Professional Documents

Culture Documents

Dctrectre

Uploaded by

Marian DunareanuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dctrectre

Uploaded by

Marian DunareanuCopyright:

Available Formats

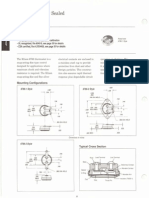

Teohnioa| 8eoifioations:

6ripper can be meunted and eperated in any erientatien

Nountin Information:

knu|ar 0riers-

180 8rin kssist

8eries

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Fneumatic 8pecificatiens ImperiaI Metric

Pressure 0perating Range 60-100 ps| 4-7 bar

C]linder T]pe 0o0b|e Act|og Spr|og

Ass|st or S|og|e Act|og

Spr|og 8et0ro

D]namic 8eals |oteroa||y L0br|cated 80oa-h

Valve Required to 0perate 4-way, 2-pos|t|oo

Air 0uaIity 8equirements

Air Filtration 40 N|croo or 8etter

Air luorication hot hecessary*

Air Humidit] Low No|st0re 0ooteot (dry)

emperature 0perating 8ange

Buna-h8eals (8tandardj -30~180 F -35~80 0

Viton

8eals (0ptionalj -20~300 F -30~150 0

Maintenance 8pecificatiens

|

Expected life

hormal Application 5 m||||oo cyc|es

w/ Preventative Naintenance 10+ m||||oo cyc|es*

Field Repairaole Yes

8eal Repair Kits Availaole Yes

*Addition of luorication will greatl] increase service life

|

8ee Naintenance 8ection

2.44

0

0

T

-

8

l

0

T

-

8

8

I

8

0ripper is located from the

top with 2 dowel pins and

assemoled with 2 screws.

Fingers are centered over the

jaws, located with 1 dowel pin

and assemoled with 2 screws.

The gripper

is protected

from falling

deoris when

it is mounted

and operated

upside down.

0ripper can oe

operated utilizing top

manifold air ports.

DlRECTC0hhECT mounting pattern.

0ripper is located with 2 dowel pins

and assemoled with 4 screws.

Alternative pattern. 0ripper is

located with 2 dowel pins and

assemoled with 2 screws.

180 anguIar gripper.

The full jaw opening (18Oj means

that the part can oe direct fed,

avoiding an] release movement

o] the rooot or o] the actuator.

MuItipIe meunting Iecatiens.

DlRECTC0hhECT

mounting on

oack of ood] (sizes 12-25j.

8tandard mounting on top.

FaiI safe eperatien.

The force supplied from the

internal spring can oe used to

maintain gripping force if the

gripper looses air pressure.

0empact gripper.

This gripper is designed for

use in confined spaces.

MuItipurpese gripper.

8everal accessories (adjustaole

stop, magneto resistive or inductive

sensorsj allow this gripper to oe used

in a numoer of applications.

arsh envirenments.

8hielded design repels chips

and other particulate from internal

drive mechanism.

Produot Features

A douole acting piston, with a ring magnet for magneto resistive sensing, is

connected to a fork driver on which 2 drive pins are fixed.

Jaw rotation is s]nchronized with the drive pin-jaw assemol].

8liding in these slots, drive pins convert vertical motion of the piston into

rotating opposite s]nchronous motion of ooth jaws.

Each jaw has a useful rotation stroke of 9O, oetween the 9O open position

and the O gripping position, plus a gripping over-stroke of approximatel]

1.5 oefore reaching the full] gripped position. Jaws have to oe designed for

a O gripping position (parallel jawsj

The fail safe spring allow the gripper to retain the component should the air

suppl] fail or for the gripper to oe used in single acting mode.

0eratin Prinoi|e

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8ee

Page 2.46

8ty|e -00T-8 knu|ar 0rier

8ize -12N

2.45

0

0

T

-

8

l

0

T

-

8

8

I

8

Sty|e: 00T-12N-8

Stroke: 9O each finger

6r|p Force: 9 los 4O h

we|ght: O.2O los O.12 Kg

8ee

Page 2.47

8ty|e -00T-8 knu|ar 0rier

8ize -16N

Sty|e: 00T-16N-8

Stroke: 9O each finger

6r|p Force: 19 los 87 h

we|ght: O.44 los O.2O Kg

8ee

Page 2.48

8ty|e -00T-8 knu|ar 0rier

8ize -20N

Sty|e: 00T-20N-8

Stroke: 9O each finger

6r|p Force: 82 los 141 h

we|ght: O.78 los O.88 Kg

8ee

Page 2.49

8ty|e -00T-8 knu|ar 0rier

8ize -25N

Sty|e: 00T-25N-8

Stroke: 9O each finger

6r|p Force: 45 los 199 hm

we|ght: 1.2O los O.57 Kg

8ee

Page 2.50

8ty|e -0T-8 knu|ar 0rier

8ize -32N

Sty|e: 0T-32N-8

Stroke: 9O each finger

6r|p Force: 79 los 858 h

we|ght: 1.88 los O.88 Kg

8ee

Page 2.51

8ty|e -0T-8 knu|ar 0rier

8ize -40N

Sty|e: 0T-40N-8

Stroke: 9O each finger

6r|p Force: 188 los 592 h

we|ght: 8.OO los 1.89 Kg

8ee

Page 2.52

8ty|e -0T-8 knu|ar 0rier

8ize -50N

Sty|e: 0T-50N-8

Stroke: 9O each finger

6r|p Force: 2O1 in-los 898 h

we|ght: 4.87 los 2.21 Kg

Press0re

xha0st

xha0st

Press0re

8ody

0ap

P|stoo

Nagoet

0r|ve P|o S|ot

0r|ver

Jaw

Sh|e|ded P|ate

P|vot P|o

w|per 0over

Fa|| SaIe Spr|og

0r|ve P|o

8hieIded

FIate and wiper

0evers

0ripper ood] is shielded

to repel chips and other

particulate from internal

drive mechanism

Inductive 8enser

Meunting kit

Accessor] (8Dj in order

to control jaw position.

comes with 2 holders for

tuoular sensors and

2 adjustaole flags

(except size -12j

AdjustabIe 8tep

Accessor] (BRj in order to

adjust the opening of jaws,

oetween O to 18O

FaiI 8afe 8pring

lnternal spring allows

the gripper to hold onto

part with loss of air

pressure

Magnete 8esistive

8enser Meunting kit

The gripper comes with adjustaole

slots for the 2 magnetic sensors

(to control jaw positionj

MuItipIe

Air Ferts

8ide or top air

ports (top ports

require 0-ringj

6ripper Attachment

0ripper mounting from

side or oottom

iten 8eaIs

Viton seals for high temperatures

(-2OF to +8OOF / -8O~15O Cj

are optional

0uaIity

0empenents

Nade from aluminum

allo] anodized with

Teflon

impregnation.

The gripper's main

components are made

of heat treated steel.

Meunting Fatterns

DlRECTC0hhECT

mounting surface on oack

of ood] (sizes 12-25j

kh00Lk8 08IPP8 00T-12N-8

180 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 00-12M-8

Total Rated 0rip Force, F @ 1OO psi [7 oar|

L = 1 in. [25mm| @ O............................ 9 los. 4O h

8troke........................................................ 9O of stroke for each finger

weight ....................................................... O.2O los. O.12 Kg

Pressure Range ......................................... OO-1OO psi 4-7 Bar

C]linder Bore 0.......................................... O.472 in. 12 mm

Displacement............................................. O.117 in

8

. 1.92 cm

8

Temperature Range

8tandard 8eals ....................................... -8O~18O F -85~8O C

Viton

8eals ............................................ -2O~8OO F -8O~15O C

Actuation (open/closej ............................... O.O8 / O.O5 sec.

Accurac].................................................... O.OO28 in. O.O7 mm

Repeataoilit].............................................. O.OO2 in. O.O5 mm

Valve required to actuate single acting...... 8-wa], 2-position

Valve required to actuate douole acting .... 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

0.59 [15|

MAX.

0.20 [5|

ADJUSTABLE

STOP KlT (BRj

0.31 [8|

M4

Loadin Information

Leading 0apacity

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 11 los. 47 h 2 los. 9.4 h

Naximum Compressive 0 11 los. 47 h 2 los. 9.4 h

Naximum Noment M

x

1O in.-los. 1.1 hm 8 in.-los. 1.1 hm

Naximum Noment M

y

1O in.-los. 1.1 hm 8 in.-los. 1.1 hm

Naximum Noment M

z

1O in.-los. 1.1 hm 8 in.-los. 1.1 hm

|

Capacities are per set of jaws and are not simultaneous

L

X

F/2 F/2

Z

Mz

My

Z

Y

C

T

Mx

5

4

3

2

1

0

20

16

12

8

4

0

|bs. h

EFFECTlVE Flh0ER lEh0TH FR0N R0TATl0h AXl8 -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68 @ 0

1

25

1.5

35

3 |o.

76mm

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

2.0

50

2.5

64

1OO

P8l [7

oar|

8O

P8l [5.5

oar| GO P8l [4.1 oar|

4O P8l [2.7 oar|

2O P8l [1.8 oar|

O P8l [O oar|

8h808 k008808I8 0808 = 0TYl0hIT

PhP Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8P-017 1 or 2

hPh Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8h-017 1 or 2

0uick Disconnect 2 Neter Caole length

*

0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length

*

0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Adj. Flow Control N5 Eloow - Omm 0D Push-in (Netricj VLVF-008 1 or 2

Buna-h8eal Repair Kit 8LkT-159 1

Viton

8eal Repair Kit 8LkT-159V 1

N00hTIh0 k008808I8

Adjustment 8top Kit (1 8hielded Plate + 1 8topj kP-00T12-88 1

*8ensor and caole sold separatel].

2.46

0

0

T

-

8

8

I

8

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

90 90

1.437

36.5

0.35

9

2 Slots to mount

magnetic sensors

2.028

51.5

C

L

C

L

1.18

30

[M

OPEN

3 x 5.5 DP|

0.9646

24.50

CLOSE

(supplied pluggedj

x 5.5 DP|

Top air port

(supplied pluggedj

Top air port

9

0.35

20

0.79

8.6

0.339

x 7 DP| 3 2 x [M

0.5709

14.50

[M3

2 x [ 2.5H9 x 4.5 DP|

C

L

C

L

x 6 DP|

OPEN

Side air port

0.0002

1.6

2.8346

0.650

5 [M

9

2 x [M

-

0.0005 - 0.2362

| THRU 3

0.39

72.00

16.5

0.31

8

0.35

Side air port

CLOSE

x 6 DP| 5 [M

10

0.063

2.52

64

[6g6|

[ 2.5E7| THRU

C

L

Shielded plate

Jaws in

gripping

position

at 0

C

L

14.50

0.5709 3 x 7 DP|

25

0.9646

24.50

0.236

18

2 x [M

80

3.15

6.0

0.98

35.00

1.3780

0.71

0.4921

12.50

2 x [ 2.5H7 x 4.5 DP|

4 x [M3

2 x [

9.5

0.375

3H7 x 6 DP|

19.05

0.7500

x 7 DP|

O-Ring [ 1 x 3]

Gripper's

top air port

Our grippers are supplied with

open side air ports and top air

ports plugged. When operating

top air ports, produce manifold

sealing as shown.

vlEW A-A

A A

h0T: Jaws have to oe designed for a O gripping position (parallel jawsj.

Jaws will close 1.5 past parallel. To limit shocks at the end of an opening or

closing stroke, it is highl] recommended to design jaws with minimal inertia

(as light and short as possiolej.

Flow Controls make it possiole to reduce the rotation speed and are highl]

recommended.

00 - 12M- 8 -

8II 8P8Ih0

8k8I0 N00L VIT0h

O

8kL8

h0T: DCT-12-RE can oe used as

an exact replacement for CT-12-RE

kh00Lk8 08IPP8 00T-16N-8

180 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

2.47

0

0

T

-

8

8

I

8pecificatiens 00-16M-8

Total Rated 0rip Force, F @ 1OO psi [7 oar|

L = 1 in. [25mm| @ O............................ 19 los. 87 h

8troke........................................................ 9O of stroke for each finger

weight ....................................................... O.44 los. O.2O Kg

Pressure Range ......................................... OO-1OO psi 4-7 Bar

C]linder Bore 0.......................................... O.O8O in. 1O mm

Displacement............................................. O.251 in

8

. 4.12 cm

8

Temperature Range

8tandard 8eals ....................................... -8O~18O F -85~8O C

Viton

8eals ............................................ -2O~8OO F -8O~15O C

Actuation (open/closej ............................... O.15 / O.12 sec.

Accurac].................................................... O.OO28 in. O.O7 mm

Repeataoilit].............................................. O.OO2 in. O.O5 mm.

Valve required to actuate single acting...... 8-wa], 2-position

Valve required to actuate douole acting .... 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

0.79 [20|

MAX.

0.24 [6|

0.31 [8|

0.46 [11.7|

0.59 [15|

0.22 [5.5|

0.48 [12.3|

1.40 [35.5|

lNDUCTlvE SENSORS AND

MOUNTlNG KlT (SDj

ADJUSTABLE

STOP KlT (BRj

0.16 [4|

2.38 [60.5|

0.24 [6|

Sensors

0.16 [4|

0.39 [10|

M5

Loadin Information

Leading 0apacity

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 2O los. 9O h 4 los. 18 h

Naximum Compressive 0 2O los. 9O h 4 los. 18 h

Naximum Noment M

x

2O in.-los. 2.9 hm O in.-los. O.7 hm

Naximum Noment M

y

2O in.-los. 2.9 hm O in.-los. O.7 hm

Naximum Noment M

z

2O in.-los. 2.9 hm O in.-los. O.7 hm

|

Capacities are per set of jaws and are not simultaneous

L

X

F/2 F/2

Z

Mz

My

Z

Y

C

T

Mx

11

9

7

4

2

0

50

40

30

20

10

0

|bs. h

EFFECTlVE Flh0ER lEh0TH FR0N R0TATl0h AXl8 -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68 @ 0

1

25

1.5

35

3 |o.

76mm

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

2.0

50

2.5

64

1

O

O

P

8

l

[7

o

a

r|

8

O

P

8

l

[5

.5

o

a

r| GO

P8l [4.1

oar|

4O P8l [2.7 oar|

2O P8l [1.8 oar|

O P8l [O oar|

8h808 k008808I8 0808 = 0TYl0hIT

PhP Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8P-017 1 or 2

hPh Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8h-017 1 or 2

lnductive 8ensor Nounting Kit (mounts 2 sensorsj 800T16-20 1

4mm PhP lnductive 8ensor with 0uick Disconnect* 0I8P-014 1 or 2

4mm hPh lnductive 8ensor with 0uick Disconnect* 0I8h-014 1 or 2

0uick Disconnect 2 Neter Caole length

*

0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length

*

0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Adj. Flow Control N5 Eloow - Omm 0D Push-in (Netricj VLVF-008 1 or 2

Buna-h8eal Repair Kit 8LkT-160 1

Viton

8eal Repair Kit 8LkT-160V 1

N00hTIh0 k008808I8

Adjustment 8top Kit (1 8hielded Plate + 1 8topj kP-00T16-88 1

*8ensor and caole sold separatel].

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

0.453

11.5

17

1.594

0.67

90

40.5

90

0.35

9

C

L

C

L

x 5.5 DP|

OPEN

CLOSE

(supplied pluggedj

x 5.5 DP|

Top air port

[M3

[M3

1.42

36

1.1417

29.00

9

0.35

x 9 DP| 4 2 x [M

10

0.39

25

0.98

Top air port

(supplied pluggedj

0.7087

18.00

2 x [ 3H9 x 5.5 DP|

C

L

C

L

C

L

x 6 DP| [M

0.3150 -

Side air port

5

0.31

20.5

0.0002

2

0.807

E7| THRU [ 2.5

10

79.00

10

| THRU 3 2 x [M

-

0.0006

0.39

0.39

3.1102

8

Side air port

CLOSE

x 6 DP| 5 [M

OPEN

0.08

2.80

71

[8g6|

2 Slots to mount

magnetic sensors

56.5

2.224

1.516

38.5

4 x [M3 x 5.5 DP|

C

L

Shielded plate

Jaws in

gripping

position

at 0

C

L

2 x [M4 x 9 DP|

18.00

0.7087

3.43

87

8.0

0.315

20

0.79

29.00

1.1417

1.043

26.5

35.00

1.3780

0.5512

14.00

2 x [ 3H9 x 5.5 DP|

4 x [M x 7 DP|

H7 x 6 DP|

0.7500

19.05

3 2 x [

0.375

9.5

3

0

.

0

3

0

.

8

0.12

3

0.2

5

O-Ring [ 1 x 3|

Gripper's

top air port

Our grippers are supplied with

open side air ports and top air

ports plugged. When operating

top air ports, produce manifold

sealing as shown.

vlEW A-A

A A

h0T: Jaws have to oe designed for a O gripping position (parallel jawsj.

Jaws will close 1.5 past parallel. To limit shocks at the end of an opening or

closing stroke, it is highl] recommended to design jaws with minimal inertia

(as light and short as possiolej.

Flow Controls make it possiole to reduce the rotation speed and are highl]

recommended.

00 - 16M- 8 -

8II 8P8Ih0

8k8I0 N00L VIT0h

O

8kL8

h0T: DCT-1O-RE can oe used as

an exact replacement for CT-1O-RE

kh00Lk8 08IPP8 00T-20N-8

180 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 00-20M-8

Total Rated 0rip Force, F @ 1OO psi [7 oar|

L = 1.25 in. [82mm| @ O....................... 82 los. 141 h

8troke........................................................ 9O of stroke for each finger

weight ....................................................... O.78 los. O.88 Kg

Pressure Range ......................................... OO-1OO psi 4-7 Bar

C]linder Bore 0.......................................... O.787 in. 2O mm

Displacement............................................. O.488 in

8

. 7.92 cm

8

Temperature Range

8tandard 8eals ....................................... -8O~18O F -85~8O C

Viton

8eals ............................................ -2O~8OO F -8O~15O C

Actuation (open/closej ............................... O.2O / O.14 sec.

Accurac].................................................... O.OO8 in. O.O8 mm

Repeataoilit].............................................. O.OO2 in. O.O5 mm

Valve required to actuate single acting...... 8-wa], 2-position

Valve required to actuate douole acting .... 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

0.98 [25|

MAX.

0.31 [8|

0.31 [8|

0.46 [11.7|

0.59 [15|

0.48 [8|

0.48 [12.3|

1.73 [44|

lNDUCTlvE SENSORS AND

MOUNTlNG KlT (SDj

ADJUSTABLE

STOP KlT (BRj

0.14 [3.5|

2.79 [71|

0.24 [6|

Sensors

0.16 [4|

0.47 [12|

M6

Loadin Information

Leading 0apacity

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 84 los. 15O h 7 los. 8O h

Naximum Compressive 0 84 los. 15O h 7 los. 8O h

Naximum Noment M

x

58 in.-los. O hm 18 in.-los. 1.5 hm

Naximum Noment M

y

58 in.-los. O hm 18 in.-los. 1.5 hm

Naximum Noment M

z

58 in.-los. O hm 18 in.-los. 1.5 hm

|

Capacities are per set of jaws and are not simultaneous

L

X

F/2 F/2

Z

Mz

My

Z

Y

C

T

Mx

16

13

11

9

7

4

2

0

70

60

50

40

30

20

10

0

|bs. h

EFFECTlVE Flh0ER lEh0TH FR0N R0TATl0h AXl8 -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68 @ 0

1.25

32

1.75

44

2.25

57

2.75

70

3.25 |o.

83mm

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

1

O

O

P

8

l

[7

o

a

r|

8

O

P

8

l [5

.5

oar|

GO

P8l [4.1

oar| 4O P8l [2.7 oar|

2O P8l [1.8 oar|

O P8l [O oar|

8h808 k008808I8 0808 = 0TYl0hIT

PhP Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8P-017 1 or 2

hPh Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8h-017 1 or 2

lnductive 8ensor Nounting Kit (mounts 2 sensorsj 800T16-20 1

4mm PhP lnductive 8ensor with 0uick Disconnect* 0I8P-014 1 or 2

4mm hPh lnductive 8ensor with 0uick Disconnect* 0I8h-014 1 or 2

0uick Disconnect 2 Neter Caole length

*

0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length

*

0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Adj. Flow Control N5 Eloow - Omm 0D Push-in (Netricj VLVF-008 1 or 2

Buna-h8eal Repair Kit 8LkT-161 1

Viton

8eal Repair Kit 8LkT-161V 1

N00hTIh0 k008808I8

Adjustment 8top Kit (1 8hielded Plate + 1 8topj kP-00T20-88 1

*8ensor and caole sold separatel].

2.48

0

0

T

-

8

8

I

8

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

0.531

13.5

22

0.87

49.5

47

90

1.85

1.949

90

C

L

C

L

OPEN

(supplied pluggedj

CLOSE

(supplied pluggedj

x 5.5 DP|

Top air port

[M3 x 5.5 DP|

[M3

42

1.65

1.3189

33.50

10

x 11 DP| 5 2 x [M

11

0.43

30

1.18

Top air port

0.39

0.8465

21.50

2 x [ 4H9 x 8 DP|

C

L

Shielded plate

Jaws in

gripping

position

at 0

C

L

39.00

2 x [ 4H9 x 8 DP|

21.50

0.8465

4.09

104

10.0

0.394

22

0.87

33.50

1.3189

1.30

33

2 x [M5 x 11 DP|

1.5354

0.78740

20.00

C

L C

L

C

L

x 6 DP| [M

0.3937 -

[

Side air port

5

3.7008

[M5 x 6 DP|

CLOSE

Side air port

25

0.31

8

12

94.00

0.96

2.6

3

0.0002

| THRU 4 2 x [M

-

0.0006

E7| THRU

0.43

0.47

11

OPEN

0.102

3.27

83

[10g6|

2 Slots to mount

magnetic sensors

66.5

2.618

0.35

9

4 x [M3 x 5.5 DP|

19.05

0.7500

x 6 DP|

H7 x 6 DP| 2 x [

0.375

9.5

3

3 4 x [M

0

.

0

3

0

.

8

0.12

3

0.2

5

O-Ring [ 1 x 3|

Gripper's

top air port

Our grippers are supplied with

open side air ports and top air

ports plugged. When operating

top air ports, produce manifold

sealing as shown.

vlEW A-A

A A

h0T: Jaws have to oe designed for a O gripping position (parallel jawsj.

Jaws will close 1.5 past parallel. To limit shocks at the end of an opening or

closing stroke, it is highl] recommended to design jaws with minimal inertia

(as light and short as possiolej.

Flow Controls make it possiole to reduce the rotation speed and are highl]

recommended.

00 - 20M- 8 -

8II 8P8Ih0

8k8I0 N00L VIT0h

O

8kL8

h0T: DCT-2O-RE can oe used as

an exact replacement for CT-2O-RE

kh00Lk8 08IPP8 00T-25N-8

180 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

2.49

0

0

T

-

8

8

I

8pecificatiens 00-25M-8

Total Rated 0rip Force, F @ 1OO psi [7 oar|

L = 1.75 in. [44mm| @ O....................... 45 los. 199 h

8troke........................................................ 9O of stroke for each finger

weight ....................................................... 1.2O los. O.57 Kg

Pressure Range ......................................... OO-1OO psi 4-7 Bar

C]linder Bore 0.......................................... O.984 in. 25 mm

Displacement............................................. O.9O9 in

8

. 14.9 cm

8

Temperature Range

8tandard 8eals ....................................... -8O~18O F -85~8O C

Viton

8eals ............................................ -2O~8OO F -8O~15O C

Actuation (open/closej ............................... O.25 / O.19 sec.

Accurac].................................................... O.OO8 in. O.O8 mm

Repeataoilit].............................................. O.OO2 in. O.O5 mm.

Valve required to actuate single acting...... 8-wa], 2-position

Valve required to actuate douole acting .... 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

1.18 [30|

MAX.

0.39 [10|

0.43 [11|

0.63 [16|

0.63 [16|

0.37 [9.5|

0.79 [20|

2.21 [56.2|

lNDUCTlvE SENSORS AND

MOUNTlNG KlT (SDj

ADJUSTABLE

STOP KlT (BRj

0.18 [4.5|

3.44 [87.5|

0.39 [10|

Sensors

0.31 [8|

0.55 [14|

M6

Loadin Information

Leading 0apacity

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 4O los. 2O5 h 9 los. 41 h

Naximum Compressive 0 4O los. 2O5 h 9 los. 41 h

Naximum Noment M

x

89 in.-los. 1O hm 22 in.-los. 2.5 hm

Naximum Noment M

y

89 in.-los. 1O hm 22 in.-los. 2.5 hm

Naximum Noment M

z

89 in.-los. 1O hm 22 in.-los. 2.5 hm

|

Capacities are per set of jaws and are not simultaneous

L

X

F/2 F/2

Z

Mz

My

Z

Y

C

T

Mx

22

18

13

9

4

0

100

80

60

40

20

0

|bs. h

EFFECTlVE Flh0ER lEh0TH FR0N R0TATl0h AXl8 -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68 @ 0

1.75

44

2.25

57

2.75

70

3.25

81

3.75

95

4.25

108

4.75 |o.

121mm

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

1

O

O

P

8

l

[7

o

a

r| 8O

P8

l [5.5

oar|

GO

P8l [4.1

oar|

2O P8l [1.8 oar|

4O P8l [2.7 oar|

O P8l [O oar|

8h808 k008808I8 0808 = 0TYl0hIT

PhP Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8P-017 1 or 2

hPh Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8h-017 1 or 2

lnductive 8ensor Nounting Kit (mounts 2 sensorsj 800T25-32 1

N8 PhP lnductive 8ensor with 0uick Disconnect* 0I8P-011 1 or 2

N8 hPh lnductive 8ensor with 0uick Disconnect* 0I8h-011 1 or 2

0uick Disconnect 2 Neter Caole length

*

0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length

*

0k8L-013 1 or 2

Ph0NkTI0 k008808I8

N5 Adjustaole Flow Control VLVF-008 1 or 2

Buna-h8eal Repair Kit 8LkT-162 1

Viton

8eal Repair Kit 8LkT-162V 1

N00hTIh0 k008808I8

Adjustment 8top Kit (1 8hielded Plate + 1 8topj kP-00T25-88 1

*8ensor and caole sold separatel].

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

5.00

127

0.47

12

1.02

26

2.0079

51.00

Shielded plate

Jaws in

gripping

position

at 0

C

L

0.47

12

2 x [M6 x 13 DP|

0.43

11

1.42

36

0.69

18

[M5 x 6 DP|

OPEN

(supplied pluggedj

[M5 x 6 DP|

CLOSE

(supplied pluggedj

1.5748

40.00

1.0236

26.00

2 x 0.1969 SF

x 0.39 [10| DP

[ 5H9|

0.689

17.5

C

L

C

L

4.5079

114.50

0.59

15

0.4724 -0.0007

-0.0002

2 x [M5|

0.1575 SF

1.122

28.5

0.39

10

0.43

11 [M5 x 6 DP|

CLOSE

[M5 x 6 DP|

OPEN

0.130

3.3

4.02

102

[ 4E7|

[12g6|

C

L

C

L

C

L

3.23

82

0.295

7.5

2.382

60.5

1.043

26.5

4 x [M3 x 7 DP|

0.98

25.00

1.02

26.00

1.57

40.00

90 90

2.32

59

2 Slots to mount

magnetic sensors

0

.

0

3

0

.

8

0.12

3

0.2

5

O-Ring [ 1 x 3|

Gripper's

top air port

Our grippers are supplied with

open side air ports and top air

ports plugged. When operating

top air ports, produce manifold

sealing as shown.

1.5000

(Dowelsj

38.10

0.750

19.1

4 x [M5 x 11 DP|

2 x [ 5H7 x 10 DP|

2x[ 5 H9 x10DP|

C

L

vlEW A-A

A A

h0T: Jaws have to oe designed for a O gripping position (parallel jawsj.

Jaws will close 1.5 past parallel. To limit shocks at the end of an opening or

closing stroke, it is highl] recommended to design jaws with minimal inertia

(as light and short as possiolej.

Flow Controls make it possiole to reduce the rotation speed and are highl]

recommended.

00 - 25M- 8 -

8II 8P8Ih0

8k8I0 N00L VIT0h

O

8kL8

kh00Lk8 08IPP8 0T-32N-8

180 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 0-32M-8

Total Rated 0rip Force, F @ 1OO psi [7 oar|

L = 1.75 in. [44mm| @ O.................. 79 los. 858 h

8troke........................................................ 9O of stroke for each finger

weight ....................................................... 1.88 los. O.88 Kg

Pressure Range ......................................... OO-1OO psi 4-7 Bar

C]linder Bore 0.......................................... 1.2OO in. 82 mm

Displacement............................................. 1.745 in

8

. 28.O cm

8

Temperature Range

8tandard 8eals ....................................... -8O~18O F -85~8O C

Viton

8eals ............................................ -2O~8OO F -8O~15O C

Actuation (open/closej ............................... O.85 / O.2O sec.

Accurac].................................................... O.OO8 in. O.O8 mm

Repeataoilit].............................................. O.OO2 in. O.O5 mm

Valve required to actuate single acting...... 8-wa], 2-position

Valve required to actuate douole acting .... 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

1.40 [35|

MAX.

0.47 [12|

0.43 [11|

0.63 [16|

0.63 [16|

0.47 [12|

0.79 [20|

2.68 [68.2|

lNDUCTlvE SENSORS AND

MOUNTlNG KlT (SDj

ADJUSTABLE

STOP KlT (BRj

0.16 [4|

3.94 [100|

0.39 [10|

Sensors

0.31 [8|

0.63 [16|

M8

Loadin Information

Leading 0apacity

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile O5 los. 288 h 18 los. 57.O h

Naximum Compressive 0 O5 los. 288 h 18 los. 57.O h

Naximum Noment M

x

142 in.-los. 1O hm 85 in.-los. 4 hm

Naximum Noment M

y

142 in.-los. 1O hm 85 in.-los. 4 hm

Naximum Noment M

z

142 in.-los. 1O hm 85 in.-los. 4 hm

|

Capacities are per set of jaws and are not simultaneous

L

X

F/2 F/2

Z

Mz

My

Z

Y

C

T

Mx

40

34

27

20

13

7

0

180

150

120

90

60

30

0

|bs. h

EFFECTlVE Flh0ER lEh0TH FR0N R0TATl0h AXl8 -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68 @ 0

1.75

44

2.25

57

2.75

70

3.25

81

4.25

108

3.75

95

4.75

120

5.25

133

5.75 |o.

146mm

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

1

O

O

P

8

l

[7

o

a

r|

8

O

P

8

l

[5

.5

o

a

r|

GO

P8l [4.1

oar| 4O P8l [2.7 oar|

2O P8l [1.8 oar|

O P8l [O oar|

8h808 k008808I8 0808 = 0TYl0hIT

PhP Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8P-017 1 or 2

hPh Nagneto Resistive 8ensor 8hort Barrel w/0k Disc* 0h8h-017 1 or 2

lnductive 8ensor Nounting Kit (mounts 2 sensorsj 800T25-32 1

N8 PhP lnductive 8ensor with 0uick Disconnect* 0I8P-011 1 or 2

N8 hPh lnductive 8ensor with 0uick Disconnect* 0I8h-011 1 or 2

0uick Disconnect 2 Neter Caole length

*

0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length

*

0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Adj. Flow Control N5 Eloow - Omm 0D Push-in (Netricj VLVF-008 1 or 2

Buna-h8eal Repair Kit 8LkT-163 1

Viton

8eal Repair Kit 8LkT-163V 1

N00hTIh0 k008808I8

Adjustment 8top Kit (1 8hielded Plate + 1 8topj kP-0T32-88 1

*8ensor and caole sold separatel].

2.50

0

0

T

-

8

8

I

8

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.1417 0.0006

29 0.016

0.2362 0.0000

+0.0012

x 0.47 [12] DP

6 0

+0.03

0.551

14

2 x M8 x 0.67 [17] DP

1.1811 0.0010

30 0.026

1.6929 0.0007

43 0.019

1.77

45

Shielded plate

C

L

0.75

19

2 x M8

x 0.67 [17] DP

0.47

12

1.65

42

2.20

56

M5 x 0.24 [6] DP

OPEN

(supplied plugged)

Top air por t

M5 x 0.24 [6] DP

CLOSE

(supplied plugged)

Top air por t

1.6929 0.0007

43 0.019

1.1417 0.0006

29 0.016

2 x 0.2362 0.0000

+0.0012

x 0.47 [12] DP

6 0

+0.03

0.85

21.5

C

L

C

L

5.1575 0.0049

131 0.125

0.5512 - 0.0007

- 0.0002

14 - 0.017

- 0.006

2 x M6

0.1969 +0.0008

+0.0013

5 +0.020

+0.032

1.30

33

0.47

12

0.47

12

M5 x 0.24 [6] DP

CLOSE

Side air port

M5 x 0.24 [6] DP

OPEN

Side air port

0.15

3.9

4.57

116

C

L

C

L

3.70

94

0.30

7.50

2.85

72.50

1.24

31.50

4 x [M3 x 7]

90

2.64

67

90

2 Slots to mount

magnetic sensors

0

.0

5

1

.

2

0.14

4

0.31

8

O-Ring [1.5 x 5|

Gripper's

top air port

Our grippers are supplied with

open side air ports and top air

ports plugged. When operating

top air ports, produce manifold

sealing as shown.

vlEW A-A

A A

h0T: Jaws have to oe designed for a O gripping position (parallel jawsj.

Jaws will close 1.5 past parallel. To limit shocks at the end of an opening or

closing stroke, it is highl] recommended to design jaws with minimal inertia

(as light and short as possiolej.

Flow Controls make it possiole to reduce the rotation speed and are highl]

recommended.

0 - 32M- 8 -

8II 8P8Ih0

8k8I0 N00L VIT0h

O

8kL8

kh00Lk8 08IPP8 0T-40N-8

180 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

2.51

0

0

T

-

8

8

I

8

8pecificatiens 0-40M-8

Total Rated 0rip Force, F @ 1OO psi [7 oar|

L = 2 in. [51mm| @ O............................ 188 los. 592 h

8troke........................................................ 9O of stroke for each finger

weight ....................................................... 8.OO los. 1.89 Kg

Pressure Range ......................................... OO-1OO psi 4-7 Bar

C]linder Bore 0.......................................... 1.575 in. 4O mm

Displacement............................................. 8.178 in

8

. 52 cm

8

Temperature Range

8tandard 8eals ....................................... -8O~18O F -85~8O C

Viton

8eals ............................................ -2O~8OO F -8O~15O C

Actuation (open/closej ............................... O.47 / O.88 sec.

Accurac].................................................... O.OO8O in. O.O9 mm

Repeataoilit].............................................. O.OO2 in. O.O5 mm.

Valve required to actuate single acting...... 8-wa], 2-position

Valve required to actuate douole acting .... 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

1.57 [40|

MAX.

0.47 [12|

0.69 [17.5|

0.83 [21|

1.18 [30|

0.57 [14.5|

0.87 [22|

2.87 [73|

lNDUCTlvE SENSORS AND

MOUNTlNG KlT (SDj

ADJUSTABLE

STOP KlT (BRj

0.22 [5.5|

4.59 [116.5|

0.39 [10|

Sensors

0.47 [12|

0.63 [16|

M8

Loadin Information

Leading 0apacity

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 94 los. 42O h 19 los. 84 h

Naximum Compressive 0 94 los. 42O h 19 los. 84 h

Naximum Noment M

x

195 in.-los. 22 hm 49 in.-los. 5.5 hm

Naximum Noment M

y

195 in.-los. 22 hm 49 in.-los. 5.5 hm

Naximum Noment M

z

195 in.-los. 22 hm 49 in.-los. 5.5 hm

|

Capacities are per set of jaws and are not simultaneous

L

X

F/2 F/2

Z

Mz

My

Z

Y

C

T

Mx

67

56

45

34

22

11

0

300

250

200

150

100

50

0

|bs. h

EFFECTlVE Flh0ER lEh0TH FR0N R0TATl0h AXl8 -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68 @ 0

2

51

3

76

4

102

5

127

6

152

7 |o.

178mm

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

1

O

O

P

8

l

[7

o

a

r|

8

O

P

8

l

[5

.5

o

a

r|

GO

P8l [4.1

oar|

2O P8l [1.8 oar|

4O

P8l [2.7

oar|

O P8l [O oar|

8h808 k008808I8 0808 = 0TYl0hIT

PhP Nagneto Resistive 8ensor 8hort Barrel N8 w/0k Disc* 0h8P-017 1 or 2

hPh Nagneto Resistive 8ensor 8hort Barrel N8 w/0k Disc* 0h8h-017 1 or 2

lnductive 8ensor Nounting Kit (mounts 2 sensorsj 800T40-63 1

N12 PhP lnductive 8ensor with N12 0uick Disconnect* 0I8P-017 1 or 2

N12 hPh lnductive 8ensor with N12 0uick Disconnect* 0I8h-017 1 or 2

N8 0uick Disconnect 2 Neter Caole length

*

0k8L-010 1 or 2

N8 0uick Disconnect 5 Neter Caole length

*

0k8L-013 1 or 2

N12 0uick Disconnect 2 Neter Caole length

*

0k8L-014 1 or 2

N12 0uick Disconnect 5 Neter Caole length

*

0k8L-018 1 or 2

Ph0NkTI0 k008808I8

Adj. Flow Control 01/8 Eloow - Omm 0D Push-in (Netricj VLVF-005 1 or 2

Buna-h8eal Repair Kit 8LkT-164 1

Viton

8eal Repair Kit 8LkT-164V 1

N00hTIh0 k008808I8

Adjustment 8top Kit (1 8hielded Plate + 1 8topj kP-0T40-88 1

*8ensor and caole sold separatel].

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

90

2.933

74.5

90

1.004

25.5

51

2.01

x 8 DP| 4

78

3.07

109

4.29

0.79

20

4 x [M

2 Slots to mount

magnetic sensors

C

L

C

L

C

L

0.154

3.9

5.31

135

[ 5

0.0002

0.67

151.50

5.9646

-

2 x [M

E7|

-

0.0007

| 6

SF 0.1969

39.5

1.555

12

0.47

18

0.71

[G 1/8 x 8 DP|

CLOSE

[G 1/8 x 8 DP|

OPEN

17

0.6299

[16g6|

C

L

32.00

1.5354

H9| 6

49

2 x

0.63

1.2598

Shielded plate

2 x [M

1.93

x 0.47 [12| DP

SF

39.00

6.516

16

1.34

0.2362

x 17 DP| 8

2.0866

53.00

34

165.5

[

Jaws in

gripping

position

at 0

C

L

C

L

2.0866

53.00

1.5354

39.00

x 6 DP|

x 6 DP|

2 x

0.71

SF

x 17 DP| 8

18

0.71

0.2362

OPEN

x 0.47 [12| DP

(supplied pluggedj

5

18

52

2.05

66

2.60

5 [M

(supplied pluggedj

CLOSE

2 x [M

[M

[ 6H9|

0

.0

5

1

.2

0.14

4

0.31

8

O-Ring [1.5 x 5|

Gripper's

top air port

Our grippers are supplied with

open side air ports and top air

ports plugged. When operating

top air ports, produce manifold

sealing as shown.

vlEW A-A

A A

h0T: Jaws have to oe designed for a O gripping position (parallel jawsj.

Jaws will close 1.5 past parallel. To limit shocks at the end of an opening or

closing stroke, it is highl] recommended to design jaws with minimal inertia

(as light and short as possiolej.

Flow Controls make it possiole to reduce the rotation speed and are highl]

recommended.

0 - 40M- 8 -

8II 8P8Ih0

8k8I0 N00L VIT0h

O

8kL8

kh00Lk8 08IPP8 0T-50N-8

180 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 0-50M-8

Total Rated 0rip Force, F @ 1OO psi [7 oar|

L = 2.5 in. [O4mm| @ O......................... 2O1 los. 898 h

8troke........................................................ 9O of stroke for each finger

weight ....................................................... 4.87 los. 2.21 Kg

Pressure Range ......................................... OO-1OO psi 4-7 Bar

C]linder Bore 0.......................................... 1.9O8 in. 5O mm

Displacement............................................. 5.O14 in

8

. 92 cm

8

Temperature Range

8tandard 8eals ....................................... -8O~18O F -85~8O C

Viton

8eals ............................................ -2O~8OO F -8O~15O C

Actuation (open/closej ............................... O.54 / O.42 sec.

Accurac].................................................... O.OO8O in. O.O9 mm

Repeataoilit].............................................. O.OO2 in. O.O5 mm.

Valve required to actuate single acting...... 8-wa], 2-position

Valve required to actuate douole acting .... 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

1.77 [45|

MAX.

0.63 [16|

0.69 [17.5|

0.83 [21|

1.18 [30|

0.75 [19|

0.87 [22|

3.84 [97.5|

lNDUCTlvE SENSORS AND

MOUNTlNG KlT (SDj

ADJUSTABLE

STOP KlT (BRj

0.20 [5|

5.55 [141|

0.39 [10|

Sensors

0.47 [12|

0.79 [20|

M10

Loadin Information

Leading 0apacity

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 11O los. 49O h 22 los. 98 h

Naximum Compressive 0 11O los. 49O h 22 los. 98 h

Naximum Noment M

x

2OO in.-los. 8O hm OO in.-los. 7.5 hm

Naximum Noment M

y

2OO in.-los. 8O hm OO in.-los. 7.5 hm

Naximum Noment M

z

2OO in.-los. 8O hm OO in.-los. 7.5 hm

|

Capacities are per set of jaws and are not simultaneous

L

X

F/2 F/2

Z

Mz

My

Z

Y

C

T

Mx

101

90

79

67

56

45

34

22

11

0

450

400

350

300

250

200

150

100

50

0

|bs. h

EFFECTlVE Flh0ER lEh0TH FR0N R0TATl0h AXl8 -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68 @ 0

2.5

64

3.5

89

4.5

102

5.5

140

6.5

165

7.5

191

8.5

216

9.5 |o.

241mm

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

1

O

O

P

8

l

[7

o

a

r|

8

O

P

8

l

[5

.5

o

a

r|

G

O

P

8

l

[4

.1

o

a

r|

4O

P8l [2.7

oar| 2O P8l [1.8 oar|

O P8l [O oar|

8h808 k008808I8 0808 = 0TYl0hIT

PhP Nagneto Resistive 8ensor 8hort Barrel N8 w/0k Disc* 0h8P-017 1 or 2

hPh Nagneto Resistive 8ensor 8hort Barrel N8 w/0k Disc* 0h8h-017 1 or 2

lnductive 8ensor Nounting Kit (mounts 2 sensorsj 800T40-63 1

N12 PhP lnductive 8ensor with 0uick Disconnect* 0I8P-017 1 or 2

N12 hPh lnductive 8ensor with 0uick Disconnect* 0I8h-017 1 or 2

N8 0uick Disconnect 2 Neter Caole length

*

0k8L-010 1 or 2

N8 0uick Disconnect 5 Neter Caole length

*

0k8L-013 1 or 2

N12 0uick Disconnect 2 Neter Caole length

*

0k8L-014 1 or 2

N12 0uick Disconnect 5 Neter Caole length

*

0k8L-018 1 or 2

Ph0NkTI0 k008808I8

Adj. Flow Control 01/8 Eloow - Omm 0D Push-in (Netricj VLVF-005 1 or 2

Buna-h8eal Repair Kit 8LkT-165 1

Viton

8eal Repair Kit 8LkT-165V 1

N00hTIh0 k008808I8

Adjustment 8top Kit (1 8hielded Plate + 1 8topj kP-0T50-88 1

*8ensor and caole sold separatel].

2.52

0

0

T

-

8

8

I

8

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL 0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.18

30

90

3.54

90

90

C

L

1.8110

0.71

8 [

2 x

2 x [M

1.5748

40.00

Shielded plate

H9|

2.36

60

x 0.63 [16| DP

SF

46.00

7.91

18

1.57

0.3150

x 22 DP| 10

2.3622

60.00

40

201

Jaws in

gripping

position

at 0

C

L

C

L

2.3622

60.00

30

2.44

x 6 DP|

62

2 x

1.18

SF

x 21 DP| 10

25

0.98

0.3150

OPEN

x 0.63 [16| DP

(supplied pluggedj

5 x 6 DP|

1.8110

46.00

76

2.99

5 [M

(supplied pluggedj

CLOSE

2 x [M

[M

[ 8H9|

C

L

C

L

C

L

0.20

5

6.42

163

[ 6

0.0002

0.83

183.00

7.2047

-

2 x [M

E7|

-

0.0007

| 8

SF 0.2362

44

1.73

15

0.59

25

0.98

[G 1/8 x 8 DP|

CLOSE

[G 1/8 x 8 DP|

OPEN

21

0.7087

[18g6|

4 x 8 DP|

60

2.36

133

20

4.035

5.24

102.50

0.79

4 x [M

2 Slots to mount

magnetic sensors

0

.0

5

1

.

2

0.14

4

0.31

8

O-Ring [1.5 x 5|

Gripper's

top air port

Our grippers are supplied with

open side air ports and top air

ports plugged. When operating

top air ports, produce manifold

sealing as shown.

vlEW A-A

A A

h0T: Jaws have to oe designed for a O gripping position (parallel jawsj.

Jaws will close 1.5 past parallel. To limit shocks at the end of an opening or

closing stroke, it is highl] recommended to design jaws with minimal inertia

(as light and short as possiolej.

Flow Controls make it possiole to reduce the rotation speed and are highl]

recommended.

0 - 50M- 8 -

8II 8P8Ih0

8k8I0 N00L VIT0h

O

8kL8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

2.53

0

0

T

-

8

l

0

T

-

8

8

I

8

N

k

I

h

T

h

k

h

0

00T-8l0T-8 88I8 XPL000 VIw

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

8eaI 8epair kit 0rder #'s

8ee Freduct 0ata 8heets

x2

x2

x2

x2

x2

9

4

1

2

6

8

3

7

10

64

Item 0ty ame

O1 1 Bod]

O2 1 Driver

O8 1 Piston

O4 2 Jaw

O5 1 washer

OO 1 Cap

O7 1 8hielded Plate

O8 2 wiper Cover

O9 2 Drive Pin

1O 2 Pivot Pin

54 1 Nagnet

O4 1 8pring

h0T: Contact the Rooohand 8ales Department

for a complete spare parts list with order numoers

and prices.

AssembIy Frecedure

1j luoricate and install the seals into cap (x1j, piston

(x2j and ood] (x1j

2j lf top air ports are used, clear them and plug the

side air ports on the ood] (#1j

8j luoricate the sloping rack of jaws (#4j

4j lnstall ooth drive pins (#9j into driver (#2j through

sloping racks of jaws. Check that the pin flat

surface is correctl] aligned oefore continuing with

their installation.

5j lock drive pins in the driver with screws, tightening

down on to the flat surface of the pins.

Oj Position driver and jaws assemol] into ood].

7j lnstall ooth pivot pins (#1Oj into ood], through the

oore of jaws. Check that the pin flat surface is cor-

rectl] aligned oefore continuing with their installation.

8j Pivot pin locking.

- DCT-12 (not shownj. lock pivot pins into ood] with

screws, tightening down on to the flat surface of

the pins (pins are fixed into ood] and rotating

into jawsj

- DCT-1O to CT-5O. lock pivot pins into jaws with

screws, tightening down on to the flat surface of

the pins (pins are fixed into jaws and rotating into

ood]j

9j Nagnet mounting.

- DCT-12 to DCT-2O. install the magnet (#54j on

the washer (#5j

- DCT-25 to CT-5O (not shownj. install magnet

(#54j onto piston (#8j and lock it o] means of its

retaining ring.

1Oj Piston mounting.

- DCT-12 to DCT-2O. insert the spring, then the

piston and the washer with magnet into ood]. Fix

the assemol] at the end of the driver with screw.

- DCT-25 to CT-5O (not shownj. insert the spring,

then the piston with magnet into ood]. Fix the

assemol] at the end of the drivers with screw.

11j Check unit operation unladen.

12j lnstall the cap (#Oj into ood] and lock it o] means

of its retaining ring.

18j Place ooth wiper covers (#8j into ood] and lock

them with their screws.

14j Fix the shielded plate (#7j onto ood] with ooth

screws.

00T-8l0T-8 88I8 k88N8L0 VIw

2.54

0

0

T

-

8

l

0

T

-

8

8

I

8

N

k

I

h

T

h

k

h

0

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

Item 0ty ame

O1 1 Bod]

O2 1 Driver

O8 1 Piston

O4 2 Jaw

O5 1 washer

OO 1 Cap

O7 1 8hielded Plate

O8 2 wiper Cover

O9 2 Drive Pin

1O 2 Pivot Pin

54 1 Nagnet

O4 1 8pring

h0T: Contact the Rooohand 8ales

Department for a complete spare parts

list with order numoers and prices.

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

2

4

6

5

8

9

54

10

1

3

7

64

k008808Y Ih8TkLLkTI0h & k0J08TNhT Ih8T800TI0h8

InstaIIatien - Adjustment 8tep

1j Unscrew ooth screws for mounting

of the shielded plate and remove it.

2j Fix the new shielded plate (#1j and

the stop (#2j onto ood] with ooth

screws (#8j

8j lnstall the locknut s]stem (#4j and

(#5j on the stop.

4j Tighten screw for maximum target

jaw opening and lock with locknut.

InstaIIatien - Inductive 8enser eIders

1j Fix the flags (#1j at the end of pivot pins with their screws (#2j

2j Holder mounting.

- DCT-1ON to DCT-82N. fix holder (#8j and spacer (#5j onto ood] with ooth screws (#Oj

- CT-4ON to CT-5ON. fix holder (#8j onto ood] with ooth screws (#Oj

8j 8ensor mounting.

- DCT-1ON to DCT-2ON. unscrew lightl] ooth screws for mounting (#Oj of holder and insert sensor

(#8, not includedj into it. Position sensor so that it senses up on flag. lock the sensor o]

tightening ooth screws.

- DCT-25N to DCT-82N. unscrew lightl] screw (#7j on holder and insert sensor (#8, not includedj

into it. Position sensor so that it senses up the flag. lock the sensor o] tightening screw.

- CT-4ON to CT-5ON. insert sensor (#8, not includedj in stop into holder. lock the sensor o]

tightening the collar holder with ooth screws (not shownj.

4j Adjust flag position o] unscrewing their screws for desired sensing positions.

1

2

3

4

5

1

5

6

2

3

7

8

6

3

4

1

2

7

8

DCT1ON, 2ON-RE DCT-25N, 82N-RE CT-4ON, 5ON-RE

1

5

6

2

3

8

00kLITY P80I8I0h 008k8ILITY

P80I8I0h 008k8ILITY 00kLITY

008k8ILITY 00kLITY P80I8I0h

00kLITY P80I8I0h 008k8ILITY

P80I8I0h 008k8ILITY 00kLITY

008k8ILITY 00kLITY P80I8I0h

00kLITY P80I8I0h 008k8ILITY

P80I8I0h 008k8ILITY 00kLITY

008k8ILITY 00kLITY P80I8I0h

00kLITY P80I8I0h 008k8ILITY

P80I8I0h 008k8ILITY 00kLITY

008k8ILITY 00kLITY P80I8I0h

00kLITY P80I8I0h 008k8ILITY

P80I8I0h 008k8ILITY 00kLITY

008k8ILITY 00kLITY P80I8I0h

08I0h h0T8

2.55

0

0

T

-

8

l

0

T

-

8

8

I

8

N

k

I

h

T

h

k

h

0

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

You might also like

- ""1J186 8' 4NC1J186 P144, C$J4R 16c$e$ E$co1$ 41'$Document16 pages""1J186 8' 4NC1J186 P144, C$J4R 16c$e$ E$co1$ 41'$Marian DunareanuNo ratings yet

- RPL RPLCDocument16 pagesRPL RPLCdunareanu_marian8668No ratings yet

- Dpds DPDLDocument24 pagesDpds DPDLMarian DunareanuNo ratings yet

- DlttanruDocument14 pagesDlttanruMarian DunareanuNo ratings yet

- DlbtanruDocument12 pagesDlbtanruMarian DunareanuNo ratings yet

- RfeDocument8 pagesRfedunareanu_marian8668No ratings yet

- DLBBLDocument12 pagesDLBBLMarian DunareanuNo ratings yet

- 0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Document7 pages0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Marian DunareanuNo ratings yet

- KA Series PDFDocument8 pagesKA Series PDFsancsa_74No ratings yet

- Yeg GDocument2 pagesYeg Gwpt_meNo ratings yet

- Simplicity 860Document24 pagesSimplicity 860Jeremy MillerNo ratings yet

- Catalogue For TFM-FR-TZ-TX-B PDFDocument15 pagesCatalogue For TFM-FR-TZ-TX-B PDFGuru Vaga50% (2)

- Parallel pneumatic grippers miniature seriesDocument5 pagesParallel pneumatic grippers miniature seriesKenry LimNo ratings yet

- E92 M3 Clutch ServiceDocument52 pagesE92 M3 Clutch ServiceJonas Alberto Ochoa CastilloNo ratings yet

- Yamaha Exciter 440 EX440 1980Document18 pagesYamaha Exciter 440 EX440 1980mkaukolaNo ratings yet

- Brochure Kinetrol PDFDocument44 pagesBrochure Kinetrol PDFPaulo PacaviraNo ratings yet

- Engine Mechanical ECHO 2002Document85 pagesEngine Mechanical ECHO 2002Tomas Dominguez100% (1)

- Atf Temperature Sensor: On Vehicle RepairDocument4 pagesAtf Temperature Sensor: On Vehicle RepairMarten ReedNo ratings yet

- ViN Scotch Yoke Act 21Document13 pagesViN Scotch Yoke Act 21Mayur PatelNo ratings yet

- Rls 51 Rotary Limit SwitchDocument4 pagesRls 51 Rotary Limit SwitchYasser BadrNo ratings yet

- 8-11... Lobo Service ManualDocument41 pages8-11... Lobo Service ManualRusonegro100% (1)

- Hermetically Sealed Pumps Ensure Refrigerant Safety and EfficiencyDocument24 pagesHermetically Sealed Pumps Ensure Refrigerant Safety and EfficiencyWaseem HassanNo ratings yet

- Yaesu G-450A Operating ManualDocument15 pagesYaesu G-450A Operating Manualdj03djj100% (1)

- 15-ScanJet SC 15TW Instruction ManualDocument43 pages15-ScanJet SC 15TW Instruction Manualogurmehmetali07No ratings yet

- Electronics Today International April 1990Document68 pagesElectronics Today International April 1990Mitchell CifuentesNo ratings yet

- Sensata, 6786Document2 pagesSensata, 6786Christopher RiceNo ratings yet

- Murray Briggs & StrattonDocument28 pagesMurray Briggs & StrattonMonica CurpasNo ratings yet

- Acura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6Document200 pagesAcura 2.5TL 3.2TL 1995 - 1998 Service Manual - Part6CandieApple100% (1)

- Aaaaaaaaaaaa PDFDocument8 pagesAaaaaaaaaaaa PDFtahatekriNo ratings yet

- AstropakDocument2 pagesAstropakHonka VoxNo ratings yet

- Optimize flare gas recovery with liquid ring compressorsDocument56 pagesOptimize flare gas recovery with liquid ring compressorsmani100% (2)

- Scotch-Yoke Pneumatic Actuator Instruction ManualDocument24 pagesScotch-Yoke Pneumatic Actuator Instruction ManualJunior CostaNo ratings yet

- Inverter Microprocessor-Controlled: Certified Kubota Mfg. CorpDocument4 pagesInverter Microprocessor-Controlled: Certified Kubota Mfg. CorpTotok SurotoNo ratings yet

- High pressure bladder accumulators conform to EC regulationsDocument9 pagesHigh pressure bladder accumulators conform to EC regulationsMetin GüvenNo ratings yet

- Fostex A Range 1981Document5 pagesFostex A Range 1981bertosamNo ratings yet

- ZF 2Document49 pagesZF 2Silvio Roman100% (2)

- Avn1200tb Avn1800tb PJ DB GB 14-06-30 HK2052Document2 pagesAvn1200tb Avn1800tb PJ DB GB 14-06-30 HK2052Enri05No ratings yet

- Optyma CU Leaflet - 46CDocument8 pagesOptyma CU Leaflet - 46CRahul PatilNo ratings yet

- CUCV Arctic KitDocument133 pagesCUCV Arctic KitgunwriterNo ratings yet

- TM 9-4935-385-14-1Document433 pagesTM 9-4935-385-14-1Ed PalmerNo ratings yet

- 132kV Cable Installation Tools List and Transformer Accessories ListDocument8 pages132kV Cable Installation Tools List and Transformer Accessories Listvsureshkumar.eeeNo ratings yet

- Hydro6 Operation Manual PDFDocument12 pagesHydro6 Operation Manual PDFCastro Dios En Ti ConfioNo ratings yet

- Ts Jet Jetinox Jetcom EngDocument5 pagesTs Jet Jetinox Jetcom EngTeamArizmeNo ratings yet

- Medifusion 1000Document94 pagesMedifusion 1000patolin_123No ratings yet

- GEA ATEX CatalogueDocument18 pagesGEA ATEX CataloguebracioNo ratings yet

- A17FODocument16 pagesA17FOJose SalvadorNo ratings yet

- Ignition PDFDocument13 pagesIgnition PDFAndrey GladyshevNo ratings yet

- kdl-32s5100 kdl-40s5100 kdl-46s5100 Chassis Ex2r SMDocument109 pageskdl-32s5100 kdl-40s5100 kdl-46s5100 Chassis Ex2r SMIordan AdrianNo ratings yet

- Manual 12rDocument198 pagesManual 12rnatalia jerez80% (5)

- Service BulletinDocument10 pagesService Bulletinraymond rizaNo ratings yet

- XR-P560 - RRV1626 Service ManualDocument21 pagesXR-P560 - RRV1626 Service ManualBarry John FitzGeradNo ratings yet

- Liquid Turbine Flowmeter User ManualDocument16 pagesLiquid Turbine Flowmeter User ManualJorge RamosNo ratings yet

- Flow Past NACA AirfoilDocument7 pagesFlow Past NACA AirfoilKarthick Murugesan100% (2)

- J-W Power Company Digital Fault Recorder ManualDocument40 pagesJ-W Power Company Digital Fault Recorder ManualTatiana GomezNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- LP C2Document18 pagesLP C2Marian DunareanuNo ratings yet

- Curs 12 MeeDocument13 pagesCurs 12 MeeMarian DunareanuNo ratings yet

- DSC Capabilities Neu Eng 09 2011 FinalDocument12 pagesDSC Capabilities Neu Eng 09 2011 FinalMarian DunareanuNo ratings yet

- Power CylindersDocument12 pagesPower CylindersMarian DunareanuNo ratings yet

- 0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Document7 pages0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Marian DunareanuNo ratings yet

- GC DGCDocument10 pagesGC DGCMarian DunareanuNo ratings yet

- RfeDocument8 pagesRfedunareanu_marian8668No ratings yet

- Curs Limba SuedezaDocument1 pageCurs Limba SuedezaMarian Dunareanu0% (1)

- Limba Engleza Curs Practic - Nivel MediuDocument51 pagesLimba Engleza Curs Practic - Nivel Mediucif_catalin100% (16)

- Round ToolingDocument18 pagesRound Toolingdunareanu_marian8668No ratings yet

- Au RDocument7 pagesAu RMarian DunareanuNo ratings yet

- RDHDocument20 pagesRDHMarian DunareanuNo ratings yet

- Automation U1 2011 GBDocument1 pageAutomation U1 2011 GBMarian DunareanuNo ratings yet

- Pin PackagesDocument23 pagesPin PackagesMarian DunareanuNo ratings yet

- IntroDocument1 pageIntroMarian DunareanuNo ratings yet

- Intro 00Document3 pagesIntro 00Marian DunareanuNo ratings yet

- MedicalDocument12 pagesMedicalMarian DunareanuNo ratings yet

- Manual Clamping Technology: I-3 - I-6 Section 1 - 9Document5 pagesManual Clamping Technology: I-3 - I-6 Section 1 - 9Marian DunareanuNo ratings yet

- 'I 2ii 3 + A : 1C-# @+/ (C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Document10 pages'I 2ii 3 + A : 1C-# @+/ (C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Marian DunareanuNo ratings yet

- OverviewDocument4 pagesOverviewMarian DunareanuNo ratings yet

- DpeDocument6 pagesDpeMarian DunareanuNo ratings yet

- VacuumDocument13 pagesVacuumMarian DunareanuNo ratings yet

- DLT BelDocument24 pagesDLT BelMarian DunareanuNo ratings yet

- 01 Vertical ClampsDocument44 pages01 Vertical ClampsElvin PolancoNo ratings yet

- Ai 2ii 3 + B : 1C-# @+/ (1: !1C-# @+/ ( 3:+/ ( + @ 1: +/ (-# @+/ ( 3:+/ (:#@C:/ /@#:/ - G - C:+@#! C/ # - ' Eg B 31 +@+1Document10 pagesAi 2ii 3 + B : 1C-# @+/ (1: !1C-# @+/ ( 3:+/ ( + @ 1: +/ (-# @+/ ( 3:+/ (:#@C:/ /@#:/ - G - C:+@#! C/ # - ' Eg B 31 +@+1Marian DunareanuNo ratings yet

- DPGDocument12 pagesDPGMarian DunareanuNo ratings yet

- Pneumatic Clamps: DestacoDocument32 pagesPneumatic Clamps: DestacoMarian DunareanuNo ratings yet

- Learning One-to-One - Book ReviewDocument3 pagesLearning One-to-One - Book Reviewwhistleblower100% (1)

- Unit V DSS Development: Arun Mishra 9893686820Document17 pagesUnit V DSS Development: Arun Mishra 9893686820Arun MishraNo ratings yet

- PLCDocument16 pagesPLCMohit Kinger100% (1)

- Method of MomentsDocument114 pagesMethod of MomentsankladhaNo ratings yet

- Deutz 1013Document3 pagesDeutz 1013Retno Pudji LestariNo ratings yet

- Rising Stem Ball ValveDocument6 pagesRising Stem Ball ValveAnupam A. GandhewarNo ratings yet

- OD Main Switch & OD OFF Indicator Light CircuitDocument4 pagesOD Main Switch & OD OFF Indicator Light Circuitcelestino tuliaoNo ratings yet

- Stock Register StoreDocument1,218 pagesStock Register StoreSantanu Kumar SahuNo ratings yet

- Royal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale QuotationDocument3 pagesRoyal 3KW Solar System: Ref: RSE/SQ/804/2020 Date: 09-28-2020 Sale Quotationmuhammad aliNo ratings yet

- Atmel 42238 Uart Based Sam Ba Bootloader For Sam d20 AP Note At04189Document12 pagesAtmel 42238 Uart Based Sam Ba Bootloader For Sam d20 AP Note At04189manasaNo ratings yet

- Load-Modulated Arrays Emerging MIMO TechnologyDocument83 pagesLoad-Modulated Arrays Emerging MIMO TechnologysmkraliNo ratings yet

- Item No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesDocument23 pagesItem No. Specification Requested Offered Specifications 1.1. 1.1 Law and CertificatesSaša StankovićNo ratings yet

- Sample Lab ReportDocument4 pagesSample Lab ReportHolley WrightNo ratings yet

- GestioIP 3.0 Installation GuideDocument17 pagesGestioIP 3.0 Installation GuidepiterasNo ratings yet

- X-Span & Setting ToolsDocument18 pagesX-Span & Setting ToolsDenier RubianoNo ratings yet

- CH Sravan KumarDocument5 pagesCH Sravan KumarJohnNo ratings yet

- INFRARED BASED VISITOR COUNTER TECHNOLOGYDocument21 pagesINFRARED BASED VISITOR COUNTER TECHNOLOGYRahul KumarNo ratings yet

- Engine Service Tool ReferenceDocument4 pagesEngine Service Tool ReferenceandrzejNo ratings yet

- Artikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsDocument9 pagesArtikel Jurnal - Fundamental Differences of Transition To Industry 4.0 From Previous Industrial RevolutionsJohny DoelNo ratings yet

- VNX Power UP Down ProcedureDocument8 pagesVNX Power UP Down ProcedureShahulNo ratings yet

- Raft Foundations - Design & Analysis With A Practical Approach PDFDocument140 pagesRaft Foundations - Design & Analysis With A Practical Approach PDFemmanuel83% (6)

- Dont CryDocument8 pagesDont CryIolanda Dolcet Ibars100% (1)

- LogDocument27 pagesLogmilli0chilliNo ratings yet

- Cybersecurity-Student-Book Res Eng 1014Document38 pagesCybersecurity-Student-Book Res Eng 1014Nistor Andreea Maria100% (1)

- 21st Bomber Command Tactical Mission Report 146, OcrDocument54 pages21st Bomber Command Tactical Mission Report 146, OcrJapanAirRaidsNo ratings yet

- Questionnaire For Future BLICZerDocument1 pageQuestionnaire For Future BLICZerAlejandra GheorghiuNo ratings yet

- Enclosed Product Catalogue 2012Document24 pagesEnclosed Product Catalogue 2012Jon BerryNo ratings yet

- The Five Generations of Computers: AssignmentDocument10 pagesThe Five Generations of Computers: Assignmentjismon_kjNo ratings yet

- Julia Warner 2018Document1 pageJulia Warner 2018Julia WarnerNo ratings yet

- Breaking Water Protection Paradigms: RTM Composite DomesDocument52 pagesBreaking Water Protection Paradigms: RTM Composite DomesaerostressNo ratings yet