Professional Documents

Culture Documents

H07826

Uploaded by

hamdi1000Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

H07826

Uploaded by

hamdi1000Copyright:

Available Formats

TESTING AND SUBSEA

OMNI

Te OMNI DT circulating valve is a next-generation annulus pressure-operated,

recloseable circulating valve.

Te OMNI DT circulation was designed and tested to be more debris tolerant than previous

recloseable circulating valves. Te OMNI DT valve consists of a nitrogen section, an oil system,

a circulating valve, and a ball valve. Troughout the operation, the tool is repeatedly cycled up to

a predetermined annulus pressure and then released. Te nitrogen section contains the nitrogen

gas that counterbalances the hydrostatic and annulus pressures. Te amount of nitrogen in the tool

depends on well hydrostatic conditions (mud weight and depth) and downhole temperature. Tis

information must be known to properly prepare the tool for running in. Te OMNI DT circulating

valve is a next-generation annulus pressure-operated, re-closeable circulating valve.

Te OMNI DT circulation has been designed and tested to be more debris tolerant than

previous re-closeable circulating valves. Te OMNI DT valve consists of a nitrogen section, an

oil system, a circulating valve, and a ball valve. Troughout the operation, the tool is repeatedly

cycled up to a predetermined annulus pressure and then released. Te nitrogen section contains

the nitrogen gas that counterbalances the hydrostatic and annulus pressures. Te amount

of nitrogen in the tool depends on well hydrostatic (mud weight and depth) and downhole

temperature. Tis information must be known to properly prepare the tool for running in.

Note that for certain completion fuids, the mud weight at the surface can be signifcantly

diferent from the actual mud weight downhole.

Te operating and control mechanisms are contained in a closed oil system activated by annulus

pressure acting on the nitrogen chamber, allowing an unlimited number of pressure cycles.

Te circulating valve and the ball valve work together to keep circulating pressure of the formation.

Te ball valve will close before the circulating valve opens. Te ball valve closes of the work string.

Features and Benefits

Permits well testing, pressure testing, and fuid circulation

Allows unlimited number of pressure cycles

Operation

Te well can be fow tested when the valve is in the well test position. When in this position, the circulating

ports are closed and the ball valve is opened. During a downhole closure drillstem test, the OMNI valve is in

the well test position during fow and shut-in periods. Te work string can be pressure-tested in the blank

position because the ball valve closes before the circulating valve opens. Fluid can be pumped in either

direction through the tool in the circulating position. Te tool does not require any specifc fow rate

to operate. In this position, the circulating ports are open and the ball valve is closed.

Before the tool is run, the hydrostatic pressure at the specifed tool depth must be known.

Tis information is required to obtain the proper nitrogen charging pressure.

OMNI DT Circulating Valve

H

A

L

1

0

6

5

1

TESTING AND SUBSEA

2013 Halliburton. All rights reserved. Sales of Halliburton products and services will be in accord solely with the terms and conditions contained in the

contract between Halliburton and the customer that is applicable to the sale. H07826 6/13

www.halliburton.com

Meets NACE-0175 requirements (>175F / 79C).

Maximum Diferential Operating Pressures for 5-in Tools:

From bottom of the ball when opening: 2,000 psi (13.8 MPa)

From top of the ball when opening: 5,000 psi (34.5 MPa)

For operating the circulating ports: 6,000 psi (41.4 MPa) OD to ID (annulus to tubing)

0 psi (0 MPa) ID (tubing to annulus)

Maximum Diferential Operation Pressures 7-in. tool:

From bottom of the ball when opening: 1,000 psi (6.90 MPa)

From top of the ball when opening: 2,500 psi (17.24 MPa)

For operating the circulation ports: 2,500 psi (17.24 MPa) OD to ID (annulus to tubing)

0 psi (0 MPa) ID to OD (tubing to annulus)

* Service temperature up to 450F (232C) (dressed with high-temperature O-rings and backup seals)

** Te values of tensile, burst, and collapse strength are calculated with new tool conditions, Lames formulas with Von-Mises

Distortion Energy Teory for burst and collapse strength, and stress area calculations for tensile strength.

*** Pressure rating is defned as the diferential pressure at the tool. (Diferential pressure is the diference in pressure between

the casing annulus and the tool ID.)

Tese ratings are guidelines only. For more information, consult your local Halliburton representative.

For more information contact your local Halliburton representative

or email us at welltesting@halliburton.com

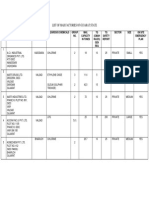

OMNI DT Circulating Valve Specications

Nominal

Tool Size

in

OD

in (cm)

ID

in (cm)

Thread

Connections

Service

Temerature*

F (C)

Length

in (cm)

Tensile

Rating**

lb (kg)

Working

Pressure***

psi (bar)

Flow Area

in

2

(cm

2

)

Number

of Ports

3 7/8

3.90

(9.91)

1.80

(4.57)

2 7/8 CAS

400

(93)

278.79

(708.13)

175,000

(79,379)

15,000

(103.4)

3.61

(23.29)

6

5

5.03

(12.78)

2.28

(5.79)

3 7/8 CAS

450

(204)

253.78

(644.60)

371,458

(168,490)

15,000

(103.4)

3.61

(23.29)

6

7

7.00

(17.78)

3.50

(8.89)

5 1/4 CAS

400

(93)

333.21

(846.35)

470,191

(213,279)

10,000

(68.9)

8.91

(57.48)

6

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Teknik PengelasanDocument84 pagesTeknik PengelasanluhurNo ratings yet

- Boiler Steam To ProcessDocument9 pagesBoiler Steam To ProcessMDR PRAPHUNo ratings yet

- Co2 Specification Guide For Analytical StepsDocument8 pagesCo2 Specification Guide For Analytical StepsMarcelo OjedaNo ratings yet

- SB Manual RA (1106)Document77 pagesSB Manual RA (1106)John100% (1)

- Fan TemplateDocument9 pagesFan TemplateHaitham YoussefNo ratings yet

- Commercial Vehicle Transmission Lubricant GuideDocument14 pagesCommercial Vehicle Transmission Lubricant GuideJason KozminskaNo ratings yet

- Maintenance Manual For Diesel Locomotives PDFDocument307 pagesMaintenance Manual For Diesel Locomotives PDFDevidatta Satapathy88% (8)

- Abstract - Air BikeDocument6 pagesAbstract - Air BikeNasruddin Shaikh33% (3)

- 1 Mah390-1Document60 pages1 Mah390-1pcp0% (2)

- Electrical Sys 988bDocument32 pagesElectrical Sys 988bnajafaliNo ratings yet

- 2009 Kawasaki MULE 4000 - Owners Manual PDFDocument135 pages2009 Kawasaki MULE 4000 - Owners Manual PDFTony MarascaNo ratings yet

- 480V 3-Line Electrical Schematics PDFDocument38 pages480V 3-Line Electrical Schematics PDFfabyanoNo ratings yet

- Fire PPT IiitdDocument48 pagesFire PPT IiitdSidhartha Sankar RoutNo ratings yet

- Alarm and Set PointDocument18 pagesAlarm and Set Pointchemsac2No ratings yet

- Westfalia Service TrainingDocument201 pagesWestfalia Service Trainingmero5595% (19)

- 13 - Idle Shutdown PDFDocument5 pages13 - Idle Shutdown PDFdinhvuNo ratings yet

- States of Matter Activity & ExerciseDocument3 pagesStates of Matter Activity & ExerciseAngelou SalangsangNo ratings yet

- Ball Injector O&m InstructionDocument12 pagesBall Injector O&m InstructionArgonauta_navegadorNo ratings yet

- KTA38-G9 Advantage Data SheetDocument3 pagesKTA38-G9 Advantage Data SheetAnjelyn SaltingNo ratings yet

- Grove RT700E: Product GuideDocument20 pagesGrove RT700E: Product GuideLuis Miguel Rivera SoplopucoNo ratings yet

- TRUFLO FullLineDocument24 pagesTRUFLO FullLine2009tamerNo ratings yet

- Development of An Appropriate Rice-Based Biomass Gasifier As Source of Power For Farm UseDocument16 pagesDevelopment of An Appropriate Rice-Based Biomass Gasifier As Source of Power For Farm UseJohn TauloNo ratings yet

- Scuter PeugeotDocument144 pagesScuter PeugeotCristi MihalceaNo ratings yet

- Material and Energy Balance Q&ADocument10 pagesMaterial and Energy Balance Q&AEmyboy AgboNo ratings yet

- Mitfuso Owners Manual 2014 FefgDocument468 pagesMitfuso Owners Manual 2014 FefgSam ArevaloNo ratings yet

- Camless Engine PDFDocument2 pagesCamless Engine PDFAnusha YadavNo ratings yet

- SMV 4527 CB5 EngDocument2 pagesSMV 4527 CB5 EngAmerico GuerreroNo ratings yet

- Fiberglass Pipes For OilDocument6 pagesFiberglass Pipes For Oilvuqar0979No ratings yet

- Common Rail Diagnostics With Frank MasseyDocument1 pageCommon Rail Diagnostics With Frank MasseyEdidjo DarwinNo ratings yet

- Overview of Jute SpinningDocument10 pagesOverview of Jute SpinningTuan Nguyen MinhNo ratings yet