Professional Documents

Culture Documents

BOG For Receiving Terminals

Uploaded by

mishraenggOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BOG For Receiving Terminals

Uploaded by

mishraenggCopyright:

Available Formats

Siemens AG 2010. All rights reserved. Siemens AG 2010. All rights reserved.

LNG16

X-pert Center

Single Shaft Turbocompressor for

BOG Recovery in LNG Terminals

Author: Sven-Erik BRINK (Feed Team Manager

BOG compressor market specialist)

Siemens AG Energy, Sector Oil & Gas Division

Siemens AG 2010. All rights reserved.

Chart 2

Lets talk about a paradigm switch

Siemens AG 2010. All rights reserved.

Chart 3

Lets talk about a paradigm switch

Picture Bombardier

Siemens AG 2010. All rights reserved.

Chart 4

Worlwide increase in LNG demand leading to:

LNG tanker sizes are increasing this results in an

increased maximum BOG volume rate at LNG Receiving

Terminals during SHIP UNLOADING.

LNG send out rates are increasing and often totally

compensate BOG volume during HOLDING the GAP

between max. and min. BOG flow is becoming larger.

Todays LNG storage tanks are most often of full contain-

ment design which allow for pressure fluctuations inside

tanks.

Todays BOG single shaft centrifugal compressor design

are customized for start/stop operation featuring variable

Inlet Guide Vanes (IGV) and heated seal carriers.

The combination of above facts implementing a change of

compressor concept.

LNG Receiving Terminals

Situation have changed plus Progress in Advanced Technology

Siemens AG 2010. All rights reserved.

Chart 5

Over 30 years experience with BOG handling at

LNG export plants as a market-leader

Siemens has developed an innovative concept for

LNG import terminals.

This concept features a single-body, single-shaft, multi-

stage, centrifugal compressor optimized for small and

medium BOG volume flows and capable of automatic

start/stop operation from ambient as well as from cold

conditions with no cool-down required.

This concept opens the door for the paradigm switch to

maintenance-free, safe, economic and environmentally

friendly BOG handling within Liquefied Natural Gas (LNG)

import terminals (onshore as well as offshore), improving

significantly the Total Cost of Ownership (TCoO)

LNG Receiving Terminals

Siemens opens the door for the paradigm switch

Picture Bombardier

Siemens AG 2010. All rights reserved.

Chart 6

Simplyfied BOG Generation Profile

along the LNG chain

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

BOG Volume /

Massflow

LNG Chain Transport Production Regas

LOADING Mode

UNLOADING Mode

HOLDING Mode HOLDING Mode

Siemens AG 2010. All rights reserved.

Chart 7

Todays LNG Plants

E

LP HP

1 bar

-160 C 22 41 bar g

Fuel Gas

System

7 10 bar

Early LNG Plants and

Todays LNG Receiving

Terminals

E

LP

6 10 bar

Recondenser or Fuel Gas System

1 bar

-160 C

BOG Turbocompressors

(two casing vs. single casing)

Export Plant (tandem)

Start / Stop Operation

8000 to 39000 m3/h

- 163 to - 120 C

1.00 to 1.15 bar

2200 to 7500 kW

Import Terminal (single)

Start / Stop Operation

5000 to 33000 m3/h

- 163 to - 100 C

1.00 to 1.25 bar

2200 to 7500 kW

800 to 3500 kW

Siemens world

market leader for

cryogenic

temperature BOG

applications for LNG

Loading Plants

New market for LNG

Receiving Terminals

(onshore and

offshore) applying

same technology as

for LNG Loading

(Export) Plants

Siemens AG 2010. All rights reserved.

Chart 8

TC

IGV setting

-10 to +75

FC

2nd stage

HP Pumps

To Vaporizer and

Gas Pipeline

Recondenser

Suction

Drum

BOG

Compressor

Desuperheater

BOG at 1 bar

BOG at 8 bar

LNG at 8 bar

-162 C (-260 F)

LNG Storage

Tank

1st stage LP

Pumps

Simplified Flow Schematic

The onboard BOG recondensing concept

Siemens AG 2010. All rights reserved.

Chart 9

Compressor selection for import terminals

BOG handling concepts

Concept B

1 x 100%

Concept A

2 x 50% or

3 x 33%

Concept D

Concept C

2 x 50%

Increasing LNG sendout / ship size

B

O

G

v

o

l

u

m

e

f

l

o

w

UNLOADING

Mode

HOLDING

Mode

1 x 100 % hybrid concept

Siemens AG 2010. All rights reserved.

Chart 10

Application range of different compressor types

D

i

s

c

h

a

r

g

e

p

r

e

s

s

u

r

e

[

b

a

r

]

Actual suction volume [m/h]

Integrally geared type

BOG references range

for LNG Carriers

Siemens single shaft

BOG references range

1.000.000

1.000 10.000

20.000 100.000

70.000 200.000

Turbo radial

Reciprocating

Screw /

Rotary vane /

Roots

Turbo

axial-(radial)

3500

1000

600

250

100

50

10

100

BOG volume flows

Siemens AG 2010. All rights reserved.

Chart 11

Among all possible

compressor designs,

the single-shaft

concept ensures

highest reliability

and availability.

BOG compressor concept

Single shaft turbocompressor with vertically split casing

Siemens AG 2010. All rights reserved.

Chart 12

Single shaft BOG compressor cross sectional drawing

Oil heated Seal Carrier

3D Impeller

Dry Gas Seal

Inlet Guide Vane Unit (IGV)

Special Design Features

Single shaft turbo compressor for cryogenic temperature BOG

Siemens AG 2010. All rights reserved.

Chart 13

IGV Animation

Siemens AG 2010. All rights reserved.

Chart 14

L x W x H [mm]: 9,500 X 3,000 X 3,000

weight [kg]: 55,000

BOG single shaft Turbocompressor Layout

Compact single lift package concept

step-up gear

compressor

seal gas panel

oil unit

single lift

baseplate

electric drive

motor

Siemens AG 2010. All rights reserved.

Chart 15

Single shaft turbo compressor guarantees

highest reliability and availability plus

maximum safety

No spare units required

Virtually maintenance free

Lowest weight, minimum footprint (ideal for

offshore)

No gas to atmosphere low noise 85 bD(A)

Easy erection and installation due to fully

piped, wired and teates singel lift compressor

packages

Improving significantly the Total Cost of

Ownership

Conclusion

Why optimize the compressor concept?

Picture Bombardier

Siemens AG 2010. All rights reserved.

Our competence

drives your profit

Sven-Erik Brink

Feed Team (BOG Market Specialist)

Energy Sector, Oil & Gas Division

Wolfgang Reuter Platz

P.O. Box.10 15 07

47053 Duisburg, Germany

E-mail: sven.brink@siemens.com

cell phone +49 172 250 9405

Copyright Siemens AG 2010. All rights reserved.

You might also like

- Aker Solutions LNGDocument27 pagesAker Solutions LNGruov100% (1)

- GascoDocument26 pagesGascoriyanNo ratings yet

- Fabrizio ViscoDocument35 pagesFabrizio ViscoKelvin XuNo ratings yet

- Drive Selection For LNG FPSODocument5 pagesDrive Selection For LNG FPSOthlim19078656No ratings yet

- Offshore Salt Caverns Enable A 'Mega' Sized LNG Receiving TerminalDocument11 pagesOffshore Salt Caverns Enable A 'Mega' Sized LNG Receiving TerminalRizka KholistianiNo ratings yet

- Selecting: A Suitable ProcessDocument6 pagesSelecting: A Suitable ProcesstermdoxaNo ratings yet

- Open Rack Vaporizer Mass and Energy BalanceDocument12 pagesOpen Rack Vaporizer Mass and Energy BalanceMuhammad Nanda100% (1)

- Floating LNG FLNG Technical Challenges and Future TrendsDocument12 pagesFloating LNG FLNG Technical Challenges and Future TrendsIsioma1100% (1)

- Ref PropDocument66 pagesRef Proppeter panNo ratings yet

- LNG15 SMR LNG Process - 0703200760743Document10 pagesLNG15 SMR LNG Process - 0703200760743radenbagusNo ratings yet

- Incheon Regas PDFDocument11 pagesIncheon Regas PDFdhanta_1412No ratings yet

- Basic Refinery Equipment - Heat Exchanger (E003/1)Document27 pagesBasic Refinery Equipment - Heat Exchanger (E003/1)ebsmsart100% (1)

- 04 Hamworthy - Stein ThorsagerDocument38 pages04 Hamworthy - Stein ThorsagerRoozbeh PNo ratings yet

- York Navy Systems PUBL6539Document6 pagesYork Navy Systems PUBL6539Maria Gabriela BusteloNo ratings yet

- Varicon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDocument1 pageVaricon Pumps & Systems Private Limited: P&Id For Gas Odorizing SystemDeva NaiduNo ratings yet

- United States Patent Application Publication: Vandor Et Al. Pub. No.: Pub. DateDocument13 pagesUnited States Patent Application Publication: Vandor Et Al. Pub. No.: Pub. Datekaspersky2009No ratings yet

- Appendix 18 - Final Report Plant 4 - Ammonia Refrigeration and Compression PDFDocument8 pagesAppendix 18 - Final Report Plant 4 - Ammonia Refrigeration and Compression PDFSDP02No ratings yet

- Process Design and Optimization of Natural Gas PDFDocument6 pagesProcess Design and Optimization of Natural Gas PDFdigecaNo ratings yet

- 2004 Submerged Motor LNG Pumps in Send-Out System Service - S. Rush - Pumps & SystemsDocument6 pages2004 Submerged Motor LNG Pumps in Send-Out System Service - S. Rush - Pumps & SystemscsNo ratings yet

- Case 1 e 002 D - H Rev 0Document16 pagesCase 1 e 002 D - H Rev 0Oswaldo GuerraNo ratings yet

- PP Aaa PP1 117Document15 pagesPP Aaa PP1 117Rabah AmidiNo ratings yet

- R&T 2007 - CO2 Issues - Halsey CascadeDocument18 pagesR&T 2007 - CO2 Issues - Halsey CascadePRKrauseNo ratings yet

- Data Sheet LNG Loading ArmDocument2 pagesData Sheet LNG Loading ArmlguardiaNo ratings yet

- DMA BrochureDocument20 pagesDMA BrochurelongttNo ratings yet

- 14 ACC Air Side PerformanceDocument24 pages14 ACC Air Side PerformanceShivakumarNo ratings yet

- Rigorous Method For Fire CaseDocument4 pagesRigorous Method For Fire CaseFlorin Daniel AnghelNo ratings yet

- Basic LNG Training: Presented By: Saurabh Girdhar Head, Marine Division. Ganpat UniversityDocument85 pagesBasic LNG Training: Presented By: Saurabh Girdhar Head, Marine Division. Ganpat UniversityVu Duc NguyenNo ratings yet

- Above Ground Full Containment LNG Storage TankDocument7 pagesAbove Ground Full Containment LNG Storage TankMelvin MagbanuaNo ratings yet

- LNG Cold Energy Utilization UpdatedDocument13 pagesLNG Cold Energy Utilization UpdateddishankmpatelNo ratings yet

- LNGDocument6 pagesLNGFahd HatemNo ratings yet

- BS 3533 PDFDocument22 pagesBS 3533 PDFKarunakaran Nallasingam100% (2)

- Linde - LBPP HistoryDocument9 pagesLinde - LBPP Historynacho_16727No ratings yet

- Flaresim Flaresim: Flare Radiation AnalysisDocument25 pagesFlaresim Flaresim: Flare Radiation Analysisnay denNo ratings yet

- Natural Gas Liquefaction Technology For Floating LNG FacilitiesDocument12 pagesNatural Gas Liquefaction Technology For Floating LNG FacilitieshortalemosNo ratings yet

- LPG Energy IntegrationDocument6 pagesLPG Energy IntegrationBandaru KiranNo ratings yet

- Revamps For Ageing Methanol Plants: by Gerard B. Hawkins Managing Director, CEODocument39 pagesRevamps For Ageing Methanol Plants: by Gerard B. Hawkins Managing Director, CEOthirumalaiNo ratings yet

- Aspentech Course Catalog Fy18Document27 pagesAspentech Course Catalog Fy18Waseem AkramNo ratings yet

- Heat Exchanger Sizing E-5000 #1Document2 pagesHeat Exchanger Sizing E-5000 #1Luis Enrique Leyva OvalleNo ratings yet

- Kulkarni 2010Document11 pagesKulkarni 2010Amirullah AbdiNo ratings yet

- Dynamic Simulation and Optimization of The Operation of Boil Off Gas CompressorDocument6 pagesDynamic Simulation and Optimization of The Operation of Boil Off Gas CompressorKong LingweiNo ratings yet

- Material Stream: 1: ConditionsDocument6 pagesMaterial Stream: 1: ConditionsAKSHEYMEHTANo ratings yet

- PP Aaa PP1 109Document18 pagesPP Aaa PP1 109Rabah AmidiNo ratings yet

- (Polish Maritime Research) Development of New Technologies For Shipping Natural Gas by SeaDocument9 pages(Polish Maritime Research) Development of New Technologies For Shipping Natural Gas by SeafarshidianNo ratings yet

- Ca0536 Bro Cascade GBR 10-04Document2 pagesCa0536 Bro Cascade GBR 10-04geoteg2011No ratings yet

- LNG TroubleshootingDocument7 pagesLNG TroubleshootingAprizal AzisNo ratings yet

- Ammonia Plant Changeover StudyDocument14 pagesAmmonia Plant Changeover StudyJatinder Saini100% (1)

- PP Aaa PP1 147Document9 pagesPP Aaa PP1 147Rabah AmidiNo ratings yet

- 7-LNG Large Capacity Single Train AP-X Hybrid LNG ProcessDocument9 pages7-LNG Large Capacity Single Train AP-X Hybrid LNG ProcesshfNo ratings yet

- Hazira PlantDocument7 pagesHazira PlantRahul BhandurgeNo ratings yet

- FEED Screen Whitepaper PlantDocument10 pagesFEED Screen Whitepaper PlantazamshafiqNo ratings yet

- Mep Multi Effect Plate Evaporator DatasheetDocument4 pagesMep Multi Effect Plate Evaporator DatasheetKarim Sowley DelgadoNo ratings yet

- Test Separator Trailer Prices 2013Document3 pagesTest Separator Trailer Prices 2013hermit44535No ratings yet

- Production of LNG Using Dual Independent Expander Refrigeration Cycles - Jorge H Foglietta (ABB Lumnus)Document19 pagesProduction of LNG Using Dual Independent Expander Refrigeration Cycles - Jorge H Foglietta (ABB Lumnus)Joe Wong100% (1)

- Single-Shaft Turbocompressors For Boil Off Gas (BOG) Recovery at LNG Re-Gasification TerminalsDocument7 pagesSingle-Shaft Turbocompressors For Boil Off Gas (BOG) Recovery at LNG Re-Gasification TerminalsLee GoochNo ratings yet

- 대우의 가스추진선박에 대한 프리젠테이션Document33 pages대우의 가스추진선박에 대한 프리젠테이션Jae Sung KangNo ratings yet

- MaK VM32C Low Emission Engine 32305Document12 pagesMaK VM32C Low Emission Engine 32305abuzer1981100% (1)

- Dual Fuel Engine Development and DesignDocument40 pagesDual Fuel Engine Development and DesignHenrique MorgadoNo ratings yet

- CNG CompressorsDocument16 pagesCNG CompressorsZoran Bralović100% (1)

- 2022 Mini Programme 2nd SDocument194 pages2022 Mini Programme 2nd Sdimas kukuhNo ratings yet

- Siemens CompressorDocument12 pagesSiemens Compressorverat81100% (1)

- Factory Acceptance Testing Guideline Process - NoRestrictionDocument16 pagesFactory Acceptance Testing Guideline Process - NoRestrictionhamed51060No ratings yet

- Grundfos Design HVACDocument68 pagesGrundfos Design HVACmishraenggNo ratings yet

- Cellular Glass DatasheetDocument2 pagesCellular Glass DatasheetmishraenggNo ratings yet

- API 613 Fifth Edition Special Purpose Gear Units For Petroleum, Chemical and Gas Industry Services - Overview PresentationDocument8 pagesAPI 613 Fifth Edition Special Purpose Gear Units For Petroleum, Chemical and Gas Industry Services - Overview PresentationLymePark100% (1)

- Offshore201608 DLDocument138 pagesOffshore201608 DLmishraengg100% (2)

- Selecting A Centrifugal Pumps by System Analysis PDFDocument27 pagesSelecting A Centrifugal Pumps by System Analysis PDFmishraenggNo ratings yet

- Understand Color (En)Document26 pagesUnderstand Color (En)api-3704660100% (2)

- Questions and Answers RFQ-DCP-12-39-5680, Rotary Screw CompressorDocument1 pageQuestions and Answers RFQ-DCP-12-39-5680, Rotary Screw CompressormishraenggNo ratings yet

- Pump Sealing Systems Scott 060712 PDFDocument50 pagesPump Sealing Systems Scott 060712 PDFmishraenggNo ratings yet

- Refrigeration Dryer DenevarDocument8 pagesRefrigeration Dryer DenevarmishraenggNo ratings yet

- Io&m CC GeDocument113 pagesIo&m CC Gemishraengg100% (1)

- Control Engineering Mar.-2016Document88 pagesControl Engineering Mar.-2016mishraenggNo ratings yet

- GE CC Axial CompressorDocument28 pagesGE CC Axial CompressormishraenggNo ratings yet

- Basic of Thermo & Reciprocating CompressorDocument63 pagesBasic of Thermo & Reciprocating Compressormishraengg100% (1)

- Regenerated Adsorption Dryer Blast-PRODUCT-Hangzhou Deyoung Purification Equipment CoDocument2 pagesRegenerated Adsorption Dryer Blast-PRODUCT-Hangzhou Deyoung Purification Equipment ComishraenggNo ratings yet

- Operating Cost Comparison of Various Air Dryers Hoc Vs Heatless Vs Blower Heat Generated Vs RefrigeratedDocument2 pagesOperating Cost Comparison of Various Air Dryers Hoc Vs Heatless Vs Blower Heat Generated Vs RefrigeratedmishraenggNo ratings yet

- Air TreatmentDocument7 pagesAir TreatmentmishraenggNo ratings yet

- Compression and Expansion of GasesDocument5 pagesCompression and Expansion of GasesmishraenggNo ratings yet

- Curriculam Vitae: Job ObjectiveDocument3 pagesCurriculam Vitae: Job ObjectiveSarin SayalNo ratings yet

- Engels SEM1 SECONDDocument2 pagesEngels SEM1 SECONDJolien DeceuninckNo ratings yet

- Transportation Systems ManagementDocument9 pagesTransportation Systems ManagementSuresh100% (4)

- Merger and Acquisition Review 2012Document2 pagesMerger and Acquisition Review 2012Putri Rizky DwisumartiNo ratings yet

- Objectivity in HistoryDocument32 pagesObjectivity in HistoryNeelab UnkaNo ratings yet

- Questionnaire of Personal and Organizational Values Congruence For Employee (Q-POVC-115)Document6 pagesQuestionnaire of Personal and Organizational Values Congruence For Employee (Q-POVC-115)Kowshik SNo ratings yet

- Insurance OperationsDocument5 pagesInsurance OperationssimplyrochNo ratings yet

- Theodore L. Sendak, Etc. v. Clyde Nihiser, Dba Movieland Drive-In Theater, 423 U.S. 976 (1975)Document4 pagesTheodore L. Sendak, Etc. v. Clyde Nihiser, Dba Movieland Drive-In Theater, 423 U.S. 976 (1975)Scribd Government DocsNo ratings yet

- Excursion Parent Consent Form - 2021 VSSECDocument8 pagesExcursion Parent Consent Form - 2021 VSSECFelix LeNo ratings yet

- Executive Summary: College of EngineeringDocument17 pagesExecutive Summary: College of Engineeringjoel c. herreraNo ratings yet

- Gabbard - Et - Al - The Many Faces of Narcissism 2016-World - Psychiatry PDFDocument2 pagesGabbard - Et - Al - The Many Faces of Narcissism 2016-World - Psychiatry PDFatelierimkellerNo ratings yet

- Selection Letter Abhishek TodkarDocument1 pageSelection Letter Abhishek TodkarDipak GiteNo ratings yet

- What Project Will You Sugggest To The Management and Why?Document8 pagesWhat Project Will You Sugggest To The Management and Why?Tin Bernadette DominicoNo ratings yet

- Public Provident Fund Card Ijariie17073Document5 pagesPublic Provident Fund Card Ijariie17073JISHAN ALAMNo ratings yet

- Sample of Notarial WillDocument3 pagesSample of Notarial WillJF Dan100% (1)

- Surviving Hetzers G13Document42 pagesSurviving Hetzers G13Mercedes Gomez Martinez100% (2)

- Chapter 2 - How To Calculate Present ValuesDocument21 pagesChapter 2 - How To Calculate Present ValuesTrọng PhạmNo ratings yet

- Project Initiation & Pre-StudyDocument36 pagesProject Initiation & Pre-StudyTuấn Nam NguyễnNo ratings yet

- General Nursing Council of Zambia: Summary of Results For Each School December 2019 Qualifying Examinations SessionDocument15 pagesGeneral Nursing Council of Zambia: Summary of Results For Each School December 2019 Qualifying Examinations SessionAndrew LukupwaNo ratings yet

- NegotiationDocument29 pagesNegotiationNina LeeNo ratings yet

- 13th Format SEX Format-1-1: Share This DocumentDocument1 page13th Format SEX Format-1-1: Share This DocumentDove LogahNo ratings yet

- Determination Letter (June 15 2023) FOIA Request For Review - 2022 PAC 71791 71791 F 95c Improper 71b Improper 71c Improper 75r Improper Sd-1Document4 pagesDetermination Letter (June 15 2023) FOIA Request For Review - 2022 PAC 71791 71791 F 95c Improper 71b Improper 71c Improper 75r Improper Sd-1John KuglerNo ratings yet

- Assignment 1Document3 pagesAssignment 1Bahle DlaminiNo ratings yet

- Role of A ManagerDocument8 pagesRole of A ManagerMandyIrestenNo ratings yet

- Unit 2 Organisational CultureDocument28 pagesUnit 2 Organisational CultureJesica MaryNo ratings yet

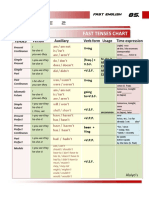

- Table 2: Fast Tenses ChartDocument5 pagesTable 2: Fast Tenses ChartAngel Julian HernandezNo ratings yet

- Infinivan Company Profile 11pageDocument11 pagesInfinivan Company Profile 11pagechristopher sunNo ratings yet

- DESIGNATIONDocument16 pagesDESIGNATIONSan Roque ES (R IV-A - Quezon)No ratings yet

- Practice Test 01 - Part ADocument9 pagesPractice Test 01 - Part AJose David Pascacio GrandaNo ratings yet

- Persephone and The PomegranateDocument3 pagesPersephone and The PomegranateLíviaNo ratings yet