Professional Documents

Culture Documents

Shed 10x16 Plans

Uploaded by

Lory Dena Heath100%(1)100% found this document useful (1 vote)

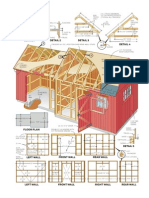

342 views8 pagesAt 10 x 16 ft., this handsome garden shed is large enough for most backyard needs. Add an interior partition so it serves double duty as a storage shed and a playroom. Figure on spending between $1600 and $2000 to build this shed.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAt 10 x 16 ft., this handsome garden shed is large enough for most backyard needs. Add an interior partition so it serves double duty as a storage shed and a playroom. Figure on spending between $1600 and $2000 to build this shed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

342 views8 pagesShed 10x16 Plans

Uploaded by

Lory Dena HeathAt 10 x 16 ft., this handsome garden shed is large enough for most backyard needs. Add an interior partition so it serves double duty as a storage shed and a playroom. Figure on spending between $1600 and $2000 to build this shed.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Backyard Barn

A Colonial-style storage shed that anyone can build.

Homeowners complain about having too much storage space about as

often as they do about having an overabundance of cash. It just doesn't

happen.

Nearly every home, regardless of its size, has a shortage of accessible

storage space. Need proof? Take a peek into the average garage and

you'll likely find it crammed full of bicycles, lumber, garden tools, trash

cans, outdoor power equipment, sports gear and car-care supplies.

An occasional spring-cleaning can help you reorganize and reclaim

some space, but it's only a matter of time before the clutter returns.

What you really need is more space, and one of the best ways to find it

is to create it by building a backyard storage shed.

At 10 x 16 ft., this handsome garden shed is large enough for most backyard needs. We've added an interior

partition so it serves double duty as a storage shed and an all-weather children's playroom. Double doors on

the side and gable end make it easy to access the space.

We built the Colonial -style garden shed shown here from a set of mail-

order building plans. The 10 x 16-ft. outbuilding has easy-to-install

plywood siding, three large windows and two pairs of doors. The entire

building could be used for storage, but we decided to divide the interior

space into two separate areas: a 4 x 10-ft. tool-storage area and a 10 x

12-ft. children's playroom.

It's hard to say exactly how much it will cost you to build this shed.

Lumber prices fluctuate almost daily and vary widely from one region of

the country to another, but figure on spending between $1600 and

$2000. Before starting construction, take your plans to your local

building department and apply for a building permit.

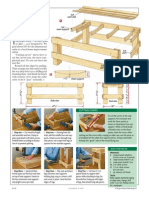

Cut all the 2 x 6 floor joists to length and set them between

the two band joists and on top of the mudsills (Photo 2).

Space the joists 16 in. on center and secure them with 16d

galvanized nails (Photo 3). Before nailing down the plywood

floor, secure the floor frame with four steel -cabled ground

anchors, which are code-required in some areas. Bolt one

anchor to each corner of the frame and drive the holddown

spikes deep into the ground.

For the shed floor, we used 3/4-in. tongue-and-groove ACX

plywood. Tongue-and-groove joints create a rigid floor that

doesn't bounce or sag. Secure the plywood with 8d

galvanized nails (Photo 4).

Framing The Roof Trusses

Each truss is made up of two 2 x 4 rafters and one 2 x 4

ceiling joist. The three boards are joined together with 1/2-

in. plywood gussets. To speed up the assembly process,

build all the trusses on the shed floor before erecting the

walls. Start by cutting all the rafters to length with a 40

angle at one end of each. Cut 2 x 4s to 10 ft. long for the

bottom chords of the trusses. Also, cut all of the plywood

gussets.

Make a template on the shed floor for assembling the

trusses. Begin by laying out the parts for one truss. Align

the bottom chord with the edge of the plywood floor. Then

cut four 24-in. -long 2 x 4s. Lay two alongside each rafter

and screw them to the plywood floor. Now use these short

boards as stopblocks for laying out and assembling each

truss. Fasten plywood gussets to each side of every truss

with carpenter's glue and 1-in. roofing nails (Photo 5) and

set the trusses aside.

Set the 2 x 6 floor joists on top of the 2 x 8 mudsills.

These floor-frame parts are cut from pressure-

treated lumber.

Install a 2 x 6 floor joist every 16 in. Fasten them by

nailing through the band joists with 16d galvanized

nails.

Use 3/4-in. exterior-grade, tongue-and-groove

plywood for the floor. Secure the plywood to the

frame with 8d nails.

Assemble all of the roof trusses on the shed floor.

Nail plywood gussets across the joints on both sides

of the trusses.

Building The Walls

Cut all the 2 x 4 parts for the end wall and lay them out on

the shed floor. Space the studs 24 in. on center and secure

them with 16d nails (Photo 6). Then cut the plywood siding

to size and nail it to the wall framing with 6d galvanized

nails.

Tilt the wall up into place (Photo 7) and secure it with 3-in.

deck screws (Photo 8). Frame and erect the rear wall,

followed by the front wall. Then, install the interior partition.

If you're including a playroom, as we did, cover the partition

side that faces that room with plywood, and screw it in

place. Then install the final wall.

Setting The Roof Trusses

Start framing the roof by installing a sheathed truss at each

end of the shed (Photo 9). Secure these with 3-in. deck

screws driven into the top wall plate. Then, install the

remaining roof trusses (Photo 10). Set one truss over every

wall stud and fasten it by driving 3-in. deck screws up

through the top wall plate.

Cover the trusses with 1/2-in. CDX plywood, then nail on

the asphalt roof shingles (Photo 11).

Build the exterior walls on the floor. Assemble the 2

x 4s with 16d nails and then add the plywood

sheathing.

Carefully raise the end wall into position. Note how

the plywood siding hangs down to cover the floor

framing.

With the wall in position, secure it by screwing down

through the bottom 2 x 4 plate and into the floor

framing.

Start the roof by installing the end trusses. Note that

the plywood siding is nailed on before the truss is

raised. A central 2 x 4 chord stiffens the sheathing.

Carefully slide the roof trusses onto the walls. Space

them 24 in. on center and secure them with 3-in.

screws.

Cover the plywood roof sheathing with asphalt

shingles. Eight bundles are needed to complete this

roof.

Finishing Touches

Secure perforated hardboard to the partition wall in the tool-

storage area (Photo 12), and install a transom window over

the gable-end doors (Photo 13). Make the window by

assembling a simple wood frame to hold a piece of double-

strength glass.

Next, build the doors from 1 x 6 tongue-and-groove cedar

boards and battens cut from 1x stock. Attach the battens

with 1-1/2-in. screws, and hang the doors with heavy-duty

strap hinges (Photo 14).

For the windows, we used wooden barn sash, which tilt in

for ventilation (Photo 15). The 2 x 3-ft. windows are

available at most lumberyards for about $60 apiece. Install

a barrel bolt at the top of each sash so they can be locked

shut.

The textured plywood siding we installed came with a

factory-applied coat of primer. We finished it with two coats

of barn-red acrylic latex paint. If you woul d prefer to stain

your shed, be sure to buy unprimed plywood siding.

Install perforated hardboard to the partition wall in

the tool-storage area. Fasten it with 1-1/4-in. screws.

Make the 5-ft.-long transom window from a wooden

frame and a single piece of glass. Install it over the

end doors.

Use tongue-and-groove cedar to build the doors.

Then, hang the doors with heavy-duty strap hinges.

Slip the barn-sash window into the window frame

and set it down on the sill. A simple barrel bolt holds

it closed.

You might also like

- Easy DIY Garden Shed Plans - 1Document4 pagesEasy DIY Garden Shed Plans - 1Fred Mirtz100% (1)

- Handy Simple ShedDocument6 pagesHandy Simple ShedMiguel Angel Rodríguez Zenteno100% (1)

- Building Plans For ShedsDocument24 pagesBuilding Plans For ShedsArik Seo100% (1)

- Multipurpose Garden ShedDocument5 pagesMultipurpose Garden ShedEloy Rodriguez100% (1)

- Handy Screen HouseDocument4 pagesHandy Screen HouseMiguel Angel Rodríguez ZentenoNo ratings yet

- Tool Shed PlansDocument26 pagesTool Shed PlansWinnie Mandela100% (2)

- Building-a-16x24-pole-barn-plansDocument38 pagesBuilding-a-16x24-pole-barn-plansPB50% (2)

- Free 12 X 8 Shed Plan: Click Here To Download 12,000 Shed PlansDocument24 pagesFree 12 X 8 Shed Plan: Click Here To Download 12,000 Shed PlansRamón Baró100% (1)

- When Nature Calls Outhouse PlansDocument18 pagesWhen Nature Calls Outhouse PlansMoreMoseySpeed100% (6)

- Makerspace Workbench PDFDocument9 pagesMakerspace Workbench PDFBeatriz FreitasNo ratings yet

- 4 Garden Shed Plan Books 10’ x 14’, 12’ x 16’, 12’ x 12’, 10’ x 14’ Step By Step Pictures, Videos, Instructions and PlansFrom Everand4 Garden Shed Plan Books 10’ x 14’, 12’ x 16’, 12’ x 12’, 10’ x 14’ Step By Step Pictures, Videos, Instructions and PlansNo ratings yet

- Building A Garden Shed Step By Step Instructions and PlansFrom EverandBuilding A Garden Shed Step By Step Instructions and PlansRating: 2 out of 5 stars2/5 (1)

- How To Build A Small Cabin Or Bunkhouse With 5 Small Cabin Plans Pictures, Plans and VideosFrom EverandHow To Build A Small Cabin Or Bunkhouse With 5 Small Cabin Plans Pictures, Plans and VideosRating: 4 out of 5 stars4/5 (2)

- How to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UseFrom EverandHow to Build Garden Furniture: Plans and Complete Instructions for Making Lawn Chairs, Benches, Settees and a Chaise Longue, Tables, Dinettes and Picnic Sets, Portable and Folding Pieces of All Kinds for Outdoor UseNo ratings yet

- Brickwork Projects for Patio & Garden: Designs, Instructions and 16 Easy-to-Build ProjectsFrom EverandBrickwork Projects for Patio & Garden: Designs, Instructions and 16 Easy-to-Build ProjectsRating: 5 out of 5 stars5/5 (1)

- 100 Weekend Projects Anyone Can Do: Easy, practical projects using basic tools and standard materialsFrom Everand100 Weekend Projects Anyone Can Do: Easy, practical projects using basic tools and standard materialsRating: 5 out of 5 stars5/5 (4)

- Build a Basic 12' x 8' ShedDocument22 pagesBuild a Basic 12' x 8' ShedEric Blanchard100% (3)

- FH01JUN CraftsmanShedDocument27 pagesFH01JUN CraftsmanShedjuan100% (3)

- Storage Shed Blueprints and DesignsDocument25 pagesStorage Shed Blueprints and Designsapi-236974610100% (1)

- Create A Relaxing Hammock Hideaway - FH03JunDocument11 pagesCreate A Relaxing Hammock Hideaway - FH03JunJvlValenzuelaNo ratings yet

- DIY Cabin Building Plans PDFDocument6 pagesDIY Cabin Building Plans PDFRoberto Landa100% (5)

- B C Y C B: Ollector S DitionDocument87 pagesB C Y C B: Ollector S Ditionandrea berna valero100% (3)

- FH04JAU RusticYardShed PDFDocument13 pagesFH04JAU RusticYardShed PDFjuan83% (6)

- DO Lookout 1 Cabin PlansDocument29 pagesDO Lookout 1 Cabin PlansJerry FoltzNo ratings yet

- 00 Folding Picnic Table DIY Out of 2x4 LumberDocument48 pages00 Folding Picnic Table DIY Out of 2x4 Lumberbf100% (2)

- Treasured Chest Build A Jewelry BoxDocument9 pagesTreasured Chest Build A Jewelry BoxThanasis KyrgiazoglouNo ratings yet

- Diy - Woodwork - Plans - Shed Framing PDFDocument0 pagesDiy - Woodwork - Plans - Shed Framing PDFSignora LofaroNo ratings yet

- Bench - Build A Classic Porch Glider - PopMecDocument8 pagesBench - Build A Classic Porch Glider - PopMecvdbroger100% (1)

- Build Your Own French Doors - Popular Woodworking MagazineDocument34 pagesBuild Your Own French Doors - Popular Woodworking Magazinekostas1977No ratings yet

- Shed Storage2Document9 pagesShed Storage2Bob Pouliot88% (8)

- FH03JAu GardenShed PDFDocument17 pagesFH03JAu GardenShed PDFMax Popp80% (5)

- #24-001: Convertible Folding Picnic Table/BenchDocument24 pages#24-001: Convertible Folding Picnic Table/BenchDorothy McDanielNo ratings yet

- David de Lossy/Photodisc/Getty ImagesDocument15 pagesDavid de Lossy/Photodisc/Getty ImagesasiasiNo ratings yet

- Wolfcraft Wooden Deck BuildingDocument16 pagesWolfcraft Wooden Deck Buildingvergopi100% (3)

- The Family Handyman-2011!07!08 520 Garden ShedDocument63 pagesThe Family Handyman-2011!07!08 520 Garden ShedVermontique100% (9)

- Download 12,000 Shed PlansDocument27 pagesDownload 12,000 Shed PlansRadu_IS100% (2)

- Folding Workbench PlansDocument11 pagesFolding Workbench Plansbwatkins6No ratings yet

- Folding Portable WorkbenchDocument19 pagesFolding Portable WorkbenchVideoSurv SynologyNo ratings yet

- Wichita Cabin Coop2Document81 pagesWichita Cabin Coop2caapromo67% (3)

- Domino Zigzag ChairDocument6 pagesDomino Zigzag ChairAlex Johnston0% (1)

- Sample Plans PDFDocument40 pagesSample Plans PDFMichal SlavíčekNo ratings yet

- Entertaining Easy ShedDocument10 pagesEntertaining Easy ShedRaidx2No ratings yet

- Black & Decker The Complete Guide To Contemporary ShedsDocument242 pagesBlack & Decker The Complete Guide To Contemporary Shedsjbonvier100% (27)

- Ana White - Easy DIY Garage Workshop Workbench - 2017-12-08Document12 pagesAna White - Easy DIY Garage Workshop Workbench - 2017-12-08Ruben MolinsNo ratings yet

- The Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsDocument211 pagesThe Complete Guide To Outdoor Carpentry - Complete Plans For Beautiful Backyard Building ProjectsAmmad Ahmad100% (2)

- S300 - Chicken Coop Plans Construction PDFDocument40 pagesS300 - Chicken Coop Plans Construction PDFGabriel Popescu100% (2)

- Free Cabin Plans PDFDocument43 pagesFree Cabin Plans PDFmuhammad armadaniNo ratings yet

- Building A Potting Bench: Top Shelf UnitDocument2 pagesBuilding A Potting Bench: Top Shelf UnitjteamNo ratings yet

- Yurt Construction DocumentDocument26 pagesYurt Construction DocumentsepaulsenNo ratings yet

- Garden ShedDocument1 pageGarden ShedWayne HenryNo ratings yet

- Shednew PM1Document1 pageShednew PM1Olin StejNo ratings yet

- How To Build Modern Barstools Like A ProDocument17 pagesHow To Build Modern Barstools Like A Progerman100% (1)

- Shed PlansDocument16 pagesShed PlansFrancis Wolfgang Urban100% (7)

- Build A Log CabinDocument7 pagesBuild A Log Cabineltorro-t50% (2)

- 18 Best Free Shed Plans That Will Help You DIY A Shed PDFDocument12 pages18 Best Free Shed Plans That Will Help You DIY A Shed PDFUdu Ogah0% (2)

- Black & Decker The Complete Guide To ShedsDocument257 pagesBlack & Decker The Complete Guide To Shedsrobertrussellny96% (27)

- DIY Solar Projects How To Put The Sun To PDFDocument297 pagesDIY Solar Projects How To Put The Sun To PDFjust_danNo ratings yet

- Best Ever Outdoor Projects 2012Document59 pagesBest Ever Outdoor Projects 2012Alina Shafir71% (7)

- 50 Contractor Garage Plans ConstructionDocument90 pages50 Contractor Garage Plans Constructionapsaraso100% (4)

- Standing Router TableDocument12 pagesStanding Router TableLory Dena HeathNo ratings yet

- Schedule of Materials Step TansuDocument1 pageSchedule of Materials Step Tansu- yAy3e -No ratings yet

- Tank HeavenDocument6 pagesTank HeavenLory Dena HeathNo ratings yet

- Backyard ProjectsDocument5 pagesBackyard Projects- yAy3e -No ratings yet

- Space Saver WorkbenchDocument8 pagesSpace Saver WorkbenchLory Dena HeathNo ratings yet

- Tapered PlanterDocument3 pagesTapered Planter- yAy3e -100% (1)

- Stickley Side Table 1Document1 pageStickley Side Table 1- yAy3e -No ratings yet

- Stickley Side Table 2 PDFDocument2 pagesStickley Side Table 2 PDFbabarrojaNo ratings yet

- Spice CabinetDocument1 pageSpice Cabinet- yAy3e -No ratings yet

- Barrie Scott Is Back With Another HomeDocument6 pagesBarrie Scott Is Back With Another Home- yAy3e -100% (1)

- Shaker NightstandDocument10 pagesShaker Nightstand- yAy3e -No ratings yet

- Single BedDocument4 pagesSingle Bed- yAy3e -No ratings yet

- Shed 6x8 PlansDocument8 pagesShed 6x8 PlansLory Dena HeathNo ratings yet

- Solar - GreenhouseDocument7 pagesSolar - Greenhouseferix69No ratings yet

- BancaDocument1 pageBancabogd32000No ratings yet

- Sink ShelfDocument8 pagesSink ShelfLory Dena HeathNo ratings yet

- Shaker Bench PDFDocument1 pageShaker Bench PDFhightecrebelNo ratings yet

- Pump House PDFDocument4 pagesPump House PDFhightecrebelNo ratings yet

- From MagazineDocument5 pagesFrom Magazine- yAy3e -No ratings yet

- Woodworking Plans - Shaker BedDocument16 pagesWoodworking Plans - Shaker BedBob KowalskiNo ratings yet

- Build a Beautiful Redwood Deck Over an Aged Concrete PatioDocument3 pagesBuild a Beautiful Redwood Deck Over an Aged Concrete PatiohightecrebelNo ratings yet

- Professional Router Table PDFDocument17 pagesProfessional Router Table PDFhightecrebelNo ratings yet

- Schedule of Materials: Shelving UnitsDocument1 pageSchedule of Materials: Shelving Units- yAy3e -No ratings yet

- Shaker Single Drop Leaf TableDocument6 pagesShaker Single Drop Leaf TableLory Dena HeathNo ratings yet

- Routed Address SignDocument4 pagesRouted Address Sign- yAy3e -No ratings yet

- Pool Cue Ball RackDocument2 pagesPool Cue Ball Rack- yAy3e -No ratings yet

- Plywood ProjectDocument2 pagesPlywood ProjectWellingtonNo ratings yet

- Panel Door PDFDocument36 pagesPanel Door PDFbabarrojaNo ratings yet

- Secretary DeskDocument14 pagesSecretary Desk- yAy3e -No ratings yet

- 8-Massing & Orientation For HeatingDocument5 pages8-Massing & Orientation For HeatingaomareltayebNo ratings yet

- NFPA-220-Table 4.1.1Document1 pageNFPA-220-Table 4.1.1JohnSerranoNo ratings yet

- The Excavations at Dura-Europos. Final Report. Volume VIII, Part 2. The Christian Building, by C.H. KraelingDocument305 pagesThe Excavations at Dura-Europos. Final Report. Volume VIII, Part 2. The Christian Building, by C.H. Kraelingebulerdo93% (14)

- Pizza Oven SchematicDocument1 pagePizza Oven Schematicsir.roy.keaneNo ratings yet

- Scheda Ordini Exedra2 - STAR - Ed 01 10 2021 - ENGDocument2 pagesScheda Ordini Exedra2 - STAR - Ed 01 10 2021 - ENGtheresiaNo ratings yet

- Repair of Fire Damage StructureDocument58 pagesRepair of Fire Damage StructureBalan-Nogi Dan57% (7)

- Ready Set GoDocument12 pagesReady Set Go9newsNo ratings yet

- CONQUASDocument50 pagesCONQUASFrankie Chan100% (2)

- 2 - Types of Stone MasonryDocument25 pages2 - Types of Stone MasonryIrshad AliNo ratings yet

- Construction of High Level Bridge EstimateDocument23 pagesConstruction of High Level Bridge Estimateparas rahangdaleNo ratings yet

- Designers' Show House 2011Document23 pagesDesigners' Show House 2011Courier JournalNo ratings yet

- GOTHIC ARCHITECTURE NotesDocument94 pagesGOTHIC ARCHITECTURE NotesElaiza RiveraNo ratings yet

- Fortifications - History of ArchitectureDocument3 pagesFortifications - History of ArchitectureChristian James TuazonNo ratings yet

- 6004NorthWood Proposed A03SeriesDocument10 pages6004NorthWood Proposed A03Seriesalmir99No ratings yet

- Swisspearl Magazine 4 Page 30 64Document31 pagesSwisspearl Magazine 4 Page 30 64dilian bikovNo ratings yet

- Palazzo Farnese - ReportingDocument63 pagesPalazzo Farnese - ReportingCyan ManaleseNo ratings yet

- Gothic Architecture TermsDocument7 pagesGothic Architecture Termschuck laygoNo ratings yet

- Site Development Plan Vicinity Map: City of Bislig Province of Surigao Del SurDocument1 pageSite Development Plan Vicinity Map: City of Bislig Province of Surigao Del SurMJian VergaraNo ratings yet

- Ornate Corinthian order architecture styleDocument3 pagesOrnate Corinthian order architecture styleJericho MejilaNo ratings yet

- Reinforced Concrete Bridges PDFDocument2 pagesReinforced Concrete Bridges PDFSubash MallampalliNo ratings yet

- GACA Buildings Progress Report 15-05-2021Document3 pagesGACA Buildings Progress Report 15-05-2021Anonymous a3K3WgNo ratings yet

- DM SAFAT Glazed-Schedule 13102020 V01-2Document1 pageDM SAFAT Glazed-Schedule 13102020 V01-2Ahmed Mohamed AliNo ratings yet

- Fire Investigation Summary 7 - 1996 PDFDocument52 pagesFire Investigation Summary 7 - 1996 PDFEden FriasNo ratings yet

- Hitchcock, Mycenaean Architecture (Oxford Hanbook of BA Aegean)Document10 pagesHitchcock, Mycenaean Architecture (Oxford Hanbook of BA Aegean)Jannis KozatsasNo ratings yet

- Symbol The Key of The World in Prayer CarpetsDocument17 pagesSymbol The Key of The World in Prayer CarpetsТелман ИбрагимовNo ratings yet

- SOR'sDocument11 pagesSOR'samkdkjjNo ratings yet

- Masonry: Prepared By: Engr. Marianne Kriscel Jean T. Dejarlo, CE, SEDocument36 pagesMasonry: Prepared By: Engr. Marianne Kriscel Jean T. Dejarlo, CE, SEKhaycee DejarloNo ratings yet

- Cyclopean MasonryDocument11 pagesCyclopean MasonryArash BarbuNo ratings yet

- EcaDocument76 pagesEcaapi-417090110No ratings yet