Professional Documents

Culture Documents

Shear

Uploaded by

cataiceCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shear

Uploaded by

cataiceCopyright:

Available Formats

D.J.Dunn www.freestudy.co.

uk 1

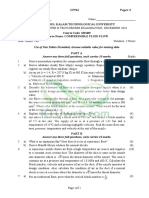

EDEXCEL NATIONAL CERTIFICATE/DIPLOMA

FURTHER MECHANICAL PRINCIPLES AND APPLICATIONS

UNIT 11 - NQF LEVEL 3

OUTCOME 2 - STRESS AND STRAIN

TUTORIAL 1 - SHEAR

CONTENT

Be able to determine the stress in structural members and joints

Single and double shear joints: fastenings e.g. bolted or riveted joints in single and double shear;

joint parameters e.g. rivet or bolt diameter, number of rivets or bolts, shear load, expressions for

shear stress in joints subjected to single and double shear, factor of safety

Structural members: members e.g. plain struts and ties, series and parallel compound bars made

from two different materials; loading e.g. expressions for direct stress and strain, thermal stress,

factor of safety

It is assumed that the student has studied Mechanical Principles and Applications Unit 6 and

is already familiar with basic stress and strain.

1. SHEAR STRESS

Shear force is a force applied sideways on to the material (transversely loaded). This occurs

typically:

(i) When a pair of shears cuts a material

Figure 1

(ii) When a material is punched

Figure 2

(iii) When a beam has a transverse load.

Figure 3

(iv) When a pin carries a load.

Figure 4

Shear stress is the force per unit area carrying the load. This means the cross sectional area of the

material being cut, the beam and pin respectively. Shear stress = F/A.

The symbol is called Tau. The sign convention for shear force and stress is based on how it shears

the materials and this is shown below.

Figure 5

D.J.Dunn www.freestudy.co.uk 2

In order to understand the basic theory of shearing, consider a block of material being deformed

sideways as shown.

Figure 6

2. SHEAR STRAIN

The force causes the material to deform as shown. The shear strain is defined as the ratio of the

distance deformed to the height x/L.

The end face rotates through an angle . Since this is a very small angle, it is accurate to say the

distance x is the length of an arc of radius L and angle so that

= x/L

It follows that is the shear strain. The symbol is called Gamma.

3. MODULUS OF RIGIDITY G

If we were to conduct an experiment and measure x for various values of F, we would find that if

the material is elastic, it behave like a spring and so long as we do not damage the material by using

too big a force, the graph of F and x is a straight line as shown.

The gradient of the graph is constant so F/x = constant and

this is the spring stiffness of the block in N/m.

If we divide F by the area A and x by the height L, the

relationship is still a constant and we get

constant

Ax

FL

L

x

A

F

= =

Figure 7

But F/A = and x/L = so constant

Ax

FL

L

x

A

F

= = =

This constant will have a special value for each elastic material and is called the Modulus of

Rigidity with symbol G.

G

=

D.J.Dunn www.freestudy.co.uk 3

4. ULTIMATE SHEAR STRESS

If a material is sheared beyond a certain limit it becomes permanently distorted and does not spring

all the way back to its original shape. The elastic limit has been exceeded. If the material is stressed

to the limit so that it parts into two(e.g. a guillotine or punch), the ultimate limit has been reached.

The ultimate shear stress is

u

and this value is used to calculate the force needed by shears and

punches.

WORKED EXAMPLE No. 1

Calculate the force needed to guillotine a sheet of metal 5 mm thick and 0.8 m wide given that

the ultimate shear stress is 50 MPa.

SOLUTION

kN 200 or N 000 200 4000 x 50 A x F so

A

F

N/mm 50 is stress shear ultimate The mm 4000 5 x 800 A

mm 5 x mm 800 rectangle a is cut be to area The

2 2

= = = =

= =

WORKED EXAMPLE No. 2

Calculate the force needed to punch a hole 30 mm diameter in a sheet of metal 3 mm thick

given that the ultimate shear stress is 60 MPa.

SOLUTION

kN 16.965 or N 16965 282.7 x 60 A x F so

A

F

N/mm 60 is stress shear ultimate The mm 282.7 3 x 30 x A

x t d ss x thickne nce circumfere the is cut be to area The

2 2

= = = =

= =

=

5. SAFETY FACTOR

It is normal to err on the side of safety when working out the forces and stresses in shear joints so a

safety factor is used. This is defined as:

Stress Working

Stress Ultimate

Factor Safety =

The use of the safety factor is shown in the next example.

D.J.Dunn www.freestudy.co.uk 4

WORKED EXAMPLE No. 3

Two sheets of steel are riveted together with 5 rivets as shown. Each rivet is 8 mm diameter.

Calculate the maximum force required to break the joint in shear given that the ultimate shear

stress is 60 MPa and a safety factor of 1.5 is to be used..

SOLUTION

kN 10.052 or N 10052 251.3 x 40 A x F so

A

F

N/mm 40 60/1.5 factor safety 60 stress Working

N/mm 60 is stress shear ultimate The mm 251.3 50.26 x 5 is area total The

50.26mm

4

8 x

4

d

A area circular the is rivet each in sheared be to area The

2

2 2

2

2

= = = =

= = =

=

= = =

SELF ASSESSMENT EXERCISE No. 1

1. A guillotine must shear a sheet of metal 0.6 m wide and 3 mm thick. The ultimate shear stress

is 45 MPa. Calculate the force required. (Answer 81 kN)

2. A punch must cut a hole 30 mm diameter in a sheet of steel 2 mm thick. The ultimate shear

stress is 55 MPa. Calculate the force required. (Answer10.37 kN)

3. Two strips of metal are pinned together as shown with a rod 10 mm diameter. The ultimate

shear stress for the rod is 60 MPa. Determine the maximum force required to break the pin.

(Answer 4.71 kN)

Figure 8

4. A riveted joint must withstand 20 kN in shear. The rivets are 5 mm diameter and have an

ultimate shear stress of 80 MPa. If a safety factor of 2 is to be used, how many rivets are

required?

(Answer 26)

D.J.Dunn www.freestudy.co.uk 5

5. DOUBLE SHEAR

Consider a pin joint with a support on both ends as shown. This is called a

CLEVIS and CLEVIS PIN. If the pin shears it will do so as shown.

By balance of forces, the force in the two supports is F/2 each.

The area sheared is twice the cross section of the pin so it takes twice as

much force to break the pin as for a case of single shear. Double shear

arrangements doubles the maximum force allowed in the pin.

Figure 9

WORKED EXAMPLE No. 4

A pin is used to attach a clevis to a rope. The force in the rope will be a maximum of 60 kN.

The maximum shear stress allowed in the pin is 40 MPa. Calculate the diameter of a suitable

pin.

SOLUTION

mm 30.9

750 x 4

d

4

d

mm 750 A

m 10 x 750

40x10 x 2

60000

2

F

A

2A

F

is sress shear the so shear double in is pin The

2

2

2 6

6

= =

= =

= = =

=

D.J.Dunn www.freestudy.co.uk 6

SELF ASSESSMENT EXERCISE No. 2

1. A clevis pin joint as shown above uses a pin 8 mm diameter. The shear stress in the pin must

not exceed 40 MPa. Determine the maximum force that can be exerted. (Answer 4.02 kN)

2.

Figure 10

A rope coupling device shown uses a pin 5 mm diameter to link the two parts. If the shear

stress in the pin must not exceed 50 MPa, determine the maximum force allowed in the ropes.

(Answer 1.96 kN)

3. Three metal plates are joined together with steel M8 screws as shown along one edge. Find the

root diameter of M8 screws and a typical ultimate shear stress for steel screws. Based on a

safety factor of 1.5, calculate the number of screws needed withstand a shearing force of 40kN.

Figure 11

(Answer approximately 20)

D.J.Dunn www.freestudy.co.uk 7

You might also like

- Mechanics of Solids - (Riveted and Welded Joints)Document37 pagesMechanics of Solids - (Riveted and Welded Joints)TusherNo ratings yet

- Mechanics of Material-1-5 PDFDocument252 pagesMechanics of Material-1-5 PDFkhan janNo ratings yet

- Simple StrainDocument12 pagesSimple StrainChristine Mae TinapayNo ratings yet

- Solution 08Document44 pagesSolution 08楊顗融No ratings yet

- Lesson 6 - TORSION PDFDocument30 pagesLesson 6 - TORSION PDFBaux/比叡0% (1)

- L That Can Be Used For The Splice Plates For An Applied Load of P 10,000Document10 pagesL That Can Be Used For The Splice Plates For An Applied Load of P 10,000Don Matias0% (1)

- CE6306 SOM Important QuestionsDocument4 pagesCE6306 SOM Important QuestionsUTHIRANo ratings yet

- Chapter 6Document26 pagesChapter 6Victoria JungNo ratings yet

- Review of Related LiteratureDocument5 pagesReview of Related LiteratureJay Ar GalangNo ratings yet

- Statics AnDocument13 pagesStatics AnIsaac Davy100% (1)

- Mechanics of Deformable Bodies M1 Post TestDocument3 pagesMechanics of Deformable Bodies M1 Post TestBenmark JabayNo ratings yet

- Thermal Stress: Mechanics of Deformable BodiesDocument10 pagesThermal Stress: Mechanics of Deformable BodiesPao CastillonNo ratings yet

- FluidsDocument1 pageFluidsnico aspraNo ratings yet

- Principles of Hydrostatics Lesson2Document14 pagesPrinciples of Hydrostatics Lesson2Tomori Nao100% (1)

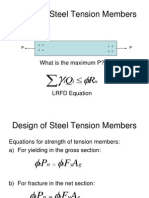

- 02 - Design of Steel Tension MembersDocument15 pages02 - Design of Steel Tension MembersMayur PatelNo ratings yet

- Day 8 Plane Geometry December 01 20212Document51 pagesDay 8 Plane Geometry December 01 20212Free student100% (1)

- Module 3 TorsionDocument13 pagesModule 3 TorsionJay LopezNo ratings yet

- Chapter 6Document31 pagesChapter 6Camille LardizabalNo ratings yet

- Exer1322 PDFDocument21 pagesExer1322 PDFNelva CSNo ratings yet

- SOM Lecture 03Document25 pagesSOM Lecture 03tvkbhanuprakashNo ratings yet

- Unit 11Document20 pagesUnit 11Venkatesh Gangadhar100% (1)

- Chapter 3 - Hydrostatic ForceDocument44 pagesChapter 3 - Hydrostatic ForceMuhammad AidilNo ratings yet

- Bending StressDocument19 pagesBending StressMohsin Islam RifatNo ratings yet

- Mechanics of Materials 6th Edition Beer Solution Chapter 1Document78 pagesMechanics of Materials 6th Edition Beer Solution Chapter 1DanielMendozaNarvaezNo ratings yet

- Deformable Bodies (Thermal Stress)Document11 pagesDeformable Bodies (Thermal Stress)Kristelle GinezNo ratings yet

- Tutorial 03 - Static Forces On SurfacesDocument2 pagesTutorial 03 - Static Forces On SurfacesafzalNo ratings yet

- T3 Current ResistanceDocument12 pagesT3 Current Resistanceleroy_quekNo ratings yet

- SolveDocument11 pagesSolveShamanAcolyteNo ratings yet

- 6 2016 Statically Indeterminate StructureDocument35 pages6 2016 Statically Indeterminate Structuremarhen santoso100% (1)

- Jessica Agar: Search Subjects LOG INDocument7 pagesJessica Agar: Search Subjects LOG INJamiel CatapangNo ratings yet

- Umay DesignDocument55 pagesUmay DesignMhel CenidozaNo ratings yet

- Beer의 재료역학 6th Edition 5장 솔루션Document200 pagesBeer의 재료역학 6th Edition 5장 솔루션남태우No ratings yet

- Esfuerzos en Vigas - PDFDocument6 pagesEsfuerzos en Vigas - PDFgerardo jose de la espriella alvarezNo ratings yet

- Homework 1 3Document6 pagesHomework 1 3inisdeprawn100% (2)

- Ge 13Document1 pageGe 13Hasib SaripadaNo ratings yet

- Fluid Mechanics Rest: Common Liquid PropertiesDocument13 pagesFluid Mechanics Rest: Common Liquid PropertiesJericho Alfred Rullog SapitulaNo ratings yet

- Strength of MaterialsDocument11 pagesStrength of Materialsjerold_arandiaNo ratings yet

- ENSC 3233 HW #1 Solution PDFDocument10 pagesENSC 3233 HW #1 Solution PDFheem bashaNo ratings yet

- Chapter-7 Shear DesignDocument14 pagesChapter-7 Shear DesignAngelo RosNo ratings yet

- MechanicsDocument2 pagesMechanicsNicole De Leon Miday0% (1)

- Fluids M4Document21 pagesFluids M4Lolly UmaliNo ratings yet

- PPSDocument94 pagesPPSaamirNo ratings yet

- Strema Act 2Document42 pagesStrema Act 2James Ryu ZagalaNo ratings yet

- Mastery Test MT1 and MT2 Solution: None of TheseDocument6 pagesMastery Test MT1 and MT2 Solution: None of TheseU-line Anne Roque VillafloresNo ratings yet

- Normal and Shear Stress PDFDocument25 pagesNormal and Shear Stress PDFmohanadymtNo ratings yet

- HW 11 SolnDocument9 pagesHW 11 SolnHebert NiceNo ratings yet

- Review 1Document8 pagesReview 1Lyka Jane Pesigan100% (1)

- Simple Stresses and StrainsDocument36 pagesSimple Stresses and Strainsfotick100% (1)

- Simple BendingDocument41 pagesSimple BendingrpsirNo ratings yet

- Chapter 2 SolutionsDocument9 pagesChapter 2 SolutionsFrendick LegaspiNo ratings yet

- Chapter 4 - Bolted Connections (Part 3)Document3 pagesChapter 4 - Bolted Connections (Part 3)John Philip NuñezNo ratings yet

- Unit-4 Induction MotorsDocument26 pagesUnit-4 Induction MotorsAnurag Singhal0% (1)

- Chapter5.4 Unsymmetrical BeamsDocument8 pagesChapter5.4 Unsymmetrical BeamsMaryanne Rempillo MarañaNo ratings yet

- DC Machine 2Document20 pagesDC Machine 2Fadhil A. HasanNo ratings yet

- Structural Members: Struts and Ties Direct Stress and Strain, Dimensional ChangesDocument6 pagesStructural Members: Struts and Ties Direct Stress and Strain, Dimensional ChangescataiceNo ratings yet

- Stress Part2Document7 pagesStress Part2raiden timberlandNo ratings yet

- Stress PDFDocument13 pagesStress PDF9966197483No ratings yet

- Stress and StrainDocument13 pagesStress and StrainMuruganandam RamadassNo ratings yet

- Structural MembersDocument14 pagesStructural MemberscataiceNo ratings yet

- (Lec Dt3 Journal BearingsDocument25 pages(Lec Dt3 Journal BearingscataiceNo ratings yet

- Machine FoundationsDocument249 pagesMachine Foundationsnizamaniza100% (32)

- ITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDDocument10 pagesITTC - Recommended Procedures and Guidelines: Practical Guidelines For Ship Self-Pro-pulsion CFDcataiceNo ratings yet

- (Design of Composite Materials and StructuresDocument108 pages(Design of Composite Materials and StructurescataiceNo ratings yet

- 00 - Propriedades Do Cobre (WWW - Copper - Org)Document114 pages00 - Propriedades Do Cobre (WWW - Copper - Org)nicacio_89507470100% (1)

- Flat Plate Deflection Chapter13 1Document29 pagesFlat Plate Deflection Chapter13 1Feeling_so_fly100% (2)

- 00 - Propriedades Do Cobre (WWW - Copper - Org)Document114 pages00 - Propriedades Do Cobre (WWW - Copper - Org)nicacio_89507470100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- AA SM 002 001 Torsion Regular SectionsDocument14 pagesAA SM 002 001 Torsion Regular SectionscataiceNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- AA SM 002 002 Torsion Irregular SectionsDocument11 pagesAA SM 002 002 Torsion Irregular SectionscataiceNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Summary of Reports, Gust Alleviation FactorsDocument52 pagesSummary of Reports, Gust Alleviation FactorscataiceNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- AA SM 001 000 Section PropertiesDocument41 pagesAA SM 001 000 Section PropertiescataiceNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Tm214323 Fastener TorqueDocument36 pagesTm214323 Fastener TorquecataiceNo ratings yet

- Physics Class Xii Sample Paper Test 02 For Board Exam 2023 AnswersDocument19 pagesPhysics Class Xii Sample Paper Test 02 For Board Exam 2023 AnswersGyan BardeNo ratings yet

- Welding ImperfectionsDocument39 pagesWelding ImperfectionsAnonymousNo ratings yet

- Gummy Bear Lab Report 1Document3 pagesGummy Bear Lab Report 1api-265869960No ratings yet

- Sensors & Instrumentation Notes Unit-02Document47 pagesSensors & Instrumentation Notes Unit-02shivangi sharmaNo ratings yet

- Units, Dimensions and Measurements MCQ (Free PDF) - Objective Question Answer For Units, Dimensions and Measurements Quiz - Download Now!Document27 pagesUnits, Dimensions and Measurements MCQ (Free PDF) - Objective Question Answer For Units, Dimensions and Measurements Quiz - Download Now!Vinayak SavarkarNo ratings yet

- BOILER PrestigeDocument2 pagesBOILER PrestigeJaime Rodri Millapan AlianteNo ratings yet

- 2017 National Exam Part I PDFDocument11 pages2017 National Exam Part I PDFNguyễn Đức TrọngNo ratings yet

- Catalyst (DMC Type)Document3 pagesCatalyst (DMC Type)Visarut RujirawanichNo ratings yet

- MT - Phys2 - Summer 23 - Version A - With AnswersDocument6 pagesMT - Phys2 - Summer 23 - Version A - With AnswersaamerbolookiNo ratings yet

- Hydraulic Calculation Lecture-PipingDocument34 pagesHydraulic Calculation Lecture-PipingFarzad Rezaei100% (2)

- Quantum Gravity and A Time Operator in Relativistic Quantum MechanicsDocument10 pagesQuantum Gravity and A Time Operator in Relativistic Quantum MechanicsJulian BermudezNo ratings yet

- Atomic Model WorksheetDocument2 pagesAtomic Model WorksheetTelle Telle100% (1)

- Effect of Weather Conditions On Quality of Free Space Optics LinksDocument5 pagesEffect of Weather Conditions On Quality of Free Space Optics LinksLương Xuân DẫnNo ratings yet

- Energy and StyffDocument18 pagesEnergy and StyffscrappyvNo ratings yet

- Use of Gas Tables Permitted, Assume Suitable Value For Missing DataDocument2 pagesUse of Gas Tables Permitted, Assume Suitable Value For Missing DataVenkitaraj K PNo ratings yet

- Aluminum E-pH (Pourbix) DiagramDocument8 pagesAluminum E-pH (Pourbix) Diagramnv10559837sdNo ratings yet

- LaminageDocument21 pagesLaminageazoughNo ratings yet

- 2nd Half Book Ist Year PHYSICSDocument4 pages2nd Half Book Ist Year PHYSICSranaateeq100% (1)

- Jack Sarfatti - Hologram UniverseDocument9 pagesJack Sarfatti - Hologram UniverseFrankOfTomorrowNo ratings yet

- Power Consumption Mixing TimeDocument10 pagesPower Consumption Mixing TimegambitfluentNo ratings yet

- Y13 EPP Full PDFDocument11 pagesY13 EPP Full PDFyolanda gaoliNo ratings yet

- Es TG Module 2 Climate RevisedDocument23 pagesEs TG Module 2 Climate RevisedNikkieIrisAlbañoNovesNo ratings yet

- Summative Test in Science 10 Mod 5Document4 pagesSummative Test in Science 10 Mod 5Ruth Anne BarriosNo ratings yet

- Ex No:6 Modelling and Simulation of Buck and Boost Converter 10.11.2014Document6 pagesEx No:6 Modelling and Simulation of Buck and Boost Converter 10.11.2014dhineshpNo ratings yet

- Laser DiffractionDocument20 pagesLaser DiffractionAshraf ShaikhNo ratings yet

- KTR Rotex GS KaplinDocument26 pagesKTR Rotex GS KaplinrudyNo ratings yet

- Surfaces: Open and Closed SurfacesDocument3 pagesSurfaces: Open and Closed SurfacesrodwellheadNo ratings yet

- Hybrid Tesla Pelton Wheel TurbineDocument6 pagesHybrid Tesla Pelton Wheel TurbineFreddy Augusto VargasNo ratings yet

- Topic 5.1 - Electric FieldsDocument67 pagesTopic 5.1 - Electric FieldsPaul AmezquitaNo ratings yet

- The Physics of WeldingDocument8 pagesThe Physics of WeldingnitinNo ratings yet