Professional Documents

Culture Documents

2 Way Slab Design

Uploaded by

Sambhav PoddarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 Way Slab Design

Uploaded by

Sambhav PoddarCopyright:

Available Formats

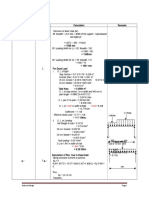

Slab design (Two way Continuous - <3kn/m2)

Data Input

Dimension of longer span (ly) = 4.5 m

Dimension of shorter span (lx) = 3.16 m

Nominal cover for steel 30 mm

Imposed load = 2.5 kN/m2 (IS 875_2)

Surface finish = 1 kN/m2

Fck = 20 N/mm2

Fy = 500 N/mm2

Unit density of concrete 25 kN/m3

Depth Calculation (Serviceablity)

ly/lx = 1.42 < 2, two way

lx/D = 30 (as per support conditions)

(use avg of S/S & cont. where applicable for cont & discont. edge)

Min. Required Overall depth D = 105.33 mm

Provide D = 120 mm (min. 100mm)

Design Moments & Detailing

Dead load of slab = 3 kN/m2

Ultimate Load (w) = 9.75 kN/m2

Maximum Shear in either direction = Vu = w (lx/2-d)

15.41 kN/m

Mulim = Rlim bd^2

Fe Rlim (N/mm2)

250 3.00

415 2.78

500 2.68

Value of Rlim to be used = 2.68 N/mm2

Min. value of shear strength = 0.28 N/mm2 (Table 19, IS 456)

multiplying factor (k) = 1.3 (Cl. 40.2.1.1, IS 456)

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.080 7.79 8 200

For

SHORT SPAN

ax Mx (kNm/m)

Reinforcement Provided

Positive moment at Mid span 0.060 5.84 8 200

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.000 0.00 8 200

Positive moment at Mid span 0.043 4.19 8 250

NOTES FOR TABLE

1) Bending moment coefficients taken from Table 26, (Annex D), IS 456

2) Moment values are calculated per unit width

3) ONLY INPUT VALUES IN THE TABLE

4) % steel (pt) calculated from Table 19, IS 456

pt = 100 As/bd

5) Minimum area of steel = 0.12% of bD

6) Minimum bar dia to be used = 8mm

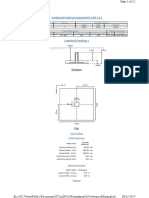

Loads for Supporting Beams

lx = 3.16 m

ly = 4.5 m

UDL on slab = 9.75 kN/m2

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

Beam 1-2

ly = 4.5

lx = 3.16 Beam 2-3

For

LONG SPAN

ay My (kNm/m)

Reinforcement Provided

A

(use avg of S/S & cont. where applicable for cont & discont. edge)

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 53.91 86 OK 0.364 0.179

SHORT SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

251.327 OK 46.69 86 OK 0.364 0.179

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 0.00 86 OK 0.364 0.179

201.062 OK 39.52 78 OK 0.364 0.198

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

max intensity of D DL = 15.41

Max. Moment = 12.82

3.16 1.28

(l) Max. Shear or Rxtn = 12.17

1.22

max intensity of D DL = 30.81

max Intensity of UDL = 26.13

1.58 1.34 1.58 Max. Moment = 59.16

(x) (y) (x) 5.92

Max. Shear or Rxtn = 41.85

LONG SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

4.18

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

SHORT SPAN

Shear Adequacy Reinforcement Requirement

OK 0.25 215 144

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

OK 0.25 195 144

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

kN/m (w)

kNm (wl

2

/12)

t-m

kN (wl/4)

t

kN/m (w1)

kN/m (w2)

kNm (w1x

2

/3 + w2y/2*(x+y/4))

t-m

kN (0.5*(w1x+w2y)

effects on beam will be due to

slab on both sides, so (x2)

LONG SPAN

Shear Adequacy Reinforcement Requirement

t

Slab design (Two way Continuous - <3kn/m2)

Data Input

Dimension of longer span (ly) = 4.5 m

Dimension of shorter span (lx) = 3.16 m

Nominal cover for steel 30 mm

Imposed load = 2.5 kN/m2 (IS 875_2)

Surface finish = 1 kN/m2

Fck = 20 N/mm2

Fy = 500 N/mm2

Unit density of concrete 25 kN/m3

Depth Calculation (Serviceablity)

ly/lx = 1.42 < 2, two way

lx/D = 30 (as per support conditions)

(use avg of S/S & cont. where applicable for cont & discont. edge)

Min. Required Overall depth D = 105.33 mm

Provide D = 120 mm (min. 100mm)

Design Moments & Detailing

Dead load of slab = 3 kN/m2

Ultimate Load (w) = 9.75 kN/m2

Maximum Shear in either direction = Vu = w (lx/2)

15.41 kN/m

Mulim = Rlim bd^2

Fe Rlim (N/mm2)

250 3.00

415 2.78

500 2.68

Value of Rlim to be used = 2.68 N/mm2

Min. value of shear strength = 0.28 N/mm2 (Table 19, IS 456)

multiplying factor (k) = 1.3 (Cl. 40.2.1.1, IS 456)

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.080 7.79 8 200

For

SHORT SPAN

ax Mx (kNm/m)

Reinforcement Provided

Positive moment at Mid span 0.060 5.84 8 200

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.000 0.00 8 200

Positive moment at Mid span 0.043 4.19 8 250

NOTES FOR TABLE

1) Bending moment coefficients taken from Table 26, (Annex D), IS 456

2) Moment values are calculated per unit width

3) ONLY INPUT VALUES IN THE TABLE

4) % steel (pt) calculated from Table 19, IS 456

pt = 100 As/bd

5) Minimum area of steel = 0.12% of bD

6) Minimum bar dia to be used = 8mm

Loads for Supporting Beams

lx = 3.16 m

ly = 4.5 m

UDL on slab = 9.75 kN/m2

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

Beam 1-2

ly = 4.5

lx = 3.16 Beam 2-3

For

LONG SPAN

ay My (kNm/m)

Reinforcement Provided

A

(use avg of S/S & cont. where applicable for cont & discont. edge)

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 53.91 86 OK 0.364 0.179

SHORT SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

251.327 OK 46.69 86 OK 0.364 0.179

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 0.00 86 OK 0.364 0.179

201.062 OK 39.52 78 OK 0.364 0.198

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

max intensity of D DL = 15.41

Max. Moment = 12.82

3.16 1.28

(l) Max. Shear or Rxtn = 12.17

1.22

max intensity of D DL = 30.81

max Intensity of UDL = 26.13

1.58 1.34 1.58 Max. Moment = 59.16

(x) (y) (x) 5.92

Max. Shear or Rxtn = 41.85

LONG SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

4.18

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

SHORT SPAN

Shear Adequacy Reinforcement Requirement

OK 0.25 215 144

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

OK 0.25 195 144

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

kN/m (w)

kNm (wl

2

/12)

t-m

kN (wl/4)

t

kN/m (w1)

kN/m (w2)

kNm (w1x

2

/3 + w2y/2*(x+y/4))

t-m

kN (0.5*(w1x+w2y)

effects on beam will be due to

slab on both sides, so (x2)

LONG SPAN

Shear Adequacy Reinforcement Requirement

t

Slab design (Two way Continuous - <3kn/m2)

Data Input

Dimension of longer span (ly) = 4.5 m

Dimension of shorter span (lx) = 3.16 m

Nominal cover for steel 30 mm

Imposed load = 2.5 kN/m2 (IS 875_2)

Surface finish = 1 kN/m2

Fck = 20 N/mm2

Fy = 500 N/mm2

Unit density of concrete 25 kN/m3

Depth Calculation (Serviceablity)

ly/lx = 1.42 < 2, two way

lx/D = 30 (as per support conditions)

(use avg of S/S & cont. where applicable for cont & discont. edge)

Min. Required Overall depth D = 105.33 mm

Provide D = 120 mm (min. 100mm)

Design Moments & Detailing

Dead load of slab = 3 kN/m2

Ultimate Load (w) = 9.75 kN/m2

Maximum Shear in either direction = Vu = w (lx/2)

15.41 kN/m

Mulim = Rlim bd^2

Fe Rlim (N/mm2)

250 3.00

415 2.78

500 2.68

Value of Rlim to be used = 2.68 N/mm2

Min. value of shear strength = 0.28 N/mm2 (Table 19, IS 456)

multiplying factor (k) = 1.3 (Cl. 40.2.1.1, IS 456)

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.080 7.79 8 200

For

SHORT SPAN

ax Mx (kNm/m)

Reinforcement Provided

Positive moment at Mid span 0.060 5.84 8 200

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.000 0.00 8 200

Positive moment at Mid span 0.043 4.19 8 250

NOTES FOR TABLE

1) Bending moment coefficients taken from Table 26, (Annex D), IS 456

2) Moment values are calculated per unit width

3) ONLY INPUT VALUES IN THE TABLE

4) % steel (pt) calculated from Table 19, IS 456

pt = 100 As/bd

5) Minimum area of steel = 0.12% of bD

6) Minimum bar dia to be used = 8mm

Loads for Supporting Beams

lx = 3.16 m

ly = 4.5 m

UDL on slab = 9.75 kN/m2

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

Beam 1-2

ly = 4.5

lx = 3.16 Beam 2-3

For

LONG SPAN

ay My (kNm/m)

Reinforcement Provided

A

(use avg of S/S & cont. where applicable for cont & discont. edge)

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 53.91 86 OK 0.364 0.179

SHORT SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

251.327 OK 46.69 86 OK 0.364 0.179

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 0.00 86 OK 0.364 0.179

201.062 OK 39.52 78 OK 0.364 0.198

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

max intensity of D DL = 15.41

Max. Moment = 12.82

3.16 1.28

(l) Max. Shear or Rxtn = 12.17

1.22

max intensity of D DL = 30.81

max Intensity of UDL = 26.13

1.58 1.34 1.58 Max. Moment = 59.16

(x) (y) (x) 5.92

Max. Shear or Rxtn = 41.85

LONG SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

4.18

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

SHORT SPAN

Shear Adequacy Reinforcement Requirement

OK 0.25 215 144

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

OK 0.25 195 144

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

kN/m (w)

kNm (wl

2

/12)

t-m

kN (wl/4)

t

kN/m (w1)

kN/m (w2)

kNm (w1x

2

/3 + w2y/2*(x+y/4))

t-m

kN (0.5*(w1x+w2y)

effects on beam will be due to

slab on both sides, so (x2)

LONG SPAN

Shear Adequacy Reinforcement Requirement

t

Slab design (Two way Continuous - <3kn/m2)

Data Input

Dimension of longer span (ly) = 4.5 m

Dimension of shorter span (lx) = 3.16 m

Nominal cover for steel 30 mm

Imposed load = 2.5 kN/m2 (IS 875_2)

Surface finish = 1 kN/m2

Fck = 20 N/mm2

Fy = 500 N/mm2

Unit density of concrete 25 kN/m3

Depth Calculation (Serviceablity)

ly/lx = 1.42 < 2, two way

lx/D = 30 (as per support conditions)

(use avg of S/S & cont. where applicable for cont & discont. edge)

Min. Required Overall depth D = 105.33 mm

Provide D = 120 mm (min. 100mm)

Design Moments & Detailing

Dead load of slab = 3 kN/m2

Ultimate Load (w) = 9.75 kN/m2

Maximum Shear in either direction = Vu = w (lx/2)

15.41 kN/m

Mulim = Rlim bd^2

Fe Rlim (N/mm2)

250 3.00

415 2.78

500 2.68

Value of Rlim to be used = 2.68 N/mm2

Min. value of shear strength = 0.28 N/mm2 (Table 19, IS 456)

multiplying factor (k) = 1.3 (Cl. 40.2.1.1, IS 456)

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.080 7.79 8 200

For

ax Mx (kNm/m)

SHORT SPAN

Reinforcement Provided

Positive moment at Mid span 0.060 5.84 8 200

Bar dia

(mm)

Spacing

(mm)

Negative moments at continuous

edge

0.000 0.00 8 200

Positive moment at Mid span 0.043 4.19 8 250

NOTES FOR TABLE

1) Bending moment coefficients taken from Table 26, (Annex D), IS 456

2) Moment values are calculated per unit width

3) ONLY INPUT VALUES IN THE TABLE

4) % steel (pt) calculated from Table 19, IS 456

pt = 100 As/bd

5) Minimum area of steel = 0.12% of bD

6) Minimum bar dia to be used = 8mm

Loads for Supporting Beams

lx = 3.16 m

ly = 4.5 m

UDL on slab = 9.75 kN/m2

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

Beam 1-2

ly = 4.5

lx = 3.16 Beam 2-3

For

LONG SPAN

ay My (kNm/m)

Reinforcement Provided

A

(use avg of S/S & cont. where applicable for cont & discont. edge)

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 53.91 86 OK 0.364 0.179

Effective depth (d) Shear Adequacy

SHORT SPAN

Reinforcement Provided

251.327 OK 46.69 86 OK 0.364 0.179

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 0.00 86 OK 0.364 0.179

201.062 OK 39.52 78 OK 0.364 0.198

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

max intensity of D DL = 15.41

Max. Moment = 12.82

3.16 1.28

(l) Max. Shear or Rxtn = 12.17

1.22

max intensity of D DL = 30.81

max Intensity of UDL = 26.13

1.58 1.34 1.58 Max. Moment = 59.16

(x) (y) (x) 5.92

Max. Shear or Rxtn = 41.85

LONG SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

4.18

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

Shear Adequacy Reinforcement Requirement

SHORT SPAN

OK 0.25 215 144

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel reqd

OK 0.25 215 144

OK 0.25 195 144

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

kN/m (w)

kNm (wl

2

/12)

t-m

kN (wl/4)

t

kN/m (w1)

kN/m (w2)

kNm (w1x

2

/3 + w2y/2*(x+y/4))

t-m

kN (0.5*(w1x+w2y)

effects on beam will be due to

slab on both sides, so (x2)

LONG SPAN

Shear Adequacy Reinforcement Requirement

t

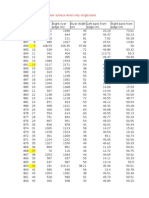

DATA

Span of the beam = 3.16 m

Assume width of beam (b) = 0.15 m

Assume depth of beam (D) = 0.18 m SIMPLE BEAM

Assume clear cover = 25 mm

Assume main reinforcement dia () = 12 mm (taken from below)

Assume width of support columns = 0.6 m

Concrete density = 2.5 t/m3

Concrete grade = M 25

Characteristic Compr. Strength (Fck) = 2548.42 t/m2

Permissible stress in concrete (Fc) = 1132.631 t/m2

Steel grade = Fe 500

Characteristic Tensile Strength (Fy) = 50968.400 t/m2

Permissible stress in steel (Fs) = 29546.898 t/m2

xu,max/d = 0.46

Maximum moment acting on the beam = 1.282 t-m (M)

Torsion acting on the beam (if any) = 0.000 t-m (T)

Equivalent Moment (Mu,lim) = 1.282 t-m

Adequacy of beam section

Effective depth calculation

support cond factor

a) From deflection criteria (L/d) = 0.127 m 26

b) From Limiting Moment = 0.158 m

max accepted = 0.158 m (REQD)

Provided = 0.180 m OK

d/b = 1.20 (generally 1.5-2)

Steel Requirement

Area of Main steel required = 256.966 mm2

Provide

12 bars @ 3 nos.

+ 0 bars @ 0 nos.

= 339.292 mm2 ADEQUATE

Pt = 1.26

Nos. in one layer = 3

Spacing = 0.044 m OK

Say 0.05 m

Side face Reinforcement = NOT REQUIRED mm2 (on each side)

Provide

10 bars @ 2 nos.

+ 12 bars @ 1 nos.

= 270.177 mm2 CHECK BAR DIA AND NOS.

Development Length (Cl. 26.2.1, IS 456)=

f = 12 mm

ss = 230 N/mm2

tbd = 1.4 N/mm2 M 25

Ld = 0.49 m

Shear Stress in Concrete

Pt = 100 As/b d = 1.257 M 25

Max shear acting (Vu) = 1.217 t (at d from support)

shear stress acting = 45.074 t/m2 OK

Design shear resistance (Vuc) = 65.24 t/m2 (calculate from table)

Design Shear (Vus = Vu - Vuc) = -20.166 t/m2

-0.544 t

Assume dia of shear reinf. = 8 mm

legged = 2

Area of steel (Asv) = 100.53 mm2

spacing (sv) = 200 mm c/c

shear resistance provided = 4.01 t OK

Crack Widths (Service Loads) - Limiting value 0.2 mm

b = 0.15 m

Ast = 339.292 mm2

M = 0.85 t-m

Es = 20387359.84 t/m2

Ec = 2548419.98 t/m2

Ece = 1274209.99 t/m2

m = 16.00 t/m2

Cmin = 25.00 mm

h = D = 0.18 m

d = 0.18 m

dia of bar = 12.00 mm

bar spacing = 0.05 m

effective cover = 31.00 mm

N.A at working loads

x^2 + 0.072x - 0.013 = 0 0.072

0.013

x = 0.084 m

Ic = 0.0001 m4

Determination of crack width at a point directly under a bar on tension face

x1 = 0.096 m

1 = 0.000811896

a = 0.18 m

m = 0.000740841

acr = Cmin = 25.00 mm

Wcr = 0.056 mm OK

Determination of crack width at a point midway between bars on tension face

x1 = 0.096 m

1 = 0.000811896

a = 0.18 m

m = 0.000740841

acr = 33.82 mm

Wcr = 0.064 mm OK

Determination of crack width at a point bottom corner of beam on tension face

x1 = 0.096 m

1 = 0.000811896

a = 0.18 m

m = 0.000740841

acr = 37.84 mm

Wcr = 0.066 mm OK

Determination of crack width at a point 2/3(d-x) from N.A.

x1 = 0.064 m

1 = 0.000541264

a = 0.15 m

m = 0.000493894

acr = 38.66 mm

Wcr = 0.045 mm OK

Cost of Conc Section

rate of steel = 72274 rs/mt

total weight = 0.01 mt

cost of reinf steel = 420.88 rs

rate of M25 concrete = 6159.15 rs/m3

total vol = 0.08 m3

cost of conc = 520.93 rs

total cost = 941.81 rs

SIMPLE BEAM

(taken from below)

support cond factor

ADEQUATE

(on each side)

CHECK BAR DIA AND NOS. (Cl. 26.5.1.3, IS 456)

(at d from support)

(calculate from table)

DATA

Span of the beam = 4.50 m

Assume width of beam (b) = 0.2 m

Assume depth of beam (D) = 0.25 m SIMPLE BEAM

Assume clear cover = 25 mm

Assume main reinforcement dia () = 16 mm (taken from below)

Assume width of support columns = 0.6 m

Concrete density = 2.5 t/m3

Concrete grade = M 25

Characteristic Compr. Strength (Fck) = 2548.42 t/m2

Permissible stress in concrete (Fc) = 1132.631 t/m2

Steel grade = Fe 500

Characteristic Tensile Strength (Fy) = 50968.400 t/m2

Permissible stress in steel (Fs) = 29546.898 t/m2

xu,max/d = 0.46

Maximum moment acting on the beam = 5.916 t-m (M)

Torsion acting on the beam (if any) = 0.000 t-m (T)

Equivalent Moment (Mu,lim) = 5.916 t-m

Adequacy of beam section

Effective depth calculation

support cond factor

a) From deflection criteria (L/d) = 0.181 m 26

b) From Limiting Moment = 0.295 m

max accepted = 0.295 m (REQD)

Provided = 0.250 m CHECK

d/b = 1.25 (generally 1.5-2)

Steel Requirement

Area of Main steel required = 475.862 mm2

Provide

16 bars @ 3 nos.

+ 0 bars @ 0 nos.

= 603.186 mm2 ADEQUATE

Pt = 1.21

Nos. in one layer = 4

Spacing = 0.045 m OK

Say 0.05 m

Side face Reinforcement = NOT REQUIRED mm2 (on each side)

Provide

10 bars @ 2 nos.

+ 12 bars @ 1 nos.

= 270.177 mm2 CHECK BAR DIA AND NOS.

Development Length (Cl. 26.2.1, IS 456)=

f = 16 mm

ss = 230 N/mm2

tbd = 1.4 N/mm2 M 25

Ld = 0.66 m

Shear Stress in Concrete

Pt = 100 As/b d = 1.206 M 25

Max shear acting (Vu) = 1.220 t (at d from support)

shear stress acting = 24.400 t/m2 OK

Design shear resistance (Vuc) = 70.1 t/m2 (calculate from table)

Design Shear (Vus = Vu - Vuc) = -45.700 t/m2

-2.285 t

Assume dia of shear reinf. = 8 mm

legged = 2

Area of steel (Asv) = 100.53 mm2

spacing (sv) = 200 mm c/c

shear resistance provided = 5.57 t OK

Crack Widths (Service Loads) - Limiting value 0.2 mm

b = 0.2 m

Ast = 603.186 mm2

M = 3.94 t-m

Es = 20387359.84 t/m2

Ec = 2548419.98 t/m2

Ece = 1274209.99 t/m2

m = 16.00 t/m2

Cmin = 25.00 mm

h = D = 0.25 m

d = 0.25 m

dia of bar = 16.00 mm

bar spacing = 0.05 m

effective cover = 33.00 mm

N.A at working loads

x^2 + 0.096x - 0.024 = 0 0.097

0.024

x = 0.114 m

Ic = 0.0003 m4

Determination of crack width at a point directly under a bar on tension face

x1 = 0.136 m

1 = 0.001520122

a = 0.25 m

m = 0.001444873

acr = Cmin = 25.00 mm

Wcr = 0.108 mm OK

Determination of crack width at a point midway between bars on tension face

x1 = 0.136 m

1 = 0.001520122

a = 0.25 m

m = 0.001444873

acr = 33.4 mm

Wcr = 0.129 mm OK

Determination of crack width at a point bottom corner of beam on tension face

x1 = 0.136 m

1 = 0.001520122

a = 0.25 m

m = 0.001444873

acr = 38.67 mm

Wcr = 0.140 mm OK

Determination of crack width at a point 2/3(d-x) from N.A.

x1 = 0.091 m

1 = 0.001013414

a = 0.20 m

m = 0.000963249

acr = 48.12 mm

Wcr = 0.104 mm OK

Cost of Conc Section

rate of steel = 72274 rs/mt

total weight = 0.01 mt

cost of reinf steel = 920.51 rs

rate of M25 concrete = 6159.15 rs/m3

total vol = 0.22 m3

cost of conc = 1375.82 rs

total cost = 2,296.33 rs

SIMPLE BEAM

(taken from below)

support cond factor

ADEQUATE

(on each side)

CHECK BAR DIA AND NOS. (Cl. 26.5.1.3, IS 456)

(at d from support)

(calculate from table)

Slab design (Simply Supported)

Data Input

Dimension of longer span (ly) = 4.5 m

Dimension of shorter span (lx) = 3.16 m

Nominal cover for steel 30 mm

Imposed load = 2.5 kN/m2 (IS 875_2)

Surface finish = 1 kN/m2

Fck = 20 N/mm2

Fy = 500 N/mm2

Unit density of concrete 25 kN/m3

Depth Calculation (Serviceablity)

ly/lx = 1.42 < 2, two way

lx/D = 28 (as per support conditions)

(use avg of S/S & cont. where applicable for cont & discont. edge)

Min. Required Overall depth D = 112.86 mm

Provide D = 120 mm (min. 150mm)

Design Moments & Shear

Dead load of slab = 3 kN/m2

Ultimate Load (w) = 9.75 kN/m2

Maximum Shear in either direction = Vu = w (lx/2)

15.41 kN/m

Mulim = Rlim bd^2

Fe Rlim (N/mm2)

250 3.00

415 2.78

500 2.68

Value of Rlim to be used = 2.68 N/mm2

Min. value of shear strength = 0.28 N/mm2 (Table 19, IS 456)

multiplying factor (k) = 1.3 (Cl. 40.2.1.1, IS 456)

Bar dia

(mm)

Spacing

(mm)

Simply Supported on Four Sides 0.099 9.64 8 200

For

SHORT SPAN

ax Mx (kNm/m)

Reinforcement Provided

Bar dia

(mm)

Spacing

(mm)

Simply Supported on Four Sides 0.051 4.97 8 200

NOTES FOR TABLE

1) Bending moment coefficients taken from Table 26, (Annex D), IS 456

2) Moment values are calculated per unit width

3) ONLY INPUT VALUES IN THE TABLE

4) % steel (pt) calculated from Table 19, IS 456

pt = 100 As/bd

5) Minimum area of steel = 0.12% of bD

6) Minimum bar dia to be used = 8mm

Loads for Supporting Beams

lx = 3.16 m

ly = 4.5 m

UDL on slab = 9.75 kN/m2

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

Beam 1-2

ly =

lx = Beam 2-3

For

LONG SPAN

ay My (kNm/m)

Reinforcement Provided

A

(use avg of S/S & cont. where applicable for cont & discont. edge)

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 59.97 86 OK 0.364 0.179

SHORT SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

Area

(mm2)

Remarks

Reqd

(mm)

Provided

(mm)

Remarks

Strength (tc)

N/mm2

Stress (tv)

N/mm2

251.327 OK 43.04 86 OK 0.364 0.179

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

max intensity of D DL = 15.41

Max. Moment = 12.82

3.16 1.28

(l) Max. Shear or Rxtn = 12.17

1.22

max intensity of D DL = 15.41

max Intensity of UDL = 13.07

1.58 1.34 1.58 Max. Moment = 29.58

(x) (y) (x) 2.96

Max. Shear or Rxtn = 20.92

2.09

LONG SPAN

Reinforcement Provided Effective depth (d) Shear Adequacy

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel

reqd

OK 0.25 215 144

SHORT SPAN

Shear Adequacy Reinforcement Requirement

Remarks

(% of

steel), pt

Area

(mm2)

Min. Steel

reqd

OK 0.25 215 144

The loads of triangular segment A will be transferred to beam 1-2 and the same of trapezoidal segment B will be transferred to beam 2-3

kN/m (w)

kNm (wl

2

/12)

t-m

kN (wl/4)

t

kN/m (w1)

kN/m (w2)

kNm (w1x

2

/3 + w2y/2*(x+y/4))

t-m

kN (0.5*(w1x+w2y)

t

LONG SPAN

Shear Adequacy Reinforcement Requirement

You might also like

- Design of Slab: Ly/lx 2. So This Is Two Way SlabDocument6 pagesDesign of Slab: Ly/lx 2. So This Is Two Way SlabSudip ShresthaNo ratings yet

- Steel Beam Load CalcDocument5 pagesSteel Beam Load Calchary9100No ratings yet

- Design of square footing for 600 KN column loadDocument2 pagesDesign of square footing for 600 KN column loadVishwajith KadriNo ratings yet

- Design of Column BaseDocument2 pagesDesign of Column BasepragneshozaNo ratings yet

- Cantilever BeamDocument3 pagesCantilever BeamFeliciano Esteban DominguezNo ratings yet

- Wind Load Calculation for 6.5m High BuildingDocument98 pagesWind Load Calculation for 6.5m High BuildingAnonymous HJ7hmihhNo ratings yet

- Design of Rectangular Columns with Biaxial BendingDocument21 pagesDesign of Rectangular Columns with Biaxial BendingBhaskar BabiNo ratings yet

- Design of Isolated FootingDocument10 pagesDesign of Isolated Footingramdev panditNo ratings yet

- Water Tank Design (With Cover Slab) RDocument13 pagesWater Tank Design (With Cover Slab) RDenishmakvanaNo ratings yet

- Design of Shear Wall FootingDocument11 pagesDesign of Shear Wall FootingJohn Paul Hilary EspejoNo ratings yet

- Purlin DesignDocument6 pagesPurlin DesignAnonymous mcHqIfbnV1No ratings yet

- One Way Slab DesignDocument2 pagesOne Way Slab DesignSadeesh Kumar0% (1)

- Column Base PlateDocument3 pagesColumn Base PlatePurnima ArkalgudNo ratings yet

- FootingDocument14 pagesFootingJaganraj SesurajNo ratings yet

- Manual Beam DesignDocument14 pagesManual Beam DesignRonald Kaaku50% (2)

- Strip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNDocument13 pagesStrip Footing Design: 4141 KN 2645 KN 1489 KN 2185 KN 2617 KNkushaljp8989No ratings yet

- Staircase Design: 8.28kN/m 15.57kN/mDocument3 pagesStaircase Design: 8.28kN/m 15.57kN/mBikki CyamaNo ratings yet

- Foundation DesignDocument15 pagesFoundation Designlokesh.lucky.nit7228No ratings yet

- Wind Load CalculationDocument8 pagesWind Load CalculationAbdulsamad RacmanNo ratings yet

- Design of Combined FootingDocument12 pagesDesign of Combined FootingAhmmed Muhsee100% (2)

- Design of PurlinsDocument10 pagesDesign of PurlinsFranklyn GenoveNo ratings yet

- Single Isolated Square Footing FPSDocument8 pagesSingle Isolated Square Footing FPSengmohamad19880% (1)

- Design of Cantilever Slab for MOI ProjectDocument6 pagesDesign of Cantilever Slab for MOI ProjectHamjaytizii Engineering TvNo ratings yet

- Column DesignDocument6 pagesColumn DesignKenneth CajefeNo ratings yet

- Slab Design ExcelDocument30 pagesSlab Design Excelwajid ahmadNo ratings yet

- Column DesignDocument56 pagesColumn DesignSakar ShresthaNo ratings yet

- Steel Column Base Plate Analysis: Blue Cells Are Input DataDocument1 pageSteel Column Base Plate Analysis: Blue Cells Are Input DataHansal Soni0% (1)

- Design of Doubly Reinforced BeamDocument2 pagesDesign of Doubly Reinforced BeamZnake Von LucasNo ratings yet

- StaircaseDocument1 pageStaircaseIsaac Mureithi MainaNo ratings yet

- BEAM DESIGN & Column DesignDocument3 pagesBEAM DESIGN & Column DesignVea Anne Austria GirayNo ratings yet

- One Way Slab DesignDocument4 pagesOne Way Slab DesignMario FeghaliNo ratings yet

- Design of Underground Water TankDocument6 pagesDesign of Underground Water TankAlfred PatrickNo ratings yet

- Wf-Section Compression Strength LRFD Method Per NSCP 2015 Edition (S.I. Units) Developed By: Joel M. Regino, CE, RMPDocument1 pageWf-Section Compression Strength LRFD Method Per NSCP 2015 Edition (S.I. Units) Developed By: Joel M. Regino, CE, RMPjoel reginoNo ratings yet

- ACI SLAB DESIGN FOR TWO-WAY RECTANGULAR EDGE SUPPORTED SLABDocument1 pageACI SLAB DESIGN FOR TWO-WAY RECTANGULAR EDGE SUPPORTED SLABMuhammad FaisalNo ratings yet

- RC Beam Deflection and Stress AnalysisDocument4 pagesRC Beam Deflection and Stress AnalysisMaxNo ratings yet

- One Way Slab ProgramDocument140 pagesOne Way Slab ProgramRachelle CapulNo ratings yet

- Design of RafterDocument6 pagesDesign of RafterRichard TagleNo ratings yet

- Anchor Bolt Design Per IS LSMDocument6 pagesAnchor Bolt Design Per IS LSMdebjyoti_das_6No ratings yet

- Beam Deflection CheckDocument7 pagesBeam Deflection Checkajith chandranNo ratings yet

- Analysis and Design of Cantilever SlabDocument9 pagesAnalysis and Design of Cantilever SlabOscarKonzultNo ratings yet

- SlabDocument6 pagesSlabBishal ShresthaNo ratings yet

- Base PlateDocument13 pagesBase PlateNaga Manikanta TatikondaNo ratings yet

- Combined Footing Design (Strap Final)Document22 pagesCombined Footing Design (Strap Final)Engineeri TadiyosNo ratings yet

- Design of Square Footing F2Document18 pagesDesign of Square Footing F2Mohammed Sumer100% (1)

- BEAM DesignDocument45 pagesBEAM DesignJoseph Cloyd L. LamberteNo ratings yet

- Isolated Footing Design (ACI 318-11) : ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNo ratings yet

- Timber Plate ComputationsDocument16 pagesTimber Plate ComputationsJerrol Macaspac100% (2)

- S2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersDocument2 pagesS2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersMuhammed Sabah100% (1)

- Strapped Footing DesignDocument10 pagesStrapped Footing DesignRyanRuceMelville0% (1)

- Design of Beams - BS 8110Document3 pagesDesign of Beams - BS 8110thanigai veluNo ratings yet

- Load Combination and Flexural Design of Roof Deck BeamsDocument123 pagesLoad Combination and Flexural Design of Roof Deck BeamsMarkNo ratings yet

- Design of Column Excel SheetDocument2 pagesDesign of Column Excel SheetAnand K RajNo ratings yet

- 2-WAY SLAB OPTIMIZATIONDocument120 pages2-WAY SLAB OPTIMIZATIONSambhav PoddarNo ratings yet

- Civil Auditorium Building DesignDocument23 pagesCivil Auditorium Building DesignRamachantran RamachantranNo ratings yet

- Design of Two Way Slab (IS 456:2000) (Limit State Method) : 1 AnalysisDocument4 pagesDesign of Two Way Slab (IS 456:2000) (Limit State Method) : 1 AnalysisRus TheengNo ratings yet

- Slab Designer As Per IS 456-2000Document7 pagesSlab Designer As Per IS 456-2000mofizahmed64% (11)

- Box Culvert at Chainage 83 10 M XLSX Depth 4 1 MDocument18 pagesBox Culvert at Chainage 83 10 M XLSX Depth 4 1 MMario Sajulga Dela Cuadra100% (1)

- Example - Slab Bridge PDFDocument7 pagesExample - Slab Bridge PDFRefisa Jiru100% (3)

- Pad Footing PDFDocument5 pagesPad Footing PDFricversyNo ratings yet

- Design SectionDocument19 pagesDesign SectionKrishna KumarNo ratings yet

- StabitsDocument18 pagesStabitsSambhav PoddarNo ratings yet

- Wave Wall - Type CDocument4 pagesWave Wall - Type CSambhav PoddarNo ratings yet

- Northeast India's ingenious living root bridgesDocument3 pagesNortheast India's ingenious living root bridgesSambhav PoddarNo ratings yet

- PCC Toe WallDocument4 pagesPCC Toe WallSambhav PoddarNo ratings yet

- Wave Wall-Type 4Document3 pagesWave Wall-Type 4Sambhav PoddarNo ratings yet

- Retaining WallDocument146 pagesRetaining WallSambhav PoddarNo ratings yet

- Wave Wall - Type CDocument4 pagesWave Wall - Type CSambhav PoddarNo ratings yet

- Wave Wall-Type 4Document3 pagesWave Wall-Type 4Sambhav PoddarNo ratings yet

- Design of Anchorage ZoneDocument6 pagesDesign of Anchorage ZoneSambhav PoddarNo ratings yet

- Checks For Reinforcement of Pedestal For LightpostDocument4 pagesChecks For Reinforcement of Pedestal For LightpostSambhav PoddarNo ratings yet

- Channel DesignDocument6 pagesChannel DesignSambhav PoddarNo ratings yet

- Check Radius From 3 PointsDocument2 pagesCheck Radius From 3 PointsSambhav PoddarNo ratings yet

- Intake Design OptimizationDocument54 pagesIntake Design OptimizationSambhav PoddarNo ratings yet

- Check Radius From 3 PointsDocument2 pagesCheck Radius From 3 PointsSambhav PoddarNo ratings yet

- Retaining WallDocument146 pagesRetaining WallSambhav PoddarNo ratings yet

- Built Up Column - ChannelDocument18 pagesBuilt Up Column - ChannelSambhav PoddarNo ratings yet

- PCC Toe WallDocument4 pagesPCC Toe WallSambhav PoddarNo ratings yet

- Design of Intake Structure DimensionsDocument2 pagesDesign of Intake Structure DimensionsSambhav PoddarNo ratings yet

- Beam and Column Design in Reinforced ConcreteDocument21 pagesBeam and Column Design in Reinforced ConcreteSambhav PoddarNo ratings yet

- PCC Toe WallDocument7 pagesPCC Toe WallSambhav PoddarNo ratings yet

- Control Room - 2 Way Slab Design-Roof SlabDocument152 pagesControl Room - 2 Way Slab Design-Roof SlabSambhav PoddarNo ratings yet

- List of Irs SpecificationsDocument4 pagesList of Irs SpecificationsSambhav PoddarNo ratings yet

- Lansdowne in a JiffyDocument5 pagesLansdowne in a JiffySambhav PoddarNo ratings yet

- ch05Document10 pagesch05Renuga DeviNo ratings yet

- Birblng 1Document5 pagesBirblng 1Sambhav PoddarNo ratings yet

- Rates of IMFL - DelhiDocument8 pagesRates of IMFL - DelhiSambhav PoddarNo ratings yet

- 500 KW - Design ReportDocument21 pages500 KW - Design ReportSambhav PoddarNo ratings yet

- Hecras Obs XsDocument6 pagesHecras Obs XsSambhav PoddarNo ratings yet

- Shear CentreDocument2 pagesShear CentreSooraj SivanNo ratings yet

- Control Room - 2 Way Slab Design-Roof SlabDocument152 pagesControl Room - 2 Way Slab Design-Roof SlabSambhav PoddarNo ratings yet

- Pre Insulated Piping Sytem HDPEDocument15 pagesPre Insulated Piping Sytem HDPEVincent SablanNo ratings yet

- Jurnal 1Document22 pagesJurnal 1Muhammad Barin ElyasaNo ratings yet

- Sewer Odor Control BiofilterDocument1 pageSewer Odor Control Biofilteralang_businessNo ratings yet

- Ek 4100a SV A01Document292 pagesEk 4100a SV A01dbo61No ratings yet

- DetailDocument4 pagesDetailAzmat ArifNo ratings yet

- Advance Cloud Computing STTPDocument2 pagesAdvance Cloud Computing STTPBhushan JadhavNo ratings yet

- Poltrone, Sedute, /armchairs, Chairs 1. 0374 - BELL CHAIR: Studio Joe ColomboDocument10 pagesPoltrone, Sedute, /armchairs, Chairs 1. 0374 - BELL CHAIR: Studio Joe ColomboAmador Blanco BlancoNo ratings yet

- SIM800 Series at Command Manual V1.07Document370 pagesSIM800 Series at Command Manual V1.07henry2109No ratings yet

- Damp Proofing-1 PDFDocument6 pagesDamp Proofing-1 PDFmaneeshaNo ratings yet

- Water Pump Station DesignDocument37 pagesWater Pump Station DesignYoussef100% (2)

- Ethernet Cable Color Coding Diagram PDFDocument2 pagesEthernet Cable Color Coding Diagram PDFFabiolaNo ratings yet

- Concrete Division 3Document9 pagesConcrete Division 3Ma Monica M. MuncadaNo ratings yet

- Dywidag Threadbar Properties - Dywidag Threadbar - Reinforcing Steel Hardware DimensionsDocument1 pageDywidag Threadbar Properties - Dywidag Threadbar - Reinforcing Steel Hardware DimensionsMangisi Haryanto ParapatNo ratings yet

- How To Build Clam Antivirus RPM Package For Fedora Core 1Document3 pagesHow To Build Clam Antivirus RPM Package For Fedora Core 1Mahir EfendiyevNo ratings yet

- Water Tank PlanDocument1 pageWater Tank PlanHussain GhaziNo ratings yet

- KnowledgeNet IP Telephony Express (IPTX) 2.0 Student Guide PDFDocument1,176 pagesKnowledgeNet IP Telephony Express (IPTX) 2.0 Student Guide PDFleonids_hmhNo ratings yet

- Left Elevation: Upper Roof DeckDocument1 pageLeft Elevation: Upper Roof DeckWilmer EudNo ratings yet

- Daniel's Resume 7.2018Document2 pagesDaniel's Resume 7.2018Anonymous C7U9203qzSNo ratings yet

- Reading Comprehension Practice TestDocument12 pagesReading Comprehension Practice TestGabino SantosNo ratings yet

- Introduction To Xamarin FormDocument37 pagesIntroduction To Xamarin FormKurniaNo ratings yet

- EHEIM Product RangeDocument10 pagesEHEIM Product RangeLeoRualesNo ratings yet

- SME PPT TCU02 Technical DescriptionDocument23 pagesSME PPT TCU02 Technical DescriptionabhinavNo ratings yet

- Zigbee Technology: "Wireless Control That Simply Works.": Submitted byDocument24 pagesZigbee Technology: "Wireless Control That Simply Works.": Submitted byAnonymous nNyOz70OHpNo ratings yet

- Quick Guides - Pressure Vessel EngineeringDocument7 pagesQuick Guides - Pressure Vessel EngineeringWaqas WaqasNo ratings yet

- CCNP Routing and Switching ROUTE 300-101 Official Cert GuideDocument189 pagesCCNP Routing and Switching ROUTE 300-101 Official Cert GuideMaruthi Halavi100% (3)

- ZTE GSM UR17 License Management Solution - V1.0 - 20171220Document21 pagesZTE GSM UR17 License Management Solution - V1.0 - 20171220Rehan Haider JafferyNo ratings yet

- (SAPPHIRE NOW and SASUG Annual ConferenceDocument321 pages(SAPPHIRE NOW and SASUG Annual ConferenceProj100% (1)

- CC-Link & CC-Link - LT CatalogDocument119 pagesCC-Link & CC-Link - LT Catalogkhonghohenk6No ratings yet

- LSI Starbeam Series Brochure 1994Document6 pagesLSI Starbeam Series Brochure 1994Alan MastersNo ratings yet

- ORACLE UCM OrderDocument17 pagesORACLE UCM OrderMohinder SinghNo ratings yet