Professional Documents

Culture Documents

B7 Versus B16 Bolts

Uploaded by

Michael SandersCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B7 Versus B16 Bolts

Uploaded by

Michael SandersCopyright:

Available Formats

Smart questions

Smart answers

Smart people

Go Find A Forum Go

Join

Directory

Search

Tell A Friend

Whitepapers

Jobs

Home > Forums > Mechanical Engineers > Actiities >!ipelines" !iping and Fluid Mechanics engineering Forum

B7 versus B16 bolts

thread#$%&'%((#$

owassokings )Mechanical* '+

May

+$

',-##

We are using .'( bolts /or e0pansion 1oints in large e0haust ducts that hae hot /langes2 The temperature ranges /rom %++ F to '+++ F 3ith an

internal duct /ailure pressure o/ 4+ inches o/ 3ater2

What is the adantage in using .'( bolts in place o/ .$ bolts5 The .'( bolts are '+6 the price o/ the .$ bolts and the 7uestion 3as as8ed i/ 3e could

use the .$ bolts instead2 The only di//erence 9 can see in the 4 bolts is the .'( bolt includes :anadium in the composition2

STYMIEDIE! )Mechanical* '+

May

+$

';-+#

<oo8 at the allo3able stress alue /or the temperatures that you speci/ied2

At %++ deg F the allo3able stress alue bet3een the .$ and .'( is small2

Ho3eer" at the '+++ deg F the allo3able stress alues are nearly 42; times higher /or the .'( as compared to the .$2

There/ore" at the eleated temperatures aboe %++ deg F the .'( is a more durable component

owassokings )Mechanical* '+

May

+$

';-,$

Stymiedpiper"

Than8 you /or the in/ormation2 =ould you tell me 3hat technical re/erence you are getting these allo3ables5 9s it /rom the ASME .oiler !ressure

:essel code5

owassokings )Mechanical* '+

May

+$

'(-'%

Stymiedpiper"

Again" 9 3ant to than8 you /or the in/ormation2 9 /ound the allo3ables you spo8e o/ in .#'2'2

un"les#$ )Materials*

%&'

Piping Expansion Joints

flexicraft.com

All Metal & Rubber Expansion Joints for Piping Systems from Flexicraft

Share This

Page 1 of 3 Pipelines, Piping and Fluid Mechanics engineering - B7 versus B16 bolts

5/5/!1" http#//$$$%eng-tips%co&/vie$thread%cf&'(id)1*6637

10

May

07

16:44

You can use B7 up 1000F using the aforementioned values as the tempering temperature used in making B7 is 1000F !nything a"ove 1000F and the

strength could fall off Being your application is duct #ork at a lo# pressure $ can see no pro"lem using B7 even if the duct insulated

$f "y design you have to use B16 $ #ould look at stud "olt%&nuts for a"out &'( of a B16 he) "olt cost ! B16 stud is &* the cost of a B7+ today,s

prices

owassokings -Mechanical. 10

May

07

16:'&

/nclesyd+

0hat is great information 0here are cases #here #e are re1uired to use the B16 "olt and that #ould "e a great alternative

jte -Mechanical. 11

May

07

11:&&

o#assokings2

3elcome to the forum4 5on,t forget to put in a little description of your "ackground in the 6personal profile6 page -"utton in the top left "o) #ith light

"lue "ackground. You can see my profile "y clicking on the 67te6 at the top of this post

8ot sure #hich design code your ducting falls under 2 lo# pressure duct#ork may not fall directly #ithin the scope of any code $f this is the case+

then $ have to ask ho# you are deriving your 900 to 1000:F design temperature for your "olting; !re those temperatures from a line list for the

duct#ork; $s it the fluid temperature; <r since you seem to "e in an operating plant+ have you directly measured the "olt temperatures;

$f $ did not have a code mandating my design+ $ #ould choose B=1= or >$$$21 simply "ecause $,m familiar #ith them+ and use them for guidance

0ake a close look at B=1= =01=&-".-4. ?ere you are allo#ed to set the design temperature of the "olts at no less than 90( of the fluid

temperature $n most cases+ it sounds as though this &0( drop in temp may "e very "eneficial for you 8o# take a close look at =01=&-".: unless

a lo#er average tempeature is determined "y test or heat transfer calculation so if you have similar duct#ork in service+ and you go out on a hot

summer day and measure the temperature of the "olting and add some margin to it -unless you pick a record hot day to do your measurements.

then you can set the design temperature of the "olts "ased on the measured values of your 6test6 duct#ork flange "olts

B=11 has a similar+ though more restrictive+ approach in 101=&-!.

7t

owassokings -Mechanical. 11

May

07

11:4&

7t+

0hanks for the information $ #ill revie# that specification you mentioned and see ho# it "enefits us <ur ducting serves as an e)haust system for

large ground po#er tur"ines 0he temperature of the "olts #as estimated from F@! models that have "een performed on our e)pansion 7oints 0he

e)haust temperature is normally 900 F to 10'0 F and the flange 7oint is not internally insulated+ therefore+ as you can imagine it gets very hot

3e prefer not to use the "oiler pressure vessel codes or the po#er piping codes "ecause our e1uipment is normally a lo# pressure

environment Aometimes our hands are tied "ecause the customer has made it a specification re1uirement ?o#ever+ for the cases #here #e can do

things that make more since+ #e #ould prefer to use suggestions similar to yours 3e #ant to use good engineering 7udgement "ut "e cost effective

as #ell 0hanks again for the help

Page of 3 Pipelines, Piping and Fluid Mechanics engineering - B7 versus B16 bolts

5/5/!1" http#//$$$%eng-tips%co&/vie$thread%cf&'(id)1*6637

Join | Indeed Jobs | Advertise | About Us | Contact Us | Site Policies

Copyright 1998!"1# $ecu%seh &roup' Inc( All rights reserved(

Unauthori)ed reproduction or lin*ing +orbidden ,ithout e-press ,ritten per%ission(

Pressure Temperature

carnwoowirelineser!ice.ca

"e #ffer $%&' (as An #il Fiel "ireline Ser!ices. )all *s Toay+

Page 3 of 3 Pipelines, Piping and Fluid Mechanics engineering - B7 versus B16 bolts

5/5/!1" http#//$$$%eng-tips%co&/vie$thread%cf&'(id)1*6637

You might also like

- Dynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionFrom EverandDynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionNo ratings yet

- Himeji Number 2 Goes CommercialDocument13 pagesHimeji Number 2 Goes CommercialSujeet KumarNo ratings yet

- Report on blade failure of LP last stages in a 210 MW steam turbineDocument5 pagesReport on blade failure of LP last stages in a 210 MW steam turbinemanojpuru100% (1)

- Se Brochure Dresser Rand Steam Turbines 2021Document24 pagesSe Brochure Dresser Rand Steam Turbines 2021Irfan FatahilahNo ratings yet

- Manual Mando A DistanciaDocument13 pagesManual Mando A DistanciaManuel SieŕraNo ratings yet

- Uk-Standard Asme Bladder AccumulatorDocument3 pagesUk-Standard Asme Bladder AccumulatorRamin SoadNo ratings yet

- Terry TurbineDocument8 pagesTerry TurbinealexmontellNo ratings yet

- Elliott Brush Ring Seals: Installation KitDocument2 pagesElliott Brush Ring Seals: Installation Kitfouzi gher100% (1)

- Material Turbine - 2 PDFDocument6 pagesMaterial Turbine - 2 PDFMonikaNo ratings yet

- MT10 Steam Turbine OverviewDocument8 pagesMT10 Steam Turbine OverviewErnesto Sánchez GómezNo ratings yet

- GE 7EA Gas Turbine DetailsDocument10 pagesGE 7EA Gas Turbine DetailsEnder Galvis100% (1)

- Veo HRSG Brochure 2012Document6 pagesVeo HRSG Brochure 2012Jayanath Nuwan SameeraNo ratings yet

- LT SL Lm5000-Ind-03-001 r0Document2 pagesLT SL Lm5000-Ind-03-001 r0Alejandro Romero BallestasNo ratings yet

- ASME Code Section 8Document14 pagesASME Code Section 8ShieeplNo ratings yet

- Gas Turbine Compressor IssuesDocument9 pagesGas Turbine Compressor IssuesJJNo ratings yet

- Turbines For BFP Drive PDFDocument10 pagesTurbines For BFP Drive PDFShameer Majeed100% (1)

- Technical Trend of Aircraft BearingsDocument5 pagesTechnical Trend of Aircraft BearingsnrNo ratings yet

- 20.06 - GEK110856j Steam Seal System RequirementsDocument24 pages20.06 - GEK110856j Steam Seal System RequirementsLIU100% (2)

- Technical Paper - SGT400 ASME 2002Document9 pagesTechnical Paper - SGT400 ASME 2002usaid saifullahNo ratings yet

- Welding Cheat SheetDocument1 pageWelding Cheat SheetDude100% (1)

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladNo ratings yet

- Abs - Approved Welding Consumables Shielded Metal Arc WeldingDocument59 pagesAbs - Approved Welding Consumables Shielded Metal Arc Weldinggeorgekc77No ratings yet

- Shin Nippon General Presentation For Americas Feb2011Document15 pagesShin Nippon General Presentation For Americas Feb2011Manoj KageNo ratings yet

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- AFBC BoilerDocument12 pagesAFBC BoilerNaman Sharma0% (1)

- Stage 1 Shroud For FS7001BDocument1 pageStage 1 Shroud For FS7001Bteedee1No ratings yet

- Secure Energy For Europe Chapter 7Document18 pagesSecure Energy For Europe Chapter 7Krishna KusumaNo ratings yet

- Es2001 PDFDocument2 pagesEs2001 PDFfrdnNo ratings yet

- I A G T C: Ndustrial Pplication OF AS Urbines OmmitteeDocument13 pagesI A G T C: Ndustrial Pplication OF AS Urbines Ommittee'Izzad AfifNo ratings yet

- DETC2009-86080: The Use of Interference Diagrams To Avoid Impeller Resonance: An Application To Igv DesignDocument8 pagesDETC2009-86080: The Use of Interference Diagrams To Avoid Impeller Resonance: An Application To Igv DesignRajesh KachrooNo ratings yet

- V005t15a001 88 GT 150Document13 pagesV005t15a001 88 GT 150Antonio CilindroNo ratings yet

- Peppers Catalogue GlandsDocument28 pagesPeppers Catalogue GlandsVlad Andronache100% (1)

- 12 SiemensDocument37 pages12 SiemensrodrigocampospkNo ratings yet

- Meraj Engineering - CatalogueDocument29 pagesMeraj Engineering - CatalogueMohammad Iqbal KhanNo ratings yet

- Fact Sheet Til 1292Document2 pagesFact Sheet Til 1292PervimNo ratings yet

- Nickel Base Alloy GTD 222Document2 pagesNickel Base Alloy GTD 222JJNo ratings yet

- Protection and Condition Monitoring of The LM5000 Gas TurbineDocument9 pagesProtection and Condition Monitoring of The LM5000 Gas TurbineSudeshNo ratings yet

- Arcraft Plasma Equipments (I) Pvt. LTD.: Plasma Transferred Arc - PtaDocument4 pagesArcraft Plasma Equipments (I) Pvt. LTD.: Plasma Transferred Arc - Ptapavi32No ratings yet

- Elliot CompressorsDocument12 pagesElliot Compressorsmatteo2009No ratings yet

- VH60-100 Presentation Philippe ChabinDocument46 pagesVH60-100 Presentation Philippe ChabinMohamedMansour50% (2)

- Air BlowersDocument4 pagesAir Blowersjkhan_724384No ratings yet

- 2012 SpiraxialDocument1 page2012 SpiraxialNistha ChakrabortyNo ratings yet

- Pre-Designed Steam Turbines enDocument8 pagesPre-Designed Steam Turbines enBoos Kanhaiya LalNo ratings yet

- Seminar - TBCDocument17 pagesSeminar - TBCTosif MansuriNo ratings yet

- Inplant TrainingDocument19 pagesInplant TrainingArun KumarNo ratings yet

- Alignment Technique - The Steam TurbineDocument2 pagesAlignment Technique - The Steam TurbineRajeswar KulanjiNo ratings yet

- Steam Turbines - TurbotechDocument29 pagesSteam Turbines - TurbotechArjun PatelNo ratings yet

- Scope of Work FR 9Document3 pagesScope of Work FR 9Dharmesh Kumar KewatNo ratings yet

- Gas Turbine NotesDocument21 pagesGas Turbine NotesJohn BlackburnNo ratings yet

- B23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Document4 pagesB23-00 (2014) Standard Specification For White Metal Bearing Alloys (Known Commercially As  Œbabbitt Metalâ )Fanir ZNo ratings yet

- Til 1539Document13 pagesTil 1539Michael JordanNo ratings yet

- Operating and maintenance norms for hydraulic cylindersDocument4 pagesOperating and maintenance norms for hydraulic cylinderszsmithNo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- Innovative: Foundry SolutionsDocument6 pagesInnovative: Foundry SolutionsInnovative Foundry SolutionsNo ratings yet

- Typical Questions For Piping EngineerDocument4 pagesTypical Questions For Piping EngineerBudy SinagaNo ratings yet

- Flange Leakage Checking in Caesar II Using ASME Section VIII MethodDocument10 pagesFlange Leakage Checking in Caesar II Using ASME Section VIII MethodMichael RobinsonNo ratings yet

- Expansion JointsDocument4 pagesExpansion Jointsjeff501No ratings yet

- Cryo Piping SystemsDocument19 pagesCryo Piping SystemsaravindhcamNo ratings yet

- API 570 Bench Mark Quiz (1-55)Document56 pagesAPI 570 Bench Mark Quiz (1-55)Christopher Randolph100% (5)

- Electroslag Strip Cladding for Hydrogen RefineriesDocument12 pagesElectroslag Strip Cladding for Hydrogen RefineriesSANKET SINGHNo ratings yet

- Double Crusher Roll-General AssemblyDocument2 pagesDouble Crusher Roll-General AssemblyMichael SandersNo ratings yet

- WRC Files BaidDocument5 pagesWRC Files BaidMichael SandersNo ratings yet

- WRC Files BaidDocument5 pagesWRC Files BaidMichael SandersNo ratings yet

- Get WRC Bulletin 506 Half Bead Temper BeadDocument1 pageGet WRC Bulletin 506 Half Bead Temper BeadMichael Sanders0% (1)

- NewsletterDocument5 pagesNewsletterMichael SandersNo ratings yet

- Excel 2007 TipsDocument3 pagesExcel 2007 TipsMichael SandersNo ratings yet

- Post Weld Heat TreatmentDocument10 pagesPost Weld Heat Treatmentcristian291011No ratings yet

- SR Cracking 2.25Cr 1moDocument8 pagesSR Cracking 2.25Cr 1moMichael SandersNo ratings yet

- Zeron100 Welding GuidelinesDocument8 pagesZeron100 Welding GuidelinesansarALLAAHNo ratings yet

- How Good Is Your Organization's Corporate Memory?: PEG ContributorDocument2 pagesHow Good Is Your Organization's Corporate Memory?: PEG ContributorMichael SandersNo ratings yet

- 25-35NB Datasheet - Rev 17Document2 pages25-35NB Datasheet - Rev 17Michael SandersNo ratings yet

- FW COAA Industrial Contracts SeminarDocument2 pagesFW COAA Industrial Contracts SeminarMichael SandersNo ratings yet

- Impulse 4.0 Quick Start SIDocument79 pagesImpulse 4.0 Quick Start SIMohammed EljammalNo ratings yet

- Parchment FormDocument1 pageParchment FormMichael SandersNo ratings yet

- Sait TDC Ilb Student GuideDocument27 pagesSait TDC Ilb Student GuideMichael SandersNo ratings yet

- Pikotek IndexDocument1 pagePikotek IndexMichael SandersNo ratings yet

- Quick Start ImpDocument79 pagesQuick Start ImpMichael SandersNo ratings yet

- Engrg MGR Mech Eng JobsCanada EnbridgeDocument2 pagesEngrg MGR Mech Eng JobsCanada EnbridgeMichael SandersNo ratings yet

- Millenium DeckingDocument2 pagesMillenium DeckingMichael SandersNo ratings yet

- Germany and The Origins of The First World War - New PerspectivesDocument29 pagesGermany and The Origins of The First World War - New PerspectivesNicolai Elena MirelaNo ratings yet

- MGMT Stakeholders Needs JergeasDocument9 pagesMGMT Stakeholders Needs JergeasMichael SandersNo ratings yet

- Parker 4bolt Flanges J-FlangeDocument28 pagesParker 4bolt Flanges J-FlangeMichael SandersNo ratings yet

- ADV CGG BrochureDocument1 pageADV CGG BrochureMichael SandersNo ratings yet

- Mine Diesel Project Land RequirementsDocument1 pageMine Diesel Project Land RequirementsMichael SandersNo ratings yet

- ADV CGG BrochureDocument1 pageADV CGG BrochureMichael SandersNo ratings yet

- HE Dynagraph Data SheetDocument1 pageHE Dynagraph Data SheetMichael SandersNo ratings yet

- COPALTITE MSDS CHEMICAL DATADocument3 pagesCOPALTITE MSDS CHEMICAL DATAsoftechq1809No ratings yet

- Convert Multi-Sheet WKBK Sample VB Standalone ExecutableDocument5 pagesConvert Multi-Sheet WKBK Sample VB Standalone ExecutableMichael SandersNo ratings yet

- Bolt Pocket ChartDocument2 pagesBolt Pocket ChartAlex LaraNo ratings yet

- Short Term Training Curriculum Handbook: General Duty AssistantDocument49 pagesShort Term Training Curriculum Handbook: General Duty AssistantASHISH BARAWALNo ratings yet

- Mba Assignment SampleDocument5 pagesMba Assignment Sampleabdallah abdNo ratings yet

- Impact of Coronavirus On Livelihoods of RMG Workers in Urban DhakaDocument11 pagesImpact of Coronavirus On Livelihoods of RMG Workers in Urban Dhakaanon_4822610110% (1)

- Bank Statement AnalysisDocument26 pagesBank Statement AnalysisAishwarya ManoharNo ratings yet

- Gaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaDocument114 pagesGaspardo Operation Manual Campo 22-32-2014 01 f07011089 UsaМихайленко МиколаNo ratings yet

- 2.8 V6 5V (Aha & Atq)Document200 pages2.8 V6 5V (Aha & Atq)Vladimir Socin ShakhbazyanNo ratings yet

- Nature of ConversionDocument18 pagesNature of ConversionKiranNo ratings yet

- Rencana Pembelajaran Semester Sistem Navigasi ElektronikDocument16 pagesRencana Pembelajaran Semester Sistem Navigasi ElektronikLastri AniNo ratings yet

- Meanwhile Elsewhere - Lizzie Le Blond.1pdfDocument1 pageMeanwhile Elsewhere - Lizzie Le Blond.1pdftheyomangamingNo ratings yet

- CFEExam Prep CourseDocument28 pagesCFEExam Prep CourseM50% (4)

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarDocument2 pagesOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossNo ratings yet

- E2 PTAct 9 7 1 DirectionsDocument4 pagesE2 PTAct 9 7 1 DirectionsEmzy SorianoNo ratings yet

- 1st Exam Practice Scratch (Answer)Document2 pages1st Exam Practice Scratch (Answer)Tang Hing Yiu, SamuelNo ratings yet

- Supply Chain ManagementDocument30 pagesSupply Chain ManagementSanchit SinghalNo ratings yet

- Bernardo Corporation Statement of Financial Position As of Year 2019 AssetsDocument3 pagesBernardo Corporation Statement of Financial Position As of Year 2019 AssetsJean Marie DelgadoNo ratings yet

- Photoshop Tools and Toolbar OverviewDocument11 pagesPhotoshop Tools and Toolbar OverviewMcheaven NojramNo ratings yet

- Academy Broadcasting Services Managerial MapDocument1 pageAcademy Broadcasting Services Managerial MapAnthony WinklesonNo ratings yet

- Econ Old Test 2Document7 pagesEcon Old Test 2Homer ViningNo ratings yet

- B3 Zoning Diagram, Atlantic Yards/Pacific ParkDocument4 pagesB3 Zoning Diagram, Atlantic Yards/Pacific ParkNorman OderNo ratings yet

- Debentures Issued Are SecuritiesDocument8 pagesDebentures Issued Are Securitiesarthimalla priyankaNo ratings yet

- DrugDocument2 pagesDrugSaleha YounusNo ratings yet

- Software EngineeringDocument3 pagesSoftware EngineeringImtiyaz BashaNo ratings yet

- 28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017Document26 pages28 Government Service Insurance System (GSIS) vs. Velasco, 834 SCRA 409, G.R. No. 196564 August 7, 2017ekangNo ratings yet

- Venturi Meter and Orifice Meter Flow Rate CalculationsDocument2 pagesVenturi Meter and Orifice Meter Flow Rate CalculationsVoora GowthamNo ratings yet

- Competency-Based Learning GuideDocument10 pagesCompetency-Based Learning GuideOliver BC Sanchez100% (2)

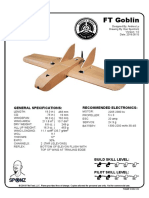

- FT Goblin Full SizeDocument7 pagesFT Goblin Full SizeDeakon Frost100% (1)

- 04 Dasmarinas Vs Reyes GR No 108229Document2 pages04 Dasmarinas Vs Reyes GR No 108229Victoria Melissa Cortejos PulidoNo ratings yet

- 3.4 Spending, Saving and Borrowing: Igcse /O Level EconomicsDocument9 pages3.4 Spending, Saving and Borrowing: Igcse /O Level EconomicsRingle JobNo ratings yet

- 1990-1994 Electrical Wiring - DiagramsDocument13 pages1990-1994 Electrical Wiring - Diagramsal exNo ratings yet

- Top 35 Brokerage Firms in PakistanDocument11 pagesTop 35 Brokerage Firms in PakistannasiralisauNo ratings yet