Professional Documents

Culture Documents

Design & Simulation of Low Loss Circular Corrugated Waveguide For 42 GHZ, 200kw Gyrotron

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design & Simulation of Low Loss Circular Corrugated Waveguide For 42 GHZ, 200kw Gyrotron

Copyright:

Available Formats

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 220

DESIGN & SIMULATION OF LOW LOSS CIRCULAR CORRUGATED

WAVEGUIDE FOR 42 GHZ, 200KW GYROTRON

Jinal A. Mistry

1

, S. V. Kulkarni

2

,

Shobhit K. Patel

3

, Kunal S. Kadiya

4

1

M.Tech Student, Chandubhai S Patel Institute of Technology, Gujarat, India

2

Scientist, ICRH, Institute for Plasma Research, Gujarat, India

3

Assistant Professor, EC Dept., Chandubhai S Patel Institute of Technology, Gujarat, India

4

Assistant Professor, DT Dept., SMC College of Dairy Science, AAU, Anand, Gujarat, India

Abstract

Corrugated waveguide is used to transmit high power microwave from the microwave devices like Gyrotron. HE

11

mode has the

lowest loss and is a fundamental mode of corrugated waveguide. Corrugated waveguides have proved to be the most efficient

waveguides for transmitting high power GHz & THz radiation compared to smooth wall circular waveguide at the operational

frequency of the transmission line. This work includes the simulation of circular corrugated waveguide for 42 GHz Gyrotron and also

includes the simulation comparison of corrugated metallic waveguide with smooth wall cylinder using HFSS (high frequency

structural simulator) software.

Keywords: Corrugated waveguide, Gyrotron, HE

11

hybrid mode, HFSS.

-----------------------------------------------------------------------***-----------------------------------------------------------------------

1. INTRODUCTION

Transmission of high power microwave radiation is a growing

research area due to the increased availability of high power

microwave sources. Developing low loss transmission lines is

especially important when dealing with high average powers,

which can damage components if are not properly designed

[1]. Transmission lines are used to transmit power in

electromagnetic waves from one point to another.

Transmission of high power microwave radiation is a

challenging task due to the lossy nature of most fundamental

mode transmission lines at such high frequencies. In low-

power experiments, simple smooth wall cylindrical

waveguides are useful, but when considering the transmission

of high power (in MW) for long distances, traditional methods

will be insufficient due to large attenuation, mode conversion,

beam scattering the possibility of microwave breakdowns, and

high heating which can lead to failures in the transmission

system. An overmoded approach to transmission lines has

been demonstrated as an efficient and practical solution for

high power microwave applications [2].

The Gyrotron is a high power microwave tube, which emits

coherent radiation at approximately the electron cyclotron

frequency or its harmonics. Gyrotron is widely used in plasma

fusions, ECRH heating, industrial heating and high

temperature processing of materials. Gyrotron oscillators are

mainly important in magnetic fusion experiments. Gyrotron

technology has significantly advanced towards meeting the

goals of providing a reliable and highly efficient source of

high-power microwave radiation.

The most common approach is the use of overmoded

waveguides, in which the guide radius is much larger than the

wavelength. Such waveguides can be corrugated metallic

waveguides, dielectric waveguides or dielectric lined metallic

waveguides. Free space beaming and corrugated waveguides

are closely related as the fundamental HE11 mode used in

corrugated waveguides has a conversion efficiency of 98% to

the Gaussian beam which is used in quasi-optical transmission

[1]. Overmoded metallic circumferentially corrugated

cylindrical waveguides have been shown to have low

attenuation over long distances, but may result in high

amounts of mode conversion and large losses due to

misalignment or manufacturing errors. Decreasing the

attenuation and mode conversion in high power experiments is

necessary for the integrity of the transmission system as well

as the success of the experiment, particularly when

transmission over long distances is necessary [2].

1.1 Need of Corrugated Waveguide

Following are the advantages of the HE11 mode through a

circular corrugated waveguide:

1) Efficient plasma heating requires axis-symmetric

narrow pencil beam with well-defined polarization

incident on the plasma, the almost perfectly linearly

polarized HE

11

hybrid mode satisfy these condition

best.

2) Low transmission loss & Large bandwidth in HE

11

3) Mode conversion loss at miter bends for HE

11

is only

about 35% to that for TE

01.

The HE

11

mode is better

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 221

separated from competing modes, so propagation is

less sensitive to wall distortions [3].

4) The HE

11

mode at open-ended corrugated waveguide

couples directly to the fundamental free space Gaussian

mode with less than 2% loss over wide bandwidths [3].

5) HE

11

mode, the fundamental mode for corrugated

waveguides, has power concentrated in the center and

small fields at the walls of the waveguide, whereas

TE

01

and TM

11

have the lowest loss modes for smooth

wall waveguides and have power that is off-center and

more susceptible to losses due to fields present at the

walls [2].

6) For oversized smooth-wall circular waveguide, the

lowest loss mode is TE

01

, which is not the fundamental

mode. This property leads to the danger of mode

conversion to lower order modes that are hard to filter

out. Also, the TE

01

mode is degenerative with the TM

11

mode, increasing the possibility of mode conversion to

an undesirable mode. On the other hand, corrugated

cylindrical waveguides have the lowest loss in the

fundamental HE

11

mode, reducing the concerns for

mode conversion to degenerate with lower order modes

[2]. Corrugated waveguides have been used in a variety

of applications for the transmission of GHz radiation

for spectroscopic and plasma heating experiments.

1.2 Brief Introduction of Corrugated Waveguide for

42 GHz, 200kw Gyrotron

The gyrotron has become an integral part of the fusion

reactors for pre-ionization, current start-up, heating, current

drive and for stabilizing neo-classical tearing modes etc. The

required frequency of gyrotron lies in the range of 42 GHz to

170 GHz and depends upon the toroidal magnetic field of the

tokamak. The power requirement also varies according to

tokamak and final requirement is from 5 MW to 20 MW. The

five organizations of India are developing 42 GHz, 200 kW

gyrotron as a part of indigenous development and IPR is

involved with the project with major responsibilities as well is

the end user of the gyrotron for doing physics experiments on

tokamaks ADITYA and SST-1.

Fig-1: Block diagram of design flow from gyrotron output to

the Tokamak / dummy load

Fig. 1 shows the conversion of TE-03 mode to HE-11 mode

and then transmission of microwave power from gyrotron to

either tokamak or HE-11 dummy load. In this work we present

the design & simulation of circular corrugated waveguide of

63.5mm diameter for 42GHz, 200kW gyrotron. The diameter

63.5mm is chosen to make it compatible with inner diameter

of miter bend.

2. DESIGN OF HIGH POWER LOW LOSS

CIRCULAR CORRUGATED WAVEGUIDE

Fig -2: Illustration of circular corrugated waveguide [1]

Fig. 2 shows a schematic of a circular corrugated waveguide

with rectangular grooves. To design corrugated waveguide for

low losses, the radius a should be much larger than a

wavelength , the corrugations are optimized when the groove

depth d / 4, period p / 3 and groove width w p / 2.

The corrugation tooth thickness is denoted by t = p-w [1].

Using above criteria we have calculated the design parameters

for the circular corrugated waveguide and are given in Table

1.

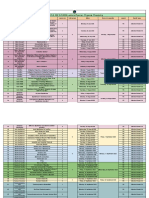

Table 1: Calculated Design parameters of circular corrugated

waveguide

Sr.

No.

Parameter

Value

1 Operating frequency (f) 42 GHz

2 Wavelength () 7.14 mm

3 Radius (a) 31.75 mm

4 Corrugation depth (d) 1.785 mm

5 Corrugation periodicity (p) 2.37 mm

6 Corrugation thickness (t) 1.37 mm

7 Groove width (w) 1 mm

8 Waveguide material Aluminum , copper

, stainless steel

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 222

2.1 Simulation of Corrugated Waveguide in HFSS

In this work, low loss circular corrugated waveguide is

designed for 42 GHz Gyrotron source using above design

parameter in HFSS. And this project also shows the

comparison between smooth wall circular waveguide and

circular corrugated waveguide and analyzed their S-

parameters using HFSS.

Fig-3: Corrugated circular waveguide in HFSS (all

dimensions according to Table 1)

Fig-4: Smooth wall circular waveguide in HFSS

2.2 Simulation Results from HFSS & Discussions

Fig- 5: Electric field in smooth wall circular waveguide for

200 kW

Fig- 6: Magnetic field in smooth wall circular waveguide for

200 kW

Fig-7: Fundamental HE11 mode in corrugated waveguide

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 223

Fig- 8: Electric field in circular corrugated waveguide for

200kW

Fig- 9: Electric field in circular corrugated waveguide for

200kW

Fig-10: Comparison of Insertion loss (S21) between

corrugated waveguide and smooth wall waveguide

Fig-11: Comparison of Return loss (S21) between corrugated

waveguide and smooth wall waveguide

Figures 5 to 9 show the magnitude of electric & magnetic field

in smooth circular waveguide and corrugated waveguide,

electric & magnetic field distibution in smooth circular

waveguide and corrugated waveguide and also shows the

fundamental mode HE11. The electric & magnetic field in

circular corrugated waveguide is higher than the smooth wall

circular waveguide which clearly shown in the above figures.

Fig-13: Variations of S11 and S21 parameters with

corrugation depth (d) of circular corrugated Waveguide

Fig. 10 and 11 shows the comparison between circular

corrugated waveguide and simple circular waveguide at

42GHz frequency, which shows that the insertion and return

losses are less at such high frequency in corrugated waveguide

compared to simple circular waveguide. If corrugation depth

(d) is varied from its optimized depth ( /4) then

insertion loss (S21) is increased but very little change in the

return loss (S11) which is shown in the fig. 13, also it shows

that insertion loss is more depends on corrugation depth (d).

-0.015

-0.58

-0.7

-0.6

-0.5

-0.4

-0.3

-0.2

-0.1

0

0.1

41.8 42 42.2 42.4 S

2

1

(

d

B

)

Frequency (GHz)

S21

corrugated

WG

S21 simple

cylinder

-25.54

-18.037

-28

-26

-24

-22

-20

-18

-16

-14

-12

41.8 41.9 42 42.1 42.2 42.3

S

1

1

(

d

B

)

Frequency (GHz)

S11

corrugated

waveguide

S11 simple

waveguide

-0.015

-0.32

-1.88

-5.91

-15

-25.55 -24.9

-25.3 -25.35

-25.47

-28

-26

-24

-22

-20

-18

-16

-14

-12

-10

-8

-6

-4

-2

0

2

1.65 1.7 1.75 1.8 1.85 1.9 1.95 2

S21

corruga

ted

WG

S11

corruga

ted

WG

S

1

1

,

S

2

1

(

d

B

)

Corrugation depth d (mm)

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 03 Issue: 05 | May-2014, Available @ http://www.ijret.org 224

Table 2: Results of variation in material used for the

corrugated waveguide in HFSS

Although the conductivity of copper is greater than aluminum,

the insertion losses for aluminum is almost same as copper

(shown in Table 2). We have also calculated the change in

temperature T by passing 200kW for 1sec duration for Cu

and Al by using equation

Q = mCT

Where m is mass of sample, C is specific heat capacity and T

is the difference between initial temperature and temperature

after 1 sec duration and found it as 0.00127 C for copper and

0.00178 C for aluminum which is almost same. Based on

additional advantage of mass (101.55gm for Al, 337gm for

Cu) and also due to its low cost and less weight we preferred

aluminum to be used in our design.

Table 3: Summary of design Results (at 42 GHz) in HFSS

Sr.

No.

Results

parameters

Smooth wall

cylinder

Corrugated

waveguide

1

Insertion loss

S21(dB)

-0.58

-0.015

2

Return loss

S11

(dB)

-18.04

- 25.55

3

VSWR

1.3

1.1

3. CONCLUSIONS

This work has presented the design and simulation of high

power low loss circular corrugated metallic waveguide for 42

GHz Gyrotron. And also presented the simulation comparison

between smooth wall circular metallic waveguide and

corrugated circular metallic waveguide. Simulation results

shows that the corrugated waveguide have low insertion and

return loss compared to smooth wall circular waveguide.

Insertion loss is affected by varying the corrugation depth (d),

whereas return loss is not that much dependent on corrugation

depth (d). For microwave transmission, material choice is also

important for design.

Corrugated waveguides have proved to be a reliable technique

with regards to their low loss nature and ability to handle high

powers with low losses.

ACKNOWLEDGEMENTS

This work was carried out at Institute for plasma Research,

Gandhinagar, India. The authors are thankful to the director &

ICRH group of Institute for plasma Research for all their

support and guidance.

REFERENCES

[1]. Nanni E.A., Jawla S. K., Shapiro M. A., Woskov P. P.,

Temkin R. J., Low Loss Transmission Lines for High Power

Terahertz Radiation, Plasma Science and Fusion Center,

Massachusetts Institute of Technology, Cambridge, MA,

02139 USA

[2]. Elizabeth J. Kowalski, thesis on Miter Bend Loss and

Higher Order Mode Content Measurements in Overmoded

Millimeter-Wave Transmission Lines, Submitted to the

Massachusetts institute of technology, Cambridge, MA 02139,

United States, September 2010

[3]. http://www.ga.com/straight-corrugated-waveguides

[4] Ansoft HFSS version 15, 3-D electromagnetic Simulation

Software

Sr.

No.

Variation in

Material used for

corrugated

waveguide

Insertion

loss S21

(dB)

Return loss

S11

(dB)

1 Copper -0.014 -25.56

2 Aluminum -0.015 -25.53

3 Stainless steel -0.044 -24.73

You might also like

- Wind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudDocument11 pagesWind Damage To Trees in The Gitam University Campus at Visakhapatnam by Cyclone HudhudInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Flood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaDocument8 pagesFlood Related Disasters Concerned To Urban Flooding in Bangalore, IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Impact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictDocument5 pagesImpact of Flood Disaster in A Drought Prone Area - Case Study of Alampur Village of Mahabub Nagar DistrictInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Low Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeDocument5 pagesLow Cost Wireless Sensor Networks and Smartphone Applications For Disaster Management and Improving Quality of LifeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Enhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingDocument8 pagesEnhancing Post Disaster Recovery by Optimal Infrastructure Capacity BuildingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesDocument9 pagesEffect of Lintel and Lintel Band On The Global Performance of Reinforced Concrete Masonry In-Filled FramesInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Role of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeDocument6 pagesRole of Voluntary Teams of Professional Engineers in Dissater Management - Experiences From Gujarat EarthquakeInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Groundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaDocument5 pagesGroundwater Investigation Using Geophysical Methods - A Case Study of Pydibhimavaram Industrial AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Shear Strength of RC Deep Beam Panels - A ReviewDocument15 pagesShear Strength of RC Deep Beam Panels - A ReviewInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Wind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamDocument10 pagesWind Damage To Buildings, Infrastrucuture and Landscape Elements Along The Beach Road at VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Likely Impacts of Hudhud On The Environment of VisakhapatnamDocument3 pagesLikely Impacts of Hudhud On The Environment of VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Assessment of Seismic Susceptibility of RC BuildingsDocument4 pagesAssessment of Seismic Susceptibility of RC BuildingsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Hudhud Cyclone - A Severe Disaster in VisakhapatnamDocument8 pagesHudhud Cyclone - A Severe Disaster in VisakhapatnamInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Monitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentDocument3 pagesMonitoring and Assessment of Air Quality With Reference To Dust Particles (Pm10 and Pm2.5) in Urban EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsDocument5 pagesCpw-Fed Uwb Antenna With Wimax Band-Notched CharacteristicsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Review Study On Performance of Seismically Tested Repaired Shear WallsDocument7 pagesReview Study On Performance of Seismically Tested Repaired Shear WallsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- A Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalDocument5 pagesA Geophysical Insight of Earthquake Occurred On 21st May 2014 Off Paradip, Bay of BengalInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Coastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaDocument4 pagesCoastal Zones - Seismic Vulnerability An Analysis From East Coast of IndiaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Detection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentDocument9 pagesDetection of Hazard Prone Areas in The Upper Himalayan Region in Gis EnvironmentInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Can Fracture Mechanics Predict Damage Due Disaster of StructuresDocument6 pagesCan Fracture Mechanics Predict Damage Due Disaster of StructuresInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Cyclone Disaster On Housing and Coastal AreaDocument7 pagesCyclone Disaster On Housing and Coastal AreaInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Comparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsDocument10 pagesComparative Study of The Forces in G+5 and G+10 Multi Storied Buildings Subjected To Different Wind SpeedsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Challenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsDocument4 pagesChallenges in Oil and Gas Industry For Major Fire and Gas Leaks - Risk Reduction MethodsInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Effect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyDocument4 pagesEffect of Hudhud Cyclone On The Development of Visakhapatnam As Smart and Green City - A Case StudyInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Brain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringDocument4 pagesBrain Tumor Segmentation Using Asymmetry Based Histogram Thresholding and K-Means ClusteringInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Disaster Recovery Sustainable HousingDocument4 pagesDisaster Recovery Sustainable HousingInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Rate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmDocument5 pagesRate Adaptive Resource Allocation in Ofdma Using Bees AlgorithmInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Developing of Decision Support System For Budget Allocation of An R&D OrganizationDocument6 pagesDeveloping of Decision Support System For Budget Allocation of An R&D OrganizationInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Analytical Solutions For Square Shape PressureDocument4 pagesAnalytical Solutions For Square Shape PressureInternational Journal of Research in Engineering and TechnologyNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Prayas JEE 3.0 2024 Lecture Planner - Physical ChemistryDocument3 pagesPrayas JEE 3.0 2024 Lecture Planner - Physical ChemistryShreyam SarvpriyamNo ratings yet

- Military Handbook Mil HDBK 411bDocument658 pagesMilitary Handbook Mil HDBK 411bthomas.bhatiaNo ratings yet

- DPE Broceure 2Document4 pagesDPE Broceure 2Debabrata SinghNo ratings yet

- Wet-bulb temperature explainedDocument12 pagesWet-bulb temperature explainedEndhy Wisnu NovindraNo ratings yet

- Mix Design Bosowa PDFDocument11 pagesMix Design Bosowa PDFEriPrawitoNo ratings yet

- Carbon Cycle Worksheet: NameDocument2 pagesCarbon Cycle Worksheet: NameBio SciencesNo ratings yet

- Fluid Mechanics Multiple Choice QuestionsDocument10 pagesFluid Mechanics Multiple Choice QuestionsCgpscAspirantNo ratings yet

- School Grade Level Teacher Learning Area Teaching Dates QuarterDocument42 pagesSchool Grade Level Teacher Learning Area Teaching Dates QuarterAngelica Beltran LazagaNo ratings yet

- FertilizantesDocument8 pagesFertilizantesLeonardo EstradaNo ratings yet

- Biological Classification and the Living WorldDocument6 pagesBiological Classification and the Living Worldtanish jainNo ratings yet

- Grade 8 Science Classifying EnergyDocument2 pagesGrade 8 Science Classifying EnergyJohnRobin AmoguisNo ratings yet

- Boardworks GCSE Science - Chemistry Contents GuideDocument20 pagesBoardworks GCSE Science - Chemistry Contents Guidedeeyamulla100% (3)

- Study About Micro-Hydro Power PlantDocument6 pagesStudy About Micro-Hydro Power PlantRRKGP Sk Md DanishNo ratings yet

- ENT 346 - Vibration MechanicsDocument9 pagesENT 346 - Vibration MechanicsAnbaananthanTheverNo ratings yet

- RBP 2023 3 04Document14 pagesRBP 2023 3 04reisvictoria1529No ratings yet

- CE 323 Geotechnical Engineering IDocument5 pagesCE 323 Geotechnical Engineering IadityaNo ratings yet

- Wayne Hu ThesisDocument250 pagesWayne Hu ThesisshafieeeeeeeNo ratings yet

- GDR Chapter 3 - VolcanoesDocument42 pagesGDR Chapter 3 - VolcanoesKurt BayalNo ratings yet

- Q3 - WEEK 6 - LAS-1-Multiple Lines of EvidenceDocument2 pagesQ3 - WEEK 6 - LAS-1-Multiple Lines of EvidenceAnjhiene CambaNo ratings yet

- RE WALL Design As Per Irc 102Document16 pagesRE WALL Design As Per Irc 102Naresh Sharma100% (2)

- Sir Ahsan Resources: Topic 4 - Energy, Work and PowerDocument12 pagesSir Ahsan Resources: Topic 4 - Energy, Work and Powermahsan abbasNo ratings yet

- Drying of Air by Fixed Bed Adsorption Using Molecular SievesDocument216 pagesDrying of Air by Fixed Bed Adsorption Using Molecular SievesKimberly BautistaNo ratings yet

- Engineering Principles-Feng 123 Lecture Notes Volume 2: BY Ing. Sahr T. NyallomaDocument12 pagesEngineering Principles-Feng 123 Lecture Notes Volume 2: BY Ing. Sahr T. NyallomaAlbert LappiaNo ratings yet

- VOLCANOESDocument65 pagesVOLCANOESPrincess Alyssa BarawidNo ratings yet

- An Introduction To The Principles of Pavement Drainage: Course No: C02-048 Credit: 2 PDHDocument25 pagesAn Introduction To The Principles of Pavement Drainage: Course No: C02-048 Credit: 2 PDHManfredi Di MaitaNo ratings yet

- Passive Solar Architecture PRDocument1 pagePassive Solar Architecture PRChelsea Green PublishingNo ratings yet

- Gr12 Learner Activities Term 1 EnglishDocument270 pagesGr12 Learner Activities Term 1 EnglishFrance MaleselaNo ratings yet

- DPS Phy - Set - ADocument3 pagesDPS Phy - Set - AscNo ratings yet

- Photocatalytic Degradation of Phenol Using Fe(III)-doped TiO2Document27 pagesPhotocatalytic Degradation of Phenol Using Fe(III)-doped TiO2Gin ManNo ratings yet

- Renewable Energy SourcesDocument486 pagesRenewable Energy SourcesKiran SugandhiNo ratings yet