Professional Documents

Culture Documents

Can Protocol Driverless Train Control System

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Can Protocol Driverless Train Control System

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 636

CAN PROTOCOL DRIVERLESS TRAIN CONTROL SYSTEM

V. Amala Rani

1

, T.V. Subha Austalekshmi

2

1

Asst Professor, Department of Electronics and Instrumentation, Sathyabama University, Tamilnadu, India

2

Asst Professor, Department of Electronics and Instrumentation, Sathyabama University, Tamilnadu, India

Abstract

This paper addresses the train running autonomously without any human operators. Provides information to avoid train to train

collisions, over speeding problem, signaling errors and unmanned railway crossing incidents. This afford a way for a passenger to

know the train location, speed and direction in real time from anywhere in India through his mobile phone.CAN protocol interconnect

all the train compartments with embedded network to ensure safety and security of passengers during disasters occurring within

trains such as bomb blasts and fire outbreaks. This make obtainable way for a passenger to know the train location, speed and

direction in real time from anywhere in India through his mobile phone. The CAN node is used to ensure the safety and comfort of the

passengers. It also have audio speakers to inform the passengers about the approaching station and also to provide alert messages

during a crisis situation.

Key Words: mobile phone, CAN protocol

----------------------------------------------------------------------***------------------------------------------------------------------------

1. INTRODUCTION

Generally when we are on railway platform waiting for a train,

eager to know about the current location and expected time of

arrival of train. Now, for this we completely depend on

announcements made by the enquiry staff. At present the

information of the running trains are monitored with the help

of manual monitoring which is not perfect. In this project the

exact location and speed movement of the train can be

monitored in real time basis. This project has been developed

for a train which provides precise location through interactive

mode on mobile phones, laptops, leading to the elimination for

telephone enquiry. The new classification would be more

useful all through winter or foggy endure stipulation as

passenger hardly get in sequence about Passenger trains

because this project use GPS data to monitor trains and offer

genuine time in order about the position of the train to users.

This proposed work aims to design a system that run the train

autonomously without human operators and also provides alert

messages during crisis situation. Here we propose an approach

to achieve efficiently design user friendly for driverless train

control system application especially target at preventing

accidents such as train to train collisions, over speeding

problem, unmanned railway crossing incidents etc.

2. LITERATURE SURVEY

CAN technology is adopt by most automotive industries

nowadays. As per Chuliang the paper presents a virtual

instrument based control system for research and enlargement

of the automotive and railway industries. This resourceful low

rate proficient and realistic arrangement contains the

applications of data acquisition, controller area network

(CAN), harmful engine exhaust emissions reduction, and spot

welding[1]. The system must be proficient to be employed in

various automation industries due to its flexibility. The

detailed applications of the system presented here, addresses

the monitoring of car engine exhaust emissions, CAN

application in reducing car engine exhaust emissions and

monitoring of automotive and railway spot welding. The

disadvantages are the data as of the gas sensors is require to be

collected and compared for each processing. The virtual

control system is used for only three applications such as

DAQ, CAN and harmful engine exhaust emissions reduction.

According to Chuliang, in this paper introduces a built

network for data CAN transmission following the data

acquisition from the necessary temperature sensors mounted

on a car engine and a train bogie in two respective tests[2].

LABVIEW is the only useful software during this network

design based in the lead of the industrial widely use. The

network should be capable to be functional in various

transportation industries suitable to its elasticity, extensibility

and achievability. The disadvantages are separate PCs are

used to operate as DAQ and CAN system for data sharing

instead of using both the system in same PC.By using only

LAN network we can transfer the data from DAQ PC to CAN

PC.More CAN nodes cannot be extended to build a complex

and functional CAN network This article introduce a method

by means of ARM as the main controller and double gateway

in a control computer in a car[3]. This system make use of the

high presentation of ARM, high speed reduction of CAN bus

communication control networks and instrument control as a

result as to get full sharing of data between nodes and improve

their collaborative work. This system features efficient data

transfer among different nodes in the practical applications.

The system leads to easy data sharing but it is done between

different control systems[4]. The process maintenance is hard

to carry out. The electric system uses a single point to point

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 637

communication approach which results in large cabling

problem.

3. EXISTING SYSTEM

RAIL RADAR is the new technology launched by Indian

Railways recently, which updates train position on a map

every time it crosses a station on its way. This system does not

provide real-time tracking since each station is located at least

1 km apart in cities and 10-20 km apart in remote places. It

does not use GPS which is a major drawback because the train

location is virtually unknown until it reaches the next station

that may be 5 to 20 minutes away. HUMAN ERROR is one of

the major reasons for train accidents. Every year we end up

with at least 2 or 3 major train accidents purely based on

human errors. Train to train collisions, over speeding trains

and signaling errors are typical cases where hundreds of lives

have been lost. Most of the time the reason would be on errors

from drivers and signal operators. Another important problem

is SAFETY AND SECURITY of passengers within trains.

Terrorist organizations want to make the country unsafe and

one of their ways is to plant bombs and explosives in of lives.

The driver has got no way to know the happenings trains.

Although security is available in railway stations, it is still not

enough to prevent such attacks. Also, we hear news such as

fire outbreak that originated in one compartment that quickly

spread to other part of the trains resulting in loss of huge

number behind the engine. Lives are also lost when

people/vehicles try to cross the tracks without noticing an

approaching train. Human error is one of the major reasons for

train accidents. The onboard passengers are not able to know

the approaching station

4. PROPOSED SYSTEM

Driverless train control system operates on the principle of a

central railway server and communication devices fixed in

each trains. All the trains on that particular route will update

the central railway server with their location, speed and

direction information. The train unit has an onboard GPS

module and a GSM module. A passenger can simply query the

location of a train via SMS from his mobile phone. The train

unit will reply to the user mobile with the GPS coordinates of

the present location it is traveling The server collects all such

information, calculates the optimum speed of travel for each

train and sends this information to those trains on the route.

The train control system will send its present GPS location

information periodically (typically every 30 sec) to the central

railway server. This message will immediately be

acknowledged with a reply message from the server that will

indicate the speed to travel. The train control system will

automatically adjust its speed to the speed indicated by the

server. The railway server is a software application that will be

running on a secured PC environment.

The onboard disaster prevention network connects all the

compartments of the train with the main control node over

CAN bus (Controller Area Network). CAN is a networking

protocol widely used in automotive applications to

interconnect different parts of the vehicle. It is also being used

in industrial automation networks. In unmanned railway

crossings, truck/car/humans/animals may cross a railway line.

The train control system oversees this and can adapt to slow

down the speed accordingly. This overrides the speed setting

from the server. It has a front SONAR ultrasonic range finder

for this purpose. The advantages are (i) a passenger can query

the location of a train via SMS. (ii) Accuracy of GPS location

is very high. (iii) Centrally controlled route server. (iv)

automatic speed adjustment

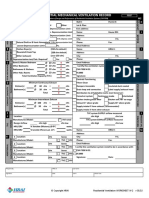

5. BLOCK DIAGRAM

It has a front SONAR ultrasonic range finder to check any

truck/car/humans/animals crossing a railway line and the train

control system oversees this and can adapt to slow down the

speed accordingly for this purpose.The onboard disaster

prevention network connects all the compartments of the train

with the main control node over CAN bus (Controller Area

Network). Each CAN node has got a variety of sensors and

devices to ensure the safety and comfort of the passengers.

The LPC11C14 are ARM cortex-M0 based microcontrollers

for embedded applications feature a high level of integration

and low power consumption. The train unit have an onboard

GPS and GSM module. The train control system send its

present GPS location information at times to the central

railway server. By using SONAR, we know how to detect the

obstacles and lessen the severity of accidents. The onboard

disaster prevention network connects all the compartments of

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 638

the train with the main control node over CAN bus. Metal

detector sensor detects explosives by sensing the variations in

the magnetic field around it. A digital MEMS magnetometer is

used for this. Temperature sensor detects fire outbreaks by

sensing large temperature variations.

It has a front SONAR ultrasonic range finder to check any

truck/car/humans/animals crossing a railway line and the train

control system oversees this and can adapt to slow down the

speed accordingly for this purpose. The onboard disaster

prevention network connects all the compartments of the train

with the main control node over CAN bus (Controller Area

Network). Each CAN node has got a variety of sensors and

devices to ensure the safety and comfort of the passengers.

The LPC11C14 are ARM cortex-M0 based microcontrollers

for embedded applications feature a high level of integration

and low power consumption. The train unit have an onboard

GPS and GSM module. The train control system send its

present GPS location information at times to the central

railway server. By using SONAR, we know how to detect the

obstacles and lessen the severity of accidents. The onboard

disaster prevention network connects all the compartments of

the train with the main control node over CAN bus. Metal

detector sensor detects explosives by sensing the variations in

the magnetic field around it. A digital MEMS magnetometer is

used for this. Temperature sensor detects fire outbreaks by

sensing large temperature variations. Audio announcement

system is designed to announce the approaching station names

found out via GPS location. This is also used to update critical

emergency information with the passengers such as fire

outbreak. Emergency push button to stop the train in critical

situation The mp3 audio files are stored in an external 2-GB

MicroSD memory card and an MP3 Decoder chip is used to

play it in speaker. The microcontroller is able to access the

files in memory card via a FAT-32 file system library.

6. RESULTS AND CONCLUSIONS

A passenger can get the location of a train via SMS from his

mobile phone in the form of longitudinal and latitudinal of the

train location. The message displays the Train location

longitude=25.32 and latitude=45.65 on the screen. All the

trains on that particular route will update the central railway

server with their location, speed and direction information.

The train control system will send its present GPS location

information periodically (typically every 30 sec) to the central

railway server. The train control system will automatically

adjust its speed to the speed indicated by the server. In

unmanned railway crossings, truck/car/humans/animals may

cross a railway line. The train control system considers this

and slow down the speed accordingly. In that case the message

is Obstacle detected. Latitude=41.32 and longitude=21.87.

Incase of any fire outbreaks in any compartment in train, the

buzzer alert is given to other compartment and an alert

message is send to central server and the train speed is

controlled. The message will be Fire detected in coach 1.

Latitude=41.32 and longitude=21.87 Incase some explosive

element is detected in any compartment of train, the buzzer

alert is given to other compartment and an alert message is

send to central server. The message will be Explosive metal

detected in coach 2. Latitude=41.32 and longitude=21.87 .In

some emergency case, the emergency switch is pressed then

the message is send to central server and the train get

controlled by stopping it. The messages will be Emergency

detected in coach 2. Latitude=41.32 and longitude=21.87

The project uses GPS data to monitor trains and offer real time

information about the location of train to users. All the trains

are monitored by a navigation system which is totally satellite

based. At present the information of the running trains are

monitored with the help of manual monitoring which is not

perfect but with the help of this project the movement of the

trains are recorded, which will also include the correct place

and speed in real time basis. Passengers can also be available

to see real time locations, as Centre of Railway Information

System (CRIS) has integrated the GPS application with

Google maps. INSAT-3C satellite will aid in location of

moving trains. The GPS system is being capable of give an

accuracy of about 10 meters, with a lag of about 2 minutes By

using this project, the controller will only plan the running and

scheduling of trains instead of co-ordination with various

other stations to confirm the status of the trains.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 639

REFERENCES

[1]. Chuliang Wei and Zhemin Zhuang, A.I.Al-

Shammaa,A.Shaw, Hwa-yaw Tam and S.L Ho, Avirtual

control system for automotive and railway industries

Intelligent Computation Technology and Automation

(ICICTA), 2011 International Conference on (Volume:1 )

978-1-61284-289- 28-29 March 2011 P580 583.

[2]. Chuliang Wei and Zhemin Zhuang(2011). A CAN

Network For Temperature Monitoring of Car Engine and

Train Bogieproceeding on International conference on

internet computing and information services. 978-1-4577-

1561-7, 17th to 18th Sep 2011, p. 302-305.

[3]. Jufang Hu, Chunru Xiong : Study on the embedded CAN

bus control system in the vehicle proceeding on International

conference on computer science and electronics engineering

2012, 978-1-4673-0689-8,. p. 440-442-305.

[4]. Li,s.; Wu,Y.;Li,g.;Zhu,Y. , Continuous and real time data

acquisition embedded system for EAST, proceeding on 16TH

IEEE-NPSS Real Time Conference 2009, 978-1-4244-4454-0,

10-15 May 2009, P499-502.

APPENDICES

You might also like

- Can Protocol Driverless Train Control SystemDocument4 pagesCan Protocol Driverless Train Control SystemesatjournalsNo ratings yet

- Railway Track Security System Report PDFDocument26 pagesRailway Track Security System Report PDFeshu50% (2)

- Railway Track Security System ReportDocument26 pagesRailway Track Security System ReportAshishNegi100% (28)

- Anti Collison - Fake ReportDocument40 pagesAnti Collison - Fake ReportVineet VijayanNo ratings yet

- Simulation of Zigbee Based Tacs For Collision Detection and Avoidance For Railway TrafficDocument5 pagesSimulation of Zigbee Based Tacs For Collision Detection and Avoidance For Railway Trafficprinceram123No ratings yet

- Anti Collision System 2012-13Document32 pagesAnti Collision System 2012-13Manoj KrishnaNo ratings yet

- Improving Railway Safety With Obstacle Detection and Tracking System Using GPS-GSM ModelDocument7 pagesImproving Railway Safety With Obstacle Detection and Tracking System Using GPS-GSM ModelFìrœ Lōv MånNo ratings yet

- Alacrity Control Using CateyeDocument5 pagesAlacrity Control Using CateyeRega RmsNo ratings yet

- REMLOT ProjectDocument66 pagesREMLOT Projectritesh_jain_1050% (2)

- Smart Materials and Techniques Used in Indian RailwaysDocument10 pagesSmart Materials and Techniques Used in Indian RailwaysNIDHI JARIWALANo ratings yet

- Obstacle Detection System For Railways: Karthick S, Aishwarya Patil, Ullas S U K. SaravanakumarDocument3 pagesObstacle Detection System For Railways: Karthick S, Aishwarya Patil, Ullas S U K. Saravanakumarkarthick sNo ratings yet

- Automatic Railway System Using Wireless Sensor NetworkDocument5 pagesAutomatic Railway System Using Wireless Sensor NetworkMar CelNo ratings yet

- Impact of Inter Vehicle Communication (IVC) On Network and Road Traffic Simulation Using Bidirectional Coupled Network Through One Hop Broadcasting TechniqueDocument6 pagesImpact of Inter Vehicle Communication (IVC) On Network and Road Traffic Simulation Using Bidirectional Coupled Network Through One Hop Broadcasting TechniqueseventhsensegroupNo ratings yet

- Remmlot TrainingDocument67 pagesRemmlot Trainingmadhwan sharmaNo ratings yet

- Inter-Vehicular Communication Using Packet Network TheoryDocument7 pagesInter-Vehicular Communication Using Packet Network TheoryInternational Journal of Research in Engineering and TechnologyNo ratings yet

- ITS Application in RailwayDocument25 pagesITS Application in RailwayNIDHI JARIWALANo ratings yet

- Railway DhruvDocument41 pagesRailway DhruvKartikNo ratings yet

- Train Monitoring SYSTEMDocument15 pagesTrain Monitoring SYSTEMMichael WilliamsNo ratings yet

- Intelligent Transportation SystemDocument13 pagesIntelligent Transportation SystemZION LIFENo ratings yet

- An Enhanced Railways Control Office Application Implementation in Cloud EnvironmentDocument6 pagesAn Enhanced Railways Control Office Application Implementation in Cloud Environmentvaruna189No ratings yet

- Automated Railways Collision Avoidance System Using Wireless NetworksDocument4 pagesAutomated Railways Collision Avoidance System Using Wireless NetworksAbhishek GoyalNo ratings yet

- Route Diversion Detection System For Public Bus Transport Using WSNDocument4 pagesRoute Diversion Detection System For Public Bus Transport Using WSNInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Simulation of Traffic Movement in Vanet Using Sumo: by AJAY KUMAR PANDEY (109cs0588)Document36 pagesSimulation of Traffic Movement in Vanet Using Sumo: by AJAY KUMAR PANDEY (109cs0588)ferronatto11No ratings yet

- Bus Tracking System and Ticket Generation Using QR Technology PDFDocument5 pagesBus Tracking System and Ticket Generation Using QR Technology PDFResearch Journal of Engineering Technology and Medical Sciences (RJETM)No ratings yet

- Automotive Railway Protection & Info SystemDocument10 pagesAutomotive Railway Protection & Info SystemSyed HussainiNo ratings yet

- Railway Track Structural Heath Monitoring SystemDocument46 pagesRailway Track Structural Heath Monitoring Systempunith100% (1)

- Vehicle To Infrastructure Communication Different Methods and Technologies Used For ItDocument3 pagesVehicle To Infrastructure Communication Different Methods and Technologies Used For ItBargavi SrinivasNo ratings yet

- Automatic Accident Detection and Ambulance RescueDocument11 pagesAutomatic Accident Detection and Ambulance Rescuesivasankar100% (2)

- Automatic Railway SystemDocument5 pagesAutomatic Railway SystemTomu RomsonNo ratings yet

- Traffic Flow Management Using Wireless Sensor Networks: Project TitleDocument8 pagesTraffic Flow Management Using Wireless Sensor Networks: Project TitlevenkateshNo ratings yet

- Chapter 1: Introduction: Smart Traffic Controlling SystemDocument41 pagesChapter 1: Introduction: Smart Traffic Controlling Systemdivya varikutiNo ratings yet

- Passenger Reservation SystemDocument22 pagesPassenger Reservation SystemlvsaruNo ratings yet

- Development of A Smart Railway System For BangladeshDocument6 pagesDevelopment of A Smart Railway System For BangladeshAchmad Agus Eko'bNo ratings yet

- Cross Layer Based Congestion Free Route Selection in Vehicular Ad Hoc NetworksDocument18 pagesCross Layer Based Congestion Free Route Selection in Vehicular Ad Hoc NetworksAIRCC - IJCNCNo ratings yet

- Ijaerv14n2spl 04Document4 pagesIjaerv14n2spl 04srinivasNo ratings yet

- Zero-Visibility Navigation For The Indian Railways: Vatsalya Mathur Kapileshwar Singh M.D.ChawhanDocument4 pagesZero-Visibility Navigation For The Indian Railways: Vatsalya Mathur Kapileshwar Singh M.D.Chawhanmanish vermaNo ratings yet

- IJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchDocument8 pagesIJCER (WWW - Ijceronline.com) International Journal of Computational Engineering ResearchInternational Journal of computational Engineering research (IJCER)No ratings yet

- Rail Track MonitoringDocument7 pagesRail Track MonitoringNarayan PradhanNo ratings yet

- Minor Projet ReportDocument15 pagesMinor Projet ReportSujata AdhikariNo ratings yet

- A Cooperative Trust Management System For VANET Integrating WSN TechnologyDocument11 pagesA Cooperative Trust Management System For VANET Integrating WSN Technologystephenlim7986No ratings yet

- Intelligent Car Parking SystemDocument8 pagesIntelligent Car Parking SystemLeo BoyNo ratings yet

- Frauscher Whitepaper APR 23Document9 pagesFrauscher Whitepaper APR 23Tamer TaskinNo ratings yet

- A Web-Based Traffic Information System Using Wireless Communication TechniquesDocument5 pagesA Web-Based Traffic Information System Using Wireless Communication TechniquesHiron NurulNo ratings yet

- GSM-R: The Standardized DigitalDocument12 pagesGSM-R: The Standardized Digitalap0026No ratings yet

- Gun RailwayDocument33 pagesGun RailwayGunjan GoyalNo ratings yet

- Design and Implementation of Control Unit For Railways Using Power Line Data TransmissionDocument5 pagesDesign and Implementation of Control Unit For Railways Using Power Line Data TransmissionEditor IJRITCCNo ratings yet

- IJCESRDocument8 pagesIJCESRAastiNo ratings yet

- Synt 05 MTRC PPT - 42 (A)Document18 pagesSynt 05 MTRC PPT - 42 (A)Praveen KumarNo ratings yet

- Saurabh Training Reap RTDocument11 pagesSaurabh Training Reap RTNitesh Kumar SinghNo ratings yet

- Local Traffic Aware Unicast Routing Scheme For Connected Car SystemDocument16 pagesLocal Traffic Aware Unicast Routing Scheme For Connected Car SystemDanang AjiNo ratings yet

- Automatic Shuttling of Metro Train Between StationsDocument5 pagesAutomatic Shuttling of Metro Train Between StationsShivamNo ratings yet

- Design and Implementation of A Vehicle Theft Control Unit Using GSM and CAN TechnologyDocument8 pagesDesign and Implementation of A Vehicle Theft Control Unit Using GSM and CAN Technologyrajabala93No ratings yet

- Vehicle-To-Vehicle and Road-Side Sensor Communication For Enhanced Road SafetyDocument12 pagesVehicle-To-Vehicle and Road-Side Sensor Communication For Enhanced Road SafetyManoj SharmaNo ratings yet

- A Proposed Model For Radio Frequency Systems To Tracking Trains Via GPSDocument8 pagesA Proposed Model For Radio Frequency Systems To Tracking Trains Via GPSRajasekar PanneerselvamNo ratings yet

- A Literature Survey On "Density Based Traffic Signal System Using Loadcells and Ir Sensors"Document3 pagesA Literature Survey On "Density Based Traffic Signal System Using Loadcells and Ir Sensors"hiraNo ratings yet

- Automatic Bus Recognition Through Mobile: International Journal of Computer Trends and Technology-volume3Issue3 - 2012Document7 pagesAutomatic Bus Recognition Through Mobile: International Journal of Computer Trends and Technology-volume3Issue3 - 2012surendiran123No ratings yet

- 1.1 General A Transducer Is A Smart Device For Harvesting Energy of Street Light orDocument37 pages1.1 General A Transducer Is A Smart Device For Harvesting Energy of Street Light orRaja RKNo ratings yet

- 4 IjecsDocument5 pages4 IjecsPiyush ChouhanNo ratings yet

- Smart Traffic Signal Using Parallel Plate CapacitorDocument6 pagesSmart Traffic Signal Using Parallel Plate CapacitorInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Kavach: Cab Signalling & Automatic Train Protection System for Digital RailwaysFrom EverandKavach: Cab Signalling & Automatic Train Protection System for Digital RailwaysNo ratings yet

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Analytical Solutions For Square Shape PressureDocument4 pagesAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Chapter 7 The Conversion Cycle: Batch Processing SystemDocument6 pagesChapter 7 The Conversion Cycle: Batch Processing SystemAnne Rose EncinaNo ratings yet

- Intelligent Transport SystemDocument17 pagesIntelligent Transport SystemsvivekNo ratings yet

- Technology EssayDocument11 pagesTechnology Essayapi-548700899No ratings yet

- RFID Telematics Folder ENDocument16 pagesRFID Telematics Folder ENreve abdoNo ratings yet

- CB Insights Construction Tech WebinarDocument61 pagesCB Insights Construction Tech WebinarSheila EnglishNo ratings yet

- 4 B637099 D 01Document52 pages4 B637099 D 01Mohd RosnizamNo ratings yet

- Company ProfileDocument20 pagesCompany ProfiletheatresonicNo ratings yet

- Residential Mechanical Ventilation CSA F3261Document1 pageResidential Mechanical Ventilation CSA F3261elrazumesNo ratings yet

- Understanding Voltage Unbalance Measurements and CalculationsDocument76 pagesUnderstanding Voltage Unbalance Measurements and CalculationsMAKENGO ELIASNo ratings yet

- Lab Ventilation SystemsDocument10 pagesLab Ventilation SystemsHyeong-Ho KimNo ratings yet

- NGIRI 2020 21 List of Shortlisted FYPsDocument23 pagesNGIRI 2020 21 List of Shortlisted FYPsSardar Rehan AhmedNo ratings yet

- Sima400h PDFDocument8 pagesSima400h PDFhtm64No ratings yet

- What Key Competencies Are Needed in The Digital Age?Document60 pagesWhat Key Competencies Are Needed in The Digital Age?marnekibNo ratings yet

- RAVS Turnover ReportDocument17 pagesRAVS Turnover ReportMhike EcoNo ratings yet

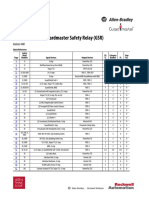

- Next Generation Guardmaster Safety Relay (GSR) : Wiring DiagramDocument124 pagesNext Generation Guardmaster Safety Relay (GSR) : Wiring DiagramPhan Van SinhNo ratings yet

- PID Controllers - Intro To Control Design - Online Engineering CoursesDocument1 pagePID Controllers - Intro To Control Design - Online Engineering CoursesMohamed AlkharashyNo ratings yet

- Crouzet Millenium3 Brochure enDocument19 pagesCrouzet Millenium3 Brochure enelmer jpnsonNo ratings yet

- ProE Lab Work 1 To 11Document11 pagesProE Lab Work 1 To 11RakeshSainiNo ratings yet

- Airtemp Portable Air Conditioner 4pp A4 Brochure - PRICEDocument2 pagesAirtemp Portable Air Conditioner 4pp A4 Brochure - PRICEDavidNo ratings yet

- TWR / TWZ: Split System Heat Pumps Single PhaseDocument6 pagesTWR / TWZ: Split System Heat Pumps Single PhaseDavid CollinsNo ratings yet

- FMS AnswersDocument8 pagesFMS AnswersAnmol SetiaNo ratings yet

- Productivity Improvement On A CNC Lathe by Automatic Loading and Unloading of Throttle Valve ComponentDocument20 pagesProductivity Improvement On A CNC Lathe by Automatic Loading and Unloading of Throttle Valve ComponentAyush NarangNo ratings yet

- AI Implementation in Org & ConclusionDocument3 pagesAI Implementation in Org & ConclusionAnish DalmiaNo ratings yet

- Hvac-Dbr - R6Document29 pagesHvac-Dbr - R6adkNo ratings yet

- KBK BRDocument36 pagesKBK BRJean-Pascal RossNo ratings yet

- HVAC Interview QuestionsDocument2 pagesHVAC Interview Questionsamithkm89% (9)

- Robotic Arm With Base Rotation Elbow and Wrist Motion With Functional GripperDocument2 pagesRobotic Arm With Base Rotation Elbow and Wrist Motion With Functional GripperHushein RasheethNo ratings yet

- Semi-Automated Roller Painting Machine-IJRASETDocument4 pagesSemi-Automated Roller Painting Machine-IJRASETIJRASETPublicationsNo ratings yet

- A Review of IoT in Banking Industry Manasvi RizviDocument5 pagesA Review of IoT in Banking Industry Manasvi RizvigualabaNo ratings yet

- PLC Mcqs Part 1Document35 pagesPLC Mcqs Part 1rak RoyNo ratings yet