Professional Documents

Culture Documents

D1103EN

Uploaded by

GustavoJanitoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D1103EN

Uploaded by

GustavoJanitoCopyright:

Available Formats

11-1999 D1103EN/01

ALSTOM 1/55

CBWatch-2

MODULAR MONITORING SYSTEM

CBW2TOOL HUMAN MACHINE INTERFACE SOFTWARE

USERS MANUAL

Manager Date of issue Written by Approved by

AHT 25-10-1999 C. Baudart Y. Brassod

11-1999 D1103EN/01

ALSTOM 2/55

CONTENTS

1 REFERENCES.................................................................................................................... 4

2 PURPOSE OF THE MANUAL ............................................................................................ 5

3 ENVIRONMENT DESCRIPTION........................................................................................ 5

3.1 Configurations for use of the Man-Machine interface............................................................. 5

3.2 PC environment .................................................................................................................... 6

3.3 Interface with CBWatch-2...................................................................................................... 6

4 INSTALLATION OF THE CBW2TOOL APPLICATION......................................................... 6

4.1 Installation............................................................................................................................ 6

4.2 Configuration of the CBW2Tool application........................................................................... 6

4.3 Deinstallation........................................................................................................................ 8

5 OPERATION .................................................................................................................. 10

5.1 Starting up the application .................................................................................................. 10

5.2 Closing the application ....................................................................................................... 11

5.3 Connection/disconnection of CBWatch-2............................................................................. 12

5.3.1 Creation/modification of an entry in the list .................................................................. 13

5.3.2 Deletion of an entry from the list................................................................................... 13

5.3.3 Connection.................................................................................................................. 14

5.3.4 Disconnection .............................................................................................................. 14

5.4 CBWatch-2 configuration.................................................................................................... 15

5.4.1 New configuration ....................................................................................................... 15

5.4.2 Reading the configuration of a CBWatch ...................................................................... 15

5.4.3 Transfer of the configuration to CBWatch ..................................................................... 15

5.4.4 Saving the configuration............................................................................................... 15

5.4.5 Restoration of a configuration....................................................................................... 16

5.4.6 Printing the configuration ............................................................................................. 16

5.4.7 Configuration of SF6 gas monitoring............................................................................ 17

5.4.8 Configuration of operations monitoring........................................................................ 18

5.4.9 Configuration of travel curve monitoring....................................................................... 20

5.4.10 Configuration of switching monitoring.......................................................................... 21

5.4.11 Configuration of monitoring of spring recharging......................................................... 24

5.4.12 Configuration of hydraulic command monitoring.......................................................... 25

5.4.13 Configuration of the monitoring of auxiliary circuits and supervision.............................. 25

5.4.14 Configuration of miscellaneous parameters .................................................................. 27

5.4.15 Configuration of factory parameters ............................................................................. 28

5.4.16 Configuration of alarms generated by CBWatch-2........................................................ 29

5.5 Access to CBWatch-2 event records ..................................................................................... 31

5.5.1 Reading event records from CBWatch-2 ....................................................................... 31

5.5.2 Saving event records .................................................................................................... 31

5.5.3 Restoration of event records ......................................................................................... 32

5.5.4 Display of event records ............................................................................................... 33

5.5.5 Details of an SF6 short term sample event .................................................................... 35

5.5.6 Details of an SF6 long term sample event ..................................................................... 36

5.5.7 Details of an SF6 fault event ......................................................................................... 37

5.5.8 Details of a closing operation....................................................................................... 38

5.5.9 Details of an opening operation ................................................................................... 39

5.5.10 Details of spring rewinding........................................................................................... 41

5.5.11 Details of re-inflating on operation............................................................................... 42

5.5.12 Details of re-inflating without operation........................................................................ 43

5.5.13 Details of a hydraulic fault............................................................................................ 44

5.5.14 Details of auxiliary and self test faults ........................................................................... 45

5.6 Access to CBWatch-2 measurements and alarms in progress ............................................... 46

5.6.1 Display of SF6 alarms and measurements in progress................................................ 47

5.6.2 Display of "opening" alarms and measurements............................................................ 48

5.6.3 Display of "closing" alarms and measurements in progress............................................ 49

5.6.4 Display of "switching" alarms and measurements in progress ........................................ 50

5.6.5 Display of spring operation alarms and measurements in progress ............................... 51

11-1999 D1103EN/01

ALSTOM 3/55

5.6.6 Display of hydraulic alarms and measurements in progress ....................................... 52

5.6.7 Display of auxiliary circuits alarms and measurements in progress ........................... 53

5.6.8 Display of self test alarms in progress ........................................................................ 54

5.7 On-line help ....................................................................................................................... 55

11-1999 D1103EN/01

ALSTOM 4/55

1 REFERENCES

[1] CBWatch-2 Users Manual

Reference: D1087EN/01

[2] CBWatch-2 Modbus Interface Reference Manual

Reference: D1104EN/01

11-1999 D1103EN/01

ALSTOM 5/55

2 PURPOSE OF THE MANUAL

The manual [1] describes the CBWatch-2 circuit breaker modular monitoring system.

CBWatch-2 has communications interfaces for connection to a PC microcomputer. The CBW2Tool

application installed on this PC gives access to CBWatch-2 configuration and measurement data.

The purpose of this manual is to describe the use of the CBW2Tool application.

3 ENVIRONMENT DESCRIPTION

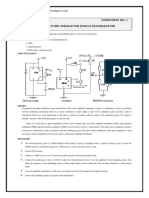

3.1 Configurations for use of the Man-Machine interface

There are 3 possible configurations for management of CBWatch-2 by the CBW2Tool application:

temporary connection via local RS232 port

permanent connection via MODBUS network

temporary connection via modem and MODBUS network.

Configuration 1:

Temporary local

Configuration 2:

Permanent MODBUS

Configuration 3:

Temporary via MODEM and

MODBUS

RS232

CBWatch-2

Sensors

MMI

MODBUS

(n modules

in network)

CBWatch-2

Sensors

MMI

CBWatch-2

Sensors

MMI

MODEM

MODEM

MODBUS

(n modules

in network)

11-1999 D1103EN/01

ALSTOM 6/55

3.2 PC environment

The CBW2Tool application is run on a PC micro-computer, type Pentium II 233 Mhz with 8 MB RAM,

equipped with an RS232 or RS485

(1)

serial link or a modem

(2)

dedicated to communications with

CBWatch-2 and a colour screen with a minimum 800x600 display. Portable computers can be used.

The PC must handle the following baud rates:

- 9600 baud for an RS232

- 4800 baud to 38400 baud for an RS485 or a modem.

The CBW2Tool application is designed to operate in a Windows 95, NT or higher environment (32 bit

application).

3.3 Interface with CBWatch-2

The various input/output parameters for CBWatch-2 are accessible from a host system, via an RS232 or

RS485 serial link using Modbus protocol (RTU mode), with or without modem.

The network interface is type RS485 (2 wires); the communications parameters can be modified by the

local serial link within the following limits:

speed : 1200 to 38400 baud

data bits : 8

parity : even, odd or none

stop bit : 1.

The local serial interface is type RS232; the communications parameters are fixed:

speed : 9600 baud

data bits : 8

parity : none

stop bit : 1.

4 INSTALLATION OF THE CBW2TOOL APPLICATION

4.1 Installation

The application is supplied on a CD-ROM. To install the CBW2Tool application proceed as follows:

start your computer and start up Windows

put the CD-ROM in the drive

using file manager, run the "setup.exe" program and follow the instructions.

The installation program asks you for the disk unit and main application folder (" C:\Program

Files\CBWatch-2 Tool\" by default) and creates a "CBW2Tool" program group in Windows "Start

Programs".

Before continuing, please read the "readme.txt" file carefully (if it exists). This file contains last minute

information which could not be included in this manual.

4.2 Configuration of the CBW2Tool application

(1)

this interface can be provided by an additional RS232C RS485 conversion module.

(2)

the modem may be internal or external to the PC; in all cases it is seen by the system as an RS232 port.

11-1999 D1103EN/01

ALSTOM 7/55

Certain operational parameters for the application can be adjusted (e.g. timeout). These parameters

are in Windows format and are located in the system register base

(HKEY_LOCAL_MACHINE\SOFTWARE\Alstom T&D\CBW2Tool\). They can be edited using the system

register editor "regedit.exe" or "regedit32.exe".

All operational parameters are taken into account at application start-up; for a modification to be

effective, it is therefore necessary to stop and restart the CBW2Tool application.

The CBW2Tool application is configured during installation; the modification of certain

parameters by an inexperienced user could give rise to system malfunctions.

11-1999 D1103EN/01

ALSTOM 8/55

4.3 Deinstallation

To deinstall the application, go into the configuration panel.

Then select the "Add/Delete programs" icon.

11-1999 D1103EN/01

ALSTOM 9/55

Select CBW2Tool and click on the Add/Delete button to start up the deinstallation procedure.

11-1999 D1103EN/01

ALSTOM 10/55

5 OPERATION

5.1 Starting up the application

First check that the computer is switched on. If not switch on the central unit, then the screen.

From the menu "Start - Programs - CBWatch-2 Tool", click on "CBW2Tool".

note: - "CBW2Tool Help" can be used to consult on-line help for the application (cf. chapter 5.6).

- "Readme" allows the user to consult last minute information which could not be included in this

manual.

Start-up of the application is followed by an initialisation phase. During this phase, the following screen

is displayed:

11-1999 D1103EN/01

ALSTOM 11/55

On completion of the initialisation phase, the application goes into the operating phase and the main

screen is displayed:

5.2 Closing the application

The application can be closed in three ways:

by selection of the item "File - Exit" in the menu on the main screen

by clicking on the box in the main window

by simultaneously pressing the "Alt" and "F4" keys.

If configuration or event record elements require saving, a confirmation dialogue box appears:

Click on:

" Yes" to save the data

" No" to close the application without prior saving

" Cancel" to return to the previous screen.

11-1999 D1103EN/01

ALSTOM 12/55

5.3 Connection/disconnection of CBWatch-2

Before any exchange with CBWatch-2, the connection between the remote device and the application

must be established. To do this, the application presents, via the "File Connect" menu, a list of

addressable CBWatch.

This list shows:

the name (or description) of the remote CBWatch

the Modbus address of the device,

the communication method (RS232, RS485 or Modem) and the physical port on the PC in

use (COM1 to COMxx),

the configuration of the serial port in use (baud rate, parity, number of stop bits) together with the

phone number in the case of a Modem.

The presence of a modem is detected automatically. Modem configuration takes place from the

Windows "configuration panel" or from the application using the "Setup" button.

11-1999 D1103EN/01

ALSTOM 13/55

5.3.1 Creation/modification of an entry in the list

You can add a connection to the list or modify the parameters for an existing connection by activating

the "Create" and "Modify" buttons respectively (the connection to be modified must first be selected in the

list).

The following dialogue box is then displayed. In the case of a modification request, the current

parameters are displayed. For creation, the entry fields are blank:

The operating procedure for this screen is as follows:

1. specify the name (or description) of the remote CBWatch: chain of alphanumeric characters

(minimum 1, maximum 20).

2. specify the Modbus address for the device: hexadecimal value from 01H to F7H (1 to 247)

inclusive.

3. indicate the communications mode (RS232, RS485 or Modem) and the physical port on the PC

used (COM1 to COMxx).

4. indicate the configuration of the serial port used (baud rate, parity, number of stop bits) and the

phone number in the case of a Modem (in standard HAYES mode without separator). The

communication parameters are fixed in the case of an RS232 (9600 baud, no parity, 1 stop bit). In

all cases data is exchanged in 8 bits.

5. confirm the entry by activating the "Apply" button. The "Cancel" button may be used to return to

initial values.

5.3.2 Deletion of an entry from the list

To delete an entry use the "Delete" button (the connection to be deleted must first be selected in the list).

A confirmation request is presented to the user, then the connection is deleted from the list.

11-1999 D1103EN/01

ALSTOM 14/55

5.3.3 Connection

Connection is by selecting a given item in the list, or selecting it then activating the Connect button.

A dialogue box informs the user of operations in progress. Throughout these operations (modem

dialling, opening of the communication port, etc.) no action is allowed.

On establishment of the connection, the dialogue box and the list of addressable CBWatch disappears;

the status of the connection is then shown in the status bar at the bottom of the main application

window.

5.3.4 Disconnection

Disconnection of the connected CBWatch is by activation of the File - Disconnect menu. A request for

confirmation is then presented to the user, then the connection with CBWatch is closed.

A dialogue box informs the user of operations in progress. Throughout these operations (completion of

an exchange in progress, closure of a communications port, etc.) no action is allowed.

On closure of the connection, the dialogue box disappears; the status of the connection is then shown

in the status bar located at the bottom of the main application window.

11-1999 D1103EN/01

ALSTOM 15/55

5.4 CBWatch-2 configuration

Via the "Configuration" menu, the application allows management of configuration parameters for a

CBWatch. These configuration parameters may be:

initialised by default via the menu "Configuration - New"

read from a CBWatch interrogated via the menu "Configuration - Read from CBWatch" (the

connection must first be established)

read from a local backup in the form of an Excel file: in this case the user must indicate the file to

be loaded.

The screens then displayed allow creation, consultation, modification and printing of the configuration

of a CBWatch-2.

5.4.1 New configuration

The user can enter a new configuration based on values by default.

This operation is performed by activating the menu "Configuration - New".

5.4.2 Reading the configuration of a CBWatch

The parameters are read by activating the menu "Configuration - Read from CBW" (the connection must

first be established). A dialogue box showing the progress of the transfer is then displayed.

5.4.3 Transfer of the configuration to CBWatch

The configuration parameters are written to a CBWatch by activating the menu "Configuration - Write to

CBW" (the connection must first be established). A dialogue box showing the progress of the transfer is

then displayed.

5.4.4 Saving the configuration

The configuration is saved by activating the menu "Configuration - Save to file..." when a configuration

or event records screen is displayed.

The following dialogue box is then shown:

The name of the saved file and its location must be specified. The saved file in Excel 5 format (.xls) and

can be consulted using Excel.

11-1999 D1103EN/01

ALSTOM 16/55

5.4.5 Restoration of a configuration

A configuration can be restored from a previously saved file (cf. chapter 5.4.4) by activating the menu

"Configuration - Load from file..." when a configuration or event records screen is displayed.

The following dialogue box is then shown:

The name of the saved file and its location must be specified.

5.4.6 Printing the configuration

All or part of the configuration of a CBWatch can be printed via the menu "Configuration - Print".

The following dialogue box is then displayed:

11-1999 D1103EN/01

ALSTOM 17/55

The operating procedure for this screen is as follows:

Select the check boxes corresponding to the configuration elements to be printed

if required, enter comments in the entry field provided for this purpose

confirm printing by activating the "Preview" button; a "print preview" window is then displayed so

that you can preview the selected prints before they are actually printed (using the "Print" button in

the latter window). The "Cancel" button can be used to return to the previous screen.

5.4.7 Configuration of SF6 gas monitoring

The "SF6" tab on the configuration screen gives access to the gas monitoring parameters contained in

the circuit breaker.

The operating procedure for this screen is as follows:

1. indicate the number of volumes to be monitored: none, 1 or 3; if "none" is specified

the following parameters are not accessible.

2. indicate the type of sensor: pressure + temperature, or density.

3. indicate gas composition: pure SF6, SF6 + CF4 mixture or SF6 + N2 mixture; in the

case of a mixture, indicate the SF6 ratio.

4. specify the alarm thresholds, by value ( 0) and hysteresis ( 0), for:

overpressure: indicates that a quantity of gas is too high and that there is a risk

of overpressure on heating

alarm 1: less than the previous threshold, indicating that the circuit breaker is still

capable of fulfilling its function but that filling is required

alarm 2: less than the previous threshold, indicating that the circuit breaker is no

longer capable of fulfilling its function.

5. specify the short and long term advance warning delays (whole numbers in the

ranges [20 to 1200] minutes and [20 to 200] days respectively. Access to the short

term delay requires monitoring of the 3 SF6 volumes. The short term delay

corresponds to the length of time the advance warning on alarm 2 appears before

the appearance of alarm 2. The long term delay corresponds to the length of time

the advance warning on alarm 1 appears before the appearance of warning alarm

1.

11-1999 D1103EN/01

ALSTOM 18/55

6. specify the pressures measured by the SF6 sensor at 4 mA and 20 mA

7. confirm the entries by activating the "Apply" button. To return to the initial values use

the "Cancel" button.

5.4.8 Configuration of operations monitoring

The "Operations" tab on the configuration screen gives access to monitoring parameters for circuit

breaker operations.

The operating procedure for this screen is as follows:

1. indicate the number of operating mechanisms to be monitored: none, 1 or 3; if no

operating mechanism is specified the following parameters are not accessible.

2. specify the two limits for the number of opening and closing operations.

3. indicate the type of sensors installed:

position sensors (auxiliary switches)

travel curve transducers, with optionnal check auxiliary switches.

4. enter the parameters related to opening operations:

a. indicate the number of opening coils: 1 or 2.

b. specify min and max times t1, corresponding to the time between the arrival of

the command on the opening coil and the time when the circuit breaker leaves

the "closed" position.

c. specify min and max times t2, corresponding to the time between the arrival of

the command on the opening coil and the time when the circuit breaker arrives

in the "open" position.

d. specify min and max times t2-t1, corresponding to the transition time from the

"open" to "closed" position on the circuit breaker.

11-1999 D1103EN/01

ALSTOM 19/55

e. where there are 3 poles, specify for each of the previous times the maximum

deviation between poles (discordance).

f. indicate whether operating times should be compensated according to the

temperature; this is achieved by the use of an entered and/or imported curve (11

points).

g. indicate whether operating times should be compensated according to the

command voltage; this is achieved, for each coil, either by the use of an entered

and/or imported curve (11 points) or by the use of a max value for the same

curve.

5. enter the parameters relating to closing operations:

a. specify min and max times t1, corresponding to the time between the arrival of

the command on the opening coil and the time when the circuit breaker leaves

the "open" position.

b. specify min and max times t2, corresponding to the time between the arrival of

the command on the opening coil and the time when the circuit breaker arrives

in the "closed" position.

c. specify min and max times t2-t1, corresponding to the transition time from the

"open" to "closed" position on the circuit breaker.

d. where there are 3 poles, specify for each of the previous times the maximum

deviation between poles (discordance).

e. indicate whether operating times should be compensated according to the

temperature; this is achieved by the use of an entered and/or imported curve (11

points).

f. indicate whether operating times should be compensated according to the

command voltage; this is achieved, for each coil, either by the use of an entered

and/or imported curve (11 points) or by the use of a max value for the same

curve.

6. confirm the entries using the "Apply" button. To return to the initial values use the

"Cancel" button.

A compensation curve is imported by activating the button to the right of the corresponding list. A

dialogue box is then presented allowing the user to specify the Excel-compatible file to be imported.

11-1999 D1103EN/01

ALSTOM 20/55

The imported file must have the following format:

Y-coordinate X-coordinate

y-coordinate value 1 x-coordinate value 1

y-coordinate value 2 x-coordinate value 2

y-coordinate value 3 x-coordinate value 3

y-coordinate value 4 x-coordinate value 4

i.e.:

1 pair [y-coordinate, x-coordinate] of numeric values per line (2 distinct columns). The y-coordinates

column is not used by the application; it enables the user to situate the x-coordinate values

no page headers or footers

file saved in CSV format (separator ";").

5.4.9 Configuration of travel curve monitoring

The "Trav. Curv." tab on of the configuration screen gives access to travel curve monitoring parameters.

Access to this tab requires the presence of a travel sensor.

The operating procedure for this screen is as follows:

1. for analysis of the opening curve:

a. specify the start of opening and end of opening positions (these positions are

used to measure t1 (reaction time ) and t2 (operating time), see section 5.4.8)

b. specify the end of stroke positions (min and max).

c. specify the rebound factor at end of stroke (min and max).

d. In case of monitoring of auxiliary switches, specify the switching position for type

a and type b switches (min and max).

11-1999 D1103EN/01

ALSTOM 21/55

e. specify the minimum threshold for the speed of separation of contacts and the

associated separation position.

2. for analysis of the closing curve:

a. specify the start of operation and end of operation positions (these positions are

used to measure t1 (reaction time ) and t2 (operating time), see section 5.4.8).

b. specify the end of stroke positions (min and max).

c. specify the rebound factor at end of stroke (min and max).

d. In case of monitoring of auxiliary switches, specify the switching position for type

a and type b switches (min and max).

e. specify minimum travel during an open-close cycle.

3. specify the correction curve for sensor kinematics (120 points) giving the travel of

contacts in the chamber according to the stroke at sensor level. The points on this

curve may be entered and/or imported from an Excel compatible file (cvs format).

4. specify the sensor output current at 0 % and 100 % travel.

5. use the "Apply" button to confirm the entries and return to the previous screen. To

return to the previous screen without memorising the modifications, use the "Cancel"

button.

A compensation curve is imported by activating the button to the right of the corresponding list. A

dialogue box is then presented allowing the user to specify the file (Excel compatible) to be imported.

The imported file must have the following format:

Y-coordinate X-coordinate

y-coordinate value 1 x-coordinate value 1

y-coordinate value 2 x-coordinate value 2

y-coordinate value 3 x-coordinate value 3

y-coordinate value 4 x-coordinate value 4

i.e.:

1 pair [y-coordinate, x-coordinate] of numeric values per line (2 distinct columns). The y-coordinates

column is not used by the application; it enables the user to situate the x-coordinate values

no page headers or footers

file saved in CSV format (separator ";").

5.4.10 Configuration of switching monitoring

CBWatch calculates cumulative totals for the square of the current cut by arcing contacts. These

"cumulated squared amperes" give an indication of the condition of the circuit breaker in terms of

electrical wear.

11-1999 D1103EN/01

ALSTOM 22/55

In addition, CBWatch-2 generates an alarm if arcing time is too long.

The "Switching" tab on the configuration screen gives access to monitoring parameters for switching.

Access to this tab is only possible if at least 1 pole is monitored in the operations tab.

The operating procedure for this screen is as follows:

1. indicate the number of poles to be monitored: none or 3; if no pole is specified the

following parameters are not accessible.

2. specify the value (> 0) of the current transformer nominal primary current for

measurement of the current going through the circuit breaker (the secondary current

is standard and fixed at 5 A. In the case of a CT with 1 A secondary, 5 turns in

auxiliary CT will be used for current measurement.

3. specify maximum arcing time ( 0).

4. specify the maximum electrical wear (in A

2

.s) and the 2 threshold of alarms on

electrical wear (in %).

5. where monitoring of the circuit breaker uses position sensors (auxiliary switches, see

section 5.4.8), specify the delay between switching the sensor from closed position

(type a) and the instant of contact separation.

6. supply the correction factor curve for electrical wear according to the intensity to be

used; the points on this curve can be entered and/or imported from an Excel

compatible file.

7. confirm the entries using the "Apply" button. To return to the initial values use the

"Cancel" button.

A compensation curve is imported by activating the button to the right of the corresponding list. A

dialogue box is then presented allowing the user to specify the Excel-compatible file to be imported.

11-1999 D1103EN/01

ALSTOM 23/55

The imported file must have the following format:

Y-coordinate X-coordinate

y-coordinate value 1 x-coordinate value 1

y-coordinate value 2 x-coordinate value 2

y-coordinate value 3 x-coordinate value 3

y-coordinate value 4 x-coordinate value 4

i.e.:

1 pair [y-coordinate, x-coordinate] of numeric values per line (2 distinct columns). The y-coordinates

column is not used by the application; it enables the user to situate x-coordinate values

no page headers or footers

file saved in CSV format (separator ";").

11-1999 D1103EN/01

ALSTOM 24/55

5.4.11 Configuration of monitoring of spring recharging

CBWatch measures spring recharging time (rewinding motor running time).

The "Spring" tab on the configuration screen gives access to spring recharging monitoring parameters.

Access to this tab is only possible if at least 1 pole is monitored in the operations tab.

The operating procedure for this screen is as follows:

1. indicate the number of operating mechanisms to be monitored: none, 1 or 3; if

"none" is specified the following parameters are not accessible.

2. specify the min and max rewinding times, corresponding to the running time of the

rewinding motor.

3. confirm the entries using the "Apply" button. To return to the initial values use the

"Cancel" button.

11-1999 D1103EN/01

ALSTOM 25/55

5.4.12 Configuration of hydraulic command monitoring

The "Hydraulic" tab of the configuration screen gives access to monitoring parameters for the hydraulic

command for the circuit breaker.

The operating procedure for this screen is as follows:

1. indicate the number of operating mechanisms to be monitored: none, 1 or 3. If

"none" is specified the following parameters are not accessible.

2. indicate the sensors installed on the command.

3. if the "pump start" contact is present:

a. specify maximum pump running times for operation types O, C, OC, CO, OCO.

b. specify the number of measurements for calculating the average hydraulic

leakage rate.

c. specify the maximum hydraulic leakage rate.

d. specify the pressure thresholds for pump starting and stopping.

e. specify the min and max values for average efficiency of the motor/pump unit.

4. if the hydraulic pressure sensor is present:

a. specify the relative pressure measured by the sensor at 4 mA and 20 mA

b. specify the locking thresholds, in value ( 0) and hysteresis ( 0), for operations

O, C, OCO.

5. confirm the entries using the "Apply" button. To return to the initial values use the

"Cancel" button.

5.4.13 Configuration of the monitoring of auxiliary circuits and supervision

11-1999 D1103EN/01

ALSTOM 26/55

The "Auxiliary" tab on the configuration screen gives access to the monitoring parameters for auxiliary

circuits and supervision.

The operating procedure for this screen is as follows:

1. indicate the presence (or not) of an ambient temperature probe at circuit breaker

command level; if present, indicate the min and max limits for ambient temperature.

2. indicate the number of temperature measurement points (0 to 4). For each

measurement point, specify the min and max limits.

3. indicate the presence (or not) of a coil monitoring relay; if present, specify the

maximum delay for "reset" of the relay indicating a coil in bad condition.

4. indicate the presence (or not) of an AC voltage presence sensor; if present, specify

the maximum time for absence of voltage before an alarm.

5. confirm the entries using the "Apply" button. To return to the initial values use the

"Cancel" button.

11-1999 D1103EN/01

ALSTOM 27/55

5.4.14 Configuration of miscellaneous parameters

The "Misc" tab on the configuration screen gives access to miscellaneous parameters for CBWatch

configuration.

-

The operating procedure for this screen is as follows:

1. indicate the presence (or not) of a local display on CBWatch; if present, indicate the

units displayed

(1)

by CBWatch for the following data:

temperature (C by default)

pressure (MPa by default)

density (absolute kPa by default)

speed (m/sec by default)

position (mm by default).

2. specify the parameters for CBWatch RS485 port:

CBWatch Modbus address: from 1 to 247

baud rate: 4800, 9600, 19200 or 38400 bits/s

parity: none, even or odd

number of stop bits: 1 or 2.

3. specify CBWatch supply voltage:

alternative

continuous; in this case indicate the value (> 0).

4. confirm the entries using the "Apply" button. To return to the initial values use the

"Cancel" button.

(1)

These choices do not have any effect on the units displayed by the CBW2Tool application.

11-1999 D1103EN/01

ALSTOM 28/55

5.4.15 Configuration of factory parameters

The "Specials" tab on the configuration screen gives access to the factory-set parameters for CBWatch. A

password must be entered for display of this screen.

The operating procedure for this screen is as follows:

1. specify measurement times and coefficients:

minimum coil signal duration

maximum rebound time for auxiliary switches

minimum wait time between two operational sequences

travel sensor correction curve filter coefficient

rapid open-close operation time

rapid close-open operation time

primary current cancellation threshold

SF6 gas pressure acquisition period.

2. timeouts:

t1 and t2 times for opening and closing the circuit breaker

rewinding time

running time for the re-inflating pump.

3. use the "Apply" button to confirm the entries and return to the previous screen. To

return to the previous screen without memorising the modifications, use the "Cancel"

button.

11-1999 D1103EN/01

ALSTOM 29/55

The shaded information is not accessible for modification and is never

transmitted to CBWatch-2. This information concerns:

the CBWatch-2serial number

the following calibration parameters:

number of points at output from A/D converter corresponding to SF6 pressure

sensors at 4 mA and 20 mA

number of points at output from A/D converter corresponding to travel sensors at

4 mA and 20 mA

number of points at output from A/D converter corresponding to temperature

sensors at given Tmin and Tmax

number of points at output from A/D converter corresponding to hydraulic

pressure sensors at 4 mA and 20 mA

number of points at output from A/D converter corresponding to current sensor

at 2.5 mA

number of points at output from A/D converter corresponding to voltage sensor

at Vmin (0 V) and Vmax.

5.4.16 Configuration of alarms generated by CBWatch-2

The "Alarms" tab on the configuration screen gives access to CBWatch-2 alarm management

parameters.

The operating procedure for this screen is as follows:

1. indicate the type of alarm by CBWatch-2; this acknowledgement may be:

impossible

entered on CBWatch keypad

11-1999 D1103EN/01

ALSTOM 30/55

entered by external push button: a TOR input allows the connection of a contact

for this purpose.

2. for each type of alarm:

indicate whether the alarm requires acknowledgement (Ack column.)

indicate associations with LEDs (L1 to L7 corresponding to LED 1 to 7) and relays

(R1 to R4 corresponding to relays 1 to 4) by checking the corresponding boxes

specify the value of the filter to be applied to the alarm (0 to 15). This filter may

be a timer or counter type, depending on the alarm concerned; in the case of a

timer alarm, the filter takes into account n times the sampling period for the

measurement concerned.

3. use the "Apply" button to confirm the entries and return to the previous screen. To

return to the previous screen without memorising the modifications, use the "Cancel"

button.

11-1999 D1103EN/01

ALSTOM 31/55

5.5 Access to CBWatch-2 event records

CBWatch-2 regularly measures the main characteristics of the HT circuit breaker monitored. These

measurements and the calculations performed are archived by CBWatch-2 in internal "stacks". The

historical record thus formed can be used to produce estimates and statistics for forecasting purposes

(protective measures, anticipation of maintenance operations, etc.).

The application allows consultation and printing of CBWatch-2 event records via the "Event Records"

menu. The event records may come from:

a CBWatch-2 interrogated (the connection must first be established),

a local saved file: the user must then indicate the file to be loaded.

5.5.1 Reading event records from CBWatch-2

This operation is performed by activating the menu "Event records - Read from CBW2" (the connection

must first be established). A dialogue box showing the progress of the transfer is then displayed.

When the event records are read, the configuration of their associated CBWatch-2 is also loaded.

5.5.2 Saving event records

Event records are saved by activating the menu "File - Save Event records" when a screen of event

records is displayed. The associated configuration is also saved.

The following dialogue box is then shown:

The name of the saved file and its location must be specified. The saved file is in Excel 5 format (.xls)

and can be consulted from Excel 5. The file containing the associated configuration is located in the

same place, with the given name suffixed by extension "CFG".

11-1999 D1103EN/01

ALSTOM 32/55

5.5.3 Restoration of event records

Restoration of event records from a previously saved file (cf. chapter 5.5.2) is by activating the menu

"Event-Records - Load from file" when an event records screen is displayed.

The following dialogue box is then shown:

The name of the saved file and its location must be specified. The file must be in Excel 5 format (.xls).

When a file of event records is loaded, the configuration of the associated CBWatch-2 is also loaded.

11-1999 D1103EN/01

ALSTOM 33/55

5.5.4 Display of event records

After reading event records, either directly from CBWatch-2, or from a previously saved file, the

following screen is displayed:

The operating procedure for this screen is as follows:

1. define the filter on the events to be displayed from:

SF6 short term trend

SF6 long term trend

SF6 faults

closing operations

opening operations

spring operation

hydraulic command on operation

hydraulic command without operation

hydraulic faults

faults on auxiliary circuits and self tests.

2. define the filters on the time interval for events to be displayed.

3. confirm the filters using the "Apply" button; the list of available events in the event

records is then updated.

4. to print the list of events just selected

(2)

:

activate the menu "Events records - Print". Printing uses the standard Windows print

driver, so page setup (margins, orientation, etc.), choice of printer, etc. is controlled

by the installed print driver.

5. to consult an event:

(2)

It is not possible to print details of events in this version of the application.

11-1999 D1103EN/01

ALSTOM 34/55

select an event from the list by double-clicking on the selected element. Depending

on the type of event (1 to 10), a detail screen is displayed

(2)

. From this screen, the

user can view the details of other events of the same type using a navigation bar.

The following operations are then possible:

consult the first event of this type,

consult the previous event of this type,

consult the next event of this type,

consult the last event of this type.

11-1999 D1103EN/01

ALSTOM 35/55

5.5.5 Details of an SF6 short term sample event

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS). This date is specified

by the application when these are read and corresponds to the date and time on the

CBWatch-2 interrogated

1 the SF6 equivalent gas pressure at 20 C for each pole (in kPa),

2 the ambient temperature (in C),

3 the RMS current (in A).

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 36/55

5.5.6 Details of an SF6 long term sample event

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS). This date is specified

by the application when these are read and corresponds to the date and time on the

CBWatch-2 interrogated

1 the SF6 equivalent gas pressure at 20 C for each pole (in kPa),

2 the ambient temperature (in C),

3 the RMS current (in A).

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 37/55

5.5.7 Details of an SF6 fault event

The following screen details the selected event.

It shows:

0 date and time of the event (DD/MM/YYYY and HH:MN:SS).

1 the alarm status for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 38/55

5.5.8 Details of a closing operation

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS),

1 the ambient temperature (in C),

2 the closing coil voltage (in V),

3 an indicator of the presence of an alarm related to closing operations

4 per pole:

the number of closing operations

the type of operation (O, C, OCO, etc.),

the reaction time t1 (in ms),

the closing time t2 (in ms),

the over travel amplitude (in mm),

the rebound amplitude (in mm),

the final position of travel (in mm),

the positions of 52a and 52b switching (in mm),

the travel curve for contacts during the closing operation (in mm). The travel

curves are shown on a graph for each pole. On these graphs the x-axis is the

time (in ms) and the y-axis is the position (in mm).

5 the status of alarms for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 39/55

5.5.9 Details of an opening operation

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS)

1 the ambient temperature (in C)

2 the closing coil voltage (in V)

3 an indicator of the presence of an alarm related to opening operations

4 per pole:

the number of opening operations

the type of operation (O, C, OCO, etc.),

the reaction time t1 (in ms),

the opening time t2 (in ms),

the speed of contact separation (in m/s),

the arcing time (in ms),

the over travel amplitude (in mm),

the rebound amplitude (in mm),

the final position of travel (in mm),

the positions of 52a and 52b switching (in mm),

electrical wear on arcing contacts (in A

2

.s),

the travel curve for arcing contacts during the opening operation (in mm),

the curve for the current going through the circuit breaker during the opening

operation (in A).

5 the status of alarms for each pole.

11-1999 D1103EN/01

ALSTOM 40/55

The travel and current curves are shown on the same graph per pole. On these graphs the x-axis is the

time (in ms) and the two y-axes are firstly the position (in mm) and secondly the current (in A).

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 41/55

5.5.10 Details of spring rewinding

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS),

1 per pole:

the running time of the rewinding motor (in s)

the presence (or absence) of a fault.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 42/55

5.5.11 Details of re-inflating on operation

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS),

1 the ambient temperature (in C),

2 by pole:

the cumulative re-inflation time (in s),

the type of operation (O, C, OCO, ).

3 the status of alarms for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 43/55

5.5.12 Details of re-inflating without operation

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS),

1 the ambient temperature (in C),

2 per pole:

the instantaneous leakage rate (in MPa/day),

the average leakage rate (in MPa/day),

the instantaneous pump efficiency (in MPa/s),

the average pump efficiency (in MPa/s).

3 the alarm status for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 44/55

5.5.13 Details of a hydraulic fault

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS),

1 the status of alarms for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 45/55

5.5.14 Details of auxiliary and self test faults

The following screen details the selected event.

It shows:

0 the date and time of the event (DD/MM/YYYY and HH:MN:SS)

1 the status of auxiliary circuit alarms for each pole

2 the status of CBWatch-2 self test alarms for each pole

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 46/55

5.6 Access to CBWatch-2 measurements and alarms in progress

The application offers real time viewing of measurements and alarms in progress, via the menu "Real

time data - View" (the connection must first be established).

The following screen is then displayed:

This "General" screen corresponds to a summary of alarms signalled by CBWatch-2. In addition it

allows:

0 display of CBWatch-2 date and time

1 the display and modification of information updating time (in s).

The CBWatch clock is modified by entering a date and time, via a dialogue box. The workstation date

and time are proposed by default. Polling operations on CBWatch-2 alarms and

measurements are suspended during CBWatch-2 clock updating operations.

11-1999 D1103EN/01

ALSTOM 47/55

5.6.1 Display of SF6 alarms and measurements in progress

The "SF6" tab details SF6 alarms and measurements.

It shows:

0 the ambient temperature (in C)

1 per pole:

the short term leakage rate (in kPA/h),

the long term leakage rate (in kPA/year),

SF6 gas pressure (in kPA),

the equivalent density of SF6 gas at 20 C (in kPA).

2 the status of alarms for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 48/55

5.6.2 Display of "opening" alarms and measurements

The "Open op." tab details the alarms and measurements related to circuit breaker opening operations.

It shows:

0 the closing coil voltage (in V),

1 per pole:

the position of the closed position sensor (auxiliary switch type a)

the position of the open position sensor (auxiliary switch type b)

the position of the circuit breaker

The contacts displacement (in mm).

2 the status of alarms for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 49/55

5.6.3 Display of "closing" alarms and measurements in progress

The "Close op." tab details the alarms and measurements related to circuit breaker closing operations.

It shows:

0 the closing coil voltage (in V)

1 per pole:

the position of the closed position sensor (auxiliary switch type a)

the position of the open position sensor (auxiliary switch type b)

the position of the circuit breaker

The contacts displacement (in mm).

3 the status of alarms for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 50/55

5.6.4 Display of "switching" alarms and measurements in progress

The "Switching" tab details the alarms and measurements related to switching.

The primary current per pole is displayed together with the status of the following alarms (per pole).

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 51/55

5.6.5 Display of spring operation alarms and measurements in progress

The "Spring" tab details closing spring operation alarms and measurements.

The presence or not of a fault is displayed for each pole together with the position of rewinding motor

contacts for each pole (in mm).

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 52/55

5.6.6 Display of hydraulic alarms and measurements in progress

The "Hydraulic" tab details the hydraulic command alarms and measurements.

It shows:

0 per pole:

the position of the motor contact (in mm),

the hydraulic pressure (in MPa),

the opening locking position (in mm),

the closing locking position (in mm),

the open-close-open locking position (in mm),

the level of nitrogen or oil.

1 the status of alarms for each pole.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 53/55

5.6.7 Display of auxiliary circuits alarms and measurements in progress

The "Aux." tab details the auxiliary circuit and supervision alarms and measurements.

It shows:

0 the position of coil supervision relay output contact

1 the position of AC presence relay output contact

2 the ambient temperature (in C),

3 the status of alarms.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 54/55

5.6.8 Display of self test alarms in progress

The "Self Test" tab details CBWatch-2 self test alarms.

The status of the following alarms is displayed.

The information displayed cannot be modified.

11-1999 D1103EN/01

ALSTOM 55/55

5.7 On-line help

On-line help is accessible from the various application screens by activating:

the "Help" button if present

the "F1" key

the item "Help - Index" or "Help - Help on" in the main screen menu.

Help can also be accessed independently of the application from the menu "Start - Programs -

CBW2Tool", item "CBW2Tool Help".

The presentation of on-line help for the application uses the Windows help mechanisms: navigation,

searches by keyword, etc. are therefore standard.

You might also like

- PowerFactory 15 TutorialDocument98 pagesPowerFactory 15 TutorialKrid JenwitthayachaiNo ratings yet

- Daikin Ducted Air Conditioning Au BrochureDocument13 pagesDaikin Ducted Air Conditioning Au BrochureChristy JosephNo ratings yet

- 04 AppendixDocument150 pages04 AppendixgjanitoNo ratings yet

- Aero Gener AdoresDocument39 pagesAero Gener AdoresRosa María De Anda Lopez100% (1)

- Pipe Stress Analysis Per ASME B 31.3Document10 pagesPipe Stress Analysis Per ASME B 31.3Agung Pramu Aji100% (1)

- Using Fast FormulaDocument92 pagesUsing Fast FormulaRohit Singh100% (1)

- Manual BUC Agilis 80 - 100 - 200WDocument108 pagesManual BUC Agilis 80 - 100 - 200WXandrey Xiveras100% (1)

- Server Virtualization Seminar PresentationDocument40 pagesServer Virtualization Seminar PresentationhanzkhanNo ratings yet

- 1323408Document70 pages1323408Romulo SmartNo ratings yet

- IEC61850 Interoperability and Implementation GET-20025E 150720 R007 LRDocument18 pagesIEC61850 Interoperability and Implementation GET-20025E 150720 R007 LRGustavoJanitoNo ratings yet

- IEC61850 Interoperability and Implementation GET-20025E 150720 R007 LRDocument18 pagesIEC61850 Interoperability and Implementation GET-20025E 150720 R007 LRGustavoJanitoNo ratings yet

- HG320 HG1110 HG1210 HG1300 HG1500 HG2300 Configuration GuideDocument184 pagesHG320 HG1110 HG1210 HG1300 HG1500 HG2300 Configuration GuideBadr BenNo ratings yet

- Reliability CalculationsDocument35 pagesReliability CalculationsEkoFujisyahMaulwantoNo ratings yet

- Manual Led PanelDocument72 pagesManual Led PanelНиколай филюкNo ratings yet

- SYS600 - Connecting LONWORKS DevicesDocument116 pagesSYS600 - Connecting LONWORKS DevicesAbhijit JNo ratings yet

- Triple Play: Building the converged network for IP, VoIP and IPTVFrom EverandTriple Play: Building the converged network for IP, VoIP and IPTVNo ratings yet

- Sci.10 Lesson Plan Electricity and MagnetismDocument5 pagesSci.10 Lesson Plan Electricity and MagnetismJeiril Divino100% (3)

- Nec Univerge Sv8300 PDFDocument234 pagesNec Univerge Sv8300 PDFRodrigoNo ratings yet

- B66273L Vol1Document244 pagesB66273L Vol1sami belkhiria100% (1)

- PCM 600Document90 pagesPCM 600Felix CristianNo ratings yet

- SIP Trunking Service Configuration Guide For Accessline: DFW Phone 972-992-4600Document38 pagesSIP Trunking Service Configuration Guide For Accessline: DFW Phone 972-992-4600Rodrigo100% (1)

- 21438390AABAAS - V1 - A1000 S12 J Family Installation Manual PDFDocument246 pages21438390AABAAS - V1 - A1000 S12 J Family Installation Manual PDFSergio DomenesNo ratings yet

- Optical Communication Certification: Optical Communication Consultant (OC-C) Occ3 Release 1.2.0 Course OutlineDocument4 pagesOptical Communication Certification: Optical Communication Consultant (OC-C) Occ3 Release 1.2.0 Course OutlineAnonymous 1UM1sIIf0% (1)

- Sma STP 110-60 Core2Document84 pagesSma STP 110-60 Core2Manuel UrdanetaNo ratings yet

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionFrom EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNo ratings yet

- 4787 - MARU 220 Manual Vol 2 PDFDocument186 pages4787 - MARU 220 Manual Vol 2 PDFWellynthon AgustinusNo ratings yet

- PHARMACY MANAGEMENT PROJECT Ahmad IbitoyDocument116 pagesPHARMACY MANAGEMENT PROJECT Ahmad IbitoyHamna BadarNo ratings yet

- Instruction Manual: October 2004 W41080061 V1.8Document42 pagesInstruction Manual: October 2004 W41080061 V1.8Anderson TpsNo ratings yet

- FMM Smart Space-Division Cell Group (ITRAN LR21+)Document63 pagesFMM Smart Space-Division Cell Group (ITRAN LR21+)Nosherwan Latif100% (2)

- Siemens - Protection, Substation Automation, Power Quality and MeasurementDocument140 pagesSiemens - Protection, Substation Automation, Power Quality and Measurementpvhoan100% (1)

- Siemens - Protection, Substation Automation, Power Quality and MeasurementDocument140 pagesSiemens - Protection, Substation Automation, Power Quality and Measurementpvhoan100% (1)

- SR-1000 User's Manual - EDocument92 pagesSR-1000 User's Manual - ECarlos MusellaNo ratings yet

- AcSELerator Quickset User ManualDocument14 pagesAcSELerator Quickset User ManualGustavoJanito100% (1)

- Alarm Alcatel 2GDocument590 pagesAlarm Alcatel 2Gsohappy2No ratings yet

- Installation and Operation ManualDocument81 pagesInstallation and Operation ManualOscar Moreno0% (1)

- BMC Impact Solutions Infrastructure Management GuideDocument304 pagesBMC Impact Solutions Infrastructure Management GuidetomtomtomtoNo ratings yet

- XMP1 System Description R5.5 PDFDocument374 pagesXMP1 System Description R5.5 PDFIan CutinNo ratings yet

- Online Examination System, Use Case ProjectDocument32 pagesOnline Examination System, Use Case ProjectMohit Sharma100% (23)

- Manual of GDGS Transformer Tangent Delta TesterDocument19 pagesManual of GDGS Transformer Tangent Delta TesterFernando Sanchez100% (1)

- AppearTV User Manual 3.04Document234 pagesAppearTV User Manual 3.04Hashim ShafquatNo ratings yet

- Cockpit 3 48000000001-ENG-UserMan PDFDocument50 pagesCockpit 3 48000000001-ENG-UserMan PDFgeorgecotoraNo ratings yet

- Installation Guide For Nortel Meridian 2Document240 pagesInstallation Guide For Nortel Meridian 2RCraftNo ratings yet

- NXE1 ManualDocument124 pagesNXE1 ManualDorival Junior Ferreira de Mello0% (1)

- Hit 7080 TSMNDocument74 pagesHit 7080 TSMNJoseMiguelBlancoAlvarez100% (1)

- GL200 SMS Protocol V102 Decrypted.100130920 PDFDocument28 pagesGL200 SMS Protocol V102 Decrypted.100130920 PDFCezaryNo ratings yet

- IM02960153 Rev F Medium Power Compact 20W 60W 3Document115 pagesIM02960153 Rev F Medium Power Compact 20W 60W 3hendpraz88No ratings yet

- Valmet (Tejas Series V) Master Protocol: Reference ManualDocument43 pagesValmet (Tejas Series V) Master Protocol: Reference ManualJOSENo ratings yet

- Release 7.2 Features Guide: For Releases 7.2 Through 7.2.4Document148 pagesRelease 7.2 Features Guide: For Releases 7.2 Through 7.2.4An AnNo ratings yet

- Harmonic HLT7706 R ManualDocument62 pagesHarmonic HLT7706 R ManualMike Rice100% (1)

- Epon Command Line-V1.1 enDocument169 pagesEpon Command Line-V1.1 enYasser Erbey Romero GonzalezNo ratings yet

- Instructions of FpThick Software 20200610Document47 pagesInstructions of FpThick Software 20200610huynh thi y viNo ratings yet

- MELSEC iQ-R Structured Text (ST) Programming Guide BookDocument106 pagesMELSEC iQ-R Structured Text (ST) Programming Guide BookyounesNo ratings yet

- SJ-20150919164026-010-ZXUN iEPC (V1.15.10) Integrated Evolved Packet Core Alarm Handling PDFDocument299 pagesSJ-20150919164026-010-ZXUN iEPC (V1.15.10) Integrated Evolved Packet Core Alarm Handling PDFK OuertaniNo ratings yet

- Voter Verifiable Paper Audit Trail - M3 (VVPAT - M3) : User ManualDocument51 pagesVoter Verifiable Paper Audit Trail - M3 (VVPAT - M3) : User Manualvhkprasad100% (1)

- Technical Bulletin: Minilab ProcessingDocument53 pagesTechnical Bulletin: Minilab Processingyarko yorkoNo ratings yet

- HN System: HN9800 Satellite Modem Installation GuideDocument66 pagesHN System: HN9800 Satellite Modem Installation GuideFawzi AlzubairyNo ratings yet

- CTD913 Hardware (En HW)Document19 pagesCTD913 Hardware (En HW)João ArtilheiroNo ratings yet

- Idteck Itdc Series User Manual Eng 20160106Document146 pagesIdteck Itdc Series User Manual Eng 20160106Gregorio FaraldoNo ratings yet

- IDC Star Generation 2Document47 pagesIDC Star Generation 2Hever RodriguezNo ratings yet

- 090.040-CS - Quantum HD 2015-09 PDFDocument116 pages090.040-CS - Quantum HD 2015-09 PDFrobert_barnette_eco100% (1)

- Install Ompc On PcfsDocument34 pagesInstall Ompc On Pcfsv_anand78No ratings yet

- ZTL Operations and Admin OrderDocument397 pagesZTL Operations and Admin OrderTom RickardNo ratings yet

- Diaper Inspection System: Application Manual Proinspect 3Document54 pagesDiaper Inspection System: Application Manual Proinspect 3Abdou DE100% (2)

- Belden Drop Catalog 041113Document25 pagesBelden Drop Catalog 041113gdfsndhgfdvhjzdNo ratings yet

- OpenScape UC Application V7 Installation and Upgrade, Installation Guide, Issue 12Document1,107 pagesOpenScape UC Application V7 Installation and Upgrade, Installation Guide, Issue 12Vasile Silion100% (1)

- Dry Cargo-Loadmaster Users ManualDocument274 pagesDry Cargo-Loadmaster Users ManualRommel RoldanNo ratings yet

- Operation and Maintenance: Symmetra PXDocument40 pagesOperation and Maintenance: Symmetra PXLeopoldo Godinez Hernandez100% (1)

- PTS 2.3 Portable Test System Operation Manual: - Version 4Document79 pagesPTS 2.3 Portable Test System Operation Manual: - Version 4ADE mrtNo ratings yet

- WMM Specification v1.1 PDFDocument36 pagesWMM Specification v1.1 PDFSorin GoldenbergNo ratings yet

- SJ-20120306200658-007-ZXUN uMAC (V4.11.20) GNGP SGSN GeneraDocument111 pagesSJ-20120306200658-007-ZXUN uMAC (V4.11.20) GNGP SGSN Generasyrish2622No ratings yet

- Transcede 2xxx Hardware Data Sheet (PN 842xx-DSH-001-A) PDFDocument257 pagesTranscede 2xxx Hardware Data Sheet (PN 842xx-DSH-001-A) PDFPedro RobertNo ratings yet

- IRC5-MultiMove Application Manual 3HAC021272-001 - RevBDocument116 pagesIRC5-MultiMove Application Manual 3HAC021272-001 - RevBmartinimartiiniNo ratings yet

- An1020-25 User ManualDocument120 pagesAn1020-25 User Manualmoonzte75% (4)

- Troubleshooting Guide 287csDocument78 pagesTroubleshooting Guide 287csanon_89666304100% (1)

- Ah en Ax SW Suite Change Notes 8040 en 24Document89 pagesAh en Ax SW Suite Change Notes 8040 en 24Igor Gonçalves100% (1)

- Orion Manual 360800-0000-024 R2 ReleasedDocument253 pagesOrion Manual 360800-0000-024 R2 ReleasedYu Shu HearnNo ratings yet

- OperationManualCPM ACT2500 MBT2500 MEK3000 MEK2500 OM2003 11 English 20200327Document84 pagesOperationManualCPM ACT2500 MBT2500 MEK3000 MEK2500 OM2003 11 English 20200327ads100% (1)

- Pub088 005 00 - 1017Document84 pagesPub088 005 00 - 1017Belos SahajiNo ratings yet

- HYDAC - Electronics - CMU 1000Document126 pagesHYDAC - Electronics - CMU 1000Mihai PopaNo ratings yet

- User Manual PW-3000PDocument55 pagesUser Manual PW-3000PSanjoy BasakNo ratings yet

- Configuración Lógica REG650Document44 pagesConfiguración Lógica REG650GustavoJanitoNo ratings yet

- 6084 PDFDocument19 pages6084 PDFGustavoJanitoNo ratings yet

- 6084 PDFDocument19 pages6084 PDFGustavoJanitoNo ratings yet

- 7PA27 30 en-AuxiliaryRelayDocument5 pages7PA27 30 en-AuxiliaryRelayLê Văn Phú100% (1)

- 3332-01EU01 - 5 - Unifilar General 3332-01EU01Document1 page3332-01EU01 - 5 - Unifilar General 3332-01EU01GustavoJanitoNo ratings yet

- 350man AjDocument314 pages350man AjGustavoJanitoNo ratings yet

- Tutorial: Introduction To Modal Analysis: Francisco M. Gonzalez-Longatt, DR - SC Manchester, UK, November, 2009Document52 pagesTutorial: Introduction To Modal Analysis: Francisco M. Gonzalez-Longatt, DR - SC Manchester, UK, November, 2009GustavoJanitoNo ratings yet

- 7PA27 30 en-AuxiliaryRelayDocument5 pages7PA27 30 en-AuxiliaryRelayLê Văn Phú100% (1)

- Copia - ENG P44x Technical Presentation MARS 2005Document51 pagesCopia - ENG P44x Technical Presentation MARS 2005GustavoJanitoNo ratings yet

- 406 (0,0) PDFDocument35 pages406 (0,0) PDFGustavoJanitoNo ratings yet

- Copia - ENG P44x Technical Presentation MARS 2005Document43 pagesCopia - ENG P44x Technical Presentation MARS 2005GustavoJanitoNo ratings yet

- Gek 113535NDocument90 pagesGek 113535NGustavoJanitoNo ratings yet

- PowerFactory Product ManualDocument94 pagesPowerFactory Product Manualchmsno111No ratings yet

- Copia - ENG P44x Technical Presentation MARS 2005Document289 pagesCopia - ENG P44x Technical Presentation MARS 2005GustavoJanitoNo ratings yet

- User Manual Stvi - SMRT PN 81757 Rev8Document297 pagesUser Manual Stvi - SMRT PN 81757 Rev8GustavoJanitoNo ratings yet

- Gek 113535NDocument90 pagesGek 113535NGustavoJanitoNo ratings yet

- Im W 1Document621 pagesIm W 1GustavoJanitoNo ratings yet

- Autocad - Tutorial Auto Cad 2002 2D 3DDocument56 pagesAutocad - Tutorial Auto Cad 2002 2D 3Dpaulordsantos100% (4)

- Im G 1Document639 pagesIm G 1GustavoJanitoNo ratings yet

- Im F 1Document908 pagesIm F 1GustavoJanitoNo ratings yet

- Im C 1Document688 pagesIm C 1GustavoJanitoNo ratings yet

- Principles of Data Integrity - Pharmaceutical GuidelinesDocument1 pagePrinciples of Data Integrity - Pharmaceutical Guidelinessandro Cardoso100% (1)

- Final Exam 2022Document3 pagesFinal Exam 2022Ngọc Nguyễn BảoNo ratings yet

- Readme145678 01Document12 pagesReadme145678 01YEahrightOk5080No ratings yet

- Alzheimer Portfolio Presentation - 2 PDFDocument1 pageAlzheimer Portfolio Presentation - 2 PDFSeshathri AathithyanNo ratings yet

- Management PricipalDocument7 pagesManagement PricipalmdivyalakshmiNo ratings yet

- Manual 903 H2SDocument145 pagesManual 903 H2SEduardo MontrealNo ratings yet

- Optimal Loan PorfolioDocument11 pagesOptimal Loan PorfoliomohshiNo ratings yet

- Related StudiesDocument8 pagesRelated StudiesZoe Bantilan MirandoNo ratings yet

- Comparison With VirdiDocument27 pagesComparison With VirdiMinesh SoniNo ratings yet

- Analysis and Design Principles of Microwave Antennas - Unit 1 - How To Access The PortalDocument4 pagesAnalysis and Design Principles of Microwave Antennas - Unit 1 - How To Access The Portalchinnujan24100% (1)

- Python - Basic - 1 - Jupyter Notebook (Student)Document44 pagesPython - Basic - 1 - Jupyter Notebook (Student)Mesbahur RahmanNo ratings yet

- Multi-Label Long Short-Term Memory-Based Framework To Analyze Drug Functions From Biological PropertiesDocument6 pagesMulti-Label Long Short-Term Memory-Based Framework To Analyze Drug Functions From Biological PropertiesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- DSPACE (DS-1104) Implementation of Detection and Control Algorithm of Dynamic Voltage Restorer (DVR) - COEPDocument9 pagesDSPACE (DS-1104) Implementation of Detection and Control Algorithm of Dynamic Voltage Restorer (DVR) - COEPDaniel GutierrezNo ratings yet

- PAMDocument11 pagesPAMMarco Alejandro Teran AguilarNo ratings yet

- 15A05502 Computer NetworksDocument1 page15A05502 Computer NetworksJaya SankarNo ratings yet

- Program Your Own LanguageDocument56 pagesProgram Your Own LanguageBcalh3No ratings yet

- Object-Oriented Programming (OOP) Lecture No. 4Document26 pagesObject-Oriented Programming (OOP) Lecture No. 4Muhammad ZeeshanNo ratings yet

- CP2600-OP, A20 DS 1-0-2 (Cat12 CPE)Document2 pagesCP2600-OP, A20 DS 1-0-2 (Cat12 CPE)hrga hrgaNo ratings yet

- BAPI EnhancementDocument6 pagesBAPI EnhancementSathish B SathishNo ratings yet