Professional Documents

Culture Documents

LNG As Marine Fuel

Uploaded by

James Robbins0 ratings0% found this document useful (0 votes)

181 views10 pagesLNG As Marine Fuel

Original Title

LNG as Marine Fuel

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentLNG As Marine Fuel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

181 views10 pagesLNG As Marine Fuel

Uploaded by

James RobbinsLNG As Marine Fuel

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

1

LNG AS MARINE FUEL

Frederick Adamchak

Amokeye Adede

Poten & Partners

ABSTRACT

The global shipping industry faces a challenge -new legislation will significantly limit sulfur emissions from

ships, firstly in North America and northern Europe in 2015. LNG is a potential solution for meeting these

requirements - it has virtually no sulfur content, and its combustion produces low NOx compared to fuel oil

and marine diesel oil. LNG is not only cleaner-burning, but may have economic advantages - on a calorific

value basis even high Asian LNG prices are lower than global bunker fuel prices. As a result there have

been recent developments to promote use of LNG as a bunker fuel. The scope for displacement of bunker

fuel oil by LNG is potentially huge excluding LNG carriers there are currently only 20 - 25 LNG-fuelled

vessels in operation - less than 1% of the total commercial marine fleet. However, LNG as a bunker fuel

faces a number of challenges; notably the investment required in ships propulsion and fuel handling systems

and in bunkering facilities, plus development of new international safety regulations, and LNG availability.

Given the potential advantages of LNG as a bunker fuel and the pace of recent developments, the probability

of LNG displacing oil as the preferred fuel will continue to increase. However, given the challenges faced, to

what extent can LNG as a bunker fuel develop by the end of decade? This paper will discuss the advantages

of LNG as a bunker fuel, challenges faced for widespread implementation, and the pace and potential for

LNG to displace established fuels.

INTRODUCTION

Annex VI of the International Maritime Organization (IMO) International Convention for the Prevention of

Pollution from Ships (MARPOL) entered into force in May 2005. The mandate limits the sulfur content of

marine fuels on a global basis to 4.5%. That limit was then lowered to 3.5% sulfur from January 2012. Annex

VI also imposed a 1.5% sulfur limit on marine fuels in Emission Control Areas (ECAs) effective May 2006.

That limit was reduced to 1.0% sulfur effective 1 July 2010, and will be further reduced to 0.1% sulfur

beginning January 2015. There are four (4) ECAs in effect: the Baltic Sea since May 2006, the North Sea

since November 2007, North America (US and Canada) since August 2011, and U.S. Caribbean since

January 2013. As a result, the effects of Annex VI sulfur reductions and initiatives to adopt lower sulfur fuels

have been largely limited to the ECAs.

The larger effect from Annex VI will come when the requirement to reduce sulfur content of marine fuels to

0.5% on a global basis effective 2020. However, implementation of this major change depends on the

outcome of an IMO low sulfur fuel availability study to be completed in 2018. If IMO decides there is

insufficient low sulfur fuel available, the 0.5% sulfur limit can be delayed until 2025. The issue for ship

owners and operators is how to find alternatives to economically meet the low sulfur fuel mandate about to

be imposed by Marpol Annex VI.

2

Source: DNV

Figure 1. MARPOL Annex VI timeline for adoption

of sulfur content in marine fuels

In the short term, ship owners and operators are switching from traditional residual bunker fuel during ocean

passages to low sulfur fuels when operating in ECAs. For the longer term ship owners are studying

alternative approaches to meet the environmental requirement for the post 2020 or 2025 era; these include

secure a reliable and affordable source of Annex VI compliant liquid fuel;

consume high sulfur residual fuel and add SOx emission reduction equipment such as scrubbers to

meet the SO

2

emission requirements;

shift to an alternative low sulfur fuel. LNG is one alternative attracting attention because of its low

sulfur content and its price, which is lower than the traditional residual oil based bunker fuels.

OBJECTIVES

As a result of several factors, LNG is being touted as a viable alternative for ship owners and operators to

meet the Annex VI low sulfur fuel requirements both for global trade and in ECAs. This paper examines a

range of issues, both pro and con related to using LNG as a marine fuel. We intend to discuss at a high

level:

the drivers for increased use of LNG as a marine fuel;

alternative approaches to meeting IMO Annex VI requirements and their comparative economics;

uncertainties related to the timing and application of low sulfur fuel requirements;

estimates of the potential demand for LNG as a marine fuel;

availability and cost of LNG as bunker fuel; and

the impact of LNG demand for marine fuel on global LNG demand and supply.

DRIVERS FOR LNG AS MARINE FUEL

LNG has been used to fuel diesel propulsion systems of LNG vessels since delivery of the Provalys in 2006.

Today 48 existing LNG ships operate with dual fuel and tri-fuel diesel electric propulsion and another 85 LNG

ships are on order. In view of the proven success of LNG as a fuel in marine diesel engines, ship owners

have already constructed an estimated 30 LNG fueled ships and have ordered more than 30 additional LNG

fuelled ships. The two primary drivers that make LNG appear an attractive alternative to meet the Annex VI

sulfur in fuel oil requirements are:

3

1. LNG allows ships to meet MARPOL Annex VI requirements for both worldwide trades and operation

in ECAs as its sulfur content that is well below the Annex VI requirements for ECAs. Moreover, LNG

reduces NO

x

emissions to levels that will meet MARPOL Annex VI without need for after treatment.

2. In some markets, natural gas and LNG are lower priced than high sulfur marine fuel oils on a heating

value basis.

There is no doubt of LNGs low sulfur content. The specification of LNG in numerous LNG Sale and

Purchase Agreements translates to about 0.004% on a mass mass basis, which is well below the 0.1% S

required in ECAs from 2015. There are at least three (3) alternative approaches to meeting MARPOL Annex

VI requirements, and ship owners must assess the relative costs of the approaches and future bunker fuel

and LNG prices before taking a decision.

Figure 2. MARPOL Annex VI SOx reduction alternatives

The relative low price of natural gas and LNG compared to current high residual bunker and distillate fuel

prices in the U.S and Europe has added to the attractiveness of LNG as an alternative marine fuel.

Figure 3. Fuel Cost Driver Fuel Oil vs. Natural Gas Prices

MARPOL Annex VI

SOx reduction requirements

Scrubber +

high sulphur fuel

LNG

Low sulphur fuel oil

MDO / MGO

LNG,

LNG bunker

facility

availability

and cost

Price relative

to alternatives

LNG

equipment

costs,

conversion

time and cost

Installation cost, waste disposal,

high sulphur fuel cost

+ No extra fuel tanks or

handling needed

- Higher fuel costs

- Scrubbers needed to meet

Tier III NOx

- Low sulphur fuel availability

and cost

- Ships required to use low

sulphur fuel, but refiners not

required to produce / supply

+ Scrubbers available

+ HFO and bunkering facilities

available

+ Fuel price

- Capital investment and off

hire time for conversion

- How many scrubbers will be

required / available in 2020?

- Waste disposal facility

availability and cost

+ Meets SOx, particulate and

NOx Tier III requirements

- More shipboard storage

capacity required

- Capital investment in LNG

equipment

- LNG and fuelling facility

availability outside limited

areas

- Price what is the basis?

Options

Issues

Pros &

cons

Low sulphur

fuel availability

0

5

10

15

20

25

30

J

a

n

F

e

b

M

a

r

A

p

r

M

a

y

J

u

n

J

u

l

A

u

g

S

e

p

O

c

t

N

o

v

D

e

c

J

a

n

F

e

b

M

a

r

A

p

r

M

a

y

J

u

n

J

u

l

A

u

g

S

e

p

O

c

t

N

o

v

D

e

c

J

a

n

F

e

b

M

a

r

A

p

r

M

a

y

J

u

n

J

u

l

A

u

g

S

e

p

O

c

t

N

o

v

D

e

c

J

a

n

F

e

b

M

a

r

A

p

r

M

a

y

J

u

n

J

u

l

A

u

g

S

e

p

O

c

t

2009 2010 2011 2012

Rotterdam IFO

Singapore IFO

Houston IFO

Rotterdam MDO

Singapore MDO

Houston MDO

NBP

Henry Hub

Japan LNG

Brent

MDO

range

IFO

range

$

/

M

M

B

t

u

4

As shown in figure 3 above there is also a clear economic incentive to consider LNG as a viable alternative

fuel on the basis of its price. In the U.S. Henry Hub natural gas price is approximately 30% of Intermediate

Fuel Oil (IFO) 380 in the Gulf Coast. In the U.K. the discount is not as large, but is still 30% below bunker

fuel price. However, we must consider that natural gas must be purchased, liquefied, stored and delivered to

a site that can fuel ships. That requires LNG infrastructure investment, and recovery of those costs to supply

LNG in competition with bunker fuels that are supplied through existing infrastructure. The costs must be

evaluated.

The situation in Asia Pacific is not as clear. LNG prices are higher than IFO 380 price, but lower than

Marine Diesel Oil. While the comparison is an LNG Fuel Oil comparison rather than a natural gas Fuel

Oil comparison; there will be a requirement to develop LNG bunkering capacity and facilities. Asian LNG

buyers LNG import capacity is heavily used to import LNG for electric power generation and distribution by

pipeline to city gas systems. These facilities are not likely to be available to provide bunkering services.

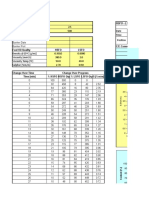

Figure 4. Comparison of LNG supply cost and alternative fuels

Potens estimate of infrastructure costs to liquefy natural gas, store and transport LNG to fuel ships, when

added to feed gas costs makes LNG competitive with MDO in Rotterdam, but questionable in comparison

with IFO. In Asia LNG is an attractive alternative compared to HFO prices, but higher priced than MDO.

Although the competitiveness of LNG seems assured in the U.S., but will LNG be sold at a reasonable

return on investment or will it be priced in competition with alternative fuels? A recent article reported that

LNG for road fuel use sold at a 30% discount to diesel fuel. However, that same LNG price was equivalent to

nearly $20.000/MMBtu while Henry Hub price was below $4.00/MMBtu. The point is that low natural gas

price does not necessarily convert to low LNG prices.

ESTIMATED DEMAND FOR LNG AS MARINE FUEL

To date LNG fuel initiatives are largely regional. Ships deployed in trade routes between ECAs or ships

trading entirely within ECAs such as ships trading from the Baltic Sea to North Sea and English Channel

routes are already living with a 1.0% sulfur in fuel oil requirement for all or a substantial portion of their

voyages. Initiatives by ship owners and governments have already resulted in construction and operation of

LNG fuelled ships and development of small scale LNG supply and fuelling infrastructure within these ECAs,

which became effective in 2006 and 2007. LNG fuelled ships are now being ordered for ships trading entirely

within the North America ECA in response to U.S. Environmental Protection Agency regulations and

introduction of the North America ECA from August 2012. However, not all ships are candidates for LNG

fuel.

0

200

400

600

800

1,000

1,200

1,400

Europe USA Asia

$

/

T

o

n

s

Port Infrastructure COS* & Fuel Costs

Container

Ship

Newbuilt**

Port

Capex/Opex

Feedgas

Cost/ LNG

Cost

MDO Price

Rotterdam

HFO Price

Rotterdam

(inc. Scrub)

?

5

Source: Lloyds Register LNG Bunkering Infrastructure Study Feb, 2012

Figure 5. Global Ship Movements per Year

As shown above routes between Western Europe and the U.S. East Coast; Asia to the U.S. West Coast and

continuing to the Gulf and East Coasts; Asia to Western Europe via Suez Canal and return; Middle East to

Western Europe; and Middle East to Asia are heavily travelled international routes.

To develop potential LNG demand, Poten assumed only new-builds would utilize LNG as fuel as conversions

are costly both in conversion costs and out of service time and technically challenging. We then focused on:

Ships employed in ECA to ECA trades for ships delivered as early as 2015 as 1.0% sulfur limits

already apply in ECAs;

We assumed that the Global reduction to 0.5% sulfur in marine fuels would be delayed until 2025

based on results of the 2018 IMO review of low sulfur fuel oil availability;

We assigned a realistic market share to LNG fuel in competition to low sulfur fuels and high sulfur

HFO with scrubbers

Figure 6. SOx limits

Vessel types International trade routes SOX limits Solutions

Containerships

Bulkers

Tankers

Others

Europe-North America

(ECA-to-ECA)

Asia-Europe

Asia-North

America

Others

Global SOx

limitation

ECA SOx

limitation

LNG marine fuel

usage (+HFO)

MDO (+HFO)

Scrubbers (+HFO)

6

0

1

2

3

4

5

6

7

8

9

2

0

1

5

2

0

1

6

2

0

1

7

2

0

1

8

2

0

1

9

2

0

2

0

2

0

2

1

2

0

2

2

2

0

2

3

2

0

2

4

2

0

2

5

M

M

t

/

y

Others

Far East

Europe

North

America

Current

ECAs only

Global

LNG marine fuel

mostly produced

from domestically

sourced natural

gas

LNG marine

fuel will mostly

rely on LNG

from global

LNG market

2018 IMO

Report

Container ships bulkers and tankers were our focus as they are engaged in ECA to ECA trades and, in the

case of container ships, have fixed routes that involve spending considerable time in ECAs before a

relatively short duration trans-Atlantic passage to another ECA. We also examined bulkers and tankers that

have fewer ECA to ECA voyages, but represent a significant portion of the world shipping fleet. Poten

believes that orders for LNG fuelled ships will increase when the implementation date of the global 0.5%

sulfur in fuel implementation date is certain.

Figure 7. LNG Marine Fuel Consumption by Location

Potens demand projection is that LNG consumed as marine fuel will reach 1 million tonnes in 2020 and will

increase rapidly to 8.5 million tonnes by 2025.

We also project that Europe and the U.S. will rely primarily on domestic natural gas production to produce

LNG for marine fuel. Asia Pacific, on the other hand will have to rely on LNG imports at prices set in the Asia

Pacific market.

A number of other projections of LNG demand as marine fuel have been published and these vary based on

assumptions made with suspect to:

global economic activity and resulting shipping and shipbuilding activity,

absolute fuel prices

relative LNG and natural gas price compared with oil price;

regulatory activity specifically as it relates to environmental issues,

costs to outfit conventional ships to use LNG as fuel;

cost of LNG fuelling infrastructure, and

LNG fuel availability

Results of these analyses have a wide range of projected LNG demand.

0.7 to 66 million tonnes in 2025 depending on scenario

8 to 33 million tonnes in 2020 depending on scenario

65 million tonnes in 2030

7

UNCERTAINTIES

Different outlooks for marine fuel will arise from ones view on resolution of uncertainties.

Timing of 1% Sulfur fuel requirement entering into force

Figure 1 above shows the first uncertainty associated with application of Annex VI provisions

timing. What will be the result of the low sulfur fuel availability review and when will the 0.1% sulfur

requirement become mandatory? IMO is required to complete a review of the availability of 0.50%

sulfur content fuel by 2018. Based on the results of such a review, the Parties to MARPOL Annex VI

will decide whether the global cap of 0.50% can be enforced from 1 January 2020. If not, the 0.50%

sulfur global cap will be enforced on 1 January 2025 without any additional review. The dilemma is

that ships are required to use lower sulfur fuel oils, but refiners are not required to supply them. In

fact, refiners have been reticent to move ahead with multi-billion dollar investments to supply low

sulfur marine fuels. Figure 2 above shows a key reason for their response. Residual bunker fuels

have a lower price than the crude oil feedstock to their refineries.

Expansion of the number of ECAs

A second issue is the uncertain pace of expansion of ECAs, that would require use of 1% sulfur fuel

from July 2010 and 0.1% sulfur fuel from January 2015. Figure 8 below shows: existing ECAs,

potential new ECAs, and the worlds major bunker ports. Few large bunker ports are located within

ECAs, and estimated 24% of bunker fuels purchased annually come from ports currently located

within ECAs. Expansion of ECAs to encompass Asian ports, which supply 32% of world bunker

sales and Middle East ports that supply 12% of world bunker sales would increase and speed the

transition to lower sulfur fuels. However, implementation of new ECAs depends on Parties

submitting a proposal to IMO to designate new ECAs; it is not an IMO led initiative.

Figure 8. Existing and Possible Future Emission

Control Areas (ECAs) & Major Bunker Ports

International Regulation

IMO, recognizing the need for regulations of non-LNG ships that use LNG as fuel and engage in

international trade, adopted Interim Guidelines on Safety for Natural Gas Fuelled Engine

Installations in Ships in 2009. IMO also convened a working group to draft an International Code of

Safety for Ships Using Gases or Other Low Flashpoint Fuels (IGF Code) with a goal of completing

the work in 2014. While the Interim Guidelines are a workable solution for domestic trades, how

Source: Poten & Partners, Marine Fuel Regulations 2010-2025

8

broadly accepted are they in international trades? If the IGF Code requirements are more stringent

than those of the Interim Guidelines, what will be the effect on ships built under the Guidelines?

Which Comes First?

Figure 9 The Chicken and Egg Problem

Port infrastructure to produce, store and transport LNG and fuelling berths, barges or vessels will be

required to reliably and economically bunker LNG fuelled ships. Ship owners will not construct LNG

fuelled ships without confidence that LNG supplies will be available throughout its route at economic

prices. Developers will be reluctant to invest in LNG fuelling infrastructure until they are confident

there will be a market for LNG to fuel ships. Coordination and cooperation between port developers

and ship owners will be particularly difficult with ships in international trades.

LNG Supply and Pricing

Various estimates of annual consumption of fuel oil for marine fuel are reported. The IEA reports that

bunker demand in 2010 was 235 million metric tonnes, comprising approximately 180 million tonnes

of residual fuel based products and 55 million tonnes of distillate fuel products. This is equivalent to

about 180 million metric tonnes of LNG - nearly 75% of worldwide LNG trade in 2012.

Worldwide LNG demand is projected to grow at more than 5% annually through 2020. Asia Pacific

LNG demand in 2012 represents nearly 70% of global demand and Poten projects that Asia

Pacific demand will continue to pace global demand. Supply must expand rapidly to meet worldwide

demand and premium priced Asia Pacific demand in particular.

Figure 10. Global LNG Demand

Reduced sulphur content

requirement

Port Developers Ship Owners

Continue normal

bunkering operations

(MDO & HFO)

Construct LNG port

Shift to MDO

Consumption

Build LNG Fueled

Ships

Shift to HFO

Consumption

The classic Chicken-and-Egg Problem: who will act first?

Cont. E

Asian market

2000 2005 2010 2015 2020 2025

0

50

100

150

200

250

300

350

400

450

M

M

t

/

y

Others

N. America

UK

Cont. Europe

9

Poten estimates that about 80% of total LNG sales are made under long-term LNG Sale and

Purchase Agreements; the remainder is sold on spot and short term transactions. With the size of

the global bunker fuel market equal to about 70% of the global LNG market, a significant shift from

marine bunker fuel to LNG would require a similar increase of LNG supply.

Does spot and short- term LNG supply provide sufficient supply security for ship owners to order

newbuilds designed to operate on LNG, and for developers to design and construct LNG bunkering

infrastructure and facilities?

Will new LNG supply develop in response to potential demand for LNG as fuel and who will act as

the aggregator?

SUMMARY

MARPOL Annex VI is a bold move by the IMO and the parties to Annex VI to reduce air pollution from ships

including SO

x.

Sulfur content in marine fuel will decrease as Annex VI regulations tighten. The question for

the LNG industry is what role will LNG play in the marine fuels market and when.

Figure 11. Natural Gas & Oil Benchmark Projection

We suggest that due to an absence of initiatives from Asian governments to request that their territorial

waters be designated as ECAs, the pace of change will be slow and the solutions regional.

Spurred by government initiatives and financial support, LNG has made important inroads in the Baltic Sea,

the North Sea and English Channel, and will expand its role.

Similarly, LNG initiatives are being taken in the U.S. by vessels that operate within the 200 mile ECA limit.

The reasons due to both are regulatory compliance and economics.

Figure 11 shows Brent crude oil price, Henry Hub and NBP natural gas price and Asia Pacific and European

LNG prices projected through 2025. The economic rationale for regional solutions is clear. Low natural gas

prices in the U.S, and LNG prices below Brent crude oil price in Europe provides incentives to move to LNG

while meeting the 0.1% sulfur limit that will become effective in 2015. It is more difficult to make a strong

economic argument in Asia Pacific as oil indexed LNG prices reduce the economic incentives. Although we

anticipate that the 2020 deadline to meet the global 0.5% sulfur in fuel limit will be extended, the 2025

deadline looms ahead, and LNG will have a role to play.

0

2

4

6

8

10

12

14

16

18

20

22

2

0

1

2

$

/

M

M

B

t

u

Brent

AP LNG

Oil Driven

Europe

LNG Oil

Driven

NBP

HH

10

This paper highlights five uncertainties affecting the decisions for both shipowners and bunker fuel providers

in global growth of LNG as marine fuel. Shipowners are faced with three alternatives to meet a regulation

with an uncertain timeline for global application. Regional ECA initiatives will lead to increase LNG utilization.

This has occurred in Scandanavia and appears to be developing in the US though neither of these cases will

impact the global LNG trade as reliance will be primarily on locally produced LNG. The global outlook,

however, will remain fog bound and no clear fuel choice will emerge as shipowners will opt for flexibility in

their ship orders until Annex VI timing and application are finally settled. Given the considerable uncertainty

around both fuel price differentials and regulations, a strategy of flexibility will prove key.

You might also like

- DNV GL Complete-Alt-Fuels Guidance Paper 2018-05 WebDocument48 pagesDNV GL Complete-Alt-Fuels Guidance Paper 2018-05 WebMohit SahNo ratings yet

- LNG FuelDocument6 pagesLNG FuelKaran DoshiNo ratings yet

- Cost Benifit of LNG As Ship FuelDocument12 pagesCost Benifit of LNG As Ship FuelSamuel JohnsonNo ratings yet

- Rise of The FSRU and The LNG Market OutlookDocument13 pagesRise of The FSRU and The LNG Market OutlookThanos PitatzisNo ratings yet

- Joint Industry Guidance On The Supply and Use of 0.50 Sulphur Marine FuelDocument64 pagesJoint Industry Guidance On The Supply and Use of 0.50 Sulphur Marine FuelharrdyNo ratings yet

- Tanker Operator 2014 06 JuneDocument44 pagesTanker Operator 2014 06 JuneVasileios IliopoulosNo ratings yet

- Gasasa Marine Fuel: Recommendations For Linked Emergency Shutdown (ESD) Arrangements For LNG BunkeringDocument14 pagesGasasa Marine Fuel: Recommendations For Linked Emergency Shutdown (ESD) Arrangements For LNG Bunkeringmhientb100% (1)

- Leaders On The Future of LNG and GasDocument20 pagesLeaders On The Future of LNG and GasShekhrendu BhardwajNo ratings yet

- LNG ShipDocument4 pagesLNG ShipAkademiks29No ratings yet

- WLPGA Annual Report 2016 PDFDocument44 pagesWLPGA Annual Report 2016 PDFSanjai bhadouriaNo ratings yet

- Container's OperationDocument30 pagesContainer's OperationNguyễn HiếuNo ratings yet

- Energy Recovery From The LNG Regasification ProcessDocument25 pagesEnergy Recovery From The LNG Regasification ProcessAn TrNo ratings yet

- JCC Crude Oil Index Price FormulasDocument9 pagesJCC Crude Oil Index Price FormulasVijendra Sah100% (1)

- Attachment 1. LNG Safety: Table 1.1 Comparison of Properties of Liquid FuelsDocument6 pagesAttachment 1. LNG Safety: Table 1.1 Comparison of Properties of Liquid FuelsLund2016No ratings yet

- Star Lite LNGDocument16 pagesStar Lite LNGelton100% (1)

- Types of LNG CarriersDocument11 pagesTypes of LNG CarriersAnonymous icnhaNsFNo ratings yet

- Wartsilla 3223v Design DRWNGDocument136 pagesWartsilla 3223v Design DRWNGKhair AzharNo ratings yet

- Shaping a Better Energy FutureDocument9 pagesShaping a Better Energy FutureJohn100% (1)

- Toshiki Miyazawa, COO, LNG Japan CorporationDocument14 pagesToshiki Miyazawa, COO, LNG Japan CorporationShah Reza DwiputraNo ratings yet

- X-DF: Latest References, Service Experience - Plus Future OutlookDocument66 pagesX-DF: Latest References, Service Experience - Plus Future OutlookLifeatseaNo ratings yet

- BOIL-OFF UTILIZATION IN LNG CARRIERSDocument19 pagesBOIL-OFF UTILIZATION IN LNG CARRIERSPrasathAKNo ratings yet

- Adnan Ezzarhouni GTTChina (Revised Version)Document17 pagesAdnan Ezzarhouni GTTChina (Revised Version)ClemenNo ratings yet

- LNG Chain: Transporting Natural Gas GloballyDocument11 pagesLNG Chain: Transporting Natural Gas Globallytsar mitchelNo ratings yet

- LNG CourseDocument4 pagesLNG CourseRuslan ZakirovNo ratings yet

- Hazards Associated With LNGDocument2 pagesHazards Associated With LNGKimNo ratings yet

- The Man B Amp W Duel Fuel Engines Starting A New Era in ShippingDocument28 pagesThe Man B Amp W Duel Fuel Engines Starting A New Era in ShippingFuchsbauNo ratings yet

- Cryo StarDocument12 pagesCryo Starelenaro1234No ratings yet

- LNG 3 - LNG Ships 7.3.09-Aacomments-Aug09Document7 pagesLNG 3 - LNG Ships 7.3.09-Aacomments-Aug09nangkarak8201No ratings yet

- Wartsila SP PPT 2011 LR Vancouver.Document40 pagesWartsila SP PPT 2011 LR Vancouver.Uhrin ImreNo ratings yet

- Energy Efficiency Definitions EEDI SEEMP EEOIDocument6 pagesEnergy Efficiency Definitions EEDI SEEMP EEOIImanustNo ratings yet

- LNG EconomicsDocument20 pagesLNG EconomicsAtul TandonNo ratings yet

- Wärtsilä 50DF dual-fuel engines promise big benefits for LNG carriersDocument2 pagesWärtsilä 50DF dual-fuel engines promise big benefits for LNG carriersbernardinodinoNo ratings yet

- LNG Production For MidscaleDocument15 pagesLNG Production For MidscaleJavid Talib100% (1)

- Small-Scale LNG DistributionDocument31 pagesSmall-Scale LNG DistributionRichard RichardNo ratings yet

- LNG-Production and UtilizationDocument48 pagesLNG-Production and UtilizationArchana Balikram R100% (2)

- Innovations in LNG TechnologyDocument15 pagesInnovations in LNG TechnologyCraigUnderwoodNo ratings yet

- 2013 LNG FSRU FPSO Pump Considerations For Ship Motion AIChE Spring G.woodDocument15 pages2013 LNG FSRU FPSO Pump Considerations For Ship Motion AIChE Spring G.woodjbloggs2007No ratings yet

- LNG FuelDocument10 pagesLNG FuelengnaderrNo ratings yet

- Construction of LPG ShipsDocument41 pagesConstruction of LPG ShipsElena100% (1)

- LNG Standard Form Charters March 2013 PDFDocument10 pagesLNG Standard Form Charters March 2013 PDFFabián BischoffNo ratings yet

- Floating Regasification: The Growing Role of FSRUs and the Case of the Aegean LNG TerminalDocument21 pagesFloating Regasification: The Growing Role of FSRUs and the Case of the Aegean LNG TerminalMehmet Ali100% (1)

- H2A Hydrogen Delivery Infrastructure Analysis Models and Conventional Pathway Options Analysis ResultsDocument153 pagesH2A Hydrogen Delivery Infrastructure Analysis Models and Conventional Pathway Options Analysis Results林立No ratings yet

- FSRU Toscana LNG and GAS Quality and Measurement ManualDocument29 pagesFSRU Toscana LNG and GAS Quality and Measurement Manualhikosko100% (1)

- Propulsion Trends in LNG Carriers Man-2009Document20 pagesPropulsion Trends in LNG Carriers Man-2009gnd100No ratings yet

- Tugs - Developments For PDFDocument28 pagesTugs - Developments For PDFP Venkata SureshNo ratings yet

- LNG AgeingDocument13 pagesLNG AgeingBenoit PuyoNo ratings yet

- Ammonia as Marine Fuel: A Synthesis of KnowledgeDocument35 pagesAmmonia as Marine Fuel: A Synthesis of KnowledgePhan Anh DuongNo ratings yet

- Natural Gas Receiving Terminal Technology OverviewDocument7 pagesNatural Gas Receiving Terminal Technology OverviewAbu SuraisyNo ratings yet

- 10 Wartsila K Portin Performance DF Engines in LNG CarriersDocument21 pages10 Wartsila K Portin Performance DF Engines in LNG Carriersali kharalNo ratings yet

- Enhanced Solution For LNG by G.EDocument28 pagesEnhanced Solution For LNG by G.EFaiz AhmadNo ratings yet

- DUAL FUEL ENGINES RUN ON GAS AND DIESELDocument11 pagesDUAL FUEL ENGINES RUN ON GAS AND DIESELMohamed Al NazooqueNo ratings yet

- Tge Marine LNG Fpso-Fsru Presentation FLNG 02 2008 Rev1 InternetDocument33 pagesTge Marine LNG Fpso-Fsru Presentation FLNG 02 2008 Rev1 InternetkkkelvinNo ratings yet

- LNG OperationsDocument61 pagesLNG OperationsMario Rossi100% (1)

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDocument6 pagesThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Marine Engineering System CODAG and SystemDocument9 pagesMarine Engineering System CODAG and SystemIkhwan Azizie100% (2)

- Ocimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014Document2 pagesOcimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014xingangNo ratings yet

- GSF Eca PaperDocument14 pagesGSF Eca PaperS SanchitNo ratings yet

- Paper No.: 13 Marine Distillate Fuels Specifications - Today and TomorrowDocument10 pagesPaper No.: 13 Marine Distillate Fuels Specifications - Today and TomorrowAnonymous 8qUHG4SlNo ratings yet

- Alt-Fuels Guidance Complete 2019-08 WebDocument56 pagesAlt-Fuels Guidance Complete 2019-08 WebFyp CcNo ratings yet

- Anhydrous AmmoniaDocument1 pageAnhydrous AmmoniaJames RobbinsNo ratings yet

- Shipping EconomistDocument52 pagesShipping EconomistJames RobbinsNo ratings yet

- CARB Advisory 07oct11 oDocument5 pagesCARB Advisory 07oct11 oJames RobbinsNo ratings yet

- TMSA Guide Improves Tanker Management StandardsDocument11 pagesTMSA Guide Improves Tanker Management StandardsJames RobbinsNo ratings yet

- Bunkering Industry & Its Effect N ShippingDocument135 pagesBunkering Industry & Its Effect N ShippingJames RobbinsNo ratings yet

- Future LNG Prices ForecastDocument4 pagesFuture LNG Prices ForecastJames RobbinsNo ratings yet

- Drop in Oil Prices Triggers New Set of ConcernsDocument2 pagesDrop in Oil Prices Triggers New Set of ConcernsJames RobbinsNo ratings yet

- Tanker Management and Self Assessment 2: A Best-Practice Guide For Ship OperatorsDocument33 pagesTanker Management and Self Assessment 2: A Best-Practice Guide For Ship OperatorsJames Robbins100% (2)

- Tanker Management Self-Assessment GuideDocument3 pagesTanker Management Self-Assessment GuideJames RobbinsNo ratings yet

- ABC Maritime TMSA 2015 Official ReleaseDocument2 pagesABC Maritime TMSA 2015 Official ReleaseJames RobbinsNo ratings yet

- Sustainability Action Plan 2012Document18 pagesSustainability Action Plan 2012James RobbinsNo ratings yet

- TMSADocument2 pagesTMSAkhoshkroudi100% (1)

- Oil Price Fears To See Rise in Bunker HedgingDocument2 pagesOil Price Fears To See Rise in Bunker HedgingJames RobbinsNo ratings yet

- Master Final Annex VIDocument106 pagesMaster Final Annex VIJames RobbinsNo ratings yet

- Air Pollution 1. Concept Design of LNG Bunkering ShipDocument32 pagesAir Pollution 1. Concept Design of LNG Bunkering ShipJames RobbinsNo ratings yet

- Bio FuelDocument90 pagesBio FuelJames RobbinsNo ratings yet

- 0031 Sin BunkerDocument1 page0031 Sin BunkerJames RobbinsNo ratings yet

- 0031 Sin BunkerDocument1 page0031 Sin BunkerJames RobbinsNo ratings yet

- Crude Oil HedgingDocument12 pagesCrude Oil HedgingJames RobbinsNo ratings yet

- WOCU Bunker FuelDocument12 pagesWOCU Bunker FuelJames RobbinsNo ratings yet

- New - Study - of - The Determinants of Oil PricesDocument6 pagesNew - Study - of - The Determinants of Oil PricesJames RobbinsNo ratings yet

- PPL.10.001.9.001.F - Oil Price Projection 10.08.11Document11 pagesPPL.10.001.9.001.F - Oil Price Projection 10.08.11James RobbinsNo ratings yet

- Hedging Against Bunker Price FluctuationDocument18 pagesHedging Against Bunker Price FluctuationJames RobbinsNo ratings yet

- Bio FuelDocument90 pagesBio FuelJames RobbinsNo ratings yet

- New - Study - of - The Determinants of Oil PricesDocument6 pagesNew - Study - of - The Determinants of Oil PricesJames RobbinsNo ratings yet

- Optimal Ship Size in LNGDocument76 pagesOptimal Ship Size in LNGJames RobbinsNo ratings yet

- Fs Bunker GoodDocument5 pagesFs Bunker GoodShekhrendu BhardwajNo ratings yet

- First L!G-fuelled Retrofit Resumes Service: Bit VikingDocument2 pagesFirst L!G-fuelled Retrofit Resumes Service: Bit VikingJames RobbinsNo ratings yet

- Bio FuelDocument90 pagesBio FuelJames RobbinsNo ratings yet

- Marine LNG Engine - WikipediaDocument3 pagesMarine LNG Engine - WikipediaJames RobbinsNo ratings yet

- 2 - 1430 Peter Sikstrom PDFDocument33 pages2 - 1430 Peter Sikstrom PDFkalaiNo ratings yet

- 2015 Directory of China's GasfieldsDocument2 pages2015 Directory of China's GasfieldsarapublicationNo ratings yet

- Comparative Study of Alternative Fuels in IndiaDocument40 pagesComparative Study of Alternative Fuels in IndiaTazammul Jamadar100% (1)

- 420 F 10009Document3 pages420 F 10009Adriano MariniNo ratings yet

- SC20-21 WorksheetsDocument64 pagesSC20-21 WorksheetsEmaadB EmaadBNo ratings yet

- MI Combined Slide Deck MDC Slides Revised PDFDocument30 pagesMI Combined Slide Deck MDC Slides Revised PDFdinaNo ratings yet

- CoalDocument5 pagesCoalPooja DhawanNo ratings yet

- Boilers Manufacturer, Steam Boilers Manufacturer, Rakhoh IndustriesDocument20 pagesBoilers Manufacturer, Steam Boilers Manufacturer, Rakhoh IndustriesRakhoh IndustryNo ratings yet

- VXV6 LPG Series2 WiringDocument2 pagesVXV6 LPG Series2 WiringDanniel PizattoNo ratings yet

- The ElonDocument12 pagesThe ElonanishNo ratings yet

- Paper 2Document8 pagesPaper 2A AnuragNo ratings yet

- Oil Demand and Chemicals Feedstocks: Increasing risk and uncertaintyDocument21 pagesOil Demand and Chemicals Feedstocks: Increasing risk and uncertaintyAswin KondapallyNo ratings yet

- Flexi CokingDocument11 pagesFlexi CokingRathva Dhiren100% (1)

- LSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)Document8 pagesLSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)dharmawanNo ratings yet

- Asia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 62 / March 30, 2020Document23 pagesAsia-Pacific/Arab Gulf Marketscan: Volume 39 / Issue 62 / March 30, 2020Donnie HavierNo ratings yet

- Sertifikat - Basic Engine Diesel - ASRUL PRATAMADocument2 pagesSertifikat - Basic Engine Diesel - ASRUL PRATAMAAsrul PratamaNo ratings yet

- PDocument70 pagesPshastrysnNo ratings yet

- Manufacture of Metallurgical CokeDocument18 pagesManufacture of Metallurgical CokeAravind GNo ratings yet

- Final Bioenergy PresentationDocument22 pagesFinal Bioenergy Presentationblossoms_diyya2998No ratings yet

- Fuels-Practice Exercise 4.1 To 4.6Document1 pageFuels-Practice Exercise 4.1 To 4.6Ryo SumidaNo ratings yet

- Daily Report Production: Project Site Penajam Date: 18-Februari-2019Document4 pagesDaily Report Production: Project Site Penajam Date: 18-Februari-2019Yanwar Ibnu LizarNo ratings yet

- Handbook for Handling, Storing, and Dispensing E85Document34 pagesHandbook for Handling, Storing, and Dispensing E85aliyildizx17730No ratings yet

- PRS - Biomass Energy Technology Experience in RuralDocument78 pagesPRS - Biomass Energy Technology Experience in RuralPrajwal Raj ShakyaNo ratings yet

- Adobe Scan 22 Feb 2024Document4 pagesAdobe Scan 22 Feb 2024Shubham ThakurNo ratings yet

- Product Transfer Loading System PDS - FinalDocument4 pagesProduct Transfer Loading System PDS - FinalJaqueline MartínezNo ratings yet

- List of Petrol Stations in Arusha RegionDocument74 pagesList of Petrol Stations in Arusha Regionalokgupta87No ratings yet

- Advancement of Ethanol As Fuel in IndiaDocument2 pagesAdvancement of Ethanol As Fuel in India9012Suchibrata MohantyNo ratings yet

- Biodiesel Plant DataDocument53 pagesBiodiesel Plant DataSAMYAK PANDEYNo ratings yet

- ClassNK CII Calculation Ver03Document7 pagesClassNK CII Calculation Ver03Prashant DuveyNo ratings yet

- GTL Process - by A.hoekDocument58 pagesGTL Process - by A.hoekDebye101100% (1)