Professional Documents

Culture Documents

Solar Report

Uploaded by

ವಿಶ್ವನಾಥ ಸಿ0 ratings0% found this document useful (0 votes)

33 views71 pagessolar energy harvesting using FPGA report

Original Title

solar Report

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsolar energy harvesting using FPGA report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

33 views71 pagesSolar Report

Uploaded by

ವಿಶ್ವನಾಥ ಸಿsolar energy harvesting using FPGA report

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 71

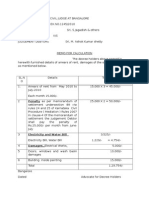

ACKNOWLEDGEMENT

The satisfaction that accompanies a successful completion of any task would be

incomplete without the mention of the people who made it possible, whose constant guidance

and encouragement crowns all the efforts with success. We would like to express our sincere

gratitude to all who have been associated with this project and have stood by us at all times.

First of all I convey my gratitude for the valuable guidance and constant encouragement

by my project guide Mr. S N Prasad, Associate Professor, Dept of Electronics and

Commnication, who showed great interest in my project and gave me ample guidelines for the

proceedings to handle the project in a systematic manner..

I would like to thank Mr. Pras!ant " #os!i !"#oordinator, $%&' IT(, )angalore, for

helping in completing the project and guiding us to organi*e the report in a systematic manner

(y profound sense of gratitude to Dr. S.S.Man$i %OD, Dept. of Electronics and

Commnication, &E"A 'TM and other staff members and non teaching staff members of the

+ept. of %,# who provided me the knowledge throughout my course.

I express my sincere gratitude to the Principal, Dr. &anaPratap &edd(, Principal,

&E"A 'TM, and the Mana)ement of &E"A 'TM, who had given a chance in pursuing my

post graduation studies in their esteemed institution at $%&' IT(..

-ast but definitely not the least I would like to thank my parents and friends who have

always supported me in every path of life.

"is!*anat! c.

ii

Abstract

To explore integrated solar energy harvesting as a power source for low power systems, an array

of energy scavenging photodiodes based on a passive-pixel architecture for CMOS imagers has

been fabricated together with storage capacitors implemented using on-chip interconnect in a

0.35- m bulk process. Integrated vertical plate capacitors enable dense energy storage without

limiting optical efficiency. Tests were conducted with both a white light source and a green laser.

Measurements indicate that 225 W/mm. The combination of integrated solar energy scavenging

and storage can enable a new generation of low cost, long lifetime, small volume systems for

future wireless sensor networks or RFID applications. For a 25 mm total photodiode area

consisting of 3 diodes in series with the metal storage capacitances for each diode connected in

parallel, D1, D2, and D3 can supply enough energy for the DSP to produce 687, 745, and 903

output samples respectively. This paper describes an array of photodiodes, modeled after a

passive-pixel imager, integrated together with storage capacitors in a commodity CMOS process.

Also described is the potential of this approach to increase the lifetime of wireless sensor nodes.

To reduce system cost and volume it is desirable to integrate energy harvesting and storage with

data acquisition, data processing, and communication circuits.Recent advances in very low

power signal processing architectures for sensors has created the opportunity to use CMOS

photodiodes, similar to those used in digital cameras, for solar energy harvesting. Moreover, the

increase in interconnect capacitance as CMOS processes scale provides an opportunity to store

the harvested energy without requiring battery materials to be integrated on-chip.

List of Figures

Fig 1.1 Low power wireless system 2

Fig 2.1 Block Diagram of integrated solar energy harvesting and storage 12

Fig 2.2 Flowchart Diagram of integrated solar energy harvesting and storage 13

Fig 3.1 the emission of electron from metal plate 14

Fig 3.2 photovoltaic effect in different conditions 15

Fig 3.3 DC motor 21

Fig 3.4 DC motor forward-reverse control 23

Fig: 3.5 Typical Application Circuits 25

Fig: 3.6 LDR Circuits 25

Fig: 3.7 Resistance As Function Of Illumination 26

Fig 3.8 stepper motor 27

Fig: 3.9 Block Diagram Of ADC 29

Fig: 3.10 The Magnitude Of The Error Ranges From Zero To 1 LSB 31

Fig: 3.11 Pin diagram of ADC0803 32

Fig: 3.12 Functional Block Diagram Of ADC0803 32

Fig 3.13 Light dependent resistor 36

Fig 3.14 single axis solar panel 38

Fig 3.15 double axis tracker 38

Fig 4.1 Model Sim Simulation Environments 42

Fig 4.2 Basic simulation flow 45

Fig: 5.1 Launching ISE Text Editor to edit SOLAR.vhd 52

Fig: 5.2 Internal RTL Diagram of solar.vhd 52

Fig: 5.3 Mux Register Schematic Diagram 53

Fig: 5.4 Program Generation Report 53

Fig: 5.6 Simulation Results of solar module 54

Fig 5.7 Simulation results of LDR_sensor1 54

Fig 5.8 RTL block diagram of LCD_data out 55

List of Tables

Table 5.1 Model sim Modes of Operation 42

Table of Contents

Acknowledgements Error!

Bookmark not defined.

Abstract 1

List of Figures iii

List of Tables iv

Chapter 1

PREFACE 1-10

1.1 Introduction 1

1.2 Background of Project 4

1.3 Objective 5

1.4 Problem Definition 5

1.5 Problem Statement 6

1.6 Existing System 6

1.7 Proposed System 8

1.8 Project Plan 9

1.9 Organization of the Report 10

Chapter 2

BLOCKDIAGRAM & FLOWCHART 12-13

2.1 Block Diagram of Project 12

2.2 Flowchart of Project 13

Chapter 3

LITERATURE SURVEY 14-39

3.1 Fundamentals of Photovoltaic System 14

3.1.1 Photovoltaic cell 14

3.1.2 The Photovoltaic Effect 15

3.1.3 Efficiency 16

3.2 Types of photovoltaic System 17

3.3 Solar Position Algorithm for Solar Radiation Applications 18

3.3.1 Solar Azimuth angle 19

3.3.2 Solar zenith angle 20

3.3.3 Solar elevation angle 20

3.4 Dc Motors 21

3.4.1. Brushed Dc Electric Motor 21

3.5 Connection Types 22

3.5.1. Series Connection 22

3.5.2. Shunt Connection 22

3.5.3. Compound Connection 23

3.6 Dc Motor Forward Reverse Control 23

3.6.1 Circuit working Description 24

3.7 Function of LDR 24

3.7.1 Spectral Response 26

3.7.2 Sensitivity 26

3.8 Stepper motor 26

3.9 Analog to Digital Converter (ADC) 29

3.9.1 Quantization Error 30

3.10 Light-Dependent Resistor 35

3.10.1 ADC 36

3.10.2 Driver Circuit 36

3.11 Solar Cell Array 36

3.11.1 Active Solar Trackers 37

3.11.2 Types Of Solar Trackers 37

3.11.2.1 Single Axis Solar Trackers 37

3.11.2.2 Dual Axis Trackers 37

3.12 Battery 39

Chapter 4

TOOLS REQUIRED 40-51

4.1 Software Tools 40

4.1.1 Xilinx ISE 13.2i 40

4.2 ModelSim 6.3 C 42

4.2.1 Model Sim Library 44

4.2.2 Model Sim modes of operation 44

4.2.3 Basic simulation flow 45

4.3 Evolution of Programmable Logic Devices 46

4.3.1 Field Programmable Gate Array (FPGA) 47

4.3.2 Applications 47

4.3.3 General workflow when working with FPGAs: 48

4.3.4 Internal logic 49

4.3.5 Internal RAM 49

4.3.6 FPGA pins 50

4.3.7 IO banks 50

4.3.8 FPGA power 50

4.3.9 Clocks and Global lines 50

4.3.10 Features in common with FPGAs 51

Chapter 5

SIMULATION RESULTS 52

Chapter 6

CONCLUSION AND FUTURE SCOPE 56-58

6.1 Conclusion 56

6.2 Future Scope 56

6.3 Advantages 57

6.4 Project Limitations 57

6.5 Applications 57

BIBLIOGRAPHY 59

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 1

CHAPTER 1

PREAMBLE

1.1 Introduction

The emerging application of wireless sensor networks continues to drive the need for ultra-low

power system design. Wireless sensors can enable a variety of applications including interactive

environments for medicine, environmental monitoring networks, military target tracking, and

detection of chemical and biological weapons. In many of these wireless systems, the power

source is a bottleneck that limits system lifetime and performance, adds manufacturing cost, and

increases system volume and maintenance expenditures. Delivering power to wireless sensor

network nodes is a significant system design challenge. Solar energy harvesting has been

proposed to extend the lifetime of these networks beyond the limitations which have been

previously imposed by batteries. In many of these wireless systems, the power source is a

bottleneck that limits system lifetime and performance, adds manufacturing cost, and increases

system volume and maintenance expenditures Prior works have successfully demonstrated

powering wireless systems through discrete photovoltaic cells together with separate energy

storage devices using board level designs.

To reduce system cost and volume it is desirable to integrate energy harvesting and

storage with data acquisition, data processing, and communication circuits. Recent advances in

very low power signal processing architectures for sensors has created the opportunity to use

CMOS photodiodes, similar to those used in digital cameras, for solar energy harvesting.

Moreover, the increase in interconnect capacitance as CMOS processes scale provides an

opportunity to store the harvested energy without requiring battery materials to be integrated on-

chip. This Project describes an array of photodiodes, modeled after a passive-pixel imager,

integrated together with storage capacitors in a commodity CMOS process. Also described is the

potential of this approach to increase the lifetime of wireless sensor nodes. The system consists

of sensors that can observe the environment, an analog-to-digital converter (ADC) that can

quantize the analog signal from the sensors, a digital signal processing (DSP) core that can

analyze and encode the quantized data and a transceiver (RF) so that the node can transmit and

receive information

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 2

.

Fig: 1.1 Low power wireless system

Light energy is converted to electrical energy through a photodiode and mechanical

vibrations are converted to electrical energy by an electromechanical transducer. A multiplexer

(mux) is used to switch between energy sources. The systems energy gathering ability will

depend on environmental conditions, which can change over time. Hence, the scavenged energy

needs to be regulated before being used by these functional blocks.Fig.1.1 shows a block diagram

of a typical wireless sensor node, which is powered by a combination of energy scavenging and

battery technology. The system consists of sensors that can observe the environment, an analog-

to-digital converter (ADC) that can quantize the analog signal from the sensors, a digital signal

processing (DSP) core that can analyze and encode the quantized data and a transceiver (RF) so

that the node can transmit and receive information. Light energy is converted to electrical energy

through a photodiode and mechanical vibrations are converted to electrical energy by an

electromechanical transducer. A multiplexer (mux) is used to switch between energy sources. The

systems energy gathering ability will depend on environmental conditions, which can change

over time. Hence, the scavenged energy needs to be regulated before being used by these

functional blocks.

In general, these types of systems work on very low duty cycles, where the sensor node

will be in a rest state for the majority of the time. Periodically, the sensor node will wake up, take

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 3

a snapshot of the environment measured by its sensors, perform its computations, and transmit

any data before returning back to the rest state.

Each of the functional blocks shown in Fig.1.1 has its own power requirement. Previous

work has shown that efficient ADCs and DSPs can achieve average power levels in the sub-

milliwatt range. However, low power ADCs usually suffer from diminished power supply

rejection. Minimizing the voltage ripple on the power supply for the ADC is important for

maintaining accuracy. The RF block typically requires significantly more peak power than the

other system blocks, and the DSP has the most relaxed supply ripple requirements due to the

robustness (large noise margin) of the digital circuitry. For Low duty cycles, the average power

for the system can be under 5microwatts.

The integration of the photovoltaic cells along with analog and digital signal processing

circuits is of interest in this work. The scaling of a photovoltaic cell from large, standalone arrays

to the integrated circuit level will impact the cells output power, efficiency, optimal load

resistance, and optical properties of the photodiode. Energy harvesting systems with high power

requirements may require a significant area allocation for integrated photodiodes. Although

integrated photodiodes can also double as power supply bypass capacitors, the additional cost

associated with the photodiodes footprint could potentially limit its usefulness to larger feature

size technologies. True integration of photodiodes and active circuitry on the same die may

require covering the active circuitry with a metal cap to block the incident light from potentially

degrading signal integrity. A substrate trench, forming a barrier, can also be employed to help

limit the lateral photocurrent traveling from the photodiodes to the active circuitry.

The construction of the storage capacitance and routing for the photodiodes must not

degrade the optical efficiency (OE), which is defined as the fraction of incident light onto the

chips surface which reaches the photodiode . In general, the optical efficiency is influenced by

three loss factors: reflection loss, absorption loss, and critical angle loss. Once photons reach the

photodiode, the quantum efficiency (QE) determines how many photons will generate electron-

hole pairs. The product of OE and QE should be maximized by the geometry of the photodiode

and storage capacitance to maximize both the energy harvesting ability and storage capacity.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 4

An ultracapacitor is an electrochemical capacitor typically made from carbon and with a

high energy density due to a large surface area to volume ratio for the internal material. It has

been previously shown that these ultra-capacitors could reduce the high power demands on

batteries in wireless systems by storing energy harvested from environmental sources . One

advantage of ultra-capacitors is the high number of charge/discharge cycles they can undergo

before deterioration, which is approximately 100 000 cycles (roughly 100 better than

contemporary battery technologies). Ultra capacitors thus far have primarily been used for hybrid

vehicle applications with individual capacitor sizes reaching thousands of farads. In this section,

we explore and compare the effect of technology scaling on interconnect capacitance density and

ultra capacitor density.

1.2 Background of Project

Solar power is an alternative technology that will hopefully lead us away from our petroleum

dependent energy sources. The major problem with solar panel technology is that the efficiencies

for solar power systems are still poor and the costs per kilo-watt-hour (kwh) are not competitive,

in most cases, to compete with petroleum energy sources. In India, the sun is always directly

overhead and its intensity do not varies by season. This give a lot more advantage for us to use

solar power compare with the place that have season. There are two most common type systems

that always use for small building generated system:-

1. The solar thermal system

2. The photovoltaic system

The solar thermal system operate by convert the radiant energy of the sun into heat then

use that heat to provide useful electric energy. On other hand, the photovoltaic system converts

directly the sun radiant into useful electric energy, which can be used as most electrical energy in

used today. Solar power (photovoltaic) systems are a sustainable way to convert the energy of

the sun into electricity. The expected lifetime of a system is 25-30 years. This show how efficient

is this system even it is quite expensive to install this system at the beginning.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 5

Amount of power produced by a photovoltaic panel depends upon the amount of sunlight

it is exposed to. In other word, more light means more power. In order to capture more light

produce by sun, the photovoltaic panel must constantly orient itself to the sun location. When the

photovoltaic panel does not intercept as much light as it can, it will not produce as much power

as it can. Fixed photovoltaic panel do not aim directly to the sun due to the constant motion of

earth. As the result, the power produce by the system is less then it capable producing. To

overcome this problem, the tracking system can be installed in order that the panel continually

adjusts so that the panel is always aim directly at the sun. As the result, Photovoltaic panel are

able to collect the maximum amount of sunlight and produce the most power possible.

1.3 Objective

The objective of this project is to develop tracking mechanism for photovoltaic panel to

maximize the generation of electrical energy. The objective of the project is to develop the

system that can constantly tracking the sun and storing the generated energy using CMOS logic

process.

1.4 Problem Definition

To explore integrated solar energy harvesting as a power source for low power systems, an array

of energy scavenging photodiodes based on a passive-pixel architecture for CMOS imagers has

been fabricated together with storage capacitors implemented using on-chip interconnect in a

0.35- m bulk process. Integrated vertical plate capacitors enable dense energy storage without

limiting optical efficiency. Light energy is converted to electrical energy through a photodiode

and mechanical vibrations are converted to electrical energy by an electromechanical transducer

.an analog-to-digital converter (ADC) that can quantize the analog signal from the sensors, a

CPLD/FPGA core that can analyze and encode the quantized data and a transceiver (RF) so that

the node can transmit and receive information. The systems energy gathering ability will depend

on environmental conditions, which can change over time. The scavenged energy needs to be

regulated before being used by these functional blocks Delivering power to wireless sensor

network nodes is a significant System design challenge.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 6

Solar energy harvesting has been proposed to extend the lifetime of these networks beyond the

limitations which have been previously imposed by batteries. Prior works have successfully

demonstrated powering wireless systems through discrete photovoltaic cells together with

separate energy storage devices using board level designs.

1.5 Problem Statement

Now, We can formally state our problem to explore integrated solar energy harvesting as a

power source for low power systems, to design and implement the solar energy harvesting

system on FPGA to take sunlight as input for LEDs and convert those signals to digital and to

target the FPGA to analyze the intensity of the light and rotate the panel accordingly and store

energy into battery. The system consists of sensors that can observe the environment, an analog-

to-digital converter (ADC) that can quantize the analog signal from the sensors, Light energy is

converted to electrical energy through a photodiode and mechanical vibrations are converted to

electrical energy by an electromechanical transducer. A multiplexer (mux) is used to switch

between energy sources. The systems energy gathering ability will depend on environmental

conditions, which can change over time. Hence, the scavenged energy needs to be regulated

before being used by these functional blocks.

1.6 Existing System

Solar energy is the most readily available source of energy. It is free. It is also the most important

of the non-conventional sources of energy because it is non-polluting. We are focusing on the

Existing which uses embedded / microcontroller hardware technologies to control the system to

capture the maximum energy from sun light. In the existing system, Solar photo voltaic (SPV)

can be used to generate electricity from the sun. Silicon solar cells play an important role in

generation of electricity. While the output of solar cells depends on the intensity of sunlight and

the angle of incidence, and The solar panels must remain in front of sun. But due to rotation of

earth those panels cant maintain their position always in front of sun. This problem results in

decrease of their efficiency in storing the power. Delivering power to wireless sensor network

nodes is a significant System design challenge. Solar energy harvesting has been proposed to

extend the lifetime of these networks beyond the limitations which have been

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 7

previously imposed by batteries. Prior works have successfully demonstrated powering wireless

systems through discrete photovoltaic cells together with separate energy storage devices using

board level designs. The system consists of sensors that can observe the environment, an analog-

to-digital converter (ADC) that can quantize the analog signal from the sensors, a digital signal

processing (DSP) core that can analyze and encode the quantized data and a transceiver (RF) so

that the node can transmit and receive information.

The layout and design of an integrated energy scavenging photodiode must balance

several competing factors. The charge generated in the depletion region of the photodiode is

meant to be stored in on-chip capacitors; therefore the physical layout of the diodes should

facilitate both the solar energy harvesting and capacitive energy storage. The light that reaches

the photodiodes depletion region must first pass through the passivation layers and avoid the

metal storage capacitance, which is constructed on top of the diode to minimize area. A figure of

merit (FOM) is needed in order to quantitatively assess the performance of the photodiodes. The

FOM used here is also known as the fill factor, which is defined as the maximum output power

obtainable divided by the product of the open circuit voltage and the short circuit current , for a

given light intensity schematic for a photodiode under illumination delivering power to a load

resistance on the left, along with an curve shown on the right. The maximum output power is the

product of and which are in general functions of the incident light intensity. Graphically, the

figure of merit can be seen as the ratio of the two rectangles and a FOM equal to one would be

ideal. To explore the photodiode design tradeoffs experimentally, three different geometries were

fabricated and tested. the top view layout for the three photodiodes along with a layer key. The

first design, photodiode D1, and is similar to a passive pixel structure used for a CMOS image

the p-substrate and n-well form the diode. The second photodiode design D2 This structure has

the addition of inter digitized p-diffusion and n-diffusion fingers inside the n-well.

These fingers help to form the additional p-diffusion to n-well diodes, which can be

wired in parallel with the well-substrate diode. The final design D3. The D3 layout is similar to

the D2 layout except the n-diffusion fingers are replaced with p-diffusion fingers allowing for

more depletion region area and energy harvesting ability. The integration of the photovoltaic

cells along with analog and digital signal processing circuits is of interest in this work. The

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 8

scaling of a photovoltaic cell from large, standalone arrays to the integrated circuit level will

impact the cells output. Power, efficiency, optimal load resistance, and optical properties of the

photodiode. Energy harvesting systems with high power requirements may require a significant

area allocation for integrated photodiodes. Integrated photodiodes can also double as power

supply bypass capacitors; the additional cost associated with the photodiodes footprint could

potentially limit its usefulness to larger feature size technologies. True integration of photodiodes

and active circuitry on the same die may require covering the active circuitry with a metal cap to

block the incident light from potentially degrading signal integrity.

A substrate trench, forming a barrier, can also be employed to help limit the lateral

photocurrent traveling from the photodiodes to the active circuitry. The construction of the

storage capacitance and routing for the photodiodes must not degrade the optical efficiency (OE),

which is defined as the fraction of incident light onto the chips surface which reaches the

photodiode. In general, the optical efficiency is influenced by three loss factors: reflection loss,

absorption loss, and critical angle loss. Once photons reach the photodiode, the quantum

efficiency (QE) determines how many photons will generate electron-hole pairs.

Problems with existing methods:

Microcontroller based systems can be existing but they dont have Automatic Sun Tracking

System by getting the maximum power in the day time.

1.7 Proposed System

Thus to get a constant output, we are implementing an automated system which should be

capable to constantly rotate the solar panel. By using the VLSI / FPGAs technology to

overcome the above problem and make the system intelligently according to our requirements

with a less complexity. The unique feature of this proposed system is that instead of taking the

earth as its reference, it takes the sun as a guiding source with the use of LDRs. By using LDRs

as its reference, The use ADC to convert the analog signal into digital .it takes the sun as a

guiding source. Depends on the constantly monitor the sunlight and rotate the panel towards the

direction where the intensity of sunlight is maximum. A motor is used to rotate the panel. The

hardware complexity is simple and low power is needed for it, and reduces the cost as well. The

advantage of proposed system can be applicable in all the solar energy systems.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 9

The relative sensitivity of a photoconductive cell is dependent on the wavelength (color)

of the incident light. Each photoconductor material type has its own unique spectral response

curve or plot of the relative response of the photocell versus wavelength of light. The sensitivity

of a photo detector is the relationship between the light falling on the device and the resulting

output signal. Two cadmium sulphide (cds) photoconductive cells with spectral responses similar

to that of the human eye. The cell resistance falls with increasing light intensity. Applications

include smoke detection, automatic lighting control, batch counting and burglar alarm systems.

Each photoconductor material type has its own unique spectral response curve or plot of

the relative response of the photocell versus wavelength of light. Light energy is converted to

electrical energy through a photodiode and mechanical vibrations are converted to electrical

energy by an electromechanical transducer. The Analog-to-Digital Converter (A/D Converter or

ADC) has both analog and digital functions; it is a mixed-signal device. Many of us consider the

ADC to be a mysterious device. It can, however, be considered very simply to be the instrument

that it is: a device that provides an output that digitally represents the input voltage or current

level. Most ADCs convert an input voltage to a digital word, but the true definition of an ADC

does include the possibility of an input current. An ADC has an analog reference voltage or

current against which the analog input is compared. This process continues through the entire

input range and the error plot is a saw tooth. The maximum error we have here is 1 LSB. This 0

to 1 LSB range is known as the quantization uncertainty because there are a range of analog

input values that could have caused any given code and we are uncertain as to exactly what the

input voltage was that caused a given code.

1.8 Project Plan

This project work is to design and implement the solar energy harvesting system on FPGA to

take sunlight as input for LEDs and convert those signals to digital and to target the FPGA to

analyze the intensity of the light and rotate the panel accordingly and store energy into battery.

The system consists of sensors that can observe the environment, an analog-to-digital converter

(ADC) that can quantize the analog signal from the sensors, Light energy is converted to

electrical energy through a photodiode and mechanical vibrations are converted to electrical

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 10

energy by an electromechanical transducer. A multiplexer (mux) is used to switch between

energy sources.

Feasibility Study

A detailed feasibility study was conducted to know the technical and financial feasibility

of the project and it was found that the project is feasible to design, develop, use, and maintain in

all respects.

Requirement Analysis and Project Planning

Before starting the design of the project, in detail the requirements of the project is analyzed

which includes system requirement specification, software and hardware requirements and after

project planning is done with the help of requirement analysis.

Coding

The coding is done according to the design strategy i.e., code is done according to the

module wise. It is done by using VHDL language which makes use of Xilinx 13.2.i.

Testing

The program is tested by giving encrypted output to decryption module as an input and it

should produce back original data.

1.9 Organization of the Report

Chapter 1: It contains Introduction and Motivation of the project.

Chapter 2: It describes the block diagram and flowchart of solar energy harvesting.

Chapter 3: It contains literature survey of the project

Chapter 4:It includes information about the language and tool used

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 11

Chapter 5: It contains the synthesis results like top module input output signals, RTL

5

schematic, technology schematic and simulation result given by ISIM..

Chapter 6: It includes the information about advantages and dis-advantages and. conclusion part

of the project

Report also contains the bibliography and appendix-A

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 12

CHAPTER 2

BLOCKDIAGRAM & FLOWCHART

2.1 Block Diagram of Project

Fig: 2.1 Block Diagram of integrated solar energy harvesting and storage

The cell resistance falls with increasing light intensity. Applications include smoke detection,

automatic lighting control, The sensitivity of a photo detector is the relationship between the

light falling on the device and the resulting output signal. The Analog-to-Digital Converter (A/D

Converter or ADC) has both analog and digital functions, it is a mixed-signal device as shown in

Fig 2.1 . Many of us consider the ADC to be a mysterious device. The digital output word tells

us what fraction of the reference voltage or current is the input voltage or current. So, basically,

the ADC is a divider. The Input/output transfer function is given by the formula indicated here.

LDR

DRIVER

CIRCUIT

FPGA

ADC

SOLAR

CELLS

DC

MOTOR

BATTER

Y

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 13

2.2 Flowchart of Project

Fig: 2.2 Flowchart Diagram of integrated solar energy harvesting and storage

The flowchart of the integrated solar energy harvesting and storage is depicted in fig 2.2 initially

the light is sensed by the LDR and converted to electrical signal. This signal is converted to

digital form by means of ADC 0804.the digital code is used by the FPGA to decide the necessary

actions to be taken .Depending upon the comparison of LDR outputs FPGA decides the direction

of robot to be either of forward motion, backward or remain in stable position. The energy

obtained by solar cells is stored in battery.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 14

CHAPTER 3

LITERATURE SURVEY

3.1 Fundamentals of Photovoltaic System

Photovoltaic panel are made of the natural element which becomes charged electrically when

subjected to sunlight. Photovoltaic is the direct conversion of light into electricity at the atomic

level. The panel works on the principle of the photovoltaic (PV) effect. For solar cells, a thin

semiconductor wafer is specially treated to form an electric field, positive on one side and

negative on the other.

3.1.1 Photovoltaic cell

When light energy strikes the PV cell, electrons are knocked loose from the atoms in the

semiconductor material and start travel from the PV cell, through electronic circuit to the load.

Then, they return to the PV cell where the silicon recaptures the electrons and the process is

repeated. The photovoltaic itself is a p-n junction, which through the process of electron

dropping and this produces a current in proportion to the solar radiation. If electrical conductors

are attached to the positive and negative sides, forming an electrical circuit, the electrons can be

captured in the form of an electric current and produce electricity. This electricity can then be

used to power a load, such as light or a tool.

Fig 3.1 The emission of electron from metal plate

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 15

3.1.2 The Photovoltaic Effect

The photovoltaic effect is the basic physical process through which a PV cell converts sunlight into

electricity .Sunlight is composed of packets of solar energy. These sunlight radiations contain

different amounts of energy that correspond to the different wavelengths of the solar spectrum. When

photons strike a PV cell, they may be reflected or absorbed, or they may pass right through. The

absorbed photons generate electricity. The photovoltaic cells generally consist of two thin regions,

one above the other, N-type and P-type. This two region structure, called a p-n junction. The

collection of light-generated carriers by the p-n junction causes a movement of electrons to the n-type

side and holes to the p-type side of the junction. When open circuit, carriers are prevented from

leaving the solar cell, then the collection of light-generated carriers causes an increase in the number

of electrons on the n-type side of the p-n junction and a similar increase in holes in the p-type

material. This separation of charge creates an electric field at the junction which is in opposition to

that already existing at the junction. Under short circuit conditions, the minority carrier concentration

on either side of the junction is increased and the drift current, which depends on the number of

minority carriers, is increased. In equilibrium (in the dark) both the diffusion and drift current are

small

Fig 3.2 photovoltaic effect in different conditions

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 16

3.1.3 Efficiency

On a bright, sunny day, the sun's rays give off approximately 1,000 watts of energy per square

meter of the planet's surface. If we could collect all of that energy, we could easily power our

homes and offices for free. However, in practically the maximum allowed by the law of physics

is between 30% and 40%. The efficiency of photovoltaic cells can be very tricky to figure out

and many of the companies that produce them take different routes when manufacturing their

products. Different companies will use different materials and as the technology improves, the

efficiency of the solar paneling options will also improve. There are basically 3 different types of

solar panels on the market today, each of which has a different efficiency rating. The following

are the 3 types and their efficiency ratings

Monocrystalline Silicon manufactured using a single crystal of silicon which has been

cut into a prescribed shape, this type of solar panel has a 13% conversion rate, meaning

that it converts 13% of the captured sunlight into electricity .

Polycrystalline Silicon these are less expensive and have a lower conversion rate

because of the multiple crystal manufacturing process. This increases internal resistance

between the silicon crystals. The conversion rate of these panels is around 12% to 12%

.

Thin Film Amorphous Silicon probably the cheapest solar panel to produce and the

least efficient at a rate of only 6% to 8%. More suited for use in cooler and tropical

climates, this type of solar panel is not very efficient in arid, hot climates.

Other then the material that use to crate solar cell its self, there are few factor that will affect

the energy efficiency.

The output will be less at:-

In cloudy condition The module is in the shade Pointed away from the sun In space, the output is

more higher due to the solar radiation is much stronger compare at the earth. Approximately, the

power density is around 1365 watt per square meter.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 17

3.2 Types of photovoltaic System

Basically, there are three main systems that commonly use in photovoltaic system. Its come

with several configurations for difference use.

1. Directly Connected System

a. The system work without battery storage.

b. The load connected to the system operates in synchronization with sunlight.

c. Usually an over current protection device is added for safety purpose.

d. Typical application are:-

i. Ventilation fan.

ii. Water pumping.

iii. Calculator.

2. Stand Alone System

a. The system may have battery storage or emergency backup supply to provide

power when the sun is not available.

b. Commonly use in a remote area where there is no power-lines.

c. This type of system need to have charge regulator to prevent battery overcharging or

over discharging.

d. Typical application are:-

i. Remote home.

ii. Outdoor lighting

iii. Solar car

3. Utility Interactive System

a. This system consist neither battery storage nor an emergency backup system.

b. This system connected with the utility grid.

c. When the sunlight not available it has battery storage

d. When the sunlight and battery storage out, the power will be supply by utility power

system.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 18

3.3 Solar Position Algorithm for Solar Radiation Application

The best uncertainty achieved is greater than 0.01/ in calculating the solar zenith and azimuth

angles. For some, the algorithm is valid for a limited number of years varying from 15 years to a

hundred years. This is a step by step procedure for implementing an algorithm to calculate the

solar zenith and azimuth angles in the period from the year -2000 to 6000, with uncertainties of

0.0003/. The algorithm is described with a focus on the sun instead of the planets and stars in

general. It also introduces some changes to accommodate for solar radiation applications. The

changes include changing the direction of measuring azimuth angles to be measured from north

and eastward instead of being measured from south and eastward, and the direction of measuring

the observers geographical longitude to be measured as positive eastward from Greenwich

meridian instead of negative. This also includes the calculation of incidence angle for a surface

that is tilted to any horizontal and vertical angle, with the continuous technological

advancements in solar radiation applications, there will always be a demand for smaller

uncertainty in calculating the solar position. Many methods to calculate the solar position have

been published in the solar radiation literature, nevertheless, their uncertainties have been greater

than 0.01/ in solar zenith and azimuth angle calculations and some are only valid for a specific

number of years.

The importance of reducing the uncertainty of calculating the solar position to lower than

0.01/, is the calibration of pyranometers that measure the global solar irradiance. During the

calibration, the responsivity of the pyranometer is calculated at zenith angles from 0/ to 90/ by

dividing its output voltage by the reference global solar irradiance (G), which is a function of the

cosine of the zenith angle. From this arises the need to use a solar position algorithm with lower

uncertainty for users that are interested in measuring the global solar irradiance with smaller

uncertainties in the full zenith angle range from 0/ to 90/.

We describe a procedure for a Solar Position Algorithm (SPA) to calculate the solar

zenith and azimuth angle with uncertainties equal to 0.0003/ in the period from the year -2000

to 6000. The azimuth angle is measured westward from south, but for solar radiation

applications, it is measured eastward from north. Also, the observers geographical longitude is

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 19

considered positive west, or negative east from Greenwich, while for solar radiation applications,

it is considered negative west, or positive east from Greenwich.

3.3.1 Solar Azimuth angle

The Solar Azimuth angle is the azimuth angle of the sun. It defines in which direction the sun is,

whereas the solar zenith angle or solar elevation defines how high the sun is. (The elevation is

the complement of the zenith.) There are several conventions for the solar azimuth; however it is

traditionally defined as the angle between a line due south and the shadow cast by a vertical rod

on Earth. This convention states the angle is positive if the line is east of south and negative if it

is west of south. For example due east would be 90 and due west would be -90. Another

convention is the reverse; it also has the origin at due south, but measures angles clockwise, so

that due east is now negative and west now positive.

However, despite tradition, the most commonly accepted convention for analyzing solar

radiation, e.g. for solar energy applications, is clockwise from due north, so east is 90, south is

180 and west is 270. This is the definition used in their solar position calculators

Note: Both of these formulas assume the north-clockwise convention. The solar azimuth

angle can be calculated to a good approximation with the following formula, however angles

should be interpreted with care due to the inverse sine, i.e. x = sin

1

(y) has two solutions (unless

y is -1 or +1), only one of which will be correct.

(1)

The following formulas can also be used to approximate the solar azimuth angle, but these

formulas use cosine, so the azimuth angle will always be positive, and should be interpreted as

the angle less than 180 degrees when the hour angle, h, is negative (morning) and the angle

greater than 180 degrees when the hour angle, h, is positive (afternoon). (These two formulas

are equivalent if you assume the "solar elevation angle" approximation formula).

(2)

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 20

(3)

The formulas use the following terminology:

is the solar azimuth angle

is the solar elevation angle

is the hour angle, in the local solar time

is the current sun declination

is the local latitude

3.3.2 Solar zenith angle

The solar zenith angle,

s

is estimated using results from spherical trigonometry

where

s

is the solar zenith angle

h is the hour angle, in the local solar time.

is the current declination of the Sun

is the local latitude.

3.3.3 Solar elevation angle

The solar elevation angle is the altitude of the sun, the angle between the horizon and the centre

of the sun's disc. The approximate value can be calculated with the following formula:

where

s

is the solar elevation angle,

s

= 90

s

h is the hour angle, in the local solar time.

is the current declination of the Sun

is the local latitude.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 21

3.4 Dc Motors

A DC motor is an electric motor that runs on direct current (DC) electricity. DC motors can

operate directly from rechargeable batteries, providing the motive power for the first electric

vehicles.

There are 2 types if DC motors.

1. Brushed DC electric motor

2. Brushless DC electric motor

Fig 3.3 DC motor

3.4.1. Brushed Dc Electric Motor

The brushed DC electric motor generates torque directly from DC power supplied to the motor

by using internal commutation, stationary magnets (permanent or electromagnets), and rotating

electrical magnets. Advantages of a brushed DC motor include low initial cost, high reliability,

and simple control of motor speed. Disadvantages are high maintenance and low life-span for

high intensity uses. Maintenance involves regularly replacing the brushes and springs which

carry the electric current, as well as cleaning or replacing the commutator.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 22

3.4.2 .Brushless Dc Electric Motor

Brushless DC motors use a rotating permanent magnet or soft magnetic core in the rotor, and

stationary electrical magnets on the motor housing. A motor controller converts DC to AC. This

design is simpler than that of brushed motors because it eliminates the complication of

transferring power from outside the motor to the spinning rotor. Advantages of brushless motors

include long life span, little or no maintenance, and high efficiency. Disadvantages include high

initial cost, and more complicated motor speed controllers. Some such brushless motors are

sometimes referred to as "synchronous motors" although they have no external power supply to

be synchronized with, as would be the case with normal AC synchronous motors. Dept. of

Instrumentation & Control

3.5 Connection Types

3.5.1. Series Connection

A series DC motor connects the armature and field windings in series with a common D.C.

power source. This motor has poor speed regulation since its speed varies approximately

inversely to load. However, a series DC motor has very high starting torque and is commonly

used for starting high inertia loads, such as trains, elevators or hoists. With no mechanical load

on the series motor, the current is low, the magnetic field produced by the field winding is weak,

and so the armature must turn faster to produce sufficient counter-EMF to balance the supply

voltage (and internal voltage drops). For some types of motor, the speed may be higher than can

be safely sustained by the motor. In a no-load condition, the motor may increase its speed until

the motor mechanically destroys itself. This is called a runaway condition. The speed/torque

characteristic is also useful in applications such as dragline excavators, where the digging tool

moves rapidly when unloaded but slowly when carrying a heavy load.

3.5.2. Shunt Connection

A shunt DC motor connects the armature and field windings in parallel or shunt with a common

D.C. power source. This type of motor has good speed regulation even as the load varies, but

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 23

does not have as high of starting torque as a series DC motor. It is typically used for industrial,

adjustable speed applications, such as machine tools, winding/unwinding machines.

3.5.3. Compound Connection

A compound DC motor connects the armature and fields windings in a shunt and a series

combination to give it characteristics of both a shunt and a series DC motor. This motor is used

when both a high starting torque and good speed regulation is needed. The motor can be

connected in two arrangements: cumulatively or differentially. Cumulative compound motors

connect the series field to aid the shunt field, which provides higher starting torque but less speed

regulation. Differential compound DC motors have good speed regulation and are typically

operated at constant speed. They are commonly used in elevators, air compressors, conveyors

and punch presses

3.6 Dc Motor Forward Reverse Control

Fig 3.4 DC motor forward-reverse control

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 24

3.6.1 Circuit working Description

This circuit is designed to control the motor in the forward and reverse direction. It consists of

two relays named as relay1, relay2. The relay ON and OFF is controlled by the pair of switching

transistors. A Relay is nothing but electromagnetic switching device which consists of three pins.

They are Common, Normally close (NC) and normally open (NO). The common pin of two relay

is connected to positive and negative terminal of motor through snubber circuit respectively. The

relays are connected in the collector terminal of the transistors T2 and T4.When high pulse signal

is given to either base of the T1 or T3 transistors, the transistor is conducting and shorts the

collector and emitter terminal and zero signals is given to base of the T2 or T4 transistor. So the

relay is turned OFF state. When low pulse is given to either base of transistor T1 or T3 transistor,

the transistor is turned OFF. Now 12v is given to base of T2 or T4 transistor so the transistor is

conducting and relay is turn ON. The NO and NC pins of two relays are interconnected so only

one relay can be operated at a time. The series combination of resistor and capacitor is called as

snubber circuit. When the relay is turn ON and turn OFF continuously, the back emf may fault

the relays. So the back emf is grounded through the snubber circuit.

When relay 1 is in the ON state and relay 2 is in the OFF state, the motor is running in the

forward direction.

When relay 2 is in the ON state and relay 1 is in the OFF state, the motor is running

in the reverse direction.

3.7 Function of LDR

Two cadmium sulphide (cds) photoconductive cells with spectral responses similar to that of the

human eye. The cell resistance falls with increasing light intensity. Applications include smoke

detection, automatic lighting control, and batch counting and burglar alarm systems in shown in

Fig 4.2. Like the human eye, the relative sensitivity of a photoconductive cell is dependent on the

wavelength (color) of the incident light. Each photoconductor material type has its own unique

spectral response of the relative response of the photocell versus wavelength of light. The LDR

circuits as in Fig: 4.3

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 25

Fig: 3.5 Typical Application Circuits

IR_GND

L

D

R

R13

1

0

k

IR_GND

L

D

R

R12

3

3

0

k

t

o

1

m

-

(

3

3

0

k

)

R8

1

0

k

VCC-IR

IR_GND

+

-

U1D

LM339 11

10

13

3

1

2

SENSOR1

SENSOR4

L

D

R

R9

1

0

k

R2

1

M

R7

1

M

R14

1

0

k

_

N

O

T

_

P

L

A

C

E

D

R10

1

0

k

1

3

2

R15

1

0

k

1

3

2

R20

1

0

k

1

3

2

R17

1

M

SENSOR2

VCC-IR

R4

1

0

k

+

-

U1C

LM339 9

8

14

3

1

2

R5

1

0

k

1

3

2

+

-

U1A

LM339 7

6

1

3

1

2

VCC-IR

+

-

U1B

LM339 5

4

2

3

1

2

R3

1

0

k

SENSOR3

L

D

R

R18

1

0

k

R19

1

0

k

IR_GND

Fig: 3.6 LDR Circuits

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 26

3.7.1 Spectral Response

Like the human eye, the relative sensitivity of a photoconductive cell is dependent on the

Wavelength (color) of the incident light. Each photoconductor material type has its own unique

spectral response curve or plot of the relative response of the photocell versus wavelength of

light as shown in Fig: 4.4

3.7.2 Sensitivity

The sensitivity of a photo detector is the relationship between the light falling on the device and

the resulting output signal. In the case of a photocell, one is dealing with the relationship

between the incident light and the corresponding resistance of the cell. of the photocell versus

wavelength of light. Light energy is converted to electrical energy through a photodiode and

mechanical vibrations are converted to electrical energy by an electromechanical transducer

Fig: 3.7 Resistance As Function Of Illumination

3.8 Stepper motor

Dc motor is controlled by the driver circuit and the positive & negative terminals of the dc motor

are connected to snubber circuit..When dc motor positive terminal gets 12v it will make the solar

cell array to move in clockwise direction. When dc motor negative terminal gets 12v it will make

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 27

the solar cell array to move in anti clockwise direction. The systems energy gathering ability

will wireless systems through discrete photovoltaic cells together depend on environmental

conditions, which can change over time with separate energy storage devices using board level

designs

Fig 3.8 stepper motor

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 28

3.9 Analog to Digital Converter (ADC)

The Analog-to-Digital Converter (A/D Converter or ADC) has both analog and digital functions;

it is a mixed-signal device. Many of us consider the ADC to be a mysterious device. It can,

however, be considered very simply to be the instrument that it is: a device that provides an

output that digitally represents the input voltage or current level. Notice I said voltage or current.

Most ADCs convert an input voltage to a digital word, but the true definition of an ADC does

include the possibility of an input current. An ADC has an analog reference voltage or current

against which the analog input is compared. So, basically, the ADC is a divider. The Input/output

transfer function is given by the formula indicated here. If you have seen this formula before,

you probably did not see the G term (gain factor).Here is an example of a 3-bit A/D converter.

Because it has 3 bits, there are 2

3

= 8 possible output codes. The difference between each output

code is VREF / 23. Assuming that the output response has no errors, every time you increase the

voltage at the input by 1 Volt, the output code will increase by one bit.

This means, in this example, that the least significant bit (LSB) represents 1 Volt, which

is the smallest increment that this converter can resolve. For this reason, we can say that the

resolution of this converter is 1.0V because we can resolve voltages as small as a volt.

Resolution may also be stated in bits. if you reduce the reference voltage to 0.8V, the LSB would

then represent 100mV, allowing you to measure a smaller range of voltages (0 to 0.8V) with

greater accuracy. The Resolution of an A/D converter is the number of output bits it has (3 bits,

in this example).Resolution may also be defined as the size of the LSB (Least Significant Bit) or

one count (1 Volt, in this example). For a 3-bit ADC, there are 8 possible output codes. In this

example, if the input voltage is 5.5V and the reference is 8V, then the output will be 101. More

bits give better resolution and The 3-bit A/D converter as in Fig: 4.5.Because it has 3 bits, there

are 2

3

= 8 possible output codes. The difference between each output code is VREF / 23.

Assuming that the output response has no errors, every time you increase the voltage at the input

by 1 Volt, the output code will increase by one bit. This means, in this example, that the least

significant bit (LSB) represents 1 Volt, which is the smallest increment that this converter can

resolve.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 29

Fig: 3.9 Block Diagram Of ADC

For this reason, we can say that the resolution of this converter is 1.0V because we can resolve

voltages as small as a volt. Resolution may also be stated in bits. Note that if you reduce the

reference voltage to 0.8V, the LSB would then represent 100mV, allowing you to measure a

smaller range of voltages (0 to 0.8V) with greater accuracy.

This is a common way for our customers to get better precision from a converter without

buying a more expensive, higher resolution converter. The Resolution of an A/D converter is the

number of output bits it has (3 bits, in this example). Resolution may also be defined as the size

of the LSB (Least Significant Bit) or one count (1 Volt, in this example).

Least Significant Bit (LSB) and Most Significant Bit (MSB)

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 30

The Least and Most Significant Bits (LSB and MSB) are just what their name implies:

those bits that have the least weight (LSB) and most weight (MSB) in a digital word. For an n-bit

word, the MSB has a weight of 2(n-1) = 2n / 2 where n is the total number of bits in the word.

The LSB has a weight of 1.

Since one LSB is equal to VREF / 2n, it stands to reason that better accuracy (lower

error) can be realized if we did either (or both) of two things: (1) use a higher resolution

converter and/or (2) use a smaller reference voltage. The problem with higher resolution (more

bits) is the cost. Also, the smaller LSB means it is difficult to find a really small signal as it

becomes lost in the noise, reducing SNR performance of the converter. The problem with

reducing the reference voltage is a loss of input dynamic range. Again, we also can lose a small

signal in the noise, causing a loss of SNR performance.

3.9.1 Quantization Error

Continuing with the simple example of a 3-bit ADC, an ADC input of zero produces an output

code of zero (000) as in Fig: 4.6 . As the input voltage increases towards VREF/8, the error also

increases because the input is no longer zero, but the output code remains at zero because a range

of input voltages is represented by a single output code. When the input reaches VREF/8, the

output code changes from 000 to 001, where the output exactly represents the input voltage and

the error reduces to zero. As the input voltage increases past VREF/8, the error again increases

until the input voltage reaches VREF/4, where the error again drops to zero.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 31

Fig: 3.10 The Magnitude Of The Error Ranges From Zero To 1 LSB

This process continues through the entire input range and the error plot is a saw tooth, as

shown here. The maximum error we have here is 1 LSB. This 0 to 1 LSB range is known as the

quantization uncertainty because there are a range of analog input values that could have

caused any given code and we are uncertain as to exactly what the input voltage was that caused

a given code. The maximum quantization uncertainty is also known as the quantization error.

This error results from the finite resolution of the ADC. That is, the ADC can only resolve the

input into 2n discrete values. Each output code represents a range of input values.

This range of values is a quantum, to which we assign the symbol q. The converter

resolution, then, is 2n. So, for an 8 Volt reference (with a unity gain factor), a 3-bit converter

resolves the input into VREF/8 = 8V/8 = 1 Volt steps as shown in Fig: 4.7. Quantization error,

then, is a round off error. But an error of 0 to 1 LSB is not as desirable as is an error of 1/2

LSB, so we introduce an offset into the A/D converter to force an error range of 1/2 LSB.

Digital output. The systems energy gathering ability will depend on environmental conditions,

which can change over time. The system consists of sensors that can observe the environment, an

analog-to-digital converter (ADC) that can quantize the analog signal from the sensors, a

CPLD/FPGA core that can analyze and encode the quantized data and a transceiver (RF) so that

the node can transmit and receive information. The scavenged energy needs to be regulated

before being used by these functional blocks as shown in fig: 4.8

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 32

Fig: 3.11 Pin diagram of ADC0803

Fig: 3.12 Functional Block Diagram Of ADC0803

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 33

Because the Analog-to-Digital Converter (A/D Converter or ADC) has both analog and digital

functions, it is a mixed-signal device. Many of us consider the ADC to be a mysterious device. It

can, however, be considered very simply to be the instrument that it is: a device that provides an

output that digitally represents the input voltage or current level. Notice I said voltage or current.

Most ADCs convert an input voltage to a digital word, but the true definition of an ADC

does include the possibility of an input current. An ADC has an analog reference voltage or

current against which the analog input is compared. The digital output word tells us what fraction

of the reference voltage or current is the input voltage or current. So, basically, the ADC is a

divider. The Input/output transfer function is given by the formula indicated here. If you have

seen this formula before, you probably did not see the G term (gain factor). This is because we

generally consider this to be unity. However, National Semiconductor has introduced ADCs with

other gain factors, so it is important to understand that this factor is present.

Here is an example of a 3-bit A/D converter. Because it has 3 bits, there are 2

3

= 8

possible output codes. The difference between each output code is VREF / 23.Assuming that the

output response has no errors, every time you increase the voltage at the input by 1 Volt, the

output code will increase by one bit. This means, in this example, that the least significant bit

(LSB) represents 1 Volt, which is the smallest increment that this converter can resolve. For this

reason, we can say that the resolution of this converter is 1.0V because we can resolve voltages

as small as a volt. Resolution may also be stated in bits.

If you reduce the reference voltage to 0.8V, the LSB would then represent 100mV,

allowing you to measure a smaller range of voltages (0 to 0.8V) with greater accuracy. This is a

common way for our customers to get better precision from a converter without buying a more

expensive, higher resolution converter. The Resolution of an A/D converter is the number of

output bits it has (3 bits, in this example). Efficient energy without requiring battery materials to

be integrated t ADCs and DSPs can achieve average power levels in the on-chip. This paper

describes an array of photodiodes, modeled sub-milliwatt range. However, low power ADCs

usually suffer from diminished power supply rejection. Minimizing Manuscript received typical

characteristics of a photodiode under illumination along with a schematic.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 34

The optimum configuration for harvesting energy is found with the load resistance that

maximizes the product of the current through the diode I and the voltage across the diode.

Capacitance can be exploited for storing the scavenged energy. In total, 11 different diodes were

fabricated in three different ports experimental integrated photodiode test sizes. Photodiodes for

energy scavenging differ from imaging results in integrated energy pixels in the way in which

they are optimized. Imagers are de-storage.

Finally provides conclusions from this signed to minimize noise, dark current, and lateral

photocurrent research (which can create pixel-to-pixel crosstalk), while photodiodes output

power. Imaging sensors are commonly designed to drive The layout and design of an integrated

energy scavenging a high impedance capacitive load presented by a sense amp, photodiode must

balance several competing factors .The while energy scavenging photodiodes are designed to

drive re-charge generated in the depletion region of the photodiode is resistive loads.

The energy storage capacitors which are bent to be stored in on-chip capacitors; therefore

the physical for storing the harvested energy from the photodiodes layout of the diodes should

facilitate both the solar energy would limit the refresh rate of an image. Harvesting and

capacitive energy storage. The light that reaches the larger photovoltaic cells were first

discovered in the mid photodiodes depletion region must first pass through the passive 1800s

and had efficiencies of less than one percent. Since then, layers and avoid the metal storage

capacitance, which is numerous advances in materials and technology have allowed constructed

on top of the diode to minimize area for substantial increases in efficiency and size. Figure of

merit (FOM) is needed in order to quantitatively available silicon photovoltaic cells boast

efficiencies near assess the performance of the photodiodes. The FOM used here 17%. which is

defined as the max-to reach efficiencies nearing 24% A commonly cited minimum output

power obtainable divided by the product of the theoretical model for the fundamental limits of

silicon solar open circuit voltage and the short circuit current ,cells that takes into account Auger

recombination and absorption-for a given light intensity.

The energy density of fully integrated storage capacitors is not competitive with system-

in-package solutions such as ultra capacitors or printable batteries, even with scaling to the end

of the ITRS roadmap.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 35

However, for applications with very low energy storage requirements or cost constraints

which limit system-in package integration, exploiting interconnect parasitic capacitance for

storage may be a viable solution.

The combination of integrated solar energy scavenging and storage can enable a new

generation of low cost, long lifetime, small volume systems for future wireless sensor networks

or RFID applications. White LED lighting systems powered by solar cells have presented for

many years, they are not widely used in today application because of their cost and low energy

conversion efficiency. The proposed system use the dc power generated by fixed solar cells

module to energize White LED light sources that are operated by directly connected White LED

with current limitation resistors, resulting in much more power consumption. This paper presents

the use of white LED as a general lighting application powered by tracking solar cells module

and using pulse to apply the electrical power to the White LED. These systems resulted in high

efficiency power.

3.10 Light-Dependent Resistor

As its name implies, the Light Dependent Resistor (LDR) is made from a piece of exposed

semiconductor material such as cadmium sulphide that changes its electrical resistance from

several thousand Ohms in the dark to only a few hundred Ohms when light falls upon it by

creating hole-electron pairs in the material. The net effect is an improvement in its conductivity

with a decrease in resistance for an increase in illumination.

When the light level is low the resistance of the LDR is high. This prevents current from

flowing. However, when light shines onto the LDR its resistance falls and current starts flowing.

An LDR has a zigzag cadmium sulphide track. It is a bilateral device, i.e., conducts in both the

direction .We make use of two LDRs as light sensors, to achieve solar cell panel to track the

sun.LDR controls the rotation of panel depending upon the LDRs resistance, the panel moves

clockwise or anticlockwise direction.LDR1 is used to move in clockwise direction and LDR2 is

used to move in anticlockwise direction.

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 36

Fig 3.13 Light dependent resistor

If LDR1 resistance < LDR2 resistance, then panel moves clockwise direction.

If LDR1 resistance > LDR2 resistance, then panel moves anti clockwise direction.

If LDR1 resistance =LDR2 resistance, then panel does not move.

3.10.1 ADC

The LDRs analog output signal is processed in ADC0809.ADC0809 converts analog output of

LDR to equivalent digital code. For example with a LDRs zero output signal ADC produces 000,

depending upon the number of bits.

3.10.2 Driver Circuit

The driver circuit is designed to control the motor rotation in turn controls the solar cell array.

We make use of two relays, namely relay1 and relay2.When relay1 is in the on state and relay2 is

in the off state, the motor is running in the forward direction. When relay2 is in the on state and

relay1 is in the off state the motor is running in reverse direction.

3.11 Solar Cell Array

The solar energy is absorbed by the solar cell arrays and converted it to electrical energy. The

solar cell array is made to track the sunlight throughout the day. SOLAR cells or photovoltaic

cells are in fact large area semiconductor diodes that convert sunlight into electrical current to

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 37

produce usable power .They have long been used in situations where electrical power from

power station is unavailable, such as in remote area power systems. The power output of a solar

array is given in watts. In order to calculate the energy needs of the application, a measurement

in watt-hours per day is often used. The output power of the solar cell depends on multiple

factors, such as sunlight intensity and direction of the cells. In order to reach the maximum

power, the solar tracker has been added to this system to avoid time limit of the fixed systems.

3.11.1 Active Solar Trackers

Active trackers measure the light intensity from the sun to determine where the solar modules

should be pointing. Light sensors are positioned on the tracker at various locations or in specially

shaped holders. If the sun is not facing the tracker directly there will be a difference in light

intensity on one light sensor compared to another and this difference can be used to determine in

which direction the tracker has to tilt in order to be facing the sun.

3.11.2 Types Of Solar Trackers

There are many different types of solar tracker which can be grouped into single axis and double

axis models.

3.11.2.1 Single Axis Solar Trackers

Single axis solar trackers can either have a horizontal or a vertical axle. The horizontal type is

used in tropical regions where the sun gets very high at noon, but the days are short. The vertical

type is used in high latitudes (such as in UK) where the sun does not get very high, but summer

days can be very long. These have a manually adjustable tilt angle of 0 - 45 and automatic

tracking of the sun from East to West. They use the PV modules themselves as light sensor to

avoid unnecessary tracking movement and for reliability. At night the trackers take up a

horizontal position.

3.11.2.2 Double Axis Solar Trackers

Double axis solar trackers have both a horizontal and a vertical axle and so can track the Sun's

apparent motion exactly anywhere in the world. This type of system is used to control astronomical

Design and implementation of solar robot controlling and storage of energy based on FPGA

Dept of ECE, REVAITM Page 38

telescopes, and so there is plenty of software available to automatically predict and track the motion

of the sun across the sky. Dual axis trackers track the sun both East to West and North to South for

added power output (approx 40% gain) and convenience