Professional Documents

Culture Documents

Pile Foundation

Uploaded by

Suresh KhangembamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pile Foundation

Uploaded by

Suresh KhangembamCopyright:

Available Formats

PILE FOUNDATION

A PROJECT REPORT

Submitted by

KHANGEMBAM SAHENDRA SINGH

in partial fulfillment for the award of the degree

of

BACHELOR OF TECHNOLOGY

IN

CIVIL ENGINEERING

Under The Guidance of Submitted by

L. Hemchandra Sharma Khangembam Sahendra Singh

Assistant Engineer Regd. No. 11110684

LOVELY PROFESSIONAL UNIVERSITY

Phagwara144401, Punjab (India)

LOVELY PROFESSIONAL UNIVERSITY

CERTIFICATE

Certified that this project entitled PILE FOUNDATION submitted by

KHANGEMBAM SAHENDRA SINGH, reg. no. 11110684 student of Civil

Engineering Department, Lovely professional university, Phagwara, Punjab who

carried out the project under my supervision.

This report has not been submitted to any other university or institution for the

award of any degree.

Mandeep Kaur L. Hemchandra Sharma

Head of Department, Civil SUPERVISOR

Assistant Engineer

PWD Department, Manipur

INTRODUCTION

ESTABLISHMENT OF A NEED FOR A DEEP FOUNDATION

The first difficult problem facing the foundation designer is to establish

whether or not the site conditions dictate that a deep foundation must be

used. Typical situations in which piles may be needed as well as additional uses of

deep foundations are shown in Fig.

Figure 9-1(a) shows the most common case in which the upper soil strata are too

compressible or too weak to support heavy vertical loads. In this case, deep

foundations transfer loads to a deeper dense stratum and act as toe bearing

foundations. In the absence of a dense stratum within a reasonable depth, the loads

must be gradually transferred, mainly through soil resistance along shaft, Figure 9-

1(b). An important point to remember is that deep foundations transfer load

through unsuitable layers to suitable layers. The foundation designer must define

at what depth suitable soil layers begin the soil profile.

Deep foundations are frequently needed because of the relative inability of

shallow footings to resist inclined, lateral, or uplift loads and overturning

moments. Deep foundations resist uplift loads by shaft resistance, Figure 9-

1(c). Lateral loads are resisted either by vertical deep foundations in bending,

Figure 9-1 (d), or by groups are vertical and battered foundations, which combine

the axial and lateral resistances of all deep foundations in the group, Figure

9-1(e). Lateral loads from overhead highway signs and noisewalls may also be

resisted by groups of deep foundations, Figure 9-1(f)

Deep foundations are often required when scour around footings could cause

loss of bearing capacity at shallow depths, Figure 9-1(g). In this case the deep

foundations must extend below the depth of scour and develop the full capacity in

the support zone below the level of expected scour. Costly damage and the need

for future underpinning can be avoided by properly designing scour conditions

DESIGN OF PILE FOUNDATIONS

Driving piles for a foundation is a crude and brutal process. The

interactions among the piles and the surrounding soil are complex.

Insertion of piles generally alters the character of the soil and intense

strains are set up locally near the piles. The nonhomogenity of soils,

along with the effects of the pile group and pile shape, add further

difficulties to the understanding of soil-pile interaction.

Broad generalizations about pile behavior are unrealistic. An

understanding of the significance of several factors involved is required

to be successful in the design of pile foundations. Because of the

inherent complexities of pile behavior, it is necessary to use practical,

semi-empirical methods of design, and to focus attention on significant

factors rather than minor or peripheral details. Thefoundation engineer

must have a thorough understanding of foundation loads,

subsurface conditions including soil/rock properties and behavior, the

significance or special design events, foundation performance criteria,

and current practices in foundation design and construction in the

area where the work is to be done to arrive at the optimum foundation

solution.

CONSTRUCTION OF PILE FOUNDATIONS

Construction of a successful driven pile foundation that meets the design objectives

depends on relating the requirements of the static analysis methods presented on

the plans to the dynamic methods of field installation and construction control. The

tools for obtaining such a foundation must be explicitly incorporated into the plans

and specifications as well as included in the contract administration of the project.

It is important that a pile foundation be installed to meet the design requirements

for compressive, lateral and uplift capacity. This may dictate driving piles for a

required ultimate capacity or to a predetermined length established by the designer.

It is equally important to avoid pile damage or foundation cost overruns by

excessive driving. These objectives can all be satisfactorily achieved by use of

wave equation analysis, dynamic monitoring of pile driving, and in some cases,

static load testing. Commonly used dynamic formulas, suchas Engineering New

formula, have proven unreliable as pile capacities increased and more

sophisticated pile installation equipment was routinely used by contractors.

Knowledgeable construction supervision and inspection are the keys to

proper installation of piles. State-of-the art designs and detailed plansand

specifications must be coupled with good construction supervision to achieve

desired results. Post construction review of pile driving results versus

predictions regarding pile driving resistances, pile length, field problems, and

load test capacities is essential. These reviews add to the experience of all

engineers involved on the project and will enhance their skills for future projects.

SELECTION OF PILE TYPE

The selection of appropriate pile types for any project involves the consideration of

several design and installation factors including pile characteristics subsurface

conditions and performance criteria. Figure 9-3 shows several pile classifications.

In addition to the considerations provided in the tables, the problems posed by the

specific project location and topography must be considered in any pile selection

process. Following are some of the usually encountered problems:

1. Driven piles may cause vibration damage to adjacent structures or facilities.

2. Remote areas may restrict driving equipment size and, therefore, pile size.

3. Local availability of certain materials and capability of contractors may have

decisive effects on pile selection.

4. Waterborne operations and transportation limitations may dictate use of shorter

pile sections due to pile handling restrictions.

5. Steep terrain may make the use of certain pile equipment costly or impossible.

Although one pile type may emerge as the only logical choice for a given set of

conditions, more often several different types may meet all the requirements

for a particular structure. In such cases, the final choice should be made on the

basis of a cost analysis that assesses the over-all cost of alternatives. This would

include uncertainties in execution, time delays, cost of load testing programs,

as well as differences in the cost of pile caps and other elements of the

structure that may differ among alternatives. For major projects, alternate

foundation designs should be considered for inclusion in the contract

documents if there is a potential for cost savings.

7. GROUP EFFECTS

7.1 GENERAL

Piles installed in a group to form a foundation will, when loaded, give rise to

interaction between individual piles as well as between the structure and the piles.

The pilesoil-pile interaction arises as a result of overlapping of stress (or strain)

fields and could affect both the capacity and the settlement of the piles. The piled

foundation as a whole also interacts with the structure by virtue of the difference in

stiffness. This foundation-structure interaction affects the distribution of loads in

the piles, together with forces and movements experienced by the structure.

The analysis of the behaviour of a pile group is a complex soil-structure interaction

problem. The behaviour of a pile group foundation will be influenced by, inter alia

:

(a) method of pile installation, e.g. replacement or displacement

piles,

(b) dominant mode of load transfer, i.e. shaft resistance or endbearing,

(c) nature of founding materials,

(d) three-dimensional geometry of the pile group configuration,

(e) presence or otherwise of a ground-bearing cap, and

(f) relative stiffness of the structure, the piles and the ground.

Traditionally, the assessment of group effects is based on some 'rules-of-thumb' or

semi-empirical rules derived from field observations. Recent advances in analytical

studies have enabled more rational design principlesto be developed. With

improved computing capabilities, general pilegroups with a combination of vertical

and raking piles subjected to complex loading can be analysed in a fairly rigorous

manner and parametric studies can be carried out relatively efficiently and

economically. This Chapter firstly considers the ultimate limit states for a range of

design situations for pile groups. Methods of assessing the deformation of single

piles and pile groups are then presented. Finally, some design considerations for

soil-structure interaction problems are

discussed.

7.2 MINIMUM SPACING OF PILES

The minimum spacing between piles in a group should be chosen in relation to the

method of pile construction and the mode of load transfer. It is recommended that

the following guidelines on minimum pile spacing may be adopted for routine

design :

(a) For bored piles which derive their capacities mainly from

shaft resistance and for all types of driven piles, minimum

166

centre-to-centre spacing should be greater than the perimeter

of the pile (which should be taken as that of the larger pile

where piles of different sizes are used); this spacing should

not be less than 1 m as stipulated in the Code of Practice for

Foundations (BD, 2004a).

(b) For bored piles which derive their capacities mainly from

end-bearing, minimum clear spacing between the surfaces

of adjacent piles should be based on practical

considerations of positional and verticality tolerances of

piles. It is prudent to provide a nominal minimum clear

spacing of about 0.5 m between shaft surfaces or edge of

bell-outs. For mini-piles socketed into rock, the minimum

spacing should be taken as the greater of 0.75 m or twice

the pile diameter (BD, 2004a).

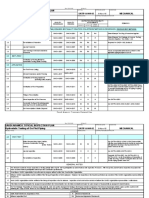

The recommended tolerances of installed piles are shown in Table 7.1 (HKG,

1992).

Closer spacing than that given above may beadopted only when it has been

justified by

detailed analyses of the effect on the settlement and bearing capacityof the pile

group.

Particular note should be taken of adjacent piles founded at different levels, in

which case the

effects of the load transfer and soil deformations arising from the piles at a higher

level on

those at a lower level need to be examined. The designer should also specify a pile

installation sequence within a group that will assure maximum spacing between

shafts being

installed and those recently concreted.

OBJECTIVES

The overall objective of this report is to document the lessons learned from the

installation of

driven piles on the CA/T project. This includes review and analysis of pile design

criteria and

specifications, pile driving equipment and methods, issues encountered during

construction,

dynamic and static load test data, and cost data for different pile types and site

conditions.

SCOPE

This report consists of six chapters, the first of which presents introductory and

background

information about the contracts where significant pile driving occurred. The second

chapter

discusses the criteria and specifications usedfor pile design and construction on the

CA/T

project. The third chapter documents the equipment and methods used for pile

driving. Major

construction issues encountered during driving, such as pile and soil heave, are

also discussed.

The fourth chapter presents the results of pile load tests performed on test piles

using static and

dynamic test methods, including a discussion of axial capacity, dynamic soil

parameters, and pile

driving criteria. The fifth chapter presents the unit costs for pile driving and

preaugering for the

different pile types used, as identified in the original construction bids. Finally, the

sixth chapter

summarizes the important findings of this study

You might also like

- 6,8dk-28 Instruction Manual (Maintenance)Document189 pages6,8dk-28 Instruction Manual (Maintenance)Ira Paschenko100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Method of Statement Grounding System & Lightning ProtectionDocument7 pagesMethod of Statement Grounding System & Lightning Protectionafm0% (1)

- Measurement of in Situ Shear Strength of Rock Mass: Rajbal SinghDocument12 pagesMeasurement of in Situ Shear Strength of Rock Mass: Rajbal SinghManish Kumar SinghNo ratings yet

- Optimum Design of An Industrial Warehouse Using Staad-ProDocument4 pagesOptimum Design of An Industrial Warehouse Using Staad-PromahalakshmiNo ratings yet

- Ch.5 Structural Design of Foundations: Q P L BDocument8 pagesCh.5 Structural Design of Foundations: Q P L BHusam A. Al-HaidriNo ratings yet

- Seminar Final ReportDocument28 pagesSeminar Final Reportkavya.dasthariNo ratings yet

- Strip FootingDocument10 pagesStrip FootingAzam Islam KhanNo ratings yet

- Hauling 2 InstallationDocument1 pageHauling 2 InstallationJuragan IwalNo ratings yet

- Buildings Ordinance (Cap 123) Environmental Permit Noise Permit SpecificationsDocument10 pagesBuildings Ordinance (Cap 123) Environmental Permit Noise Permit SpecificationsJasim AbdNo ratings yet

- Comparison of Seismic Response of Multi-Storied Structures With and Without Soil Structure InteractionDocument4 pagesComparison of Seismic Response of Multi-Storied Structures With and Without Soil Structure InteractionAkhil LamdadeNo ratings yet

- Geometrical Issues On The Structural Analysis of TDocument20 pagesGeometrical Issues On The Structural Analysis of TPower System OperationNo ratings yet

- One Way Joist FlorrDocument15 pagesOne Way Joist Florrak47_uziiNo ratings yet

- Delhi Metrorail Tender Documents Volume-1Document187 pagesDelhi Metrorail Tender Documents Volume-1Donato GaloisNo ratings yet

- Concrete Foundation DesignDocument3 pagesConcrete Foundation DesignPradeep Kumar SukumaranNo ratings yet

- Analytical Method in Reinforced ConcreteDocument0 pagesAnalytical Method in Reinforced Concretefoush bashaNo ratings yet

- Flooring Design GuideDocument81 pagesFlooring Design GuideArmin KovacevicNo ratings yet

- Dicusson On Moment Release in StaadDocument4 pagesDicusson On Moment Release in StaadGautam PaulNo ratings yet

- Pushover Analysis For Seismic Assessment and Design of StructuresDocument287 pagesPushover Analysis For Seismic Assessment and Design of Structuresapirakq100% (2)

- Transmission Towers With Different Configurations AnalysisDocument6 pagesTransmission Towers With Different Configurations AnalysisFarhadNo ratings yet

- Review Paper Study On Steel Transmission TowerDocument4 pagesReview Paper Study On Steel Transmission TowerEditor IJTSRDNo ratings yet

- SC348-ME-FDN-006 - RE - Foundation DrawingDocument6 pagesSC348-ME-FDN-006 - RE - Foundation DrawingsajanNo ratings yet

- CE5710 Assignment IDocument1 pageCE5710 Assignment INani RujaNo ratings yet

- Design Aids of Flexural Members and Beam Columns Based On Limit State Method PDFDocument16 pagesDesign Aids of Flexural Members and Beam Columns Based On Limit State Method PDFscshekarNo ratings yet

- Guidelines For Design and Selection of Module Mounting StructuresDocument5 pagesGuidelines For Design and Selection of Module Mounting StructuresRabindra SinghNo ratings yet

- Pole Design by PLS-POLE ProgramDocument5 pagesPole Design by PLS-POLE ProgramMohammed K. HayderNo ratings yet

- Shear Design of Beams PDFDocument7 pagesShear Design of Beams PDFBlend DlerNo ratings yet

- Seismic Analysis and Design of Multistoried Steel Structure Using IS 1893:2016Document14 pagesSeismic Analysis and Design of Multistoried Steel Structure Using IS 1893:2016Shantanu DateraoNo ratings yet

- Study of Substitute Frame Method of Analysis For Lateral Loading ConditionsDocument39 pagesStudy of Substitute Frame Method of Analysis For Lateral Loading ConditionschauhannishargNo ratings yet

- Dynamic Active Earth Pressure On Retaining StructuresDocument10 pagesDynamic Active Earth Pressure On Retaining StructurescristiannecivilNo ratings yet

- Mac Alloy Post Tensioning - Macalloy 1030 - Nov 2011Document12 pagesMac Alloy Post Tensioning - Macalloy 1030 - Nov 2011Karl FarrugiaNo ratings yet

- Corrosion On Solar StructuresDocument2 pagesCorrosion On Solar StructuresyounNo ratings yet

- Slim Floor: Long Carbon Europe Sections and Merchant BarsDocument36 pagesSlim Floor: Long Carbon Europe Sections and Merchant BarstankeanleongNo ratings yet

- Minimum Depth and CoverDocument1 pageMinimum Depth and CovershafiullahNo ratings yet

- Comparative Response Assessment of Steel Frames With Different Bracing PDFDocument14 pagesComparative Response Assessment of Steel Frames With Different Bracing PDFaxl_calin82No ratings yet

- Ple-02 VSL Brian LimDocument22 pagesPle-02 VSL Brian LimAsep SummitNo ratings yet

- Working Draft of Combined Piled-Raft Foundation, Doc - CED 43 (196) WDDocument19 pagesWorking Draft of Combined Piled-Raft Foundation, Doc - CED 43 (196) WDKedarNo ratings yet

- Analysis and Comparison of Connection in Steel Structures PDFDocument55 pagesAnalysis and Comparison of Connection in Steel Structures PDFsililloNo ratings yet

- Cost Comparison Between RCC Slab Steel Composite Slab Structure of G 5 Storied BuildingDocument4 pagesCost Comparison Between RCC Slab Steel Composite Slab Structure of G 5 Storied BuildingSuman PolleyNo ratings yet

- Design and Analysis of Prestressed Shell Roof StructuresDocument13 pagesDesign and Analysis of Prestressed Shell Roof StructuresIJRASETPublicationsNo ratings yet

- Hoisting FacilitiesDocument22 pagesHoisting FacilitiesArmie May RicoNo ratings yet

- Sand Cushion: 1. IntroductionDocument2 pagesSand Cushion: 1. Introductionlokesh nandinaNo ratings yet

- 53-Steel Structures (Gantry Structure)Document13 pages53-Steel Structures (Gantry Structure)Sarmad HussainNo ratings yet

- Strength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsDocument6 pagesStrength and Behavior of Reinforced Concrete Obtuse Corners Under Opening Bending MomentsValdemir ColaresNo ratings yet

- Midas Gen AnalysisDocument305 pagesMidas Gen AnalysisMyrah MirandaNo ratings yet

- Comparative Study of TRUSS Bridges Under Static ConditionsDocument6 pagesComparative Study of TRUSS Bridges Under Static ConditionsIJRASETPublicationsNo ratings yet

- Revision of Is - 1893 Part 1Document8 pagesRevision of Is - 1893 Part 1BMSF khaliqeNo ratings yet

- Design and Construction of Mat (Raft) Foundations - BookDocument10 pagesDesign and Construction of Mat (Raft) Foundations - BookbatteekhNo ratings yet

- 8 - One Way Slabs SDocument23 pages8 - One Way Slabs SHamaaaNo ratings yet

- Hilti HIT System - Rebar ApplicationDocument34 pagesHilti HIT System - Rebar ApplicationTerence CheeNo ratings yet

- Unit Iii-Sub Structure ConstructionDocument30 pagesUnit Iii-Sub Structure Constructionumamaheswari skNo ratings yet

- Design of Driven Pile FoundationDocument25 pagesDesign of Driven Pile FoundationDedi ApriadiNo ratings yet

- Short RCC Column Performances in Different ConditionsDocument16 pagesShort RCC Column Performances in Different ConditionssjmorabadNo ratings yet

- Lateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16Document12 pagesLateral Loads of 4 Level Shelving, With Hilti Anchorage, Based On ASCE 7-16kosdsdsNo ratings yet

- WA209 01F02 (Rev0) BB ReportDocument92 pagesWA209 01F02 (Rev0) BB ReportnilangNo ratings yet

- 4 Control of Deflections in Post-Tensioned SlabsDocument4 pages4 Control of Deflections in Post-Tensioned SlabsMqAshlady100% (1)

- Amendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeDocument9 pagesAmendment No. 1 November 2014 TO Is 4326: 2013 Earthquake Resistant Design and Construction of Buildings - Code of PracticeAKSNo ratings yet

- Diagrid Systems For Response Spectrum Analysis With Regular and Irregular Structures Using ETABSDocument7 pagesDiagrid Systems For Response Spectrum Analysis With Regular and Irregular Structures Using ETABSEditor IJTSRD100% (1)

- Phase 1Document32 pagesPhase 1KamarajanNo ratings yet

- Foundation Design IsOCD 19902Document38 pagesFoundation Design IsOCD 19902Abdulkadir DinçerNo ratings yet

- Why Soil Conditions Are Important To Solar DesignsDocument4 pagesWhy Soil Conditions Are Important To Solar DesignsNITIN MISHRANo ratings yet

- Ar010Document340 pagesAr010Maritza EnriquezNo ratings yet

- Piles and Caissons PDFDocument30 pagesPiles and Caissons PDFMahmood MuftiNo ratings yet

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- InspirationDocument1 pageInspirationSuresh KhangembamNo ratings yet

- CIV407 Earthquake Engineering 17413::gaurav Sharma 3.0 0.0 0.0 3.0 Courses With Numerical and Conceptual FocusDocument10 pagesCIV407 Earthquake Engineering 17413::gaurav Sharma 3.0 0.0 0.0 3.0 Courses With Numerical and Conceptual FocusSuresh KhangembamNo ratings yet

- Improvement of Soil Subgrade Characteristics Using Coir FibreDocument73 pagesImprovement of Soil Subgrade Characteristics Using Coir FibreSuresh KhangembamNo ratings yet

- Cement Material PDFDocument2 pagesCement Material PDFMarlena RossNo ratings yet

- Composite MaterialDocument2 pagesComposite MaterialSuresh KhangembamNo ratings yet

- 1 - Academic Calendar of Spring Term 2014-15 For Regular Programmes Including B.pharmacy and Programmes Offered Under LsadDocument2 pages1 - Academic Calendar of Spring Term 2014-15 For Regular Programmes Including B.pharmacy and Programmes Offered Under LsadDhirendra Kumar SinghNo ratings yet

- SYPNOSISDocument3 pagesSYPNOSISSuresh KhangembamNo ratings yet

- The Generalized Heat Equation For Laser-Crystalline Solid InteractionDocument4 pagesThe Generalized Heat Equation For Laser-Crystalline Solid InteractionSuresh KhangembamNo ratings yet

- Presentation 1Document1 pagePresentation 1Suresh KhangembamNo ratings yet

- Lecture6 Locating EpicenterDocument15 pagesLecture6 Locating EpicenterArun Goyal100% (2)

- Cover Page PDFDocument6 pagesCover Page PDFSuresh KhangembamNo ratings yet

- 2 - Guidelines For Summer Internship Report CivilDocument6 pages2 - Guidelines For Summer Internship Report CivilSuresh KhangembamNo ratings yet

- R PT Timetable StudentDocument1 pageR PT Timetable StudentSuresh KhangembamNo ratings yet

- The Generalized Heat Equation For Laser-Crystalline Solid InteractionDocument4 pagesThe Generalized Heat Equation For Laser-Crystalline Solid InteractionSuresh KhangembamNo ratings yet

- InTech-Pulsed Laser Heating and MeltingDocument24 pagesInTech-Pulsed Laser Heating and MeltingDaniel RosenNo ratings yet

- PrintDocument1 pagePrintSuresh KhangembamNo ratings yet

- Theoretical Study of Laser Heating and Dissociation Reactions in Solids Using Ultrafast Timeresolved Xray DiffractionDocument6 pagesTheoretical Study of Laser Heating and Dissociation Reactions in Solids Using Ultrafast Timeresolved Xray DiffractionSuresh KhangembamNo ratings yet

- R PT Timetable StudentDocument2 pagesR PT Timetable StudentSuresh KhangembamNo ratings yet

- 2 - Guidelines For Summer Internship Report CivilDocument6 pages2 - Guidelines For Summer Internship Report CivilSuresh KhangembamNo ratings yet

- Interglobe Aviation LTDDocument2 pagesInterglobe Aviation LTDSuresh KhangembamNo ratings yet

- To Whom So Ever It May Concern: 1207::B.Tech.-CEDocument1 pageTo Whom So Ever It May Concern: 1207::B.Tech.-CESuresh KhangembamNo ratings yet

- 2 - Guidelines For Summer Internship Report CivilDocument6 pages2 - Guidelines For Summer Internship Report CivilSuresh KhangembamNo ratings yet

- SyllabusDocument2 pagesSyllabusSuresh KhangembamNo ratings yet

- Solid SolnDocument3 pagesSolid SolnSuresh KhangembamNo ratings yet

- IRRIGation CompleteDocument65 pagesIRRIGation CompleteSuresh KhangembamNo ratings yet

- Building ConstructionDocument26 pagesBuilding ConstructionSuresh KhangembamNo ratings yet

- Project Headingproject HeadingDocument3 pagesProject Headingproject HeadingSuresh KhangembamNo ratings yet

- Project Report - Six Months Summer TrainingDocument12 pagesProject Report - Six Months Summer TrainingSuresh KhangembamNo ratings yet

- Construction Program - Kishnagarh-part-II - Rev-01 PDFDocument8 pagesConstruction Program - Kishnagarh-part-II - Rev-01 PDFnitinNo ratings yet

- Statement of Requirements For Roof ProjectDocument2 pagesStatement of Requirements For Roof ProjectJun OrtizNo ratings yet

- Report On Bridge Development in PakistanDocument8 pagesReport On Bridge Development in Pakistankhawaja Ali100% (1)

- Ramset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSDocument2 pagesRamset SARB ANZ Ed.3 DynaBolt Plus SLEEVE ANCHORSScott McCallumNo ratings yet

- Testing and Commissioning Procedure: 2017 EDITIONDocument26 pagesTesting and Commissioning Procedure: 2017 EDITIONvin ssNo ratings yet

- WMCAUS2017 Book PDFDocument843 pagesWMCAUS2017 Book PDFEmre ILGINNo ratings yet

- Valvulas CheckDocument4 pagesValvulas CheckLAM AAANo ratings yet

- Soil Reinforcement Using CSA A Case Study of Indian SoilDocument6 pagesSoil Reinforcement Using CSA A Case Study of Indian SoilPj RoblesNo ratings yet

- MBCC ProfileDocument107 pagesMBCC ProfileNajeeb Ibn AbdullaNo ratings yet

- List of Jsce Stands 2010Document3 pagesList of Jsce Stands 2010dsbisht100% (1)

- CET 513 Lecturer NoteDocument13 pagesCET 513 Lecturer NoteAminu AbdullahiNo ratings yet

- QP DB November 2016Document2 pagesQP DB November 2016UmaGunaNo ratings yet

- Bowles J. E. - FDN - Analysis & DSNDocument2 pagesBowles J. E. - FDN - Analysis & DSNharishNo ratings yet

- Sources of Water (Water Supply Engineering)Document9 pagesSources of Water (Water Supply Engineering)Shuvanjan Dahal86% (7)

- Project Asset Integrity Plan (EPCIC Execute Phase) For XXX Development ProjectDocument45 pagesProject Asset Integrity Plan (EPCIC Execute Phase) For XXX Development ProjectMohd Zaieri100% (1)

- C1398Document3 pagesC1398Jorge Luis Arevalo Lopez100% (1)

- DiaphragmDocument8 pagesDiaphragmTrần Bé ThêuNo ratings yet

- ASTM A351 (Stainless Steel Castings)Document5 pagesASTM A351 (Stainless Steel Castings)Fendi MirandaNo ratings yet

- Earthquake Resistant Structure - NOTES 3rd YR V SEMDocument12 pagesEarthquake Resistant Structure - NOTES 3rd YR V SEMrutuja100% (1)

- Memorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyDocument7 pagesMemorandum: Project: Library Archives Museum Project Date: 11 30 2010 Subject: Alternate Sites Feasibility StudyECI HyerNo ratings yet

- Design of Composite Steel DeckDocument1 pageDesign of Composite Steel DeckAndro Rebuyas0% (1)

- Catalogo BVMDocument16 pagesCatalogo BVMLeonardo Rachen RodriguezNo ratings yet

- Uet LahoreDocument43 pagesUet LahoreMunawwar KhanNo ratings yet

- D Instruction To TenderersDocument11 pagesD Instruction To TenderersHUI NEE ONGNo ratings yet

- Renewable Energy Technologies (Elective) Sample Question Paper (Msbte Study Resources)Document4 pagesRenewable Energy Technologies (Elective) Sample Question Paper (Msbte Study Resources)Lakshman Naik100% (1)

- Saudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingDocument10 pagesSaudi Aramco Typical Inspection Plan Hydrostatic Testing of On-Plot PipingAhdal NoushadNo ratings yet