Professional Documents

Culture Documents

RPL RPLC

Uploaded by

dunareanu_marian8668Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RPL RPLC

Uploaded by

dunareanu_marian8668Copyright:

Available Formats

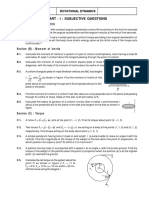

Teohnioa| 8eoifioations:

6ripper can be meunted and eperated in any erientatien

Nountin Information:

Para||e| 0riers-

Low Profi|e 8eries

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Frecisien appIicatiens.

Preloaded "Dual-V" roller oearings

eliminate side pla] for excellent part

position repeataoilit].

8epeatabIe grip ferce.

low friction mechanism allows for

consistent, repeataole gripping forces.

To grip delicate parts, grip force can oe

easil] altered o] adjusting air pressure.

Lenger finger appIicatiens.

Rigid design allows for longer gripper

finger lengths to oe used when compared

to other grippers of equal weight & size.

en-synchreneus metien.

The unit can oe made non-s]nchronous

providing independent jaw motion

allowing the gripper to pick or place

at a point other than it's center.

waro|og! Protect drive

and oearing mechanism

from falling deoris when

mounted upside down

Fingers attach to jaws with screws and locate o] ke]ing

Bod] mounts with

screws and locates

with slip fit dowel pins

for accurac]

Fneumatic 8pecificatiens ImperiaI Metric

Pressure 0perating Range 5-100 ps| .3-7 bar

C]linder T]pe 00a| 0o0b|e Act|og

D]namic 8eals |oteroa||y L0br|cated 80oa-h

Valve Required to 0perate 4-way, 2-pos|t|oo

Air 0uaIity 8equirements

Air Filtration 40 N|croo or 8etter

Air luorication hot hecessary*

Air Humidit] Low No|st0re 0ooteot (dry)

emperature 0perating 8ange

Buna-h 8eals (standardj -30~180 F -35~80 0

Viton

8eals (optionalj -20~250 F -30~120 0

Maintenance 8pecificatiens

|

Expected life

hormal Application 5 m||||oo cyc|es

w/ Preventative Naintenance 10+ m||||oo cyc|es*

Field Repairaole Yes

8eal Repair Kits Availaole Yes

AppIicatien 8estrictiens

Dirt] or gritt] environments

Nachining operations generating chips

Environments with loose particulate

Applications where mechanism luoricant could

cause contamination

*Addition of luorication will greatl] increase service life

|

8ee Naintenance 8ection

1.90

8

P

L

8

8

I

8

8ee

Page 1.92

Sty|e: 8PL-1 8PL-1N

Stroke: O.25 in. O.4 mm

6r|p Force: 2O los. 11O h

we|ght: .1O los. .O7 Kg

Produot Features

Dual douole acting opposed pistons, connected to ooth a jaw and a

s]nchronizing oar o] a drive pin, actuate in opposite directions.

The s]nchronizing oars are connected to the equalizer which s]nchronizes

the motion.

8uitaole for internal or external gripping.

The s]nchronizing elements can oe removed for non-s]nchronous operation.

8ty|e-8PL Para||e| 0rier

8ize -1N

0eratin Prinoi|e

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

0.8. Fatent # 5,529,359

0esigned and manufactured in the 08A

en-8ynchreneus

0peratien AvaiIabIe

0ne Fiece 8edy

0ne piece lightweight

aluminum ood]

ard 0eat

Anedize

The ood] has

hard-coat anodize

OO RC with Teflon

impregnation

0uaIity 0empenents

lnternal components are made

from hardened oearing

& tool steels

Fatented

8earing 8uppert

"Dual-V" roller oearings provide

low friction rolling motion

FreIeaded 8earings

Roller oearings are

preloaded for maximum

support and zero side pla]

igh 6rip Ferce

High grip force with respect to

weight due to extremel] efficient

drive mechanism

0eweI eIes

8lip fit dowel pin

holes in ood]

8ensers

Reads position of jaw

(8old 8eparatel]-

8ee "How to 0rder"

8ection for more infoj

Accessery

Meunting

8racket

8eIf Lubricating 8eaIs

8elf luoricating d]namic seals

(Buna-h onl]j

Fre-Lead

Adjustment

8crews

Adjustaole preload

screws allow for

adjustment of

preload on roller

oearings

xha0st Press0re

0peo

Pos|t|oo

Press0re xha0st

0ap

8o||er 8ear|ogs

& 0ages

8o||er

way

Jaw

8ody

g0a||zer

P|stoo

0r|ve

P|o

Seosor

Nagoet

Staodard

Syochroo|z|og

8ar

0|osed

Pos|t|oo

8ee

Page 1.93

Sty|e: 8PL-2 8PL-2N

Stroke: O.5O in. 12.7 mm

6r|p Force: 2O los. 11O h

we|ght: .2O los. .O9 Kg

8ty|e-8PL Para||e| 0rier

8ize -2N

8ee

Page 1.94

Sty|e: 8PL-3 8PL-3N

Stroke: O.75 in. 19.1 mm

6r|p Force: 8O los. 1OO h

we|ght: .82 los. .14 Kg

8ty|e-8PL Para||e| 0rier

8ize -3N

8ee

Page 1.95

Sty|e: 8PL-4 8PL-4N

Stroke: 1.OO in. 25.4 mm

6r|p Force: 8O los. 1OO h

we|ght: .88 los. .17 Kg

8ty|e-8PL Para||e| 0rier

8ize -4N

1.91

8

P

L

8

8

I

8

vlEW A-A

A

A

L

C

L

C

L

C

L

C

L

C

JAW MOUNTlNG PATTERN

(SHOWN lN OPEN POSlTlONj

.750

[19.1|

1.750

[44.5|

.750

[19.1|

2X .0938 SF X .18 DP

[ 3 SF X 4 DP|

.22 [6|

1.164

[29.6|

.750

[19.1|

1.031

[26.2|

#4-40 X .11 DP [M3 X 3 DP|

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTHj

.5940

[15.09|

4X #4-40 X .15 DP

[M3 X 4 DP|

4X #4-40 X .18 DP

[M3 X 4 DP|

.224 .001

[5.69 0.03|

OPEN

2X #10-32 [M5| AlR PORTS (CLOSEj

.250

[6.4|

.250

[6.4|

1.75 [44| (OPENj

1.50 [38| (CLOSEDj

.52

[13|

.44

[11|

.45

[11|

.31 [8|

L

C

Pk8kLLL 08IPP8 8PL-1N

P80I8I0h 00kL "V' L0w P80FIL 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 8FL-1 8FL-1M

Total Rated 0rip Force F @ 1OO psi, 7 oar 2O los. 11O h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . O.25 in. O.4 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.1O los. O.O7 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . . O.488 in. 11.1 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.O88 in

8

. O.O cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.1O sec. O.1O sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-010 1

Viton

8eal Repair Kit 8LkT-010V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

8FL-1

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

FAlL SAFE

vALvE OPTlON

2.30 [58|

.63 [16|

MAGNETO RESlTlvE

SENSOR OPTlON

.30 [8|

MAX

.36 [9|

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 5O los. 222 h 15 los. O7 h

Naximum Compressive 0 5O los. 222 h 15 los. O7 h

Naximum Noment M

x

8O in.-l os. 8.4 hm 1O in.-l os. 1.1 hm

Naximum Noment M

y

4O in.-l os. 4.5 hm 12 in.-l os. 1.4 hm

Naximum Noment M

z

8O in.-l os. 8.4 hm 1O in.-l os. 1.1 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

1OO P8l [7 oar|

2O P8l [1.4 oar|

4O P8l [2.7 oar|

OO P8l [4.1 oar|

8O P8l [5.5 oar|

14

12

10

8

6

4

2

0

62

53

44

35

26

18

9

0

|bs. h

EFFECTlVE Flh0ER lEh0TH L

F

l

h

0

E

R

F

0

R

C

E

F

l

2

68|P F080 P8 F|h68

0

0

1

25

2

50

3 |o.

75mm

wk8hIh6!

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.92

8

P

L

8

8

I

8

Pk8kLLL 08IPP8 8PL-2N

P80I8I0h 00kL "V' L0w P80FIL 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

L

C

L

C

L

C

L

C

L

C

JAW MOUNTlNG PATTERN

(SHOWN lN OPEN POSlTlONj

2.344

[59.5|

.22 [6|

.62 [16|

.31 [8|

.52

[13|

.44

[11|

2.25 [57| (OPENj

1.75 [44| (CLOSEDj

.224 .001

[5.69 0.03|

.875

[22.2|

.250

[6.4|

.250

[6.4|

1.031

[26.2|

1.164

[29.6|

OPEN

2X #10-32 [M5| AlR PORTS (CLOSEj

4X #4-40 X .15DP

[M3 X 4DP|

#4-40 X .11 DP [M3 X 3 DP|

(SENSOR MNTG HOLE,

DO NOT EXCEED DEPTHj

2X .0938 SF X .18 DP

[ 3 SF X 4 DP|

.5940

[15.09|

4X #4-40 X .18 DP

[M3 X 4 DP|

.750

[19.1|

.750

[19.1|

L

C

vlEW A-A

A

A

8pecificatiens 8FL-2 8FL-2M

Total Rated 0rip Force F @ 1OO psi, 7 oar 2O los. 11O h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . O.5O in. 12.7 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.2O los. O.O9 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . . O.488 in. 11.1 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.O75 in

8

. 1.2 cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.18 sec. O.18 sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-010 1

Viton

8eal Repair Kit 8LkT-010V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

8FL-2

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

MAGNETO RESlTlvE

SENSOR OPTlON

.36 [9|

2.30 [58| MlN.

.63 [16|

FAlL SAFE

vALvE OPTlON

.12 [3|

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile O5 los. 289 h 2O los. 89 h

Naximum Compressive 0 O5 los. 289 h 2O los. 89 h

Naximum Noment M

x

45 in.-l os. 5.1 hm 15 in.-l os. 1.7 hm

Naximum Noment M

y

OO in.-l os. O.8 hm 2O in.-l os. 2.8 hm

Naximum Noment M

z

45 in.-l os. 5.1 hm 15 in.-l os. 1.7 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

14

12

10

8

6

4

2

0

62

53

44

35

26

18

9

0

1OO P8l [7 oar|

2O P8l [1.4 oar|

4O P8l [2.7 oar|

OO P8l [4.1 oar|

8O P8l [5.5 oar|

|bs. h

EFFECTlVE Flh0ER lEh0TH L

F

l

h

0

E

R

F

0

R

C

E

F

l

2

68|P F080 P8 F|h68

0

0

1

25

2

50

3 |o.

75mm

wk8hIh6!

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.93

8

P

L

8

8

I

8

L

C

JAW MOUNTlNG PATTERN

(SHOWN lN OPEN POSlTlONj

L

C

L

C

L

C

L

C

3.150

[80.0|

1.000

[25.4|

.875

[22.2|

.6560

[16.66|

.53

[13|

.44

[11|

.76

[19|

3.00 [76| (OPENj

2.25 [57| (CLOSEDj

.224 .001

[5.69 0.03| 1.125

[28.6|

.250

[6.4|

.250

[6.4|

.250

[6.4|

1.125

[28.6|

1.283

[32.6|

6X #5-40 X .15 DP

[M3 X 4 DP|

OPEN

2X #10-32 [M5| AlR PORTS (CLOSEj

4X #5-40 X .31 DP

[M3 X 8 DP|

#4-40 X .15DP [M3 X 3DP|

(SENSOR MNTG HOLEj

2X .1250 SF X .25 DP

[ 3 SF X 6 DP|

.31 [8|

L

C

.58 [15|

vlEW A-A

A

A

Pk8kLLL 08IPP8 8PL-3N

P80I8I0h 00kL "V' L0w P80FIL 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 8FL-3 8FL-3M

Total Rated 0rip Force F @ 1OO psi, 7 oar 8O los. 1OO h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . O.75 in. 19.1 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.82 los. O.15 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . O.5OO in. 12.7 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.147 in

8

. 2.4 cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.14 sec. O.14 sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-012 1

Viton

8eal Repair Kit 8LkT-012V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

8FL-3

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

FAlL SAFE

vALvE OPTlON

MAGNETO RESlTlvE

SENSOR OPTlON

.63 [16|

2.36 [60| MlN.

.36 [9|

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 9O los. 4OO h 8O los. 188 h

Naximum Compressive 0 9O los. 4OO h 8O los. 188 h

Naximum Noment M

x

OO in.-l os. O.8 hm 2O in.-l os. 2.8 hm

Naximum Noment M

y

8O in.-l os. 9.O hm 25 in.-l os. 2.8 hm

Naximum Noment M

z

OO in.-l os. O.8 hm 2O in.-l os. 2.8 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

18

16

14

12

10

8

6

4

2

0

79

70

62

53

44

35

26

18

9

0

|bs. h

EFFECTlVE Flh0ER lEh0TH -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68

1OO P8l [7 oar|

0

0

1

25

2

50

3

75

4 |o.

102 mm

2O P8l [1.4 oar|

4O P8l [2.7 oar|

GO P8l [4.1 oar|

8O P8l [5.5 oar|

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.94

8

P

L

8

8

I

8

Pk8kLLL 08IPP8 8PL-4N

P80I8I0h 00kL "V' L0w P80FIL 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

L

C

L

C

L

C

L

C

L

C

JAW MOUNTlNG PATTERN

(SHOWN lN OPEN POSlTlONj

3.875

[98.4|

1.000

[25.4|

.875

[22.2|

.6560

[16.66|

1.19

[30|

.53

[13|

.44

[11|

1.00

[25|

.31 [8|

3.63 [92| (OPENj

2.63 [66| (CLOSEDj

.224 .001

[5.69 0.03|

1.313

[33.3|

.250

[6.4|

.250

[6.4|

.250

[6.4|

1.125

[28.6|

1.283

[32.6|

6X #5-40 X .15 DP

[M3 X 4 DP|

4X #5-40 X .31DP

[M3 X 8 DP|

2X .1250 SF X .25 DP

[ 3 SF X 6 DP|

#4-40 X .15 DP [M3 X 3 DP|

(SENSOR MNTG HOLEj

OPEN

2X #10-32 [M5| AlR PORTS (CLOSEj

L

C

vlEW A-A

A

A

8pecificatiens 8FL-4 8FL-4M

Total Rated 0rip Force F @ 1OO psi, 7 oar 8O los. 1OO h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.OO in. 25.4 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.88 los. O.17 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . . O.5OO in. 12.7 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.19O in

8

. 8.2 cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.19 sec. O.19 sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-012 1

Viton

8eal Repair Kit 8LkT-012V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

FAlL SAFE

vALvE OPTlON

MAGNETO RESlTlvE

SENSOR OPTlON

.36 [9|

.63 [16|

2.36 [60| MlN.

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 12O los. 584 h 4O los. 178 h

Naximum Compressive 0 12O los. 584 h 4O los. 178 h

Naximum Noment M

x

75 in.-l os. 8.5 hm 25 in.-l os. 2.8 hm

Naximum Noment M

y

1OO in.-l os. 11.8 hm 85 in.-l os. 4.O hm

Naximum Noment M

z

75 in.-l os. 8.5 hm 25 in.-l os. 2.8 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

18

16

14

12

10

8

6

4

2

0

79

70

62

53

44

35

26

18

9

0

|bs. h

EFFECTlVE Flh0ER lEh0TH -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68

1OO P8l [7 oar|

0

0

1

25

2

50

3

75

4

102

5 |o.

127mm

2O P8l [1.4 oar|

4O P8l [2.7 oar|

GO P8l [4.1 oar|

8O P8l [5.5 oar|

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

8FL-4

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.95

8

P

L

8

8

I

8

1

40

20

32

5

21

8

13

31

3

2

30

6

4

(3 S08wS)

Sk

Sk

Sk

Sk

8PL 88I8 XPL000 VIw

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

Item 0ty ame

O1 1 Bod]

O2 1 Piston

O8 2 Cap

O4 1 Equalizer

O5 2 link

OO 4 wa]

O8 2 Jaw

18 2 Pin

2O 1 Piston w/Nagnet 8lot

21 4 8'ass],Cage & Rollers

8O 8 8HC8

81 1 Dowel Pin

82 2 Dowel Pin

4O 2 Nagnet

h0I: Contact the Rooohand 8ales

Department for a complete spare parts list

with order numoers and prices.

AssembIy Frecedure

1j luoricate and install seals.

2j Press dowel pin into center of ood].

8j Place links and equalizers into ood].

4j Press dowel pins into jaws.

5j Place jaws through links and into pistons.

Oj lnstall cages on jaws.

7j Place wa]s oehind cages with flat facing

out and install screws.

8j Adjust preload.

FreIead Adjustment Frecedure

1j Tighten center screw (#8Oj so that

fingers oind slightl].

2j Tighten outer screws in the same

fashion.

8j C]cle the gripper.

4j Re-adjust screws so that when ]ou push

the cage, the finger moves freel]. (the

finger movement should not feel gritt].j

en-8ynchreneus Frecedure

1j Remove preload screws (#8Oj and wa]s.

2j Remove cages, jaws and dowel pins.

8j Remove equalizer, links, and roller

oearings.

4j Re-assemole jaws and dowel pins into

pistons.

5j Re-install cages on jaws.

Oj Place wa]s oehind cages with flat facing

out and install preload screws.

7j Adjust preload.

8eaI 8epair kit 0rder #'s

8ee Freduct 0ata 8heets

1.96

8

P

L

8

8

I

8

N

k

I

h

T

h

k

h

0

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

8PL 88I8 k88N8L0 VIw

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Item 0ty ame

O1 1 Bod]

O2 1 Piston

O8 2 Cap

O4 1 Equalizer

O5 2 link

OO 4 wa]

O8 2 Jaw

18 2 Bearing,Roller

2O 1 Piston w/Nagnet 8lot

21 4 8'ass],Cage & Rollers

8O 8 8HC8

81 1 Dowel Pin

82 2 Dowel Pin

4O 2 Nagnet

h0I: Contact the Rooohand 8ales Depart-

ment for a complete spare parts list with

order numoers and prices.

k008808Y Ih8TkLLkTI0h & k0J08TNhT Ih8T800TI0h8

InstaIIation

1. lnstall sensors as shown.

2. Adjust for desired end of stroke detection.

2

19

20

21

20

1

32

5

8

4

6

21

30

3

2

31

40

1.97

8

P

L

8

8

I

8

N

k

I

h

T

h

k

h

0

Teohnioa| 8eoifioations:

6ripper can be meunted and eperated in any erientatien

Nountin Information:

Para||e| 0riers

0|ean 8oom l harsh nvironments 8eries

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Frecisien appIicatiens.

Preloaded "Dual-V" roller oearings

eliminate side pla] for excellent part

position repeataoilit].

0Iean 8eem rated.

A corrosion resistant shield protects the

drive and oearing mechanism. All internal

components are luoricated with clean room

grade luoricant. The scavenge port can oe

used with vacuum pressure to prevent

escape of particulate generated o] the

internal mechanism.

arsh envirenments.

All moving components are located within

the stainless steel shield. The ood] has a

purge port which can expel contaminates

from the mechanism using low air pressure.

8epeatabIe grip ferce.

low friction mechanism allows for

consistent, repeataole gripping forces.

To grip delicate parts, grip force can oe

easil] altered o] adjusting air pressure.

Lenger finger appIicatiens.

Rigid design allows for longer gripper

finger lengths to oe used when compared

to other grippers of equal weight.

en-synchreneus metien.

The unit can made non-s]nchronous

providing independent jaw motion

allowing the gripper to pick or place

at a point other than it's center.

8hields provide protection

from falling deoris when

mounted upside down

Fingers attach to jaws with screws and locate o] ke]ing

Bod] mounts with

screws and locates

with slip fit dowel pins

for accurac]

Fneumatic 8pecificatiens ImperiaI Metric

Pressure 0perating Range 5-100 ps| .3-7 bar

C]linder T]pe 00a| 0o0b|e Act|og

D]namic 8eals |oteroa||y L0br|cated 80oa-h

Valve Required to 0perate 4-way, 2-pos|t|oo

Air 0uaIity 8equirements

Air Filtration 40 N|croo or 8etter

Air luorication hot hecessary*

Air Humidit] Low No|st0re 0ooteot (dry)

emperature 0perating 8ange

Buna-h 8eals (standardj -30~180 F -35~80 0

Viton

8eals (optionalj -20~250 F -30~120 0

Maintenance 8pecificatiens

|

Expected life

hormal Application 5 m||||oo cyc|es

w/ Preventative Naintenance 10+ m||||oo cyc|es*

Field Repairaole Yes

8eal Repair Kits Availaole Yes

*Addition of luorication will greatl] increase service life

|

8ee Naintenance 8ection

1.98

8

P

L

0

8

8

I

8

8ee

Page 1.100

Sty|e: 8PL0-1 8PL0-1N

Stroke: O.25 in. O.4 mm

6r|p Force: 2O lo 11O h

we|ght: .1O lo .O7 Kg

Produot Features

Dual douole acting opposed pistons, connected to ooth a jaw and a

s]nchronizing oar o] a drive pin, actuate in opposite directions.

The s]nchronizing oars are connected to the equalizer which s]nchronizes

the motion.

The purge/scavenge port can oe used to expel or retain contaminates using

pressure or vacuum respectivel].

8uitaole for internal or external gripping.

The s]nchronizing elements can oe removed for non-s]nchronous operation.

8ty|e-8PL0 Para||e| 0rier

8ize -1N

0eratin Prinoi|e

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

0.8. Fatent # 5,529,359

0esigned and manufactured in the 08A

8ee

Page 1.101

Sty|e: 8PL0-2 8PL0-2N

Stroke: O.5O in. 12.7 mm

6r|p Force: 2O lo 11O h

we|ght: .2O lo .O9 Kg

8ty|e-8PL0 Para||e| 0rier

8ize -2N

8ee

Page 1.102

Sty|e: 8PL0-3 8PL0-3N

Stroke: O.75 in. 19.1 mm

6r|p Force: 8O lo 1OO h

we|ght: .82 lo .15 Kg

8ty|e-8PL0 Para||e| 0rier

8ize -3N

8ee

Page 1.103

Sty|e: 8PL0-4 8PL0-4N

Stroke: 1.OO in. 25.4 mm

6r|p Force: 8O lo 1OO h

we|ght: .88 lo .17 Kg

8ty|e-8PL0 Para||e| 0rier

8ize -4N

en-8ynchreneus

0peratien AvaiIabIe

0ne Fiece 8edy

0ne piece lightweight

aluminum ood]

FurgeI8cavenge Fert

For extreme environments from

dirt] & gritt] to clean-room

Class 1O or oetter

ard 0eat

Anedize

The ood] has

hard-coat anodize

OO RC with Teflon

impregnation

0uaIity 0empenents

lnternal components are made

from hardened oearing & tool steels

External components are made

from corrosion resistant materials

for resistance to de-ionized water

or for use in FDA & medical parts

handling applications

Fatented

8earing 8uppert

Dual "V" roller oearings provide

low friction rolling motion

FreIeaded 8earings

Roller oearings are preloaded

for maximum support and

zero side pla]

igh 6rip Ferce

High grip force with respect to weight due

to extremel] efficient drive mechanism

8ensers

Reads position of jaw

(8old 8eparatel]-8ee

"How to 0rder" 8ection

for more infoj

8tainIess

8teeI 8hieIds

8tationar] and

non-contacting shields

eliminate the possioilit]

of particle generation.

8tainIess 8teeI 8crews

Provides protection against corrosion

0Iean-8eem Lubricatien

Units are luoricated with a clean-

room grade grease

8eIf Lubricating 8eaIs

8elf luoricating d]namic seals

(Buna-h onl]j

xha0st Press0re

0peo

Pos|t|oo

Fre-Lead

Adjustment

8crews

Adjustaole preload

screws allow for

adjustment of

preload on roller

oearings

Press0re xha0st

0ap

8o||er 8ear|ogs

& 0ages Jaw

Sh|e|ds

8ody

g0a||zer

P|stoo

0r|ve

P|o

Seosor

Nagoet

Staodard

Syochroo|z|og

8ar

0|osed

Pos|t|oo

Scaveoge or P0rge Port

For clean room or harsh environments

0eweI eIes

8lip fit dowel pin

holes in ood]

Accessery

Meunting

eIes

8o||er

way

1.99

8

P

L

0

8

8

I

8

L

C

L

C

L

C

L

C

L

C

JAW MOUNTlNG PATTERN

( SHOWN lN OPEN POSlTlON j

.750

[19.1|

.5940

[15.09|

.750

[19.1|

1.163

[29.5|

.44

[11|

.31

[8|

1.096

[27.8|

.22

[6|

.52

[13|

1.75 [44| ( OPEN j

1.50 [38| ( CLOSED j

#4-40 X .11 DP [M3 X 3 DP|

( SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH j

.44

[11|

.66

[17|

.224 .001

[5.69 0.03|

.250

[6.4|

.250

[6.4|

.750

[19.1|

#10-32 [M5|

PURGE OR SCAvENGE

PORT

1.900

[48.3|

OPEN

4X #4-40 X .15 DP

[M3 X 4 DP|

2X .0938 SF X .18 DP

[ 3 SF X 4 DP|

2X #10-32 [M5|

AlR PORTS (CLOSEj

.33

[8|

4X #4-40 X .18 DP

[M3 X 4 DP|

L

C

vlEW A-A

A

A

Pk8kLLL 08IPP8 8PL0-1N

P80I8I0h 00kL "V' 0Lkh 800N 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 8FL0-1 8FL0-1M

Total Rated 0rip Force F @ 1OO psi, 7 oar 2O lo 11O h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . O.25 in. O.4 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.1O lo O.O7 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . . O.488 in. 11.1 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.O88 in

8

. O.O cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.1O sec. O.1O sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-010 1

Viton

8eal Repair Kit 8LkT-010V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

MAGNETO RESlTlvE

SENSOR OPTlON

FAlL SAFE

vALvE OPTlON

.36 [9|

.30 [8|

MAX

2.30 [58| MlN.

.63 [16|

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 5O los. 222 h 15 los. O7 h

Naximum Compressive 0 5O los. 222 h 15 los. O7 h

Naximum Noment M

x

8O in.-los. 8.4 hm 1O in.-los. 1.1 hm

Naximum Noment M

y

4O in.-los. 4.5 hm 12 in.-los. 1.4 hm

Naximum Noment M

z

8O in.-los. 8.4 hm 1O in.-los. 1.1 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

1OO P8l [7 oar|

2O P8l [1.4 oar|

4O P8l [2.7 oar|

OO P8l [4.1 oar|

8O P8l [5.5 oar|

14

12

10

8

6

4

2

0

62

53

44

35

26

18

9

0

|bs. h

EFFECTlVE Flh0ER lEh0TH L

F

l

h

0

E

R

F

0

R

C

E

F

l

2

68|P F080 P8 F|h68

0

0

1

25

2

50

3 |o.

75mm

wk8hIh6!

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8 8FL0-1

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.100

8

P

L

0

8

8

I

8

Pk8kLLL 08IPP8 8PL0-2N

P80I8I0h 00kL "V' 0Lkh 800N 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

JAW MOUNTlNG PATTERN

(SHOWN lN OPEN POSlTlONj

L

C

L

C

L

C

L

C

L

C

.750

[19.0|

.750

[19.1|

2.476

[62.9|

.5940

[15.09|

2X .0938SF X .18 DP

[ 3 SF X 4 DP|

4X #4-40 X .18 DP

[M3 X 4 DP|

.62 [16|

.31 [8| .44

[11|

.52

[13|

.66

[17|

2.33 [59| (OPENj

1.83 [46| (CLOSEDj

#10-32 [M5|

PURGE OR SCAvENGE

PORT

OPEN

.22 [6|

.50 [13|

2X #10-32 [M5|

AlR PORTS (CLOSEj

#4-40 X .11DP [M3 X 3 DP|

( SENSOR MNTG HOLE,

DO NOT EXCEED DEPTH j

4X #4-40 X .15 DP

[M3 X 4 DP|

.224 .001

[5.69 0.03|

.913

[23.2|

.328

[8.3|

.250

[6.4|

1.163

[29.5|

1.096

[27.8|

L

C

vlEW A-A

A

A

8pecificatiens 8FL0-2 8FL0-2M

Total Rated 0rip Force F @ 1OO psi, 7 oar 2O lo 11O h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . O.5O in. 12.7 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.2O lo O.O9 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . . O.488 in. 11.1 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.O75 in

8

. 1.2 cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.18 sec. O.18 sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-010 1

Viton

8eal Repair Kit 8LkT-010V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

MAGNETO RESlTlvE

SENSOR OPTlON

FAlL SAFE

vALvE OPTlON

.36 [9|

.12 [3|

MAX

2.30 [58| MlN.

.63 [16|

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile O5 los. 289 h 2O lo 89 h

Naximum Compressive 0 O5 los. 289 h 2O lo 89 h

Naximum Noment M

x

45 in.-los. 5.1 hm 15 in.-los. 1.7 hm

Naximum Noment M

y

OO in.-los. O.8 hm 2O in.-los. 2.8 hm

Naximum Noment M

z

45 in.-los. 5.1 hm 15 in.-los. 1.7 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

14

12

10

8

6

4

2

0

62

53

44

35

26

18

9

0

1OO P8l [7 oar|

2O P8l [1.4 oar|

4O P8l [2.7 oar|

OO P8l [4.1 oar|

8O P8l [5.5 oar|

|bs. h

EFFECTlVE Flh0ER lEh0TH L

F

l

h

0

E

R

F

0

R

C

E

F

l

2

68|P F080 P8 F|h68

0

0

1

25

2

50

3 |o.

75mm

wk8hIh6!

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

8FL0-2

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.101

8

P

L

0

8

8

I

8

JAW MOUNTlNG PATTERN

( SHOWN lN OPEN POSlTlON j

L

C

L

C

L

C

L

C

L

C

.224 .001

[5.69 0.03|

.250

[6.4|

1.250

[31.8|

1.191

[30.3|

1.283

[32.6|

3.282

[83.4|

1.000

[25.4|

.875

[22.2|

4X #5-40 X .31 DP

[M3 X 8 DP|

OPEN

#4-40 X .14 DP [M3 X 3 DP|

(SENSOR MNTG HOLEj

#10-32 [M5|

PURGE OR SCAvENGE

PORT

.53

[13|

.74

[18|

.44

[11|

.31 [8|

.500

[12.7|

.6560

[16.66|

.58 [15|

.76 [19|

2X #10-32 [M5|

AlR PORT (CLOSEj

4X #5-40 X .15 DP

[M3 X 4 DP|

3.25 [83| (OPENj

2.50 [63| (CLOSEDj

.55 [14|

2X .1250 SF X .25 DP

[ 3 SF X 6 DP|

L

C

vlEW A-A

A

A

Pk8kLLL 08IPP8 8PL0-3N

P80I8I0h 00kL "V' 0Lkh 800N 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

8pecificatiens 8FL0-3 8FL0-3M

Total Rated 0rip Force F @ 1OO psi, 7 oar 8O lo 1OO h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . O.75 in. 19.1 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.82 lo O.15 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . O.5OO in. 12.7 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.147 in

8

. 2.4 cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.14 sec. O.14 sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-012 1

Viton

8eal Repair Kit 8LkT-012V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

MAGNETO RESlTlvE

SENSOR OPTlON

FAlL SAFE

vALvE OPTlON

2.36 [60| MlN.

.63 [16|

.36 [9|

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 9O los. 4OO h 8O los. 188 h

Naximum Compressive 0 9O los. 4OO h 8O los. 188 h

Naximum Noment M

x

OO in.-los. O.8 hm 2O in.-los. 2.8 hm

Naximum Noment M

y

8O in.-los. 9.O hm 25 in.-los. 2.8 hm

Naximum Noment M

z

OO in.-los. O.8 hm 2O in.-los. 2.8 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

18

16

14

12

10

8

6

4

2

0

79

70

62

53

44

35

26

18

9

0

|bs. h

EFFECTlVE Flh0ER lEh0TH -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68

1OO P8l [7 oar|

0

0

1

25

2

50

3

75

4 |o.

102 mm

2O P8l [1.4 oar|

4O P8l [2.7 oar|

GO P8l [4.1 oar|

8O P8l [5.5 oar|

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

8FL0-3

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.102

8

P

L

0

8

8

I

8

Pk8kLLL 08IPP8 8PL0-4N

P80I8I0h 00kL "V' 0Lkh 800N 88I8

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

L

C

L

C

L

C

L

C

L

C

JAW MOUNTlNG PATTERN

(SHOWN lN OPEN POSlTlONj

1.191

[30.3|

1.283

[32.6|

4.007

[101.8|

1.000

[25.4|

.875

[22.2|

1.500

[38.1|

.250

[6.4|

.625

[15.9|

.224 .001

[5.69 0.03|

.53

[13|

.44

[11|

.74

[18|

2X .1250 SF X .25 DP

[ 3 SF X 6 DP|

4X #5-40 X .31 DP

[M3 X 8 DP|

4.00 [101| (OPENj

3.00 [76| (CLOSEDj

#10-32 [M5| PURGE OR SCAvENGE PORTS

#4-40 X .14 DP [M3 X 3 DP|

(SENSOR MNTG HOLEj

.31 [8|

.94 [24|

1.00 [25|

.6560

[16.66|

OPEN

2X #10-32 [M5|

AlR PORTS (CLOSEj

4X #5-40 X .15 DP

[M3 X 4 DP|

L

C

.55 [14|

vlEW A-A

A

A

8pecificatiens 8FL0-4 8FL0-4M

Total Rated 0rip Force F @ 1OO psi, 7 oar 8O lo 1OO h

8troke . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.OO in. 25.4 mm

weight . . . . . . . . . . . . . . . . . . . . . . . . . . . O.88 lo O.17 Kg

Pressure Range . . . . . . . . . . . . . . . . . . . . 5-1OO psi O.8-7 oar

C]linder Bore 0 . . . . . . . . . . . . . . . . . . . . . O.5OO in. 12.7 mm

Displacement . . . . . . . . . . . . . . . . . . . . . . O.19O in

8

. 8.2 cm

8

Temperature Range

8tandard 8eals . . . . . . . . . . . . . . . . . . . -8O~18O F -85~8O C

Viton

8eals . . . . . . . . . . . . . . . . . . . . . . -2O~25O F -8O~12O C

Actuation . . . . . . . . . . . . . . . . . . . . . . . . . O.19 sec. O.19 sec.

Accurac] . . . . . . . . . . . . . . . . . . . . . . . . . . O.OO2 in. O.O5 mm

Repeataoilit] . . . . . . . . . . . . . . . . . . . . . . . O.OO1 in. O.O8 mm

Valve required to actuate . . . . . . . . . . . . . 4-wa], 2-position

how to 0rder: (0rder Accessories separatel] from Basic Nodelj

8h808 k008808I8

*

|

0808 = 0TYl0hIT

8ensor Nounting Kit for lmperial & Netric Units (mounts 2 sensorsj 08Nk-008 1

hPh Nagneto Resistive 8ensor with 0uick Disconnect* 0h8h-017 1 or 2

PhP Nagneto Resistive 8ensor with 0uick Disconnect* 0h8P-017 1 or 2

0uick Disconnect 2 Neter Caole length* 0k8L-010 1 or 2

0uick Disconnect 5 Neter Caole length* 0k8L-013 1 or 2

Ph0NkTI0 k008808I8

Fail 8afe Valve (lmperialj 0F8V-001 1

Fail 8afe Valve (Netricj 0F8V-004 1

8tandard 8eal Repair Kit 8LkT-012 1

Viton

8eal Repair Kit 8LkT-012V 1

*8ensor and caole sold separatel]

|

Piston magnet standard

MAGNETO RESlTlvE

SENSOR OPTlON

FAlL SAFE

vALvE OPTlON

2.36 [60| MlN.

.36 [9|

.63 [16|

Loadin Information

Leading 0apacity

|

8tatic 0ynamic

lmperial Netric lmperial Netric

NaximumTensile 12O los. 584 h 4O los. 178 h

Naximum Compressive 0 12O los. 584 h 4O los. 178 h

Naximum Noment M

x

75 in.-los. 8.5 hm 25 in.-los. 2.8 hm

Naximum Noment M

y

1OO in.-los. 11.8 hm 85 in.-los. 4.O hm

Naximum Noment M

z

75 in.-los. 8.5 hm 25 in.-los. 2.8 hm

|

Capacities are per set of jaws and are not simultaneous

Y X

L

Z Z

F/2 F/2

T C

M

M MX Y

Z

18

16

14

12

10

8

6

4

2

0

79

70

62

53

44

35

26

18

9

0

|bs. h

EFFECTlVE Flh0ER lEh0TH -

F

l

h

0

E

R

F

0

R

C

E

-

68|P F080 P8 F|h68

1OO P8l [7 oar|

0

0

1

25

2

50

3

75

4

102

5 |o.

127mm

2O P8l [1.4 oar|

4O P8l [2.7 oar|

GO P8l [4.1 oar|

8O P8l [5.5 oar|

D0 h0T EXCEED

NAXlNUN EFFECTlVE

Flh0ER lEh0TH8

8FL0-4

- - 8 M

h0h-8Yh0h80h008

VIT0h

8kL8 NT8I0

8k8I0 N00L

Third Angle

Projection

Dimensions are

s]mmetrical aoout

centerline

|mper|a| |o. Netr|c [mm]

O.OO = .O1 [O.| = [.25|

O.OOO = .OO5 [O.O| = [.18|

O.OOOO = .OOO5 [O.OO| = [.O18|

All Dowel Holes are 8F (8lip Fitj.

locational Tolerance

.OOO5" or [.O18mm|

0L88 08wI8 00 ALL

0L8A08 A8 A8 80w 8L0w

Netric Threads

Course Pitch

1.103

8

P

L

0

8

8

I

8

1

30

31

32

5

21

10

11

8

13

12

3

2

6

40

4

(3 S08wS)

20

Sk

Sk

Sk

Sk

Sk

k8YT0X k8YT0X

k8YT0X k8YT0X

k8YT0X k8YT0X

8PL0 88I8 XPL000 VIw

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

Item 0ty ame

O1 1 Bod]

O2 1 Piston

O8 2 Cap

O4 1 Equalizer

O5 2 link

OO 4 wa]

O8 2 Jaw

1O 1 Cover, Bottom

11 2 Cover, Bottom, Corners

12 2 Cover, End

18 2 Bearing, Roller

2O 1 Piston w/Nagnet 8lot

21 4 8'ass], Cage & Rollers

8O 8 8HC8

81 1 Dowel Pin

82 2 Dowel Pin

4O 2 Nagnet

ete. contact the rooohand sales department for

a complete spare parts list with order numoers

and prices.

AssembIy precedure

1j luoricate and install seals.

2j 0lue magnets into one piston, install pistons,

caps and retaining rings.

8j Press dowel pin into center of ood].

4j Place links and equalizers into ood].

5j Press dowel pins into jaws.

Oj Place jaws through links and into pistons.

7j lnstall cages on jaws.

8j Place wa]s oehind cages with flat facing out

and install screws.

9j Adjust preload.

1Oj lnstall oottom cover, oottom cover corners

and end covers.

FreIead adjustment precedure

1j Tighten center screw (#8Oj so that fingers

preload adjustment procedure

2j Tighten outer screws in the same fashion.

Bind slightl].

8j C]cle the gripper.

4j Re-adjust screws so that when ]ou push the

cage, the finger moves freel]. (the finger

movement should not feel gritt].j

en-synchreneus precedure

1j Remove end covers, oottom cover corners,

and oottom cover.

2j Remove preload screws (#8Oj and wa]s.

8j Remove cages, jaws and dowel pins.

4j Remove equalizer, links, and roller oearings.

5j Re-assemole jaws and dowel pins into

pistons.

Oj Re-install cages on jaws.

7j Place wa]s oehind cages with flat facing

out and

8j Adjust preload. lnstall preload screws.

9j Re-attach oottom cover, oottom cover

corners and end covers. 0ripper is now

non-s]nchronous.

8eaI 8epair kit 0rder #'s

8ee Freduct 0ata 8heets

1.104

8

P

L

0

8

8

I

8

N

k

I

h

T

h

k

h

0

Third Angle

Projection

8eal Kit

ltems

Thread

locker

Kr]tox

luoricant

Teflon

Based

0rease

lightweight

Nachine 0il

8uper

Bonder

Sk

k8YT0X k8YT0X

8PL0 88I8 k88N8L0 VIw

P|ease see back cover for 0F-STA-00 0|oba| Locat|ons. www.destaco.com

Item 0ty ame

O1 1 Bod]

O2 1 Piston

O8 2 Cap

O4 1 Equalizer

O5 2 link

OO 4 wa]

O8 2 Jaw

1O 1 Cover, Bottom

11 2 Cover, Bottom, Corners

12 2 Cover, End

18 2 Bearing, Roller

2O 1 Piston w/Nagnet 8lot

21 4 8'ass], Cage & Rollers

8O 8 8HC8

81 1 Dowel Pin

82 2 Dowel Pin

4O 2 Nagnet

ete. contact the rooohand sales

department for a complete spare parts list

with order numoers and prices.

k008808Y Ih8TkLLkTI0h & k0J08TNhT Ih8T800TI0h8

InstaIIation

1j lnstall sensors as shown.

2j Adjust for desired end of stroke detection.

2

23

24

25

1

32

5

4

6

8

30

3

2

31

40

20

12

1.105

8

P

L

0

8

8

I

8

N

k

I

h

T

h

k

h

0

You might also like

- Honda Xr250r Service Manual Repair 1986-1995 Xr250Document258 pagesHonda Xr250r Service Manual Repair 1986-1995 Xr250ronald.197893% (15)

- FS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service ManualDocument63 pagesFS120-FS200-FS300-FS350-FS400-FS450-FR350-FR450 Service Manualnik_nicholson_189% (18)

- Yamaha Exciter 440 EX440 1980Document18 pagesYamaha Exciter 440 EX440 1980mkaukolaNo ratings yet

- Rs125 Race: De-Restrict An Aprilia Rs 125 2006 Euro 3Document9 pagesRs125 Race: De-Restrict An Aprilia Rs 125 2006 Euro 3Administrator100% (9)

- CH 13Document48 pagesCH 13Graeme KendallNo ratings yet

- Simplicity 860Document24 pagesSimplicity 860Jeremy MillerNo ratings yet

- Optimize flare gas recovery with liquid ring compressorsDocument56 pagesOptimize flare gas recovery with liquid ring compressorsmani100% (2)

- S-8B1 8B1TDocument6 pagesS-8B1 8B1TbryandownNo ratings yet

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- Husaberg 1999 Repair ManualDocument48 pagesHusaberg 1999 Repair ManualAndré Duestad100% (1)

- P-Y Criterion For Rock Mass: Robert Liang, M.ASCE Ke Yang, M.ASCE and Jamal Nusairat, M.ASCEDocument11 pagesP-Y Criterion For Rock Mass: Robert Liang, M.ASCE Ke Yang, M.ASCE and Jamal Nusairat, M.ASCEAltan ErdemNo ratings yet

- Penetration Into Ductile Metal Targets With Rigid Spherical-Nose RodsDocument12 pagesPenetration Into Ductile Metal Targets With Rigid Spherical-Nose Rodsamar100% (1)

- Advances in Mechanical Conveyor Design for Bulk Materials HandlingDocument27 pagesAdvances in Mechanical Conveyor Design for Bulk Materials HandlingJakes100% (1)

- ""1J186 8' 4NC1J186 P144, C$J4R 16c$e$ E$co1$ 41'$Document16 pages""1J186 8' 4NC1J186 P144, C$J4R 16c$e$ E$co1$ 41'$Marian DunareanuNo ratings yet

- DctrectreDocument12 pagesDctrectreMarian DunareanuNo ratings yet

- RfeDocument8 pagesRfedunareanu_marian8668No ratings yet

- DLBBLDocument12 pagesDLBBLMarian DunareanuNo ratings yet

- DlbtanruDocument12 pagesDlbtanruMarian DunareanuNo ratings yet

- DlttanruDocument14 pagesDlttanruMarian DunareanuNo ratings yet

- Dpds DPDLDocument24 pagesDpds DPDLMarian DunareanuNo ratings yet

- 0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Document7 pages0?"90..e 2C"9"! "9,": 0?"90..e 2C"9"! "9,":, 0, .. ,. .,!" "9,"Marian DunareanuNo ratings yet

- Parallel pneumatic grippers miniature seriesDocument5 pagesParallel pneumatic grippers miniature seriesKenry LimNo ratings yet

- KA Series PDFDocument8 pagesKA Series PDFsancsa_74No ratings yet

- Yeg GDocument2 pagesYeg Gwpt_meNo ratings yet

- Murray Briggs & StrattonDocument28 pagesMurray Briggs & StrattonMonica CurpasNo ratings yet

- Rexnord Elastomer CouplingDocument20 pagesRexnord Elastomer Couplingidontlikeebooks100% (1)

- Technical Data Products 2009 CompletDocument62 pagesTechnical Data Products 2009 CompletRobert NedelcuNo ratings yet

- Inverter Microprocessor-Controlled: Certified Kubota Mfg. CorpDocument4 pagesInverter Microprocessor-Controlled: Certified Kubota Mfg. CorpTotok SurotoNo ratings yet

- ViN Scotch Yoke Act 21Document13 pagesViN Scotch Yoke Act 21Mayur PatelNo ratings yet

- Olaer EhvDocument12 pagesOlaer EhvandinoNo ratings yet

- 10.piston CylinderDocument19 pages10.piston Cylinderprihartono_diasNo ratings yet

- J-W Power Company Digital Fault Recorder ManualDocument40 pagesJ-W Power Company Digital Fault Recorder ManualTatiana GomezNo ratings yet

- Structural Bearings From Sneha PDFDocument5 pagesStructural Bearings From Sneha PDFAmitabha DebNo ratings yet

- Parker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Document21 pagesParker 3349112014 PGP511 Series, Pgp511a0140ab1h2vf5f3b1b1Anonymous srN69mFE100% (1)

- Workshopmanual xl500r 1982 Multi 09062014 2148Document100 pagesWorkshopmanual xl500r 1982 Multi 09062014 2148daqyou daqNo ratings yet

- NOVA Servo CatalogueDocument7 pagesNOVA Servo CatalogueDip Narayan BiswasNo ratings yet

- 15-ScanJet SC 15TW Instruction ManualDocument43 pages15-ScanJet SC 15TW Instruction Manualogurmehmetali07No ratings yet

- 23.bladder AccumlatorDocument12 pages23.bladder AccumlatorM S GokulNo ratings yet

- Winche Neumatico JoyDocument6 pagesWinche Neumatico JoyWilliam QuilicheNo ratings yet

- Rotary valves and airlocks guideDocument6 pagesRotary valves and airlocks guidegallowdrNo ratings yet

- CNP 6SD Sub MotorDocument2 pagesCNP 6SD Sub Motormuhammadirsyad230793No ratings yet

- Catalog HRC Jaw CouplingsDocument8 pagesCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Multi-Function Air Conditioner GuideDocument21 pagesMulti-Function Air Conditioner GuideLaura VillarroelNo ratings yet

- TYCO Keystone F14.Lined - Butterfly.valve enDocument4 pagesTYCO Keystone F14.Lined - Butterfly.valve enIrina CretuNo ratings yet

- Stihl FC 90 95 100 110 FS 90 100 110 FS 130 HL 100 HT 100 HT 101 KM 90 100 110 130 Ra - 933 - 00 - 01 - 05Document66 pagesStihl FC 90 95 100 110 FS 90 100 110 FS 130 HL 100 HT 100 HT 101 KM 90 100 110 130 Ra - 933 - 00 - 01 - 05detonat100% (2)

- Norbro40 PDFDocument11 pagesNorbro40 PDFMargaret DaughertyNo ratings yet

- MS270 280 WSMDocument86 pagesMS270 280 WSMJohn DoeeNo ratings yet

- Bucket Control Mounting GroupDocument4 pagesBucket Control Mounting Groupcristian chuquicondor torresNo ratings yet

- Mod 70 SWL 100tDocument2 pagesMod 70 SWL 100tKintali Vinod100% (1)

- ServiceManuals LG Aircon LK1580BH LK1580BH Service ManualDocument66 pagesServiceManuals LG Aircon LK1580BH LK1580BH Service ManualArman Atienza Magcawas100% (1)

- CBTTT Sales Leaflet PDFDocument2 pagesCBTTT Sales Leaflet PDFElmer RaulNo ratings yet

- Set Up Instructions - InvictaDocument12 pagesSet Up Instructions - InvictaRicardo XlvNo ratings yet

- AUT-1044 OPC Basic & SuperDocument2 pagesAUT-1044 OPC Basic & SuperTh NattapongNo ratings yet

- Hydro6 Operation Manual PDFDocument12 pagesHydro6 Operation Manual PDFCastro Dios En Ti ConfioNo ratings yet

- Warning: Mudguards (Kit P/N 715 001 208)Document5 pagesWarning: Mudguards (Kit P/N 715 001 208)bapal1986No ratings yet

- Optyma CU Leaflet - 46CDocument8 pagesOptyma CU Leaflet - 46CRahul PatilNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Type of Mounting: Type of Mounting: Type of Mounting:: G Series FO Series FL SeriesDocument7 pagesType of Mounting: Type of Mounting: Type of Mounting:: G Series FO Series FL Seriesdunareanu_marian8668No ratings yet

- RpeDocument6 pagesRpedunareanu_marian8668No ratings yet

- RPDocument16 pagesRPdunareanu_marian8668No ratings yet

- J. N. Darby - DisciplinaDocument37 pagesJ. N. Darby - Disciplinadunareanu_marian8668No ratings yet

- Round ToolingDocument18 pagesRound Toolingdunareanu_marian8668No ratings yet

- RuaDocument12 pagesRuadunareanu_marian8668No ratings yet

- 'I 2ii 3 + A : 1C-# @+/ (/@#:/ - G C:+@#! C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Document12 pages'I 2ii 3 + A : 1C-# @+/ (/@#:/ - G C:+@#! C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"dunareanu_marian8668No ratings yet

- RTH DTHDocument22 pagesRTH DTHdunareanu_marian8668No ratings yet

- Tpi152 de enDocument26 pagesTpi152 de endunareanu_marian8668No ratings yet

- SheetDocument69 pagesSheetdunareanu_marian8668No ratings yet

- Spider GripDocument7 pagesSpider Gripdunareanu_marian8668No ratings yet

- Squeeze Action Plier Clamps: Max. Holding Capacity N (LBF.) Maximum Clamping Thickness MM (Inch)Document9 pagesSqueeze Action Plier Clamps: Max. Holding Capacity N (LBF.) Maximum Clamping Thickness MM (Inch)dunareanu_marian8668No ratings yet

- Straight Line Action Clamps: DestacoDocument28 pagesStraight Line Action Clamps: Destacodunareanu_marian8668No ratings yet

- Pneumatic Swing Clamps: DestacoDocument16 pagesPneumatic Swing Clamps: Destacodunareanu_marian8668No ratings yet

- Swingclamps AccessDocument9 pagesSwingclamps Accessdunareanu_marian8668No ratings yet

- Swingclamps AccessDocument9 pagesSwingclamps Accessdunareanu_marian8668No ratings yet

- The Magic of Magnets: Current NewsDocument8 pagesThe Magic of Magnets: Current Newsdunareanu_marian8668No ratings yet

- Rfb7 - de - en Triple Mas 6000Document2 pagesRfb7 - de - en Triple Mas 6000Miguel GonzalezNo ratings yet

- ELGES Alloy Steel Rod Ends: Corrosion-ResistantDocument8 pagesELGES Alloy Steel Rod Ends: Corrosion-Resistantdunareanu_marian8668No ratings yet

- rfb6 de enDocument2 pagesrfb6 de endunareanu_marian8668No ratings yet

- Relevant Suffixes: For Spherical Roller Bearings in The Paper IndustryDocument4 pagesRelevant Suffixes: For Spherical Roller Bearings in The Paper IndustryHemanthSKFNo ratings yet

- SSD 14 de enDocument10 pagesSSD 14 de endunareanu_marian8668No ratings yet

- Pew de UsDocument8 pagesPew de Usdunareanu_marian8668No ratings yet

- FAG Self Aligning Cylindrical Roller BearingsDocument22 pagesFAG Self Aligning Cylindrical Roller BearingsJose MorenoNo ratings yet

- Pew de UsDocument8 pagesPew de Usdunareanu_marian8668No ratings yet

- rfb6 de enDocument2 pagesrfb6 de endunareanu_marian8668No ratings yet

- rfb6 de enDocument2 pagesrfb6 de endunareanu_marian8668No ratings yet

- ELGES Alloy Steel Rod Ends: Corrosion-ResistantDocument8 pagesELGES Alloy Steel Rod Ends: Corrosion-Resistantdunareanu_marian8668No ratings yet

- Tutorial 1: Energy and Momentum Methods of Particle: Applied Mechanics II, Ramesh Khanal, Nepal Engineering College, 2016Document5 pagesTutorial 1: Energy and Momentum Methods of Particle: Applied Mechanics II, Ramesh Khanal, Nepal Engineering College, 2016Romharsh OliNo ratings yet

- Science 6.1Document6 pagesScience 6.1Nestlee ArnaizNo ratings yet

- Fulltext - Example IIIDocument8 pagesFulltext - Example IIIManolo GipielaNo ratings yet

- Bolt ConnectionDocument98 pagesBolt ConnectiondanessatiriaNo ratings yet

- Chapter 1: Introduction: Mechanic Static DynamicDocument8 pagesChapter 1: Introduction: Mechanic Static DynamicAlia RizalNo ratings yet

- Solids Notes 10 Hopper DesignDocument26 pagesSolids Notes 10 Hopper DesignCss GaneshNo ratings yet

- Ali Karami 2016Document7 pagesAli Karami 2016Agripino FilhoNo ratings yet

- Glosarios de Correas Transportadoras Letras M - Z y Archivo AdicionalDocument63 pagesGlosarios de Correas Transportadoras Letras M - Z y Archivo AdicionalJosé BocicNo ratings yet

- #HVAC - Five Easy Steps To Estimate External Static Pressure Drop in HVAC Ducts Using Equal Friction MethodDocument4 pages#HVAC - Five Easy Steps To Estimate External Static Pressure Drop in HVAC Ducts Using Equal Friction MethodNagarjun ReddyNo ratings yet

- CPP1 RotationaldynamicsDocument14 pagesCPP1 RotationaldynamicsBNo ratings yet

- Physics Question Sets 11 077 FalgunDocument7 pagesPhysics Question Sets 11 077 FalgunPunit ChauhanNo ratings yet

- FST 130 OutlineDocument3 pagesFST 130 OutlineArgel LargadoNo ratings yet

- C1 PanelDocument24 pagesC1 PanelChandra MohanNo ratings yet

- NA XX Mobil Synturion 6Document3 pagesNA XX Mobil Synturion 6Julian CadenaNo ratings yet

- 118 Worm Gear LubesDocument4 pages118 Worm Gear LubesWajahat RasoolNo ratings yet

- Science 6 SyllabusDocument23 pagesScience 6 SyllabusKassandra Garvil Vincent Elizabeth AprestoNo ratings yet

- NeakodDocument2 pagesNeakodNekia9imeNo ratings yet

- Sri Chaitanya IIT Academy - India: New C2 Ipl (%Document4 pagesSri Chaitanya IIT Academy - India: New C2 Ipl (%MADDINENI VASU75% (4)

- 05 - German Bank Protection Waterways Guide MBL - 88Document153 pages05 - German Bank Protection Waterways Guide MBL - 88Alejandro Urquieta QuirogaNo ratings yet

- Newtons Laws of Motion 1Document25 pagesNewtons Laws of Motion 1tracycamilla01No ratings yet

- Nozzle & Sadle ProcedureDocument25 pagesNozzle & Sadle Procedureaike_5100% (1)

- Free Fall Motion at Holy Cross of Davao CollegeDocument6 pagesFree Fall Motion at Holy Cross of Davao CollegeBrena PearlNo ratings yet

- B TECH Civil 2018 Syllabus II Yr To IV Yr 30-10-2019Document159 pagesB TECH Civil 2018 Syllabus II Yr To IV Yr 30-10-2019Tushar AnandNo ratings yet

- FMM Question BankDocument36 pagesFMM Question Banksmg26thmayNo ratings yet

- Question 1Document12 pagesQuestion 1eka123No ratings yet

- TYRE DYNAMICS - Part 1 PDFDocument24 pagesTYRE DYNAMICS - Part 1 PDFManoj ShanmugamNo ratings yet