Professional Documents

Culture Documents

Oil and Gas Facilities Engineering Coursework

Uploaded by

Oghosa Ken O100%(2)100% found this document useful (2 votes)

167 views18 pagesShows a conceptual facilities field development including a basic economic and technical comparison of subsea tie-back vs new facility option for sour crude

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentShows a conceptual facilities field development including a basic economic and technical comparison of subsea tie-back vs new facility option for sour crude

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

100%(2)100% found this document useful (2 votes)

167 views18 pagesOil and Gas Facilities Engineering Coursework

Uploaded by

Oghosa Ken OShows a conceptual facilities field development including a basic economic and technical comparison of subsea tie-back vs new facility option for sour crude

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 18

EXECUTIVE SUMMARY

Casablanca oilfield is a virgin field, about to start undergoing

development, in order to commence production of oil and gas for high

return on investment values on money spent during development. During

exploration stage of this field, data and facts about the oilfield were taken

by geoscientist, and passed on to engineers in order to help support and

influence decisions taken, and choose certified equipments fit for use

during the field development phase. The data details are shown below:

ield !ocation "# kilometres away from nearest land fall$

ield %ater Depth &## feet deep$

'umber of wells planned ( wells$

)ate *redicted for *roduction &#,### bbls oil quantity per day$

ield life Duration expected +# years$

Depth of reservoir +,,### feet$

-nitial *ressure ",### psia

*ressure of oil bubble point &,(## psia

.uality of Crude /our 0 1# Degrees 2*-

rom the data taken by geologist, seismic survey information were

acquired with the most important and a little bit disturbing one being the

presence of sour crude as the quality of crude to be produced during

development. /our crude simply means that the crude contains high

amount of hydrogen sulphide and other sulphuric compounds, which

gives it a sour smell. *resence of this have tendencies of causing

problems and therefore treatment would have to be undertaken on all

produce 34il, 5as, %ater6 to prevent future problems with the

government.

2lso occurring flow assurance issues like 2sphaltene *recipitation,

%ax formation etc. are expected during development so prevention

methods would be placed to prevent this from occurring and causing

obstruction of fluids flow from well heads to their final point of export or

sales point.

!astly, a preferred option is recommended for the progress of this pro7ect

and all of this would be discussed as development planning is carried out.

TABLE OF CONTENTS

898C:T-;8 /:<<2)=......................................................................&

-'T)4D:CT-4'..............................................................................(

+.+ 2ims of this report..................................................................(

+., 4b7ectives of this report..........................................................."

+.& 2ssumptions taking during Development...................................."

/8CT-4' 2:....................................................................................>

,.# 2nalysis for ield Development..................................................>

,.+ %ell ?ead:.............................................................................@

,., <anifold.................................................................................@

,.& /eparator:.............................................................................@

,.1 5as /crubber:........................................................................A

,.( Compressor:..........................................................................A

,." 5as Conditioning :nit:.............................................................A

,.> <eters:................................................................................+#

,.@ *umps:................................................................................+#

,.A ?ydrocyclones:.....................................................................++

,.+# %ater DeBgassing Drum:......................................................++

,.++ ?eater Treater:...................................................................+,

,.+, /torage Tank:.....................................................................+,

,.+& /C<:.................................................................................+,

,.+1 /huttle Tankers:..................................................................+,

/8CT-4' 2 *art ,:.........................................................................+&

&.# Tie Cack Development............................................................+&

&.+ /ubsea *roduction Template:..................................................+&

&., /ubsea Tree:........................................................................+&

&.& :nderwater <anifold..............................................................+&

&.1 <ultiB*hase <eters:...............................................................+&

&.( )isers:.................................................................................+1

&." low !ines:...........................................................................+1

&.> :mbilical Cables:...................................................................+1

/8CT-4' C...................................................................................+1

1.# low assurance issues faced by Casablanca and <orella facility....+1

1.+ ?ydrates ormation:..............................................................+1

1., Corrosion:............................................................................+(

1.& *araffin %axes:.....................................................................+(

1.1 2sphaltene *recipitation:........................................................+(

1.( Technical 2dvantages of Casablanca and <orella *latform...........+"

1." Technical Disadvantages of Casablanca and <orella *latform.......+"

1.> Commercial 2dvantages of Casablanca and <orella *latform.......+>

1.@ Commercial Disadvantages of Casablanca and <orella *latform.. .+>

/ection C:....................................................................................+@

(.+ )ecommendation of *referred option........................................+@

INTRODUCTION

Page 2

2s a field consultant, - am commencing the development of a new oil

field that - have been assigned to, create a flow diagram for superiors to

propose on structures to be followed and carried out ensuring that

equipments installed are fit of use and operation working conditions. 2lso

perform a tieback operation to a preBexisting facility located nearby called

<orella with distance of approximately +#km choosing most appropriate

means with less production risk.

1.1 Aims of this report

+6 To prepare a plan, for the successful development of the

Casablanca oil field.

,6 To show <r <ike )obinson, - do understand all concepts up to an

adequate level of all the information he has been passing in class

sections.

&6 To further students knowledge from that of the course notes by

means of web and publication searches.

1. O!"e#ti$es of this report

+6 To learn how to prepare a flow diagram so as to help give some

structure of development for Casablanca oil field.

,6 To know the functions of how various 8quipments utilised in

development stage work e.g. the roles played by a separator.

&6 To know how water treatment is carried out before being

discharged into the environment.

16 To give recommendation, and discuss a preferred option with

reasons why it was selected from both development concepts.

1.% Ass&mptio's t()i'* +&ri'* De$e,opme't

+6 <inimal amount of sand present, due to lack of high water cuts so

sand cyclones are not installed in development.

,6 ?igh viscosity crudes present so heater treater would be needed in

development.

&6 luid coming in from the wellhead comes in at very high pressure

and therefore a three stage 3multi6 separator is needed to step

down fluid pressure.

Page 3

16 <orella platform is producing above, 1(,### stock tank barrel oil

per day and this is going to take some years to decline to 1(,###

stock tank barrel oil.

(6 *resence of acidic gases 3?ydrogen sulphide and Carbon dioxide6

in crude, so gas sweetening is carried out.

"6 'o presence of 'itrogen in acidic gases so gas sweeting would not

be carried out on it using Cryogenic removal process.

>6 <inimal and acceptable amount salt present when oil is been

separated so electrostatic deBsalters are not installed.

@6 ?ealth and /afety requirement of oil in water before disposal is

1#ppm maximum, for the region where oilfield is located.

SECTION A-

.. A'(,/sis for Fie,+ De$e,opme't

Page 4

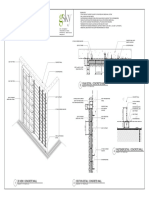

2s the field development consultant working for )5 8D*, in charge of

developing the Casablanca oil field a flow diagram has been prepared

shown in igure +.# below to help give structure on the processes and

steps that would be taken for successful development of this new oil field.

Fi*&re 1..- A pro#ess f,o0 s#hem(ti# +i(*r(m +es#ri!i'* the

pro#ess steps re1&ire+ for the +e$e,opme't of C(s(!,('#( fie,+.

.1 2e,, 3e(+- During production, fluids from reservoir flow to the top

of the earth surface, and are being produced at the wellhead. The

Page 5

wellhead helps provide a pressure containment interface for production

activities carried out. The quality and quantity of reservoir fluids

produced are dependent on three main factors, which are composition of

hydrocarbon present, characteristics of the reservoir produced from and

lastly the field development scheme set in place. The earlier first two,

aforementioned factors are controlled by <other 'ature itself and the last

mentioned are manipulated within the constraints of technological and

market value. 3rank Eahn, et.al$ pg ,&", ,#+&6.Chemical -n7ection is

provided at the wellhead to prevent issues occurring due to flow

assurance.

. M('ifo,+- *roductions gotten from wellheads are connected through

flow lines to a tubular steel structure called manifold. This manifold acts

as a focal point and gathering centre for all flow lines attached to various

wellheads, in which the stream of fluids from each wellhead are

commingled together and fluid production now starts here for all

wellheads. This process saves time and unnecessary expenses of

producing from each wellhead independently. -n7ection of demulsifiers

occurs here to prevent an emulsion from occurring between the oil and

water interphase. This makes the oil soluble in water so there would 7ust

be a single flow phase and not multiple flows because oil floats on water

due to its density difference. luids then flow from the manifold into a

separator, passing through a choke valve installed on the flow line, which

causes the first pressure drop of fluid during production.

.% Sep(r(tor- 'ormally referred to as the heart of processing facilities

during production. -t separates the fluids into phases gas, oil, and water,

and help to support accurate metering of it during production. %hen fluid

flows from the manifold through the choke valve into the separator

system, it comes in at a highBpressure rate and then a pressure drop

occurs as it goes through each of the various phases of separation

installed. 2s fluids enter the separator, it hits an inlet diverter, which

causes a change in flow direction and velocity of the fluid. -nitial gross

separation in the separator, occurs at this point first with water going to

bottom, oil in the middle and gas at the top. -n the separator, gravity

Page 6

forces cause the heavier liquid droplets to fall out of the gas stream to

the bottom where the liquid is collected. The liquid phase holds the liquid

until an appropriate residence time required to allow the entrained gas

break out of the oil and rise to the gas phase, and they do so under

buoyancy forces. -n addition, how easy the gases breaks out of the liquid

is determined by the viscosity of the liquid present, as liquid with high

viscosities imply longer residence times.

.4 5(s S#r&!!er- 2s the gas, flows out of the separator it passes a

mist extractor, which acts as a barrier and causes small drops of liquid

that were difficult to be separated by gravity to fall back into the liquid

phase. The gas then flows into a gas scrubber, whose function is to

restrict and trap condensed liquids 3i.e. water and hydrocarbons6 from

the gases as it leaves the separators. This function of the gas scrubber

helps prevent liquids from getting into the suction of the compressor

thereby disrupting functionality and causing erode on compressor

rotating blades.

.6 Compressor- 2s gas moves through the processing stages, a drop in

pressure accompanies it and energy would need to be imparted into it to

cause an increase in pressure, before it can be transported to the next

processing stage. -n this scenario, three separators are used in stepping

down the pressure, so the gas pressure escaping the first separator is not

same with the gas pressure escaping the second and the third separator,

so in such a compressor is used to increase the gas pressure of the

second and third separator to be in range with the first separator.

.7 5(s Co'+itio'i'* U'it- Cefore the gas is made use of as fuel or

flared, it goes through the condition unit, which ensures water vapour is

absent in gases, as this can lead to hydrate formation and cause

corrosion in the presence of carbon dioxide and hydrogen sulphide. -t

also ensures that contaminants like carbon dioxide and hydrogen sulphide

are removed, as hydrogen sulphide is toxic.

To prevent such hindrances, two processes are undertaken which are:

Page 7

i. 5(s Deh/+r(tio'- This simply means removal of water vapour

present in gases.

ii. 5(s S0eete'i'*- This means the removal of hydrogen sulphide

and carbon dioxide 3acid gases6 that are present.

These two processes are performed together using absorption technique

in a contact tower or absorber. Chemical solvents such as

<onoethanolamine and TriBethylene glycol are combined together in the

contact tower, then the gases are bubbled as heat is being applied

slightly above atmospheric pressure. -n the contact tower, the glycol

reduces the water contents sufficient to prevent water dropout from the

gases, and allows for efficient removal of the hydrogen sulphide and

carbon dioxide by the <onoethanolamine in the gases. This help remove

possibilities of hydrate formation, which causes corrosion and blockages.

.8 Meters- %hen produce such as oil and gas, are ready for export

from the production installation, it goes through meters, which are used

to manage and monitor the volume and quantity of produce 3oil and gas6

transported out of the production installation from one party to another.

/pecialised meters are used to perform this process, to measure the gas

:ltrasonic meters are used and for the oil turbine meters are used.

rom the diagram in igure +.#, the water at the bottom leaves the

separator through water dump valves installed below, which are

controlled accordingly by the water level controller at the side of the

separator as water changes are sensed. %ater flows out of the separators

and heater treater as shown in figure +.#, to the hydrocyclones and due

to pressure drops already occurred, pumps are used for the second and

third separator independently to boost its flow to the hydrocyclones.

.9 :&mps- This are devices which work similar to gas compressors,

with the ma7or difference being that they are used to impart pressure on

the fluids and not gases, in order to increase flow rate, and prevent

occurrence of slippage during production.

Page 8

.; 3/+ro#/#,o'es- %hen water enters the hydrocyclones, it removes

the oil contents from the water before sent out to sea. This process is

known as DeBoiling.

i. De<Oi,i'*- This simply means the removal of oil concentration

from water. There are many deBoiling techniques e.g. skimming

tank, corrugated interceptor, gas floatation unit etc... Cut

hydrocyclones are used, due to itFs the most common technique

used offshore, and is capable of producing oil in water disposal

standards of less than 1#ppm or 1#ppm which falls in line with

regulatory health and safety requirements of region, before it is

allowed to be discharged to sea.

The way hydrocyclones works is it relies on centrifugal forces to separate

the light oil particles left in the water phase as it passed through

processing stages, leaving the water to rest at the bottom and oil on top

of the water in the equipment. %ater then gets collected in the water deB

gassing drum.

.1. 2(ter De<*(ssi'* Dr&m- 2s the water is collected here, it

performs another effective process, by removing the gases still present

even as fluid has gone through various processing stages, before the

water is discharged to sea. This process is known as DeBgassing.

i. De<5(ssi'*- This simply means the removal of gas concentration

from water. 2 deBgassing drum is used in this development for that

purpose.

The way the deBgassing drum works is, as water enters the deBgassing

drum dispersed gases slowly rise out of it and by floatation, the gases

pull along with it remaining droplets of oil to the surface that were not

separated by the hydrocyclones. The surface oil film is drained out and

channelled back to the heater treater for dehydration, and produced now

treated water is now discharged to sea through a skim pipe. ?ydrogen

sulphide and Carbon dioxide are also treated here as explained earlier by

making use of the <onoethanolamine solvent to remove its presence.

-n igure +.#, you would have a view of the process through which the oil

flows in the separator. The oil seats in the middle between the gas phase

Page 9

and water phase then it leaves the separator through oil dump valves

installed below, which are controlled accordingly by the oil level controller

at the side of the separator as oil changes are sensed from the weir

located in the separator. The oil then flows out into a heater treater.

.11 3e(ter Tre(ter- %ith the assumption of high viscosity crudes,

heater treater is installed in order to promote separation and fast break

out of the gas from the liquid phase. 2s high viscosity, fluids have

tendencies of taking longer retention time to break out the liquid phase.

This gives stabiliGation and dehydration of the oil before it goes to the

storage tank and then later transport. 2s it is necessary for fluids to be

stabiliGed during transport, and gas to be dehydrated to its dew point to

prevent liquid drop out during transportation.

.1 Stor(*e T(')- %hen the oil comes into the storage tank, it does

so with the support of a pump to impart pressure into the liquid to

prevent occurrence of slippage due to the pressure dropped already

occurred in process. This device simply stores oil produced from the fluid

after it has gone through all processing stages available and is now

awaiting exportation. );* is carried out on the oil using )eid bomb

apparatus before transportation to ensure true vapour pressure is within

range of +#B+, psia required for transport by shuttle tankers. This

process ensures vapour is not too high, as it is flammable and gives rise

to explosion haGards if escaped to atmosphere.

.1% SBM- %hen the oil stored in the storage is now ready to be

transported, this provides the tankers with support during extraction as

the tanker is tied up to the /C< and through it, the tankers have the

ability to rotate around and accommodate the weather conditions present

at time of export.

.14 Sh&tt,e T(')ers- They simply are the boats, which come and take

the oil away to the storage facility when it is ready for export.

Page 10

SECTION A :(rt -

%.. Tie B(#) De$e,opme't

or tieback in this development, it can be performed by either introducing

a new 7acket, and making use of a linking bridge to link both facilities, 4r

by making use of subsea equipments for the development of the tie back.

This - believe to be a better option as the distance of +#km between both

facilities is quite much for use of a linking bridge though it cost less, the

risk involved if problems were to occur are very high. /ubsea tiebacks

equipments utilised are:

%.1 S&!se( :ro+&#tio' Temp,(te- This support production activities to

be carried out, acting as the base foundation for other subsea structures

to be installed upon. Construction is carried out nearby, and taken to

seabed location when constructed, in which it is gently lowered unto the

seabed using a crane barge, and pile drivers installed on it are loosened,

and piled into the bottom of the seabed to hold template in place and

promote stability of the equipment.

%. S&!se( Tree- This equipment is placed at the bottom of the sea to

seat on the template that seats on the seabed. -t is required as the final

step taken for completion of a well to make it viable for production startB

up. -t helps control and support the fluid flow from the Casablanca field

providing safe conduit through it and the flow lines into the manifold.

%.% U'+er0(ter M('ifo,+- 2s described earlier this has the same

function, acts as a gathering centre and focal point for production of

fluids. -t connects all series of wells together through flow lines, while

also seating on the subsea template.

%.4 M&,ti<:h(se Meters- 2lso described earlier, as meters are used for

many reasons e.g. government, personal files, court cases etc. it is used

to know the quantity and volume of produce been sent out from one

party to another party.

Page 11

%.6 Risers- This is a large steel pipe diameters installed, and the

function it plays is, it serves as a drill string conduit raising and collecting

fluids gathered at the seabed manifold installed below and then sends it

upwards for processing through the subsea flow lines installed.

%.7 F,o0 Li'es- This plays the part of conveying and transportation of

oil, gas, and all other constituents around installations, and also from the

Casablanca facility to the preBexisting <orella facility.

%.8 Um!i,i#(, C(!,es- These are offshore underwater cables installed

and deployed into the seabed to ensure safe transfer of electrical or

hydraulic energy to equipments used subsea.

SECTION B

4.. F,o0 (ss&r('#e iss&es f(#e+ !/ C(s(!,('#( ('+ More,,(

f(#i,it/.

Coth platforms face few common flow assurance issues likely to occur,

though they may occur at different areas, they do still occur. <oreover,

some have low tendencies of occurring due to presence of <editerranean

climate. oreseen issues on both platforms are:

4.1 3/+r(tes Form(tio'- 4ccurs due to physical bonding of lighter

constituents and water present in gases, and is visible to human eyes in

the form of iceberg structures. They are formed in conditions of high

pressure and low temperature, and the risk of it occurring here are low

due to <editerranean climate but they can still occur. -f it were to occur,

on the Casablanca field it would occur on wellheads and flow lines. Then

on <orella, it would also occur on flow lines and available equipments.

These plug equipments and pipelines there by obstructing flow and

causing blockage to flow of fluids.

Co'tro, Me(s&res- -f it occurred, its controlled with use of TriB8thylene

glycol solvent in which performs water dehydration present in gases.

Page 12

4. Corrosio'- 4ccurs from the hydrates formed, but in the presence of

acid gases 3?ydrogen sulphide and Carbon dioxide6. Corrosion leads to

many problems such as contamination of fluids, structural failure, rusting,

and operation shutdown. 4n both fields they can occur on flow lines and

equipments used in the presence of hydrates.

Co'tro, Me(s&res- Can be controlled by making use of corrosion

resistant pipes, and through chemicals solvents such as corrosion

inhibitors like <onoethanolamine and -modaGolines

4.% :(r(ffi' 2(=es- These are crystalline in nature, and are formed at

temperatures below cloud point. 2lso it has low tendency of occurring

due to <editerranean climate. -f waxes were to occur, they would cause

production choking. 4n both platforms, if it occurred it would occur in

flow lines.

Co'tro, Me(s&res- -f it occurred, its controlled by in7ection of paraffin

inhibitors such as, 8thylene vinyl acetate or 2lkyl phenols or ;inyl

*olymers or through insulation of flow lines.

4.4 Asph(,te'e :re#ipit(tio'- ormed through oxidation, in the

presence of impurities along with resins and aromatics in the crude oil,

giving rise to metallic looking molecular substances 32sphaltene6. -n both

platforms they can occur in flow lines, and cause the flow lines to have

depositional tendencies. 2lso causes reduction in diffusion rate.

Co'tro, Me(s&res- Can also be controlled through in7ection of

2sphaltene inhibitors such as 2romatic solvents or Dodecyl benGene

/ulphuric 2cid.

Page 13

4.6 Te#h'i#(, A+$('t(*es of C(s(!,('#( ('+ More,,( :,(tform.

C(s(!,('#( :,(tform >F:SO? More,,( :,(tform >Tie!(#)?

+ Decommissioning of the well once

depletion has occurred in reserves

is easily done, as */4 are floating

structures that can be easily

moved from Casablanca field to a

new location.

-nstallation of the tieback from

Casablanca would stop <orella

reservoir reserves from depleting

in coming years and give

maximiGation and extension of the

reservoir life span.

, They have capacities to handle

more variable and large production

streams due to the availability of

storage and offloading equipments

installed onBboard vessels.

4.7 Te#h'i#(, Dis(+$('t(*es of C(s(!,('#( ('+ More,,( :,(tform.

C(s(!,('#( :,(tform >F:SO? More,,( :,(tform >Tie!(#)?

+ During exportation of produced

fluids to the facility, it is done by

use of shuttle tankers, in which are

constrained to weather conditions

at time of export.

2t a combined production rate it

would produce above >(,###

barrels per day and its more than

the required capacity. This means

a delay in start date of production

, During offloading of produce, there

is risk of spillage occurring on

surface when offloading from */4

into shuttle tankers.

2s subsea equipment are utiliGed,

it is at a ma7or financial

disadvantage, as equipments

needed for subsea operations are

very expensive to purchase.

& *resence of flow assurance issues

are likely to occur such as

2sphaltene *recipitation

2fter the purchase of equipments,

it is very difficult to carry out

interventions or equipment

maintenance processes if problems

are to occur.

4.8 Commer#i(, A+$('t(*es of C(s(!,('#( ('+ More,,( :,(tform.

Page 14

C(s(!,('#( :,(tform >F:SO? More,,( :,(tform >Tie!(#)?

+ !ess extra added cost involved

during processing as all

requirements needed for

processing, storage and

transportation are installed upon

vessels.

-t cost a lot less to acquire as

*/4 are very expensive to rent,

and also do take longer duration to

construct one together.

, -t can be recycled thereby

reducing cost. 2s at the end of its

life span, it can be converted to a

tanker used in transportation of

produce 3oil and gas6 to locations.

Compared to the */4 this

requires a lower initial capital

investment to be used in

development planning stage.

4.9 Commer#i(, Dis(+$('t(*es of C(s(!,('#( ('+ More,,(

:,(tform.

C(s(!,('#( :,(tform >F:SO? More,,( :,(tform >Tie!(#)?

+ !esser allocation of sales returned

back from the <orella facility after

sale of produce, since they possess

sweet crude and we possess sour

crude so we are is contaminating

the sweet crude in their facility.

/ince subsea equipments are

utiliGed, staffs would have to be

trained to achieve required

competent skills in order to be able

to manage subsea equipments.

, *remium would still be paid to the

<orella facility for processing of

the sour crude in the Casablanca

facility.

)eduction of produce value will

occur from this operation, due to

the mixture of the sweet crude in

this facility with the sour crude in

the Casablanca facility, as the sour

would contaminate the sweet

crude.

Se#tio' C-

6.1 Re#omme'+(tio' of :referre+ optio'

Page 15

2fter careful assessment of all field development options, - do

recommend the use of option + that is the wellhead 7acket and */4

structure over option , for four main reasons, which are:

i. */4 are very flexible structures, can be used on subsequent

upcoming pro7ects immediately after decommissioning of one, and

even can be used on tieback development as well.

ii. -n option ,, there would be a delay in cash flow, because engineers

would have to wait for a couple of years before production can

commence at its full capacity, or they can decide to start

production and later on choke wells. 'evertheless, this has effects

on the flow of cash.

iii. rom option ,, there would be a decrease in revenue when making

use of it, because measuring meters are not +## percent accurate

iv. :se of option ,, has technological requirements as subsea

expertise and costly subsea interventions are needed.

Refere'#es

Page 16

D8;4!D ?., ,#+&. An Introduction to Oil and Gas Production, Transport,

Refining and Petrochemical Industry 4il and 5as *roduction ?andbook.

8dition &.# 4slo H ,##" 0 ,#+&, 2CC 4il and 5as. -/C' A>@B@,BAA>@@"B

&B,.

http-@@000.4.(!!.#om@*,o!(,@seitp@seitp..'sf@.@f9414ee7#

791%f664968#14..1f11f@Afi,e@Oi,B('+B*(sBpro+&#tio'Bh('+

!oo).p+f I2ccessed on A

0 1 ,#+1J.

<C T8C?'4!45=: Flow Assurance ompetence entre!

https-@@000.*oo*,e.#o.&)@&r,C

s(DtEr#tD"E1DEesr#DsEso&r#eD0e!E#+D;E#(+Dr"(E&(#tD9E$e

+D.C3AFF"AIE&r,DhttpsG%AGFGF000.fm#te#h'o,o*ies.#om

GFHGFme+i(GFS&!se(GFSer$i#esGFF,o0

G6.M('(*eme'tGFD(t(sheetIF,o0Ass&r('#eCC.(sh=

G%Ffor#eG%D1G7tr(#)G%D1EeiDo:pIU<

:#C#T/8A()rIC*A0E&s*DAFF"CNE'0F$"0JKU*JS;o5s0B&4LFe,

'#FEsi*D&"LmS/J1M64!I=0DM7:sB*E!$mD!$.7464619N+.+)

I2ccessed +, B#1 B ,#+1J.

?8)<2', 5.'., ,##". Flow Assurance and "ultiphase Pumping!

*etroleum *roduction pdf. /ubmitted to the 4ffice of 5raduate /tudies

Texas 2 D < :niversity. https-@@000.*oo*,e.#o.&)@&r,C

s(DtEr#tD"E1DEesr#DsEso&r#eD0e!E#+D1E#(+Dr"(E&(#tD9E$e

+D.CC9FF"AAE&r,DhttpG%AGFGFrepositor/.t(m&.e+&

GF!itstre(mGFh('+,eGF1;7;.1GFETD<TAMU<

119.GFNIJ3AR<T3ESIS.p+fG%Fse1&e'#e

G%D1EeiD=6+IU4LmC#i=.AXL=YDIBFE&s*DAFF"CNF7'Uo'EhtIN

/(ED"CA93!.VELMMAEsi*DI/3(LF2.Mr:Rr;IO:LJ!AE!$mD!

$.7464619N+.+) I2ccessed ,A 0 #& B ,#+1J.

E2?', ., C44K, <., and 5)2?2<, <., ,##&. ?ydrocarbon 8xploration

and *roduction, 8!/8;-8), +AA@. -/C': # 111 @,A,+ # 3*aperback6.

Bi!,io*r(ph/

Page 17

)obert 5ordon :niversity Campus <oodle L5as /weeting 'otesL.

)obert 5ordon :niversity Campus <oodle L/eparator /ystems 'otesL.

)obert 5ordon :niversity Campus <oodle L4il Treating 'otesL.

)obert 5ordon :niversity Campus <oodle L*roduced %ater Treatment

'otesL.

Page 18

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2021 Aquifer Storage and Recovery Science PlanDocument72 pages2021 Aquifer Storage and Recovery Science PlanThomasina HubbardNo ratings yet

- Family Nursing Care PlanDocument34 pagesFamily Nursing Care PlanJai - Ho57% (14)

- Monroe County Fallout Shelter ProgrzamOVERVIEWDocument2 pagesMonroe County Fallout Shelter ProgrzamOVERVIEWRobert GatesNo ratings yet

- Introduction to Water and Wastewater Treatment ProcessesDocument202 pagesIntroduction to Water and Wastewater Treatment ProcessesChristian D. Orbe100% (1)

- Saber and Shadow - S. M. StirlingDocument518 pagesSaber and Shadow - S. M. StirlingPeter McLaughlin100% (1)

- GIS-Based Derivation of Unit Hydrograph for Rukni River Watershed in IndiaDocument9 pagesGIS-Based Derivation of Unit Hydrograph for Rukni River Watershed in IndiaPatrick Joseph RoblesNo ratings yet

- CSEC-Chemistry-p2 May-June 2012 PDFDocument20 pagesCSEC-Chemistry-p2 May-June 2012 PDFdela250% (4)

- Arahan Makmal Sem 11718-NewDocument18 pagesArahan Makmal Sem 11718-NewAidaFarzanaNanaNo ratings yet

- FISPQ - Lauril Eter Sulfato S Dio 70 Rev 01 2019 GHS enDocument7 pagesFISPQ - Lauril Eter Sulfato S Dio 70 Rev 01 2019 GHS enMarko NenkNo ratings yet

- Propoasal FinalDocument47 pagesPropoasal FinaldebelaNo ratings yet

- T685WSDocument2 pagesT685WSHerman BugueñoNo ratings yet

- GSKY Green Wall Panel Installation on Concrete WallDocument1 pageGSKY Green Wall Panel Installation on Concrete WallAbbasi HussainNo ratings yet

- I. Nature of PetitionDocument77 pagesI. Nature of PetitionMaxShelbyNo ratings yet

- Air Masses and Fronts LectureDocument23 pagesAir Masses and Fronts LectureA S VermaNo ratings yet

- Warranty Book FullDocument27 pagesWarranty Book FullGeemoNo ratings yet

- KDF GAC Filters and HousingsDocument37 pagesKDF GAC Filters and HousingsGreen EnergyNo ratings yet

- Solar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaDocument10 pagesSolar Stills For Desalination of Water in Rural Households: Amitava BhattacharyyaTrimo Wahyu Bimantoro100% (1)

- 10.6.1 Conexiones Domiciliarias de Agua Potable - Sector 1Document1 page10.6.1 Conexiones Domiciliarias de Agua Potable - Sector 1Giovany Levano SaldañaNo ratings yet

- Household ProductsDocument5 pagesHousehold Productsr'BrilePonjeNo ratings yet

- Planning and management of aquaculture parks for sustainable development of cage farms in the PhilippinesDocument74 pagesPlanning and management of aquaculture parks for sustainable development of cage farms in the PhilippinesHafez MabroukNo ratings yet

- Design and startup tips for decoupled aquaponic systemsDocument22 pagesDesign and startup tips for decoupled aquaponic systemsCristian AcevedoNo ratings yet

- IoT-Based Data Analytics For Freshwater Prawn Hatchery in MSC College of Fisheries and Aquatic SciencesDocument36 pagesIoT-Based Data Analytics For Freshwater Prawn Hatchery in MSC College of Fisheries and Aquatic SciencesCharlene Joy LayaoNo ratings yet

- Brine Discharge - Quick ResearchDocument3 pagesBrine Discharge - Quick Researchrodel manaloNo ratings yet

- Flood Contingency Plan for MalapatanDocument100 pagesFlood Contingency Plan for MalapatanJonathan GutangNo ratings yet

- How leaves and roots help plants make their own foodDocument11 pagesHow leaves and roots help plants make their own foodLeocarl Fabunan Simon RANo ratings yet

- Coca ColaDocument25 pagesCoca ColaKush BansalNo ratings yet

- Flora: Leh Ladakh Jammu and Kashmir IndiaDocument39 pagesFlora: Leh Ladakh Jammu and Kashmir IndiamahadevanNo ratings yet

- 85386lytronDocument15 pages85386lytronRamon Alberto Portillo MedinaNo ratings yet

- Marinem Advisory 01 - 2023 - Guidance For Recording Entries in The Ballast Water Record BookDocument7 pagesMarinem Advisory 01 - 2023 - Guidance For Recording Entries in The Ballast Water Record BookSteliosNo ratings yet

- CD Module Datasheet PDFDocument8 pagesCD Module Datasheet PDFunconformistNo ratings yet