces the separation of water (bleeding) from the mixture

Prevents premature setting

Makes a reduction of the amount of gauging water possible

Non-toxic and non-flammable

No chloride or other ingredients of corrosive nature

Product Data

Form

Appearance / Colour Ready to use powder, grey

Packaging 20 x 1 kg packs per bag

Storage

Storage Conditions /

Shelf Life

12 months from the date of production if stored properly in original, unopened and

undamaged sealed packaging in dry conditions.

2 2/3

Intraplast

-Z

Mechanical / Physical

Properties

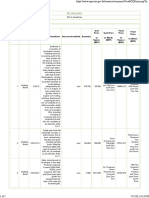

Typical Results

Control Sample 1 Sample 2

Mix Design Cement

Water

Intraplast

-Z per 50 kg OPC

1

0.5

-

1

0.45

500 g

1

0.4

1000 g

Flow Test JA Cone 3 mins after mixing

(3 mins 0.3 sec)

3.09

seconds

3.18

seconds

3.31

seconds

Density (kg/m) 1,840 1,850 1,885

Air Content (%) 8.2 5.8 6.4

Expansion (%) 30 minutes

1 hour

3 hours

5 hours

7 hours

24 hours

0.663

0.550

0.325

0.050

-0.110

-0.280

1.150

1.088

0.963

0.700

0.525

0.350

3.638

3.850

3.775

3.525

3.238

1.850

Compressive Strength (N/mm

2

) 1 day

7 days

28 days

13.4

26.0

41.7

11.8

29.2

44.2

13.7

31.6

49.5

System Information

Application Details

Recommended Dosage 1 2% by weight of cement (0.5 1.0 kg per 50 kg cement)

Application Instructions

Mixing When grout containing sand is to be used the mixing sequence should be Sand

Cement Intraplast

-Z Water.

For prestressed concrete work where batching of the mixture is done in the usual

mechanical way, a mixing time of 4 minutes together with a w / c ratio of 0.40 0.45

are found to be satisfactory. Generally the most suitable mixing sequence is Water

Cement Intraplast

-Z.

Application Method /

Tools

Place the grouting material within 15 minutes of mixing to gain the full benefit of the

expansion process. The normal means of placing and pumping of grouting material

should be used to ensure a continuous flow.

It is not recommended to add sand for prestressed concrete work.

Cleaning of Tools Clean all tools and application equipment with water immediately after use.

Hardened and/or cured material can only be removed mechanically.

Notes on Application /

Limitations

Intraplast

-Z is essentially a product for use by specialists working in the field of

prestressing and grouting techniques

It is known that the properties of the injection aid can be significantly influenced

by the mixing procedure, cement properties, addition of water and sand and

temperatures

For important work it is necessary to determine the most suitable procedure by

means of preliminary site tests

Cement containing fly ash may show lower expansion

3 3/3

Intraplast

-Z

Curing Details

Applied Product

Ready For Use

All exposed areas which have been grouted should be cured using Sikas range of

curing compounds or wet hessian.

Value Base

All technical data stated in this Product Data Sheet are based on laboratory tests.

Actual measured data may vary due to circumstances beyond our control.

Health and Safety

Information

For information and advice on the safe handling, storage and disposal of chemical

products, users shall refer to the most recent Material Safety Data Sheet (available

upon request) containing physical, ecological, toxicological and other safety-related

data.

Legal Note

The information, and, in particular, the recommendations relating to the application

and end-use of Sika products, are given in good faith based on Sika's current

knowledge and experience of the products when properly stored, handled and

applied under normal conditions in accordance with Sikas recommendations. In

practice, the differences in materials, substrates and actual site conditions are such

that no warranty in respect of merchantability or of fitness for a particular purpose,

nor any liability arising out of any legal relationship whatsoever, can be inferred

either from this information, or from any written recommendations, or from any other

advice offered. The user of the product must test the products suitability for the

intended application and purpose. Sika reserves the right to change the properties

of its products. The proprietary rights of third parties must be observed. All orders

are accepted subject to our current terms of sale and delivery. Users must always

refer to the most recent issue of the local Product Data Sheet for the product

concerned, copies of which will be supplied on request.

C

o

n

s

t

r

u

c

t

i

o

n

Sika Kimia Sdn Bhd

Lot 689 Nilai Industrial Estate

71800 Nilai, Negeri Sembilan DK

MALAYSIA

Phone: +6 06 799 1762

Fax: +6 06 799 1980

e-mail: info@my.sika.com

www.sika.com.my

You might also like

- Reinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part PrintDocument7 pagesReinforced Concrete Designers Handbook 10th Edition Reynolds Steedman 2 Part Printikanyu79No ratings yet

- John McClod CampbellDocument52 pagesJohn McClod Campbellreborn_willyNo ratings yet

- Thumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb Rules - Civil SiteDocument36 pagesThumb Rules in Building Construction For Civil Engineers - Important Point of Civil Engineering - Construction Thumb Rules - Civil SiteSandeep Kumar100% (2)

- Classification of Soil and Soil-Aggregate AASHTO M-145Document4 pagesClassification of Soil and Soil-Aggregate AASHTO M-145caballerolang0% (1)

- WTP Cost Estimate PDFDocument13 pagesWTP Cost Estimate PDFSurangaGNo ratings yet

- C1155Document8 pagesC1155dinhtung2210No ratings yet

- Base-Course CBR 80Document2 pagesBase-Course CBR 80dr0% (1)

- Concrete Mix Design (ACI)Document8 pagesConcrete Mix Design (ACI)Oby RobiniNo ratings yet

- Jacobs RiggingDocument27 pagesJacobs Riggingreborn_willy50% (2)

- WSDOT FOP For AASHTO T 106Document14 pagesWSDOT FOP For AASHTO T 106malaya tripathyNo ratings yet

- Augustine The Spirit and The LetterDocument7 pagesAugustine The Spirit and The Letterreborn_willyNo ratings yet

- D1194 Bearing Capacity of Soil For Static Load and SpreadDocument3 pagesD1194 Bearing Capacity of Soil For Static Load and SpreadShehab AhmedNo ratings yet

- Twisting Tower DesignDocument17 pagesTwisting Tower Designmajkil1988100% (1)

- 100% Fly Ash in ConcreteDocument19 pages100% Fly Ash in ConcreteVinay BabuNo ratings yet

- PLT Test (Astm d1196)Document113 pagesPLT Test (Astm d1196)Rango SantosoNo ratings yet

- Reinforced Concrete Design of A 5 Storey Seminary Main BuildingDocument117 pagesReinforced Concrete Design of A 5 Storey Seminary Main Buildingjedsclement100% (1)

- Desain Angkur BoltDocument23 pagesDesain Angkur BoltWidyanto TomiNo ratings yet

- C1666 1207960-1Document4 pagesC1666 1207960-1Fabio Teodoro100% (1)

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDocument3 pagesSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarNo ratings yet

- Method StatementDocument3 pagesMethod Statementreborn_willyNo ratings yet

- Sika® Viscocrete®-8007: Product Data SheetDocument3 pagesSika® Viscocrete®-8007: Product Data SheetAgus MakbulNo ratings yet

- Sika Viscoflow®-3880 LV: Product Data SheetDocument3 pagesSika Viscoflow®-3880 LV: Product Data Sheetedars08100% (1)

- False Setting N Flash SettingDocument1 pageFalse Setting N Flash SettingSai Datta100% (1)

- Nitowrap FRC BaruDocument2 pagesNitowrap FRC BaruZax SantanaNo ratings yet

- Detail Penulangan Tiang Pancang 30cm by Satria Bali Januari 2019Document1 pageDetail Penulangan Tiang Pancang 30cm by Satria Bali Januari 2019Wili JanuarsaNo ratings yet

- Lokfix E75 TDS 8072020Document5 pagesLokfix E75 TDS 8072020KumarRamNo ratings yet

- Kelebihan Dan Kekurangan Soldier PileDocument1 pageKelebihan Dan Kekurangan Soldier PileDeny Tri Achmadi Zulkarnain100% (1)

- Neopor Mix Design Metric PDFDocument1 pageNeopor Mix Design Metric PDFJustin BeiterNo ratings yet

- Mastertop 100 PDFDocument2 pagesMastertop 100 PDFMohiuddin MuhinNo ratings yet

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDocument3 pagesTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForNazmus SakibNo ratings yet

- Brosur Jembatan (Terbaru) OKkkDocument24 pagesBrosur Jembatan (Terbaru) OKkkdede_anfieldNo ratings yet

- Utilizing Shotcrete and Gunite For Infrastructure RehabilitationDocument30 pagesUtilizing Shotcrete and Gunite For Infrastructure RehabilitationMurali CkNo ratings yet

- TamRez 220 TG PDFDocument2 pagesTamRez 220 TG PDFlim kang hai100% (2)

- Cebex 100Document19 pagesCebex 100Putu Roby Adhitya Sapanca100% (1)

- EXCEL Tabel BajaDocument2 pagesEXCEL Tabel Bajaayu2023No ratings yet

- Dartar Berat BesiDocument12 pagesDartar Berat BesiIskak UnoNo ratings yet

- Wiremesh InstallationDocument3 pagesWiremesh InstallationFitriansyah Adi Putra IrwanNo ratings yet

- Astm C131Document2 pagesAstm C131Salahuddin Al-Habal75% (4)

- Roman Catalog KeramikDocument2 pagesRoman Catalog KeramikAnci Ewen ItahNo ratings yet

- C1386 07 PDFDocument4 pagesC1386 07 PDFGanesh BhusariNo ratings yet

- Pengaruh Plstiment VZ Terhadap BetonDocument20 pagesPengaruh Plstiment VZ Terhadap BetonMalikNo ratings yet

- D946D946M 15.pdf (EngPedia - Ir)Document2 pagesD946D946M 15.pdf (EngPedia - Ir)Baba Mountain Gem ServicesNo ratings yet

- 17-1 Usage of Recycled Tyre MCRJ Volume 29, No.3, 2019 PDFDocument10 pages17-1 Usage of Recycled Tyre MCRJ Volume 29, No.3, 2019 PDFNor Intang Setyo HNo ratings yet

- Pile Cap DesignDocument4 pagesPile Cap DesignMohamed RifdyNo ratings yet

- Core Strength Variation of In-Place Concrete - tcm77-1305833Document3 pagesCore Strength Variation of In-Place Concrete - tcm77-1305833usama anterNo ratings yet

- Masterbrace® Fib (Formerly Known As Mbrace® Fibre)Document3 pagesMasterbrace® Fib (Formerly Known As Mbrace® Fibre)KY Peng100% (1)

- As 1289.6.9.1-2000 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation Test - DDocument2 pagesAs 1289.6.9.1-2000 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation Test - DSAI Global - APACNo ratings yet

- 4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As AggregateDocument9 pages4 Strengths of Recycled Aggregate Concrete Made Using Field-Demolished Concrete As Aggregateget100% (2)

- Brosur - PT. Jaya Beton IndonesiaDocument8 pagesBrosur - PT. Jaya Beton IndonesiaDita DitaNo ratings yet

- Facade & Fenestration Glass Embedding General GuidelinesDocument20 pagesFacade & Fenestration Glass Embedding General GuidelinesFrancisco BastidasNo ratings yet

- Square PipeDocument2 pagesSquare PipeWijayanto BekasiNo ratings yet

- Astm d2345Document4 pagesAstm d2345mithileshNo ratings yet

- Aci 213R-87Document27 pagesAci 213R-87farhadamNo ratings yet

- CMP0000599 - PC - Katalog Bevananda PDFDocument8 pagesCMP0000599 - PC - Katalog Bevananda PDFRieskeIswardhanyNo ratings yet

- Precast 3 Floors PDFDocument90 pagesPrecast 3 Floors PDFyaya_putraaNo ratings yet

- Astm A615 09bDocument6 pagesAstm A615 09bJad LouisNo ratings yet

- Astm C-88Document5 pagesAstm C-88Fernanda MenesesNo ratings yet

- 6 ASTM C138 Density Yield Air ContentDocument4 pages6 ASTM C138 Density Yield Air Contentdidavaran tejaratNo ratings yet

- ASTM C 535 03 Abrasion TestDocument3 pagesASTM C 535 03 Abrasion TestIsmaelMartinezNo ratings yet

- Mutu Beton Standar EropaDocument1 pageMutu Beton Standar EropaDedy RachayuNo ratings yet

- Intraplast Z 2011-10-1Document3 pagesIntraplast Z 2011-10-1le thanhNo ratings yet

- Intraplast Z Pds enDocument2 pagesIntraplast Z Pds enmpm bandungNo ratings yet

- Plastiment V105 PDFDocument2 pagesPlastiment V105 PDFDarwin SyahputraNo ratings yet

- Sika Grout 114Document5 pagesSika Grout 114Hassan MehmoodNo ratings yet

- Sika Grout 214 (HE)Document3 pagesSika Grout 214 (HE)aselabollegalaNo ratings yet

- Sikaflex 11FCDocument3 pagesSikaflex 11FCthe pilotNo ratings yet

- SikaTop Seal-109 MY 2012-08 - 1Document3 pagesSikaTop Seal-109 MY 2012-08 - 1Mashithah AhmadNo ratings yet

- Sika PDS - E - SikaGrout - Aid PDFDocument3 pagesSika PDS - E - SikaGrout - Aid PDFlwin_oo2435No ratings yet

- Binary Interaction Parameters For Nonpolar Systems With Equations of State. A Theoretical Approach. 1. CO2-HC Using SRK (Coutinho Et - Al., 1994) PDFDocument30 pagesBinary Interaction Parameters For Nonpolar Systems With Equations of State. A Theoretical Approach. 1. CO2-HC Using SRK (Coutinho Et - Al., 1994) PDFreborn_willyNo ratings yet

- Test ProcedureDocument15 pagesTest ProcedureAbhishek TuliNo ratings yet

- Eaton Pipeline Strainer Pressure Drop CalculationsDocument1 pageEaton Pipeline Strainer Pressure Drop Calculationsreborn_willyNo ratings yet

- Theological MethodDocument10 pagesTheological Methodreborn_willyNo ratings yet

- Thermal Properties of The Product of Palm Stearin and Linseed Oil TransesterificationDocument8 pagesThermal Properties of The Product of Palm Stearin and Linseed Oil Transesterificationreborn_willyNo ratings yet

- Biodiesel Production From Palm Fatty Acid Distillate (Pfad) Using Reactive DistillationDocument7 pagesBiodiesel Production From Palm Fatty Acid Distillate (Pfad) Using Reactive Distillationreborn_willyNo ratings yet

- 200M3 IGNITION OIL TANK 2 (R-03) - ModelDocument1 page200M3 IGNITION OIL TANK 2 (R-03) - Modelery achjariNo ratings yet

- The Optimum Amount of Waste Glass Aggregate That Can Substitute FineDocument13 pagesThe Optimum Amount of Waste Glass Aggregate That Can Substitute FineAper ZavaNo ratings yet

- MARKER POST-ISOMATRIC ModelDocument1 pageMARKER POST-ISOMATRIC Modelmostafa ibrahimNo ratings yet

- Sikafloor 225N: UV Resistant Epoxy SystemDocument4 pagesSikafloor 225N: UV Resistant Epoxy SystemBudhi KurniawanNo ratings yet

- Self Healing 4Document9 pagesSelf Healing 4Toni ArangelovskiNo ratings yet

- High Strength ConcreteDocument6 pagesHigh Strength ConcreteOnline AdoroNo ratings yet

- W Brochure SP25-SP25i 0316 LO enDocument48 pagesW Brochure SP25-SP25i 0316 LO enaniteisilviu8No ratings yet

- Application of Bamboo For Flexural and Shear Reinforcement in Con PDFDocument271 pagesApplication of Bamboo For Flexural and Shear Reinforcement in Con PDFKarthik MHNo ratings yet

- Developments in Structural Design Standards With Bamboo-Trujillo, DavidDocument8 pagesDevelopments in Structural Design Standards With Bamboo-Trujillo, DavidJohn HansNo ratings yet

- Concure DPM PDFDocument2 pagesConcure DPM PDFmilanbrasinaNo ratings yet

- 01 Flyash Brick1Document142 pages01 Flyash Brick1Jigar M. Upadhyay100% (2)

- Package II Part I.1 Civil BOQ For Transit House BuildingDocument29 pagesPackage II Part I.1 Civil BOQ For Transit House Buildingdox4useNo ratings yet

- DM Fillerboard - HuntonDocument65 pagesDM Fillerboard - HuntonFahis V MNo ratings yet

- R07 HC3D02 MML 02 XX DWG Ci 55501Document1 pageR07 HC3D02 MML 02 XX DWG Ci 55501moh amohNo ratings yet

- Point Load Test 2Document12 pagesPoint Load Test 2Rajitha ShehanNo ratings yet

- Fugro Technical Services (Guangzhou) Limited: Registration No. HOKLAS 170 Page 1 of 11 28 March 2014 Ref: 170-24Document11 pagesFugro Technical Services (Guangzhou) Limited: Registration No. HOKLAS 170 Page 1 of 11 28 March 2014 Ref: 170-24Ahmed AyadNo ratings yet

- Lastic 450 I 120427Document4 pagesLastic 450 I 120427Mohiuddin MuhinNo ratings yet

- Full Thesis PDFDocument87 pagesFull Thesis PDFAli HossainNo ratings yet

- M/s. Abdul HakimDocument5 pagesM/s. Abdul Hakimmd. shaju ahamedNo ratings yet

- M40 Grade Concrete Mix Design As Per ACI MethodDocument7 pagesM40 Grade Concrete Mix Design As Per ACI Methodugrasen chaudharyNo ratings yet

- 1032 1561 1 PBDocument9 pages1032 1561 1 PBJHON WILMAR CARDENAS PULIDONo ratings yet

- DSR PuneDocument8 pagesDSR Punedigvijayjagatap50% (2)

- Solar Hybrid Chimney Final ReportDocument51 pagesSolar Hybrid Chimney Final ReportInder Mankotia50% (2)

- CusumDocument8 pagesCusumanjum100% (1)

- Training For Trainers of ZRTI/DTC (Bridges & Works Module) Training For Trainers of ZRTI/DTC (P.Way Module)Document5 pagesTraining For Trainers of ZRTI/DTC (Bridges & Works Module) Training For Trainers of ZRTI/DTC (P.Way Module)Thiyagarajan kNo ratings yet