Professional Documents

Culture Documents

Economic Design Concept For Small LNG Carriers Rev 3

Uploaded by

hardik58180 ratings0% found this document useful (0 votes)

131 views26 pagesThis document discusses economic design concepts for small LNG carriers. It notes trends toward smaller LNG carriers to serve new markets like power plants in remote areas without pipeline access. It proposes using Type C independent cargo tanks, as with ethane carriers, to minimize costs for ships up to 35,000 cubic meters. These self-supporting pressure vessels could be cylindrical or bilobe-shaped. Boil-off gas could be used for propulsion or reliquefied. A 7,500 cubic meter design for LNG/ethane/LPG is presented. Overall capital costs are estimated as 10-15% above comparable ethane carriers. The approach is concluded to meet the needs of developing small-scale LNG markets

Original Description:

Lng fuel tank

Original Title

Economic Design Concept for Small Lng Carriers Rev 3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document discusses economic design concepts for small LNG carriers. It notes trends toward smaller LNG carriers to serve new markets like power plants in remote areas without pipeline access. It proposes using Type C independent cargo tanks, as with ethane carriers, to minimize costs for ships up to 35,000 cubic meters. These self-supporting pressure vessels could be cylindrical or bilobe-shaped. Boil-off gas could be used for propulsion or reliquefied. A 7,500 cubic meter design for LNG/ethane/LPG is presented. Overall capital costs are estimated as 10-15% above comparable ethane carriers. The approach is concluded to meet the needs of developing small-scale LNG markets

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

131 views26 pagesEconomic Design Concept For Small LNG Carriers Rev 3

Uploaded by

hardik5818This document discusses economic design concepts for small LNG carriers. It notes trends toward smaller LNG carriers to serve new markets like power plants in remote areas without pipeline access. It proposes using Type C independent cargo tanks, as with ethane carriers, to minimize costs for ships up to 35,000 cubic meters. These self-supporting pressure vessels could be cylindrical or bilobe-shaped. Boil-off gas could be used for propulsion or reliquefied. A 7,500 cubic meter design for LNG/ethane/LPG is presented. Overall capital costs are estimated as 10-15% above comparable ethane carriers. The approach is concluded to meet the needs of developing small-scale LNG markets

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 26

Economic Design Concept for

S G C Small LNG Carriers

Klaus Dieter Gerdsmeyer

TGE Gas Engineering TGE Gas Engineering

Trends in LNG shipping

Larger LNG carriers for classicalLNG Larger LNG carriers for classical LNG

transportation market (up to 270,000 m)

S ll LNG i f LNG t t ti Smaller LNG carriers for new LNG transportation

market

Clean f el po er plants for remote ind strial areas or Clean fuel power plants for remote industrial areas or

islands

Regions without pipeline grid (e g Norwegian coast) Regions without pipeline grid (e. g. Norwegian coast)

Short sailing times in relation to LNG consumption

Design requirement for partial filling Design requirement for partial filling

Gastech 2006

2

Trends in LNG shipping

Smaller LNG carriers

A J apanese yard is building a 19 000 m vessel with 3 A J apanese yard is building a 19,000 m vessel with 3

spherical tanks (delivery: 2007).

An Australian company is developing projects of up to An Australian company is developing projects of up to

30,000 m transport capacity.

Standard designs for LNG ships (spherical aluminium Standard designs for LNG ships (spherical aluminium

tanks or membrane tanks) are expensive economics

for such niche markets have to be improved.

Gastech 2006

3

Trends in LNG shipping

Very Small LNG carriers (for coastal trade)

First very small ship (1,000 m) for Norwegian coast First very small ship (1,000 m) for Norwegian coast

delivered in 2004 (stainless steel tanks, electric

propulsion)

Two LNG ships of 2,500 m delivered in 2003/5 for

J apanese coast (cylindrical aluminium tanks)

Anthony Veder (NL) is building a 7,500 m

LNG/Ethylene carrier for coastal transport in Norway

(vessel design and gas plant supplied by TGE)

Gastech 2006

4

TGEs design approach to small LNG carriers

Objective: minimize the CAPEX Objective: minimize the CAPEX

Utilize the know-how from design of Ethylene carriers

Eth l hi TGE k t h f d li f Ethylene ships: TGEs market share for delivery of gas

handling systems and cargo tanks is more than 80%

Actual order book: 32 ethylene carriers Actual order book: 32 ethylene carriers

Maximize operation flexibility for a combined

LNG/Eth l /LPG i LNG/Ethylene/LPG-carrier

Main questions:

Cargo tank design

Boil-off gas handling / propulsion system

Gastech 2006

5

Types of cargo tanks for gas carriers

(Internal insulation tanks)

(Integral tanks) ( g )

(Semi-membrane tanks: very few applications)

M b t k Membrane tanks

Independent tanks

(Type A)

Type B Type B

Type C

Gastech 2006

6

TGEs design approach: independent Type C tanks

self supporting pressure self-supporting pressure

vessel

cylindrical or bilobe with y

outside insulation

no secondary barrier

i d required

no restriction concerning

partial filling partial filling

Gastech 2006

7

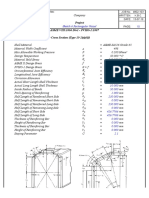

Cargo tanks for 22,000 m Ethylene-carrier

5 700 m (4 tanks) 5,700 m (4 tanks)

4.7 bar g

480 t 480 t

5% Nickel steel

Gastech 2006

8

Type C tanks for LNG

Ship capacity below 15,000 m

Cylindrical tank design Cylindrical tank design

o 2 tank design up to abt. 10,000 m

3 tank design upto abt 15 000 m o 3 tank design up to abt. 15,000 m

Ship capacity above 15,000 m

Bilobe tank design

o 3 tank design up to 25,000 m

o 4 tank design up to 35,000 m (or even 40,000 m)

Gastech 2006

9

Type C tanks for LNG

Tank design temperature: -163C

Tank material: Tank material:

(Aluminium)

(9% Ni-steel)

SS AISI 304L

Gastech 2006

10

Type C tanks for LNG

Ship design example: 30,000 m capacity:

4 Bilobe tanks each abt 7 500 m capacity 4 Bilobe tanks each abt. 7,500 m capacity

Min. design pressure @ density 500 kg/m:

AISI 304L 2 74 b o AISI 304L: 2.74 bar g

Tank weights:

o AISI 304L: abt. 530 tons

Gastech 2006

11

30,000 m LNG-Carrier

lbp = 175.2 m

b = 27.6 m

d = 8.8 m

speed = 17.5 kn

Gastech 2006

12

Type C tanks for LNG

Design constraints for LNG compared to Ethylene:

Higher material shrinkage due to: Higher material shrinkage due to:

o Larger delta T during cooling down

Higher material shrinkage factor for AISI 304L o Higher material shrinkage factor for AISI 304L

Problem especially for bi-lobe tanks:

for 15 mdiameter tanks the shrinkage is 35 mm(304L) for 15 m diameter tanks the shrinkage is 35 mm (304L)

Detailed design review and complete re-design of

supports necessary (displacement and stress analysis supports necessary (displacement and stress analysis,

temperature profiles)!

Gastech 2006

13

Type C tanks for LNG

D i i l b l ifi ti i t Design appraisal by a classification society

FEM analysis of tank shell, supports and shipside

steel structure for different loading cases steel structure for different loading cases

Gastech 2006

14

Tank insulation for LNG

Tank insulation for Ethylene: Tank insulation for Ethylene:

Typical Polystyrene panels glued to tank surface with

abt 230 mmthickness abt. 230 mm thickness

Tank insulation for LNG application

Same insulation type may be applied (spherical LNG

tanks use same technology)

I l ti thi k f 300 (b il ff t bt 0 35 Insulation thickness of 300 mm (boil-off rate abt. 0.35

0.45 %/day)

Design details modified (shrinkage stress) Design details modified (shrinkage, stress)

Gastech 2006

15

Type C tanks for LNG new design

Concept approval certificate already issued by Class

Patent pending Patent pending

30 35,000 m designs have been discussed for a

ifi j t ith th hi d th b i f specific project with three shipyards on the basis of

confidentiality agreements concerning design details

Gastech 2006

16

Boil-off gas handling / propulsion system

Alternatives for boil-off gas handling considering

typically short voyages and small BOG quantities: yp y y g q

a) Burn the BOG in a thermal oxidiser (combustor) ) ( )

b) Accept a pressure increase during voyage, provided

that receiving terminal can accept it g p

c) Utilize BOG for propulsion (electric power production)

d) Reliquefaction d) Reliquefaction

Gastech 2006

17

Boil-off gas handling g g

b) Pressure increase

3,5

4

9% Ni

2,5

3

b

a

r

g

]

SS 304L

1,5

2

P

r

e

s

s

u

r

e

[

b

Basic LNG

Composition

N2:2%

CO2:0%

0,5

1

C1:89%

C2:5,5%

C3:2,5%

C4:1%

Tank Volume: 30.000 m

Insulation: 300 mm

Polystyrene

Initial pressure: 140 mbar g

0

0 10 20 30 40 50 60

Sailing Time [days]

Gastech 2006

18

Boil-off gas handling g g

c) Utilize BOG for propulsion

Owner: Anthony Veder, NL (design and gas plant supplied by TGE)

Project: Coastal transport in Norway

LNG to be used as fuel

HFO to be used as fuel for transportation of other cargoes

Gastech 2006

19

Boil-off gas handling g g

c) Utilize BOG for propulsion

GAS

HFO

GAS HFO

7,500 m LNG/LEG/LPG carrier for Anthony Veder

Electric propulsion (Gas, HFO):

HFO generator sets: 2 x 3,685 kW

Gas generator sets: 2 x 2 280 kW Gas generator sets: 2 x 2,280 kW

thrusters for optimum manoeuvrability

Gastech 2006

20

Boil-off gas handling g g

d) Reliquefaction

Electric propulsion (utilize LNG and HFO as fuel) Electric propulsion (utilize LNG and HFO as fuel)

high CAPEX

Conventional slow speed diesel-mechanic (HFO)

BOG reliquefaction needed (CAPEX !), if pressure

increase is not an option increase is not an option

Alternative concepts based on mature technology:

pure LNG carriers: nitrogen system (Brayton cycle)

combined LNG/LEG carrier: utilize cascade technology

from Ethylene ships (under development)

Gastech 2006

21

Combined LNG/Ethylene/LPG Carrier

Ch i d f LNG t Eth l LPG Changing grade from LNG to Ethylene or LPG

requires tank warming up

Changing grade is time consuming (especially from

LNG to LPG)

Cargo contamination may be an issue (for some

cargoes visual inspection may be required) g y )

Frequent grade changes are not economic

Gastech 2006

22

Combined LNG/Ethylene/LPG Carrier

S ll LNG hi ith t C t k il b Small LNG ships with type C cargo tanks can easily be

upgraded to combined gas carriers (installation of

BOG reliquefaction for Ethylene) BOG reliquefaction for Ethylene)

LNG transportation in smaller quantities is not a mature

market market

Combined LNG/Ethylene/LPG carriers like 7,500 m

vessel meet the demands of a developing market vessel meet the demands of a developing market

increase operating flexibility

seasonal LNG transportation demands

up to 35,000 m

Gastech 2006

23

Economics of small LNG carriers

CAPEX:

Little changes for ships hull construction (steel Little changes for ships hull construction (steel

grade of tank supports)

Tanks and cargo handling systemmore Tanks and cargo handling system more

expensive than for Ethylene carriers

TGE estimation shows an overall CAPEX abt TGE estimation shows an overall CAPEX abt.

10 15 % above the corresponding Ethylene-

carrier price, depending BOG handling concept

Gastech 2006

24

Conclusion

Target market: small gas consumers without access to a Target market: small gas consumers without access to a

pipeline grid

TGEs design approach with type C tanks is based in vast g pp yp

experience with Ethylene carriers

The combined 7,500 m LNG/Ethylene/LPG carrier

d t t th t TGE h t th i t f demonstrates that TGEs approach meets the requirements of

this developing market

Small LNG carriers can be economical with type C cargo tanks Small LNG carriers can be economical with type C cargo tanks

up to 35,000 m capacity

TGE has received a Concept Approvalof a modified tank TGE has received a Concept Approval of a modified tank

design with a classification society

A patent is pending for the new tank design

Gastech 2006

25

Thank you for your attention!

For any questions please contact TGE:

email: sales@tge-marine com email: sales@tge marine.com

phone: +49-228-60448-160

You might also like

- Economic Design of Small Scale LNG Tankers and TerminalsDocument37 pagesEconomic Design of Small Scale LNG Tankers and TerminalsCalNo ratings yet

- LNG - Initiative Nordwest: FachsymposiumDocument45 pagesLNG - Initiative Nordwest: FachsymposiumKelvin XuNo ratings yet

- LNG AgeingDocument13 pagesLNG AgeingBenoit PuyoNo ratings yet

- Dstenersen Pres (Full Permission)Document38 pagesDstenersen Pres (Full Permission)Salvatore BuonoNo ratings yet

- Small-Scale LNG DistributionDocument31 pagesSmall-Scale LNG DistributionRichard RichardNo ratings yet

- LNGDocument15 pagesLNGSushant PaiNo ratings yet

- Adnan Ezzarhouni GTTChina (Revised Version)Document17 pagesAdnan Ezzarhouni GTTChina (Revised Version)ClemenNo ratings yet

- LNG Standard Form Charters March 2013 PDFDocument10 pagesLNG Standard Form Charters March 2013 PDFFabián BischoffNo ratings yet

- Tackling FSRU Operational ChallengesDocument22 pagesTackling FSRU Operational ChallengesAnonymous icnhaNsFNo ratings yet

- Gasasa Marine Fuel: Recommendations For Linked Emergency Shutdown (ESD) Arrangements For LNG BunkeringDocument14 pagesGasasa Marine Fuel: Recommendations For Linked Emergency Shutdown (ESD) Arrangements For LNG Bunkeringmhientb100% (1)

- Small Scale Import LNG Terminal PDFDocument9 pagesSmall Scale Import LNG Terminal PDFamirlngNo ratings yet

- LNG FuelDocument6 pagesLNG FuelKaran DoshiNo ratings yet

- FSRU Toscana LNG and GAS Quality and Measurement ManualDocument29 pagesFSRU Toscana LNG and GAS Quality and Measurement Manualhikosko100% (1)

- 10 Wartsila K Portin Performance DF Engines in LNG CarriersDocument21 pages10 Wartsila K Portin Performance DF Engines in LNG Carriersali kharalNo ratings yet

- Energy Recovery From The LNG Regasification ProcessDocument25 pagesEnergy Recovery From The LNG Regasification ProcessAn TrNo ratings yet

- Leaders On The Future of LNG and GasDocument20 pagesLeaders On The Future of LNG and GasShekhrendu BhardwajNo ratings yet

- Concept of Mini LNG Onshore TerminalDocument12 pagesConcept of Mini LNG Onshore TerminalNkantan RamachandranNo ratings yet

- 7,500 CBM LNG/LPG/Ethylene/Ammonia/VCM-Carrier: "Coral Methane" For ANTHONY VEDER, The NetherlandsDocument1 page7,500 CBM LNG/LPG/Ethylene/Ammonia/VCM-Carrier: "Coral Methane" For ANTHONY VEDER, The NetherlandsKelvin XuNo ratings yet

- 1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachineryDocument2 pages1200m Self-Propelled LNG (Type C) Barge: Main Particulars MachinerysirvoltusNo ratings yet

- LNGDocument2 pagesLNGbernardinodinoNo ratings yet

- Generation of LNG Tank ContainersDocument11 pagesGeneration of LNG Tank ContainersInfo MelikNo ratings yet

- Design Study of LNG ShipDocument21 pagesDesign Study of LNG ShipssnisharNo ratings yet

- Abbas - Bilgrami CNG Transportation Trans CanadaDocument48 pagesAbbas - Bilgrami CNG Transportation Trans CanadaMustafa100% (1)

- Oil and Gas Technology UpdateDocument66 pagesOil and Gas Technology Updatemuhammad habib chusnul fikriNo ratings yet

- Presentation For Gas Naturally Complete and Final Klapeidos NaftaDocument30 pagesPresentation For Gas Naturally Complete and Final Klapeidos Naftamilham09100% (1)

- Compact LNG C Design Brochure - 110609Document4 pagesCompact LNG C Design Brochure - 110609pal_malayNo ratings yet

- United States Patent Application Publication: Vandor Et Al. Pub. No.: Pub. DateDocument13 pagesUnited States Patent Application Publication: Vandor Et Al. Pub. No.: Pub. Datekaspersky2009No ratings yet

- LNG Offshore Receiving TerminalsDocument54 pagesLNG Offshore Receiving TerminalspoetoetNo ratings yet

- LNG CarrierDocument94 pagesLNG CarrierJEET BANERJEENo ratings yet

- 4 - LNG ShippingDocument29 pages4 - LNG ShippingAhmed FaragNo ratings yet

- Stena BlueGas Form C Sky - Gas Form CDocument17 pagesStena BlueGas Form C Sky - Gas Form CpoetoetNo ratings yet

- Floating Storage and Regasification Units Report - Version 1.2 - September 2016 - LM - 2Document46 pagesFloating Storage and Regasification Units Report - Version 1.2 - September 2016 - LM - 2NgoVietCuongNo ratings yet

- Leif Höegh & Co LNG Floating Storage and Regas Unit Fsru: LNG: Moving Off-ShoreDocument21 pagesLeif Höegh & Co LNG Floating Storage and Regas Unit Fsru: LNG: Moving Off-Shorejomafeba100% (2)

- DNV GL Complete-Alt-Fuels Guidance Paper 2018-05 WebDocument48 pagesDNV GL Complete-Alt-Fuels Guidance Paper 2018-05 WebMohit SahNo ratings yet

- Gas Ship Measurement Guidelines: 1 Gas Measure 9/99 Version 01/98 Rev 4Document40 pagesGas Ship Measurement Guidelines: 1 Gas Measure 9/99 Version 01/98 Rev 4Henry MaedaNo ratings yet

- Hoegh LNG Technical PresentationDocument58 pagesHoegh LNG Technical PresentationKong LingweiNo ratings yet

- NI 618 - Guidelines On LNG BunkeringDocument36 pagesNI 618 - Guidelines On LNG BunkeringyoungfpNo ratings yet

- X-DF: Latest References, Service Experience - Plus Future OutlookDocument66 pagesX-DF: Latest References, Service Experience - Plus Future OutlookLifeatseaNo ratings yet

- LNG Conversion Cost Estimation PDFDocument4 pagesLNG Conversion Cost Estimation PDF123habib123fikriNo ratings yet

- LNGC Optimised Designs of Me Gi Engines and Fuel Gas Supply Systems 5510 0242 01Document32 pagesLNGC Optimised Designs of Me Gi Engines and Fuel Gas Supply Systems 5510 0242 01simhadri sangani100% (1)

- GASLOC WESTMINISTER2021 Machinery Operating ManualDocument370 pagesGASLOC WESTMINISTER2021 Machinery Operating ManualPEDRO alvaroe100% (1)

- LNG Mottakterm Moss Maritime OffshoreDocument30 pagesLNG Mottakterm Moss Maritime OffshorePatricio LeonardoNo ratings yet

- Tanker Operator 2014 06 JuneDocument44 pagesTanker Operator 2014 06 JuneVasileios IliopoulosNo ratings yet

- Ftops 2a - LPG-LNG Hazards and ControlDocument26 pagesFtops 2a - LPG-LNG Hazards and ControlmyscriblkNo ratings yet

- Safety Concept - Dual Fuel EnginesDocument104 pagesSafety Concept - Dual Fuel EnginesSergei KurpishNo ratings yet

- Disha-Cargo Operating ManualDocument279 pagesDisha-Cargo Operating ManualGeoffreyHunter100% (3)

- Wartsila FSRU LNG Regasification ModulesDocument8 pagesWartsila FSRU LNG Regasification Moduleshermit44535100% (3)

- Cryo StarDocument12 pagesCryo Starelenaro1234No ratings yet

- Assessment of Gas Supply SystemDocument23 pagesAssessment of Gas Supply SystemfayzaNo ratings yet

- Joint Industry Guidance On The Supply and Use of 0.50 Sulphur Marine FuelDocument64 pagesJoint Industry Guidance On The Supply and Use of 0.50 Sulphur Marine FuelharrdyNo ratings yet

- Keynote LNG Wartsila LNG Fuel Gas Systems - 2nd Generation October 2015Document51 pagesKeynote LNG Wartsila LNG Fuel Gas Systems - 2nd Generation October 2015Cees van ZandvlietNo ratings yet

- Alternative Fuels Low Speed Diesel EnginesDocument16 pagesAlternative Fuels Low Speed Diesel EnginesŞansal DikmenerNo ratings yet

- GIIGNL-LNG CUSTODY TRANSFER HANDBOOK - 3rd Edtion - Final 2010-03-26 PDFDocument103 pagesGIIGNL-LNG CUSTODY TRANSFER HANDBOOK - 3rd Edtion - Final 2010-03-26 PDFmathijn75No ratings yet

- LNG Operational PracticesDocument7 pagesLNG Operational Practicesatm4231No ratings yet

- LNG Shipping at 50compressed PDFDocument128 pagesLNG Shipping at 50compressed PDFSudherson Jagannathan100% (1)

- LNG Bunker SlidesDocument38 pagesLNG Bunker SlidesChristopher Hoo100% (5)

- Bureau Veritas Issues FSU, FSRU Conversion GuidelinesDocument1 pageBureau Veritas Issues FSU, FSRU Conversion GuidelinesamirlngNo ratings yet

- LNG Ships: by F. R. ChowdhuryDocument6 pagesLNG Ships: by F. R. ChowdhuryThusitha DalpathaduNo ratings yet

- Design Concepts For LNG FSRUDocument34 pagesDesign Concepts For LNG FSRU조대제100% (2)

- Mechanical Design Basics of Tall ColumnsDocument45 pagesMechanical Design Basics of Tall Columnshardik5818No ratings yet

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Document14 pagesASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (2)

- PH - Acidity H2S Level Temperature Duration of Exposure Nature of The MaterialDocument9 pagesPH - Acidity H2S Level Temperature Duration of Exposure Nature of The Materialhardik5818No ratings yet

- Collar Type BoltDocument1 pageCollar Type Bolthardik5818No ratings yet

- Deflection of Beam FundaDocument11 pagesDeflection of Beam Fundahardik5818100% (1)

- PV Elite Heat Exchanger CalculationsDocument99 pagesPV Elite Heat Exchanger CalculationscbousmuNo ratings yet

- Wood Thermal ConductivityDocument8 pagesWood Thermal Conductivityhardik5818No ratings yet

- Pressure Drop Calc - STDDocument25 pagesPressure Drop Calc - STDhardik5818No ratings yet

- Appendix 2) : Optional Type Flange (Fig. 2-4 (8) )Document18 pagesAppendix 2) : Optional Type Flange (Fig. 2-4 (8) )hardik5818No ratings yet

- Railway TimetableDocument6 pagesRailway Timetablehardik5818No ratings yet

- Risk Management For Tata MotorsDocument9 pagesRisk Management For Tata MotorsAbdullah Saghir AhmadNo ratings yet

- Thomas Crouch - CVDocument2 pagesThomas Crouch - CVtcrouchRMNo ratings yet

- BTMA Tyre Management On Heavy Vehicles BookletDocument20 pagesBTMA Tyre Management On Heavy Vehicles BookletBina PertiwiNo ratings yet

- Army Regulations Listing - 2Document6 pagesArmy Regulations Listing - 2Dongelx100% (1)

- MosaicDocument219 pagesMosaicGenna ContinoNo ratings yet

- Denso CR - Hp2 NissanDocument31 pagesDenso CR - Hp2 NissanMarcelo Diesel86% (7)

- A6 Dalmia CaseDocument16 pagesA6 Dalmia CaseTrilochan MohantaNo ratings yet

- Docslide - Us Jet Blue Airways Managing Growth Case SolutionDocument12 pagesDocslide - Us Jet Blue Airways Managing Growth Case SolutionarnabnitwNo ratings yet

- R64ZQIDocument1 pageR64ZQImicheleNo ratings yet

- Name Company Name CategoryDocument3 pagesName Company Name CategoryAnish JhaNo ratings yet

- 006 Cat-6060 Servo SystemDocument17 pages006 Cat-6060 Servo SystemJorby CuadrosNo ratings yet

- 767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)Document2 pages767-05-20-08-TFL B767 125 HOUR SERVICE CHECK (FLIGHT HOURS) TFL (Iss 07)samyghallabNo ratings yet

- UGTP-1000 - Motor Sich 2Document1 pageUGTP-1000 - Motor Sich 2Kevin RichardNo ratings yet

- Crown ESR4500Document230 pagesCrown ESR4500CergeyNo ratings yet

- ENC Product List 25 2021Document408 pagesENC Product List 25 2021Anup Dange100% (1)

- Vehicular Emissions TrinidadDocument4 pagesVehicular Emissions Trinidadstephen_debique9455No ratings yet

- TLILIC0003 Learner Guide.v2.2Document58 pagesTLILIC0003 Learner Guide.v2.2ipemesananNo ratings yet

- Part 14 Lifting, Moving and JackingDocument7 pagesPart 14 Lifting, Moving and JackingYiannis GregoriouNo ratings yet

- Monthly Progress Report - Feb2023 - R0 PDFDocument146 pagesMonthly Progress Report - Feb2023 - R0 PDFEmdad MunnaNo ratings yet

- Extraordinary Construction On GermanyDocument1 pageExtraordinary Construction On Germanyzainulmhd867No ratings yet

- Guidelines and Procedure of Assessment of An Individual Onboard TrainingDocument5 pagesGuidelines and Procedure of Assessment of An Individual Onboard TrainingChynk Jr AuditionCordNo ratings yet

- Sampling Bituminous Paving Mixtures: Standard Practice ForDocument3 pagesSampling Bituminous Paving Mixtures: Standard Practice Foraastha mehtaNo ratings yet

- Ibc Code New 2 PDFDocument8 pagesIbc Code New 2 PDFrajishrrrNo ratings yet

- Pursuing Maritime Education - Motivations and Expectations PDFDocument27 pagesPursuing Maritime Education - Motivations and Expectations PDFsukhjit78No ratings yet

- Epc Mode Vs PPP Mode For National HighwaysDocument3 pagesEpc Mode Vs PPP Mode For National HighwaysHimanshu Patel100% (1)

- List of Participants ACMEE 2012Document11 pagesList of Participants ACMEE 2012Pranav AhujaNo ratings yet

- Procurement Manual For LGUs - Goods and Services PDFDocument131 pagesProcurement Manual For LGUs - Goods and Services PDFjejemonch100% (1)

- Your Boarding Pass To Varanasi - VISTARADocument1 pageYour Boarding Pass To Varanasi - VISTARAKhushboo JhalaniNo ratings yet

- Construction Quality and MaintenanceDocument40 pagesConstruction Quality and MaintenanceRamesh AnanthanarayananNo ratings yet

- Analysis of Modified Lifting-Line Theory (1933) With Multiple WingletsDocument9 pagesAnalysis of Modified Lifting-Line Theory (1933) With Multiple WingletsSamuel ZimmermannNo ratings yet