Professional Documents

Culture Documents

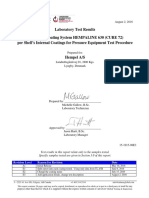

Coatings For Wind Power Uk

Uploaded by

charles083Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coatings For Wind Power Uk

Uploaded by

charles083Copyright:

Available Formats

Coatings for Wind Power

Onshore Wind, Offshore Wind and Substations

Complete coating solutions

for wind power assets,

with a track record to match

Contents

Hubs

Solutions

for...

Blades

Towers

Foundations

Nacelles

Components

Complete Coating

Solutions

Truly Global Total Customer

Support

A product range developed

with our customers in mind

With a range of coatings for every aspect of

your wind asset why go anywhere else but

International Paint? From tip to transition

piece we have the solution for you, whether

that be coating offshore foundations for your

substation, a one-coat direct to metal coating

for ISO12944 C3 environments, a rapid cure

blade coating or tower coatings for some of

the harshest environments in the world.

Choosing International Paint as your single

source supplier could drive down costs,

increase productivity, ensure consistency

and simplify the specification process.

Our testing programme includes coatings

systems that are rigorously tested in-house

and at world-renowned external test houses

to ISO 12944, ISO 20340 and NORSOK M-501.

Our extensive track record of 20 years in the

wind industry and over 40 years in protecting

structures offshore means you can be confident

that we have the solutions to meet your needs.

Infrastructure developed to

support you across the globe

What else can International Paint bring to

your business? We strive to add value to

the services which we can offer alongside

our coatings and strengthening our global

infrastructure is a key part of that. With

offices in over 50 countries and over 20 key

manufacturing locations, International Paint

can bring consistency and competency

to every corner of the globe; whether that

is ensuring consistent product quality

from Beijing to Berlin through our product

fingerprinting program or by offering a global

network of NACE qualified technical sales

representatives, bringing vast knowledge

to every one of your coating projects.

We have a proud history of environmental

leadership, ensuring we are always ahead of

legislation, removing hazardous raw materials

from our products through our product

stewardship program and keeping pace with

the most stringent of environmental regulations.

The benefits of working

as partners

At International Paint not only can we supply

coating solutions for your wind assets

regardless of location, but we also have a world

class support structure in place to back this up.

From a centrally-dedicated power market team

to experienced sales and NACE and FROSIO

qualified technical sales representatives local to

your business, International Paint is in a position

to assist with your project from the specification

writing phase, through construction and

painting, to ongoing maintenance and repair.

In addition to this we work tirelessly to

build real relationships with our customers,

learning and growing alongside your business,

matching changing requirements stride for

stride. If specifications need writing, new

products are required or training is needed,

you can be sure that International Paint

will deliver.

4 - Onshore

6 - Offshore

8 - Substations

10 - Blades

MANUFACTURI NG LOCATI ONS

OFFI CE LOCATI ONS

Track Record

More than 40,000 towers coated worldwide, supporting the growth of the industry

Onshore

Global Capability

International Paint have been involved in the wind industry from

the very beginning, giving us the technical know how, to provide

the best coating solutions. Backed up by a track record which

includes coating over 40,000 turbines worldwide over the past

20 years; true global capability from the Americas to Australasia.

5

Onshore

4

Onshore

Track Record Paracuru | Brazil

Year: 2005

Project Size: 7.5MW

Products: Interzinc 52 | Intergard 345 | Interthane 870

Jersey Atlantic | USA

Project Year: 2010

Project Size: 150MW

Products: Interzinc

52

Intercure

420

Interthane

990

At International Paint we continue to develop key

relationships with fabricators, applicators, owners and

engineers alike. This means International Paint understands

the wind markets key drivers better than anyone.

In these nancially testing times it is key that paint

manufacturers look at methods and means of improving

the economics of wind projects. International Paint has

a global network of sales and manufacturing locations

which means real economies of scale can be brought

about through close working partnerships. This could be

through the creation of global specications, ensuring

consistency, or through utilising some of International

Paints market-leading products

which can cut the number of

coats required or extend the

lifetime of your turbines.

International Paint want to grow

alongside your business; whether

you require support in new market

entry in areas such as South

America or Africa or you are

working on long-term cost-effective

solutions for your wind turbines.

Challicum Hills | Australia

Year: 2003

Project Size: 24.4MW

Products: Interzinc 52 | Intercure 420 | Interthane 990

Intercure 4500

Our high performance Intercure 4500

semi-gloss primer nish can vastly

improve your productivity. Excellent

anti-corrosion and aesthetic properties

allow you to replace a two coat

system for ISO12944 C3 environments

with a single coat. Productivity is

further enhanced with hard dry times

as low as two hours at 25C (77F).

Rapid cure even at

low temperatures

A feature of Intercure 4500 is its rapid

cure even at low temperatures. This

maximises productivity, allows use in

colder climates and reduces the need

for forced drying equipment, meaning

facilities can cut heating costs and

reduce environmental impact.

Benets throughout

the contract chain

Whether youre an applicator, contractor

or owner, in todays competitive market

it is essential that you make the most

of your assets, delivering on time

and without compromise. Intercure 4500

has been engineered to boost

productivity while offering outstanding

performance; maximising output from

paint shops, allowing contractors to

meet deadlines and giving owners

long term corrosion protection.

Lower VOC emissions

High solids and low VOCs in

Intercure 4500, combined with

a reduction in the number of coats

required can help to reduce overall

VOC emissions.

Project Name Location Products Project Size

Le Nordais - Wind Farm - Gaspe Quebec Canada Interzinc 52 Winter | Intergard 345 | Interthane 990 99MW

Meenadreen Wind Farm Ireland Intergard 405 | Intercure 420 | Interthane 990 3.4MW

Bowbeat Wind Farm Scotland Interzinc 52 | Intercure 420 | Interthane 870 31.2MW

Cemmaes Wind Farm Wales Intergard 405 | Intercure 420 | Interthane 990 15.3MW

Hare Hill Wind Farm Scotland Intergard 405 | Intercure 420 | Interthane 990 13MW

Lowca Wind Farm England Intergard 405 | Intercure 420 | Interthane 990 4.62MW

Maebongsan Wind Farm Korea Interzinc 52 | Intergard 400 7MW

Jilin Taobei China Interzinc 52 | Intergard 475HS | Interthane 990 | Interzinc 42 | Intergard 410 49.5MW

Xinjiang Tuoli China Interzinc 42 | Intergard 475HS | Interthane 870 | Interzinc 52 30MW

Hebei Zhangbei China Interzinc 52 | Intergard 475HS | Interthane 870 100.5MW

University of Minnesota Turbine USA Intercure 99 2.5MW

Dun Law Wind Farm UK Intercure 420 | Intergard 405 | Interthane 990 17MW

Woolnorth Wind Farm Tasmania Interzinc 52 | Interthane 990 140MW

Challicum Hills Wind Farm Australia Interzinc 52 | Intercure 420 | Interthane 990 52.5MW

Hasaki Wind Farm Japan Interzinc 52 | Intergard 345 | Interthane 870 16 MW

Beinn an Tuirc Scotland Intergard 405 | Intercure 420 | Interthane 990 31MW

Kings Mountain Wind Farm Ireland Interzinc 52 | Intercure 420 25MW

Regen Powertech India Interzinc 52 | Intergard 410 15MW

Paracuru Brazil Interzinc 52 | Intercure 420 | Interthane 990 | Interseal

670HS 24.4MW

Jersey Atlantic USA Interzinc 52 | Intergard 345 | Interthane 870 7.5MW

Some highlights from our track record

Offshore

An Enviable Track Record

Typical conditions for offshore wind assets vary signicantly from

onshore wind farms; knowledge and experience of these conditions

is key in meeting the lifetime expectations for offshore assets.

International Paint has a 40 year track record coating offshore

structures and understand what is required to protect your assets.

7

Offshore

6

Offshore

Testing for offshore structures

ISO 12944 This sets the baseline for performance assessment

for specication of coating systems across onshore environments.

However, when it comes to offshore environments, our extensive

real world experience has taught us that ISO 12944 is not indicative

of actual offshore performance.

ISO 20340 In order to more accurately predict offshore coatings

performance, we turn to another internationally recognised test

standard, ISO 20340. This adds a cyclic test to better replicate

real world conditions. The cyclic test subjects the coating

system to alternating condensation and UV exposure periods,

salt spray and low temperature to put more corrosive pressure

on the coating system. The length in terms of exposure hours is

also increased compared to ISO 12944 and extra dimensions,

such as cathodic disbondment and adhesion, are added for the

immersion test. The high regard for the ISO 20340 test method

has lead to its adoption as a fundamental part of the Internationally

recognised Norwegian NORSOK M-501 rev 5 standard.

We actively participated in the committee of experts who created

the ISO 20340 standard, bringing our extensive experience in the

offshore environment to the industry and helping to further the

development of new products and services.

Whether your wind turbines will

be in the birthplace of offshore

wind in North Western Europe or

in a growing area of the industry

such as China or the USA, the

environmental conditions differ

greatly from onshore wind farms.

Forget the glossy pictures

and serene seas, offshore wind

farms can face waves 20 metres

(65 feet) high and winds in

excess of 200 km/h (120mph).

Understanding how to protect the

turbines from corrosion and erosion

in these environments is

International Paints forte.

We use this in-eld experience

with a huge range of testing to

industry standards such as

ISO 20340 and NORSOK M-501

to provide coatings that can

be specied with condence

(see opposite page).

Over the past 40 years International

Paint has developed some of the best

products available for offshore assets.

Project Name Location Asset Area Products Year Project Size

Belwind Offshore Wind Farm Belgium Foundation Transition pieces Interzone 954 | Interthane 990 2009 165MW

Beatrice Demonstrator UK Turbine

Foundation

Towers

Jacket

Interzinc 52 | Intergard 475HS | Interne 629HS

Interzone 505

2006 10MW

Alpha Ventus Germany Foundation Jackets

Decks

Transition pieces

Interzone 1000

Interzone 954

Interzone 954

2009 60MW

London Array UK Foundation Transition pieces Interzone 954 | Interthane 990 2010 630MW

Ormonde UK Foundation Jackets

Decks

Steel

Interzone 1000

Interzone 954

Interzinc 52 | Intergard 475HS | Interne 691

2010 150MW

Donghai Bridge China Turbine Towers Interzinc 52 | Intergard 475HS | Interthane 990 2010 102MW

Anholt Denmark Foundation Transition pieces Interzone 954 | Interthane 990 2011 400MW

Hornsea UK Met Mast Jacket - twisted Interzone 954 2011 1500MW

Track Record Ormonde | United Kingdom

Year: 2010

Project Size: 400MW

Products: Interzinc 52 | Intergard 475HS | Interthane

990

Donghai | China

Project Year: 2010

Project Size: 150MW

Products: Interzone

1000 | Interzone 954

Interzinc

52 | Intergard

475HS

Interne

691

Beatrice | United Kingdom

Year: 2006

Project Size: 10MW

Products: Interzinc 52 | Intergard 475HS | Interne 629HS

Interzone 505

P

h

o

t

o

T

o

n

y

W

e

s

t

Interzone 954

The star of the International

Paint offshore range is

Interzone 954. A favourite

of speciers and applicators

alike, it has been protecting

steel for over 25 years; the

trusted industry solution for

protecting and maintaining

structures operating in the

most severe environments.

A unique blend of properties

gives Interzone 954 long term

performance in environments

that combine a high potential

for mechanical damage, chemical

attack, atmospheric corrosion

and immersion conditions.

This versatility makes

Interzone 954 the all-round

heavy duty coating of choice.

Some highlights from our track record

Substations

As well as protecting your wind turbines offshore, you will need

to ensure that supporting structures such as substations are also

protected. With International Paints longstanding track record offshore

and our strong product range, we can provide the complete solution.

9

Substations

8

Substations

Track Record Lincolnshire | UK

Year: 2010

Project Size: 102MW

Products: Interzinc 52 | Intergard 475HS | Interthane 990

London Array | United Kingdom

Year: 2007

Project Size: 250MW

Products: Interzinc

52 | Intercure

384

Interne

691 | Interzone 1000

Interzone

954

Not only do you need protection

against corrosion and erosion

but also consideration must

be given to re protection and

access areas. With a wide range

of coatings available, many

developed specically for the

offshore market, you can be

condent that International Paint

has the coatings you require.

Access areas, such as decks and

walkways, also need particular

attention to ensure they are

protected and safe. This will

include corrosion protection,

potentially re protection and also

non-slip surfaces, provided by

International Paints aggregates.

However, the products at the core

of International Paints success

offshore are the Interzone range,

with up to 25 years lifetime, for use

above and below the waterline.

With manned or frequently

serviced assets, re protection

could be a requirement.

With our industry-renowned

Chartek

range, our dedicated re

protection team, a recently opened

7million re protection research

facility and extensive track record

in re protection, we are the ideal

partner to protect your offshore

asset from the effects of re.

Belwind Wind Farm | Belgium

Year: 2010

Project Size: 165MW

Products: Interzinc 52 | Intergard

475HS | Interthane

990

Project Name Location Asset Area Products Year Project Size

Belwind Offshore Wind Farm Belgium Offshore substation Topsides Interzinc 52 | Intergard 475HS | Interthane 990 2003 165MW

Greater Gabbard UK Offshore substation Jackets

Transition pieces

Topsides

Interzone 954

Interzone 954

Interzinc 52 | Intergard 475HS | Interne 691

2008 500MW

Galloper UK Offshore substation Topsides Interzinc 52 | Intergard 475HS | Interne 691 2008 504MW

Lincs UK Offshore substation Topside

Jacket

Interzinc 52 | Intercure 384 | Interne 691

Interzone 1000 | Interzone 954

2007 250MW

Sheringham Shoal UK Offshore substation x 2 Topsides Interzinc 52 | Intergard 475HS | Interne 629HS 2008 317MW

Rdsand Denmark Offshore substation Jacket Interzone 1000 2008 166MW

London Array UK Offshore substation Jacket Interzinc 52 | Intergard 475HS | Interthane 990 2012 1000MW

Substations

Coatings Characteristics

P

h

o

t

o

L

o

n

d

o

n

A

r

r

a

y

P

h

o

t

o

L

o

n

d

o

n

A

r

r

a

y

Some highlights from our track record

Deck Coatings

Durable

Abrasion Resistant

Fire Protection

Employee Safety

Asset Protection

Splashzone &

Immersed

Anti-corrosive

Barrier Protection

Coatings for Every Surface

The Interzone series

In addition to the ever popular Interzone 954

there are two other key members of the Interzone

family for offshore wind.

Interzone 1000 is the workhorse of the

Interzone range and is a glass reinforced

epoxy coating which contains greater

than 30% chemically resistant glass

ake in the dry lm. Excellent resistance

to cathodic disbondment, abrasion and

corrosion makes Interzone 1000 the

choice for long term protection of offshore

structures, up to and beyond 25 years.

Interzone 485 is an ultra high build, high

volume solids, two component catalysed

epoxy, capable of being applied up to

3000 microns (120 mils) dry lm thickness,

and providing excellent impact resistance,

abrasion resistance and adhesion properties.

All of this makes the Interzone series the

most appropriate solution to problems

found in splashzones, tidal areas and the

harsh offshore environment in general.

International Paint is a one stop shop for wind

turbine coatings in any environment.

Blades are an integral part of the turbine and are

exposed to erosive forces which can damage

the blades and affect subsequent performance.

Speeds at the tip of wind turbine blades can

exceed 480 km/h (300mph) as they come into

contact with rain, hail and other atmospheric

conditions in very harsh environments.

Blades are also exposed to items carried

upon the wind and by sea spray, such as

sand, pebbles and other small objects which

have the ability to cause impact damage

to the surface and the coatings on it.

Gloss retention, substrate adhesion, abrasion

resistance, exibility and good rain erosion

performance are just some of the characteristics

that coatings for wind blades should have.

In addition, manufacturers can also benet from

coatings which keep up with environmental

legislation, as well as hitting demanding

production timeframes to increase throughput.

International Paint have gone above and

beyond industry specication requirements to

deliver a coating system; gap ller, pore ller

and topcoat; which has been rigorously tested,

performing particularly well in the areas of rain

erosion and adhesion to substrate. As part

of AkzoNobel we have more than 20 years

experience of coating composite materials.

The Interplus

coating system from

International Paint aims to reduce complexity,

increase productivity and deliver improved

performance in the eld with superb

rain erosion test results.

High erosion area

Blade Coatings Complete Solutions

11

Blade Coatings

10

Blade Coatings

Total protection from tip to transition piece

Protecting your complete wind turbine is

what International Paint does best.

Over 35 years offshore track record

Over 20 years wind track record

Global manufacturing and supply

Products for applications in any environment

Intercure

fast cure, low VOC

Interzone

offshore coatings with a pedigree

Interplus

outstanding rain erosion test results

Interthane

top coat of choice

Intergard

high build protection for your asset

Interzinc

anti-corrosive zinc rich primers

Solutions for the entire

contract chain

Interplus gap filler for

larger gaps and defects

2

Interplus pore filler for

smaller pores and defects

2 1 Composite substrate

Interplus finish 3

1

2

3

OWNERS

Trusted, long life

coating systems

What can our coatings do for you?

At International Paint we pride ourselves on our industry

expertise from project concept to delivery.

Our coatings range and wind market knowledge enable

us to add value to all companies throughout the contract

chain, ensuring your wind projects run smoothly.

ENGINEERS

Specication

assistance, based

on industry

experience

M&R

CONTRACTORS

Brush and aerosol

applied M&R offer

FABRICATORS/

APPLICATORS

Quick cure, easy to

apply coatings

www.international-pc.com

pc.communication@akzonobel.com

and and all product names mentioned in this publication are trademarks of, or licensed to, AkzoNobel. AKZONOBEL 2013.

International Paints Protective Coatings business has used its best endeavours to ensure that the information contained in this publication is correct at the time

of printing. Please contact your local International Paints Protective Coatings business representative if you have any questions.

Unless otherwise agreed by us in writing, any contract to purchase products referred to in this brochure and any advice which we give in connection

with the supply of products are subject to our standard conditions of sale. A

N

0

2

8

0

1

_

1

4

1

2

0

9

G

1

2

_

W

IN

D

M

K

T

_

U

K

0

3

/

1

3

As a global organisation we can supply coatings from a

number of worldwide manufacturing locations through our

local distribution networks straight to your project location.

If your project requires materials to be sourced from

overseas then International Paint can supply to multiple

locations across country and even continental borders.

As well as our track record in worldwide projects,

our global product range ensures that you can have

condence in receiving a consistent quality of product

and service wherever and whenever you need it.

Furthermore, our experienced local sales teams and

technical service representatives can offer valuable

insight into the approvals and testing required to bring

your project in on schedule without untimely delays.

Global Organisation

You might also like

- Cathodic Protection Course BrochureDocument2 pagesCathodic Protection Course BrochurechkzaNo ratings yet

- BS en 12068.1999Document33 pagesBS en 12068.1999yy20100% (1)

- JPCL Transpipe EbookDocument82 pagesJPCL Transpipe Ebookvincent.w.stone6724No ratings yet

- Interspec: Tangguh Expansion ProjectDocument43 pagesInterspec: Tangguh Expansion ProjectZamri Rahmat SikumbangNo ratings yet

- 15-1915-08e3-Hempaline Defend 630 (Cure 72)Document28 pages15-1915-08e3-Hempaline Defend 630 (Cure 72)ashishpearlNo ratings yet

- Outgassing 101 1 EpoxyTechDocument10 pagesOutgassing 101 1 EpoxyTechLarry Wayne Sumpter, JrNo ratings yet

- Acceptance Criteria For Damaged PFP Info Sheet 12-2007Document9 pagesAcceptance Criteria For Damaged PFP Info Sheet 12-2007Richard HollidayNo ratings yet

- IMO PSPC ImplementationDocument15 pagesIMO PSPC ImplementationHugo Wizenberg100% (1)

- ISO 4628engDocument4 pagesISO 4628engLuisArmandoFranyuttiArciaNo ratings yet

- Study Electromagnetic Environment Multi-Circuit: On of Transmission Lines On Same TowerDocument5 pagesStudy Electromagnetic Environment Multi-Circuit: On of Transmission Lines On Same TowerDayan YasarangaNo ratings yet

- Rehabilitation of Concrete Tank Using Epoxy and FRP LiningDocument5 pagesRehabilitation of Concrete Tank Using Epoxy and FRP LiningChaitanya ShahNo ratings yet

- The Repair OptionDocument4 pagesThe Repair OptionMAGUNAMNo ratings yet

- MarineLine784 Protective CoatingsDocument8 pagesMarineLine784 Protective CoatingsTimuçin ÇolakelNo ratings yet

- Internal Launch Presentation Version 01 - SingaporeDocument100 pagesInternal Launch Presentation Version 01 - SingaporeEnrico Savira100% (1)

- Cte Ongc SpecDocument21 pagesCte Ongc SpecMohamed HushainNo ratings yet

- Epoxy Vs GalvanizedDocument6 pagesEpoxy Vs GalvanizedLewoskiNo ratings yet

- 07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementDocument8 pages07 - Ajie Manggala Putra (TML) - 26in BOC - BOD Pipeline ReplacementSamuel JohnNo ratings yet

- Combined CIPS and DCVG surveys for pipeline integrityDocument9 pagesCombined CIPS and DCVG surveys for pipeline integrityadeoye_okunoyeNo ratings yet

- PDFDocument12 pagesPDFThamaraikani ManiNo ratings yet

- Meccoct18 12573Document9 pagesMeccoct18 12573Malik Ansar HayatNo ratings yet

- Polyken Pipeline #1027,: Primers #1019Document3 pagesPolyken Pipeline #1027,: Primers #1019Azmi SyariefNo ratings yet

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFDocument8 pagesEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefNo ratings yet

- Standard TM0497 2012Document1 pageStandard TM0497 2012Raul Enrique TrejoNo ratings yet

- Technical Data Sheet for Unsaturated Vinyl Ester CoatingDocument5 pagesTechnical Data Sheet for Unsaturated Vinyl Ester CoatingBiju_PottayilNo ratings yet

- Icorr Certification Scheme: Icorr Training Courses (Itc)Document5 pagesIcorr Certification Scheme: Icorr Training Courses (Itc)sheikbbaNo ratings yet

- Conventional AirsprayDocument218 pagesConventional AirspraylambtranNo ratings yet

- ChemicalDocument5 pagesChemicalisaac2408No ratings yet

- Pipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge TavesDocument51 pagesPipeline Coatings The Petrobrás Experience: Joaquim P. Quintela Jorge Tavesnathgsurendra100% (2)

- New Earth Potential Equations and Applications PDFDocument16 pagesNew Earth Potential Equations and Applications PDFapar demangNo ratings yet

- Com Su 202 DDocument23 pagesCom Su 202 Dsuriya100% (2)

- Corrosion Protection of Offshore StructuresDocument10 pagesCorrosion Protection of Offshore StructuresHo Minh Viet100% (1)

- Pull-Off Adhesion Testing ExplainedDocument5 pagesPull-Off Adhesion Testing Explainedzavisa2No ratings yet

- WW 11 Corrosion Prevention of Steel Pipe 2012Document100 pagesWW 11 Corrosion Prevention of Steel Pipe 2012daskirNo ratings yet

- Adhesion Characteristics of Protective Coatings for Nuclear Power PlantsDocument8 pagesAdhesion Characteristics of Protective Coatings for Nuclear Power PlantsHaidarHussaini100% (1)

- Iso 22475 1 2021Document15 pagesIso 22475 1 2021ANo ratings yet

- As 4822-2008 External Field Joint Coatings For Steel PipelinesDocument8 pagesAs 4822-2008 External Field Joint Coatings For Steel PipelinesSAI Global - APAC0% (1)

- Guide To Protective Coating Systems Using Iso12944 27feb2023Document12 pagesGuide To Protective Coating Systems Using Iso12944 27feb2023CeciliaNo ratings yet

- Evaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelDocument9 pagesEvaluation of Corrosion Protection Properties of Additives For Waterborne Epoxy Coatings On SteelJhon jairo100% (1)

- 028120-SPL-004 Pipeline Weight Coating Rev. CDocument11 pages028120-SPL-004 Pipeline Weight Coating Rev. CRokan Pipeline100% (1)

- TR External Polymeric FailureDocument3 pagesTR External Polymeric FailureJuliano SampaioNo ratings yet

- A - Pipe CoatingDocument25 pagesA - Pipe Coatingpaivensolidsnake100% (1)

- Coating-Failure-Defects 2 PDFDocument10 pagesCoating-Failure-Defects 2 PDFaahil ahmadNo ratings yet

- Ul 1709 (2022)Document34 pagesUl 1709 (2022)gaso99100% (1)

- Trouble With Paint Blistering of Paint On Metal 1Document10 pagesTrouble With Paint Blistering of Paint On Metal 1ravi00098No ratings yet

- Challenges With Using Ethyl Silicate Inorganic Zinc-Rich PrimerDocument43 pagesChallenges With Using Ethyl Silicate Inorganic Zinc-Rich PrimerMOHAMEDNo ratings yet

- Coatings and Cathodic Disbondment - The True StoryDocument23 pagesCoatings and Cathodic Disbondment - The True StoryCamilo Godoy V100% (1)

- Phenolic FoamDocument20 pagesPhenolic FoamkenandyouNo ratings yet

- ID-PRC 19 - PE Coating RepairDocument7 pagesID-PRC 19 - PE Coating Repaircloud23No ratings yet

- Glass Flake Coatings PDFDocument4 pagesGlass Flake Coatings PDFDinesh ChouguleNo ratings yet

- Calculation Procedure For Ground Potentials With Multiple AnodesDocument17 pagesCalculation Procedure For Ground Potentials With Multiple AnodesIwan Husdiantama100% (1)

- Corrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium PigmentsDocument14 pagesCorrosion Resistance Performance of Epoxy Coatings Incorporated With Unmilled Micro Aluminium Pigmentssmith100% (1)

- Sika-Wrap Struct StrengthDocument7 pagesSika-Wrap Struct StrengthMiky CastenNo ratings yet

- Coatings For Wind Power - Uk - 010213Document7 pagesCoatings For Wind Power - Uk - 010213King SabiNo ratings yet

- Flexitallic Products PDFDocument108 pagesFlexitallic Products PDFNguyễn Xuân NamNo ratings yet

- Vantrunk 2013 CatalogueDocument132 pagesVantrunk 2013 CatalogueAndrew JeyakumarNo ratings yet

- SFTI Zbrush James Cain PDFDocument13 pagesSFTI Zbrush James Cain PDFBlu SandersNo ratings yet

- Beyond Space Girl CoverDocument5 pagesBeyond Space Girl CoverProtesilaosNo ratings yet

- The Magic Behind Tux PaintDocument16 pagesThe Magic Behind Tux PaintMohan KrishnaNo ratings yet

- Virginia Woolf - To The LighthouseDocument21 pagesVirginia Woolf - To The LighthouseAlina Grațiela100% (1)

- Caron Simplysoftstripes C Parquettilescrochetblanket Web enDocument1 pageCaron Simplysoftstripes C Parquettilescrochetblanket Web enRosu LoredanaNo ratings yet

- A - Design 1979-Roma InterrottaDocument107 pagesA - Design 1979-Roma InterrottaJuan Piñeros100% (2)

- Deleuze, Gilles - Image and TextDocument289 pagesDeleuze, Gilles - Image and TextAline Job100% (8)

- Script For My Video PresentationDocument4 pagesScript For My Video PresentationJomar EnriquezNo ratings yet

- El Greco S The Burial of The Count of Orgaz: Mudéjar and Gothic Style ArchitectureDocument2 pagesEl Greco S The Burial of The Count of Orgaz: Mudéjar and Gothic Style ArchitecturePhantomfreaxNo ratings yet

- Jonathan Fineberg - Art Since 1940 - Strategies of Being-Harry N. Abrams (1995)Document498 pagesJonathan Fineberg - Art Since 1940 - Strategies of Being-Harry N. Abrams (1995)Cihan Mertoz45% (11)

- ExcDocument23 pagesExckonainglincho001No ratings yet

- DATE:21-12-2018 Refurbishment of Palladium Washroom - Material ListDocument6 pagesDATE:21-12-2018 Refurbishment of Palladium Washroom - Material ListVishal KediaNo ratings yet

- AnnexureDocument1 pageAnnexureLokesh BhatiNo ratings yet

- How To Create A Magick Mirror PDFDocument16 pagesHow To Create A Magick Mirror PDFDiego Leonardo Trevisan100% (1)

- HT 521 81071 000 ENDocument6 pagesHT 521 81071 000 ENEdward AguillónNo ratings yet

- DTP: Using PageMaker to Design a Program for EventsDocument33 pagesDTP: Using PageMaker to Design a Program for EventsKingsley MNo ratings yet

- Poly-Wood 2011 CatalogDocument56 pagesPoly-Wood 2011 CatalogPoly Furniture100% (1)

- SMA AfricanArt Vol1Document69 pagesSMA AfricanArt Vol1renato100% (1)

- Collab and Desktop PublishingDocument14 pagesCollab and Desktop Publishingtala lalalaNo ratings yet

- The Mysticism of William Blake - Helen C White 1927Document290 pagesThe Mysticism of William Blake - Helen C White 1927Waterwind100% (7)

- 4 Journey From Semi Darkness Into LightDocument36 pages4 Journey From Semi Darkness Into Lightsleepy changNo ratings yet

- Wilson, Mabel 'Dancing in The Dark'Document11 pagesWilson, Mabel 'Dancing in The Dark'Aleix Saura VallverdúNo ratings yet

- Burger - Theory of The Avant Garde Chap 4Document15 pagesBurger - Theory of The Avant Garde Chap 4monkeys8823No ratings yet

- Adult Coloring Therapy Book - MandalaDocument31 pagesAdult Coloring Therapy Book - MandalaSandra Deaconu100% (1)

- Bio - Okwui EnwezorDocument2 pagesBio - Okwui EnwezorJan HoppeNo ratings yet

- Le Corbusier's Villa SavoyeDocument14 pagesLe Corbusier's Villa SavoyeADYASA CHOUDHURYNo ratings yet

- Laurence King Children's & Gift Spring 2016Document51 pagesLaurence King Children's & Gift Spring 2016ChronicleBooks100% (1)

- Monemvasia SimpleDocument4 pagesMonemvasia Simplesammy2121No ratings yet

- Kahnweiler's Lesson on Cubism's Early DefenderDocument37 pagesKahnweiler's Lesson on Cubism's Early DefenderKarine RaynorNo ratings yet