Professional Documents

Culture Documents

Counterflow Distribution System: Self-Draining Economical Operation

Uploaded by

Oscar Cruz0 ratings0% found this document useful (0 votes)

14 views2 pagesMarley counterflow cooling tower distribution systems offer you the following benefits: Corrosion Resistant Plastic Construction --All piping is either PVC or FRP fiberglass. Self-Draining--The nozzle outlet is always the lowest elevation in the distribution system.

Original Description:

Original Title

SP-DIST-E

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMarley counterflow cooling tower distribution systems offer you the following benefits: Corrosion Resistant Plastic Construction --All piping is either PVC or FRP fiberglass. Self-Draining--The nozzle outlet is always the lowest elevation in the distribution system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views2 pagesCounterflow Distribution System: Self-Draining Economical Operation

Uploaded by

Oscar CruzMarley counterflow cooling tower distribution systems offer you the following benefits: Corrosion Resistant Plastic Construction --All piping is either PVC or FRP fiberglass. Self-Draining--The nozzle outlet is always the lowest elevation in the distribution system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Marley

counterow cooling tower

distribution systems offer you the following

benets:

Corrosion Resistant Plastic

Construction All piping is either PVC

or FRP berglass. Plastic pipe provides

low friction loss to reduce pump head

requirements. Other materials are available

for special applications.

Non-CloggingHigh performance

Marley NS nozzles are available with 1" to

3

1

2"orice sizes. Each system is designed

to minimize silt or debris collection.

Self-DrainingThe nozzle outlet is always

the lowest elevation in the distribution

system. This arrangement is self draining

when the supply water is shut off. There

are no special valves to open or close.

Economical InstallationNozzles are

installed in pairseach supply pipe serving

multiple pairs of nozzles. Multiple nozzle

pairs per supply pipe mean larger pipe

spacing and, therefore, lower installed cost

than most other systems.

Economical OperationThe entire

system is computer-designed to maximize

thermal performance and can be optimized

to minimize pump head. The design also

minimizes structural interference with

water distribution. The Marley system

avoids the uneven water distribution and

high operating pressures associated with

upspray nozzle systems.

Easy Disassembly and

ReassemblyAssembly of the entire

system requires only a few simple hand

tools. All connections are positiveyet the

design allows repeated disassembly and

reassembly.

counterow distribution system

NOZZLES

The system will distribute hot water to the ll of a counterow

cooling tower.

Construction and Materials

The circulating water will be distributed to the ll by

injection-molded polypropylene nozzles complete with

polypropylene diffuser rings. Nozzles will be spaced on 3'-0"

(maximum) centers.

Each pair of nozzles shall be fed by a single

polypropylene distributor tee attached to the bottom of a PVC

distribution pipe by a gasketed bolted joint.

The PVC distribution pipes shall be connected to a side inlet

header of heavy-duty plastic pipe (PVC or FRP).

The inlet header shall terminate just outside the tower casing at

the face of a at faced ange. The ange drilling must conform to

Class 125 ANSI B 16.1 specications .

SUGGESTED SPECIFICATION

Nozzles

The nozzles shall be non-clogging down-spray types, with no

orices or internal passageways less than one inch diameter.

Internal turbulators or moving parts are not acceptable.

The nozzles shall develop a full cone spray pattern at pressures

as low as two feet of water to assure proper water distribution to

all areas of the ll.

Operation

The system shall be self-draining and must contain no blind

connections or other locations where silt or debris might

accumulate. The nozzle outlets shall be the lowest point in the

system. Upspray systems are not acceptable.

counterow distribution system

In the interest of technological progress, all products are subject to design and/or material change without notice ISSUED 04/2013 SP-DIST-E

COPYRIGHT 2013 SPX Corporation

SPX COOLING TECHNOLOGIES, INC.

|

OVERLAND PARK, KS 66213

P: 913 664 7400 F: 913 664 7439 spxcooling@spx.com

spxcooling.com

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Chiller CarrierDocument40 pagesChiller CarrierNicolas MatiasNo ratings yet

- LASCOSCH80CPVCDocument14 pagesLASCOSCH80CPVCRoger Broca AriasNo ratings yet

- LPD BrochureDocument8 pagesLPD BrochureOscar CruzNo ratings yet

- Installation Operating Instructions Couplings TSCHAN S SDD-5 SDDL-5 enDocument23 pagesInstallation Operating Instructions Couplings TSCHAN S SDD-5 SDDL-5 enOscar CruzNo ratings yet

- Spherical Bearings enDocument32 pagesSpherical Bearings enOscar CruzNo ratings yet

- Pipesupport MDocument199 pagesPipesupport MOscar CruzNo ratings yet

- Deva - BM ENDocument24 pagesDeva - BM ENOscar CruzNo ratings yet

- 02 Wire Rope StrandDocument39 pages02 Wire Rope Strandmanuelperezz2567% (3)

- Usha Martin Wirerope HandbookDocument72 pagesUsha Martin Wirerope Handbookhaydarburedah100% (2)

- Deva - BM ENDocument24 pagesDeva - BM ENOscar CruzNo ratings yet

- THG Hooks Forged Hooks Catalogue SheetDocument5 pagesTHG Hooks Forged Hooks Catalogue SheetAnderson SantosNo ratings yet

- Miller 09Document5 pagesMiller 09Muhammad RaHadian WiranataNo ratings yet

- Energrease LS-EP SeriesDocument2 pagesEnergrease LS-EP SeriesOscar CruzNo ratings yet

- Qa Manual - Current EditionDocument51 pagesQa Manual - Current EditionAnonymous qhVGVpNo ratings yet

- Industrial Grease Lubricant Application GuideDocument2 pagesIndustrial Grease Lubricant Application GuideOscar Cruz100% (2)

- Asme Specifications SA36 ToSA423Document4 pagesAsme Specifications SA36 ToSA423nadhabindhu0% (1)

- CadenasDocument77 pagesCadenasRicardo SGNo ratings yet

- BPL Equiv ChartDocument1 pageBPL Equiv ChartOscar CruzNo ratings yet

- Roller Chain Bs-AnsienDocument3 pagesRoller Chain Bs-AnsienOscar CruzNo ratings yet

- LMX GreaseDocument2 pagesLMX GreaseOscar CruzNo ratings yet

- German Schematic DiagramDocument28 pagesGerman Schematic DiagramMajida HannanNo ratings yet

- G06Document6 pagesG06Oscar CruzNo ratings yet

- F1554 Anchor Rod Straight SubmittalDocument1 pageF1554 Anchor Rod Straight SubmittalOscar CruzNo ratings yet

- DIN 8187-1 - Corrente SimplesDocument10 pagesDIN 8187-1 - Corrente Simplesmarcoszurc0% (1)

- Threads&Threaded Joints 2007-08Document24 pagesThreads&Threaded Joints 2007-08Vikram Puttenahalli Nagesh GowdaNo ratings yet

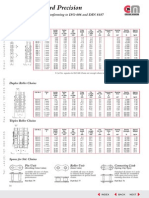

- Equivalents of Carbon Steel QualitiesDocument11 pagesEquivalents of Carbon Steel QualitiesOscar CruzNo ratings yet

- KettenHandbuch E Iwis ChainDocument86 pagesKettenHandbuch E Iwis ChainKiran Kumar K TNo ratings yet

- Re17047 2003-11Document8 pagesRe17047 2003-11Oscar CruzNo ratings yet

- Cata - Flange ANSI - pdf1299758077 PDFDocument48 pagesCata - Flange ANSI - pdf1299758077 PDFNikhil PanchalNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Pharmacological and Toxicological Screening Methods I (MPL 103T)Document50 pagesPharmacological and Toxicological Screening Methods I (MPL 103T)Sandeep MewadaNo ratings yet

- Balauro Worksheet Protein SynthesisDocument4 pagesBalauro Worksheet Protein SynthesisHami BalauroNo ratings yet

- I) Introduction To Polymer Nanocomposites For Food Packaging Applications II) Overview On An European Activity in The FieldDocument39 pagesI) Introduction To Polymer Nanocomposites For Food Packaging Applications II) Overview On An European Activity in The FieldNormanBatesNo ratings yet

- Metamorphic Petrology: Processes and ProductsDocument27 pagesMetamorphic Petrology: Processes and ProductsAnnisaBestariNo ratings yet

- Elsanhouty Pharma Hold Time Study NotesDocument6 pagesElsanhouty Pharma Hold Time Study NotesHuỳnh Ngọc SángNo ratings yet

- C2!6!455 Grout and Adhesive Rev.BDocument50 pagesC2!6!455 Grout and Adhesive Rev.BAreaya mahetemNo ratings yet

- Melin Catalog 2005Document122 pagesMelin Catalog 2005Sujata KulkarniNo ratings yet

- Calculations of Elastic Moduli of Polymer Crystals." II. TeryleneDocument11 pagesCalculations of Elastic Moduli of Polymer Crystals." II. Teryleneapi-3733260No ratings yet

- Turbopump Shaft NasaDocument136 pagesTurbopump Shaft NasacarlfelipeNo ratings yet

- Principle of Kill Method: Well ControlDocument17 pagesPrinciple of Kill Method: Well ControlfarajNo ratings yet

- 13 - Chapter 3Document32 pages13 - Chapter 3Wahab Al-QaisiNo ratings yet

- M2P12 JacsDocument10 pagesM2P12 JacspedroNo ratings yet

- Confined SpaceDocument31 pagesConfined SpacegshdavidNo ratings yet

- Cells and BatteriesDocument3 pagesCells and BatteriesmelissaNo ratings yet

- ASTM Bolting Specification Temperature MDocument2 pagesASTM Bolting Specification Temperature Mrazvan65100% (1)

- Sensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Document7 pagesSensory and nutritional value of flatbread with banana peelsWheat flourBanana peels12.2010.1011.203.201.2111.201.500.800.601.20Bagas Aryo SasongkoNo ratings yet

- CH HP OverviewDocument44 pagesCH HP Overviewprabhanshu241991No ratings yet

- MT12550FTDocument1 pageMT12550FTJuan carlosNo ratings yet

- Pipes, Tubes, Fittings, FlangesDocument121 pagesPipes, Tubes, Fittings, FlangesCarl Jones100% (2)

- Lecture 2 MassMicroDocument25 pagesLecture 2 MassMicroPelin KınıkNo ratings yet

- Road Construction QuotationDocument2 pagesRoad Construction QuotationVinod Kumar Verma100% (6)

- Design Manual For Waste Stabilization Ponds in India BY MARA D.Document135 pagesDesign Manual For Waste Stabilization Ponds in India BY MARA D.cherogonyaNo ratings yet

- Basic Mechanical Engineering MCQ PDF Part 3Document10 pagesBasic Mechanical Engineering MCQ PDF Part 3kibrom atsbhaNo ratings yet

- Technical Data Sheet: Ptfe + 20% PeekDocument1 pageTechnical Data Sheet: Ptfe + 20% PeekRohan KulkarniNo ratings yet

- Zak SystemDocument10 pagesZak SystemSlavisa BjelicNo ratings yet

- Class 9 Matter in Our Surroundings McqsDocument3 pagesClass 9 Matter in Our Surroundings McqsHariharan VIIA1No ratings yet

- S&T Roofing Solutions Product Guide Mar2018-DP1 0Document12 pagesS&T Roofing Solutions Product Guide Mar2018-DP1 0sattar12345No ratings yet

- Everything You Need to Know About Pig Iron ProductionDocument52 pagesEverything You Need to Know About Pig Iron ProductionberhaneNo ratings yet

- 2012 - Cosmetic Ingredient Review - Amended Safety Assessment of Alkyl Esters As Used in CosmeticsDocument83 pages2012 - Cosmetic Ingredient Review - Amended Safety Assessment of Alkyl Esters As Used in CosmeticsymiyazyNo ratings yet

- ICIS PetrochemicalsPosterDocument2 pagesICIS PetrochemicalsPosterstavros7100% (3)