Professional Documents

Culture Documents

Bends Requirement As Ibr & Asme

Uploaded by

Simbu ArasanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bends Requirement As Ibr & Asme

Uploaded by

Simbu ArasanCopyright:

Available Formats

As per 31.

1

102.4.5 Bending. The minimum wall thickness at

any point in a completed bend shall not be less than

required by Formulas (3) or (3A) of para. 10.1.!(A).

(A) Table 102.4.5 is a "uide to the desi"ner who

must speci# wall thickness for orderin" pipe. $n "eneral

it has been the e%perience that when "ood shop practices

are employed& the minimum thicknesses of strai"ht pipe

shown in Table 10!..' should be sufficient for bendin"&

and still meet the minimum thickness requirements of

para. 10.1.!(A).

(B) The bend thinnin" allowance in Table 10!..'

may be pro(ided in all parts of the cross section of

the pipe circumference without any detrimental effects

bein" produced.

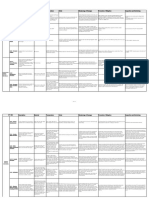

TABLE 102.4.5

Min. Thickness

Recommended Prior to

Radius of Bends Bending

!i!e diameters or greater 1.0tm

4 !i!e diameters 1.14tm

" !i!e diameters 1.25tm

5 !i!e diameters #.ostm

-

$E%ERAL %&TE'(

)ai inter!o#ation is !ermissi*#e tor *ending to intermediate radii.

t*+ fm is determined *, -ormu#a (3) or )"A+ of !ara. 104.1.2)A+.

)c# Pi!e diameter is the nomina# diameter as ta*u#ated in A'ME

.".10/0 Ta*#es 2 and 40 and A'ME B".11M0 Ta*#e 1. -or

!i!ing 2ith a diameter not #isted in these Ta*#es0 and a#so for

tu*ing0 the nomina# diameter corres!onds 2ith the outside

diameter.

$)*

3+. Method of Manufacture, Heat Treatent and Mar!ing, (a) -n completion of any

work which in(ol(es heatin"& whether for hot bendin" of the pipe or for any other similar

purpose& the pipe shall be carefully annealed.

.. (b) (i) The cold drawn seamless carbon steel pipes and welded carbon steel pipes

shall be supplied in normali/ed condition.

(ii) 0ot finished seamless carbon steel pipes shall be supplied in hot finished

condition or in normali/ed condition at the option of the manufacturer.

(iii) The seamless alloy steel pipe either cold finished or hot finished and

welded pipes shall be supplied in normali/ed and tempered condition.

(i() )y a"reement between the users and the manufacturer& the pipes may be

deli(ered in a condition

other than normali/ed and tempered condition in which case they shall be suitable for

subsequent

manipulation and the user shall be informed of the heat,treatment necessary to "i(e

required properties.

(c) (i) 1ipe bendin" and formin" ((i/. reducin" 2 swa"in") operation shall be

done by any hot or cold method and to any radius which shall result in a surface

free from cracks& buckles or other defects as determined by the method of

inspection specified in the desi"n. A post bendin" or post formin" heat treatment

for carbon steel material is required with a nominal wall thickness in e%cess of 13.0

millimeters unless the bendin" or formin" operation are performed and completed

at normali/in" temperatures& where no further heat treatment is required. The heat

treatment where required shall be normali/ed or stress relie(ed& as the case may be.

(ii) A post bendin" or post formin" heat treatment shall be require for all

ferritic alloy steel material with

nominal pipe si/e 100.00 millimeters and lar"er or with a nominal thickness 13.0

millimeters or "reater.

(iii) $f hot bendin" or formin" is performed the material shall recei(ed

normali/e and temper or temperin" heat,treatment as required by the desi"n. For cold

operation& temperin" heat,treatment shall be applied.

(d) 4arkin", 4arkin" shall be carried out in accordance with re"ulation 33',F.

351. "rought Bends, (a) 1ipes of thickness determined in accordance with equation

31 with increase of 1!.'6 shall not be bent to radii less than those "i(en in the followin"

Table (7lick here to (iew the Table). 8here smaller radii are necessary& further allowance

shall be made for thinnin" at the back of the bend e%cept where it can be demonstrated to

the satisfaction of the $nspectin" Authority that the use oft b will not reduce the thickness

below y t at any point after bendin"9

where&

t : min. thickness as per ;qn. 31&

tb : min. thickness before bendin".

(b) The thickness of the pipes& from which bends are made shall be such that the

minimum thickness required by equation (31) is maintained throu"hout after the bendin"

operation. The de(iation from circularity in percenta"e at any cross,section of a bend

shall be calculated by the followin" formula

where&

7 : The percenta"e de(iation of circularity&

< ma%. : ma%imum e%ternal diameter of the pipe as "au"ed at the bend&

< min. : minimum e%ternal diameter of the pipe as "au"ed at the bend&

< : nominal e%ternal diameter of the pipe&

* : *adius of the bend on the central line of the bend.

.. (c) Fabricated pipe bends may be made by 8eldin" to"ether be(elled section of

strai"ht pipe& pro(ided,.

(i) the an"le between the a%is of the ad=oinin" sections does not e%ceed 30> and

(ii) the thickness is at least 9 ? , 0.' 2 ? , 1 times the minimum thickness required for

the strai"ht pipe to which the bend is =oined.

where&

?:ratio of the radius of the bend (from center of cur(ature to center of pipe) to

the inside radius of the pipe.

@ote. Ausseted )ends shall be used for pressure not e%ceedin" !1 kilo"ramme per

square centimeter and

temperature not e%ceedin" !50 <e"ree 7enti"rade.

.. (d) For the for"ed bends& the radii shall be not less than those "i(en below9,

Bon" radii for"ed bends , * : 1.' % d

Chort radii for"ed bends , * : 1.0 % d

The thickness at any point of the bend shall not be less than +D.'6 of the nominal

thickness of the bend. The thickness at any point of the bend shall be such that the

minimum thickness required equation 31 is maintained throu"hout after finishin"

operation

You might also like

- Impact Test Exemptions PEDDocument7 pagesImpact Test Exemptions PEDoberaiNo ratings yet

- Test Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )Document7 pagesTest Ring Calculation (Based On L&T Std. (6249-Lt-Eq-00-Od-0004 - Rev-1) )alokbdasNo ratings yet

- Piping Thickness Calculation for Steam LinesDocument21 pagesPiping Thickness Calculation for Steam LinesAmit BansalNo ratings yet

- ASME B31.12 hydrogen piping standards errataDocument2 pagesASME B31.12 hydrogen piping standards errataISMAEL IGNACIO ARCHILA CASTILLONo ratings yet

- Thermal CuttingDocument32 pagesThermal CuttingoviemeNo ratings yet

- Thermal Power Plant Color Code For Piping PDFDocument11 pagesThermal Power Plant Color Code For Piping PDFalwynnithinherbert50% (4)

- Bolted Joint DesignDocument5 pagesBolted Joint Designperdhana2000No ratings yet

- IBR CalculationDocument1 pageIBR CalculationKarthic Keyan100% (1)

- Boiler Tube GradesDocument12 pagesBoiler Tube Gradesfelram100% (1)

- BAsic Technology NoteDocument9 pagesBAsic Technology Notemally4d0% (1)

- 4.4 Technical Specification For Structural SteelworkDocument11 pages4.4 Technical Specification For Structural SteelworkHazim HaNo ratings yet

- PDFDocument139 pagesPDFAnonymous ItzBhUGoi100% (2)

- API 660 Vs TEMADocument5 pagesAPI 660 Vs TEMAALONSO GOMEZNo ratings yet

- TWI Welding Training 4Document36 pagesTWI Welding Training 4Simbu Arasan100% (1)

- Thermal fatigue and brittle fracture mechanismsDocument3 pagesThermal fatigue and brittle fracture mechanismsSimbu Arasan100% (1)

- Repair ProcedureDocument6 pagesRepair ProcedureTomy GeorgeNo ratings yet

- PWHTDocument79 pagesPWHTnguyenNo ratings yet

- Cswip-Reviewer - DAY 3 HOME WORKDocument43 pagesCswip-Reviewer - DAY 3 HOME WORKshrikantajit100% (1)

- Miter Bend Calculation FormulasDocument4 pagesMiter Bend Calculation FormulasRavindra S. Jivani100% (3)

- BS 3059-1 PDFDocument9 pagesBS 3059-1 PDFabhiNo ratings yet

- STEAM-PIPES AND FITTINGS REGULATIONSDocument7 pagesSTEAM-PIPES AND FITTINGS REGULATIONSRajivharolikar100% (2)

- Steam Turbine Q & ADocument47 pagesSteam Turbine Q & Asrikanth9555100% (1)

- Code Case 183 - 2Document2 pagesCode Case 183 - 2Bruno ManzettiNo ratings yet

- Material Standard for Flanges and FittingsDocument73 pagesMaterial Standard for Flanges and FittingsBoban Stanojlović100% (2)

- Hot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 MannessmanDocument3 pagesHot Forming/Bending: Material BS 806 ANSI B 31.1 DIN 17175 Mannessmandnageshm4n244No ratings yet

- Sa 335 PDFDocument12 pagesSa 335 PDFAnilNo ratings yet

- Boiler Design Calculations GuideDocument163 pagesBoiler Design Calculations GuideRajesh Kumar100% (2)

- IBR - 1950 - Reg. 360Document3 pagesIBR - 1950 - Reg. 360ayoki100% (2)

- GB-T8163-1999 英文版Document11 pagesGB-T8163-1999 英文版saasim_1100% (1)

- REGULATIONS UPDATEDDocument74 pagesREGULATIONS UPDATEDSakthi VelNo ratings yet

- HRSG ITP (Rev E)Document5 pagesHRSG ITP (Rev E)rvsreddysena100% (5)

- Ibr RegDocument6 pagesIbr RegSitaram Jha100% (1)

- GB 5310Document25 pagesGB 5310Cong Son100% (1)

- Report on boiler tube failures and remedial measures for Kothagudem Thermal Power StationDocument4 pagesReport on boiler tube failures and remedial measures for Kothagudem Thermal Power StationNaveen ChodagiriNo ratings yet

- Drum Lifting MethodDocument4 pagesDrum Lifting MethodRajeev MaheshwariNo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- KHR35CTDocument2 pagesKHR35CTKiatchai IttivikulNo ratings yet

- Limits and State of The Art of The New Creep Resistant SteelsDocument64 pagesLimits and State of The Art of The New Creep Resistant SteelsRené Galbraith BerraNo ratings yet

- Ibr CalDocument11 pagesIbr Calmailtosamraj100% (4)

- Example of Thermodynamic Calculation of Fire Tube Boiler With Boiler ...Document6 pagesExample of Thermodynamic Calculation of Fire Tube Boiler With Boiler ...Kazem QarebeiglooNo ratings yet

- Asme Sec I PWHT RequirementDocument6 pagesAsme Sec I PWHT RequirementSajin ChandranNo ratings yet

- CondenserDocument4 pagesCondenseratulbhogare7100% (1)

- International Standard For High Frequency Welded Fins DownloadDocument3 pagesInternational Standard For High Frequency Welded Fins DownloadPrasad Dhume50% (2)

- Lathe ManualDocument14 pagesLathe ManualRC Villeda100% (1)

- Stainless steel electrode AWS specifications guideDocument11 pagesStainless steel electrode AWS specifications guideTito FernandezNo ratings yet

- CHAPTER XIII IBR Welder QualificationDocument11 pagesCHAPTER XIII IBR Welder QualificationAnubhav Lakhmani100% (1)

- Asme Section II A Sa-302 Sa-302mDocument4 pagesAsme Section II A Sa-302 Sa-302mAnonymous GhPzn1xNo ratings yet

- Metal TempDocument101 pagesMetal TempJKKNo ratings yet

- Weldolet InfoDocument4 pagesWeldolet InfoChoon Wei WongNo ratings yet

- Welding of P91Document37 pagesWelding of P91Shyam Sundar GayenNo ratings yet

- Checklist For Roof Skin CasingDocument7 pagesChecklist For Roof Skin CasingRamalingam PrabhakaranNo ratings yet

- Tube and Pipe Material Comparison ChartDocument2 pagesTube and Pipe Material Comparison Chartvalli rajuNo ratings yet

- Boiler Material and Typical ApplicationsDocument1 pageBoiler Material and Typical Applicationsmtbecerrap100% (1)

- Description of Damage: 4.2.11 Steam Blanketing 4.2.11.1Document2 pagesDescription of Damage: 4.2.11 Steam Blanketing 4.2.11.1Ajmi HmidaNo ratings yet

- Welding Advanced Chromium Alloys for High-Temperature ServiceDocument5 pagesWelding Advanced Chromium Alloys for High-Temperature Servicesaji_t1984100% (1)

- Engineering Failure Analysis: H. Kazempour-Liacy, M. Mehdizadeh, M. Akbari-Garakani, S. AboualiDocument10 pagesEngineering Failure Analysis: H. Kazempour-Liacy, M. Mehdizadeh, M. Akbari-Garakani, S. AboualiAndrie MaulanaNo ratings yet

- Bed Ash CoolerDocument2 pagesBed Ash CoolerPrudhvi RajNo ratings yet

- Materials: Pressure Parts and Applicable Service TemperaturesDocument14 pagesMaterials: Pressure Parts and Applicable Service Temperaturesmohan babuNo ratings yet

- Boiler Tube MaterialsDocument12 pagesBoiler Tube MaterialsSnehashis MaityNo ratings yet

- Ucs 56Document1 pageUcs 56enemesio_85100% (1)

- 6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFDocument20 pages6-15-0001 Rev 2 Gen Spec For Heat Exchanger PDFsumit kumarNo ratings yet

- CFB Boiler BrochureDocument2 pagesCFB Boiler BrochuremechguybalaNo ratings yet

- Ug-116 - RT4Document3 pagesUg-116 - RT4miteshpatel191No ratings yet

- Bends Requirement As Ibr AsmeDocument3 pagesBends Requirement As Ibr AsmeAgniva DuttaNo ratings yet

- Reg. 353 Flanges Types and RequirementsDocument5 pagesReg. 353 Flanges Types and RequirementsRajivharolikarNo ratings yet

- IBR DetailsDocument10 pagesIBR Detailsreach_arindomNo ratings yet

- Jai Ganesh Ibr-Design Chapter-1Document10 pagesJai Ganesh Ibr-Design Chapter-1Sivi NallamothuNo ratings yet

- 49 CFR 178.61 Cylinder Specification RequirementsDocument7 pages49 CFR 178.61 Cylinder Specification RequirementsFarhan AliNo ratings yet

- General Notes-MS TANKDocument2 pagesGeneral Notes-MS TANKvipul gandhiNo ratings yet

- IBR Amendment 2001,3Document6 pagesIBR Amendment 2001,3Agniva DuttaNo ratings yet

- OPES2024_Brochure_V7Document12 pagesOPES2024_Brochure_V7Simbu ArasanNo ratings yet

- Mitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateDocument4 pagesMitsui Engineering & Shipbuilding Asia Pte. LTD.: Name: DateSimbu ArasanNo ratings yet

- 510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFDocument1 page510 - May 2017 Jan 2018 - PublicationsEffectivity - Final 12 05 16 PDFshakeelahmadjsrNo ratings yet

- My Desk: Time Is GoldDocument22 pagesMy Desk: Time Is GoldSimbu ArasanNo ratings yet

- Serag4000 NotesDocument19 pagesSerag4000 NotesSimbu ArasanNo ratings yet

- CSWIP-WI-6-92 13th Edition July 2015 PDFDocument17 pagesCSWIP-WI-6-92 13th Edition July 2015 PDFjaisonaeroNo ratings yet

- 003 - Standard Procedure For Coating and WrappingDocument6 pages003 - Standard Procedure For Coating and WrappingSimbu ArasanNo ratings yet

- Pipe Schedule PDFDocument1 pagePipe Schedule PDFSrinivasan SeenuNo ratings yet

- XtrasDocument3 pagesXtrasSimbu ArasanNo ratings yet

- 004 - Standard Procedure For Surface Preparation and PaintingDocument9 pages004 - Standard Procedure For Surface Preparation and PaintingSimbu ArasanNo ratings yet

- Fe-C Phase DiagramDocument34 pagesFe-C Phase DiagramYoung-long Choi100% (1)

- Fe-C Phase DiagramDocument34 pagesFe-C Phase DiagramYoung-long Choi100% (1)

- BHEL Earthing SystemDocument8 pagesBHEL Earthing SystemSimbu ArasanNo ratings yet

- Uts, Utn, Dry - Weld History Sheet - MasterDocument461 pagesUts, Utn, Dry - Weld History Sheet - MasterSimbu ArasanNo ratings yet

- 001 - Standard Procedure For Hydrostatic Pressure Test of PipingDocument8 pages001 - Standard Procedure For Hydrostatic Pressure Test of PipingSimbu Arasan0% (1)

- SaarnaDocument3 pagesSaarnagueridiNo ratings yet

- TATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Document4 pagesTATA PROJECTS LIMITED, SBU-Utility Services: Material Requisition Cum Issue Voucher (MRIV)Simbu ArasanNo ratings yet

- UF Membrane Storage & PreservationDocument1 pageUF Membrane Storage & PreservationSimbu ArasanNo ratings yet

- EPS Withdrawal FormDocument5 pagesEPS Withdrawal FormArun AbNo ratings yet

- Electrode Backing RegisterDocument4 pagesElectrode Backing RegisterSimbu Arasan100% (1)

- UF NF Dispatch Master Data 04-11-15Document47 pagesUF NF Dispatch Master Data 04-11-15Simbu ArasanNo ratings yet

- 006 CBCRDT Tata ProjectsDocument3 pages006 CBCRDT Tata ProjectsSimbu ArasanNo ratings yet

- 2645r - Waterproofing Compounds For Concrete and Cement MortarsDocument13 pages2645r - Waterproofing Compounds For Concrete and Cement MortarsSimbu ArasanNo ratings yet

- Structural Tank Instructions 11967-ADocument22 pagesStructural Tank Instructions 11967-Aiftikhar_khalid_1No ratings yet

- SWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtyDocument2 pagesSWRO-Mobile Plant Requirements: S.No Item Previous Qty Changed / Required QtySimbu ArasanNo ratings yet

- RO Plant Operation GuidelinesDocument5 pagesRO Plant Operation GuidelinesSimbu ArasanNo ratings yet

- Specifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionDocument12 pagesSpecifying Bolt Length For High-Strength Bolts: Manual of Steel ConstructionalbertoxinaNo ratings yet

- Mechanical Properties: Steel NutsDocument1 pageMechanical Properties: Steel NutsJoseph BookerNo ratings yet

- Course NotesDocument79 pagesCourse NotesMukesh KumarNo ratings yet

- G-Code Explained - List of Most Important G-Code CommandsDocument28 pagesG-Code Explained - List of Most Important G-Code CommandsAlejandro Nuñez VelasquezNo ratings yet

- External Metric ISO Thread Table Chart Sizes M20 - M55 - Engineers EdgeDocument5 pagesExternal Metric ISO Thread Table Chart Sizes M20 - M55 - Engineers EdgeMantasNo ratings yet

- 3Document8 pages3Muhammad HannanNo ratings yet

- ISO System of Limits and Fits (Tolerances)Document6 pagesISO System of Limits and Fits (Tolerances)skakerNo ratings yet

- Jis G 4053-2008Document21 pagesJis G 4053-2008ali ahmadNo ratings yet

- Extrusion Process Seminar ReportDocument11 pagesExtrusion Process Seminar ReportHimanshu PatelNo ratings yet

- Larslap Model K: Tools With The Cutting EdgeDocument4 pagesLarslap Model K: Tools With The Cutting Edgeemperor_vamsiNo ratings yet

- Datasheet For Metals GX 6 Crnimo 24-8-2Document2 pagesDatasheet For Metals GX 6 Crnimo 24-8-2andreNo ratings yet

- 1299 Ec1650Document4 pages1299 Ec1650Deepak HoleNo ratings yet

- SKD61-Die Steel Round BarDocument2 pagesSKD61-Die Steel Round BarAgustine SetiawanNo ratings yet

- Powerpoint Presentation: Cutting Tool and MaterialDocument27 pagesPowerpoint Presentation: Cutting Tool and MaterialMayank RawatNo ratings yet

- Sprue Bushing JIS B Type 635-636Document1 pageSprue Bushing JIS B Type 635-636NazriNo ratings yet

- Mcqs of CH 22 (B)Document3 pagesMcqs of CH 22 (B)shahnawaz875No ratings yet

- CNC Lathes for Bar, Rod and Section MillsDocument2 pagesCNC Lathes for Bar, Rod and Section Millsjeorgepoletto50% (2)

- STPE600 - Dadi A ProiezioneDocument17 pagesSTPE600 - Dadi A ProiezioneLucaNo ratings yet

- NERDC JSS3 BST Unified Schemes of WorkDocument3 pagesNERDC JSS3 BST Unified Schemes of WorkJonathan OjoNo ratings yet

- Is 1363 - 1 2002Document13 pagesIs 1363 - 1 2002Sourav HaitNo ratings yet

- Casting Material WCBDocument8 pagesCasting Material WCBYusri WyeuserieyNo ratings yet

- TES 101-158 - 7 - Hi PDFDocument8 pagesTES 101-158 - 7 - Hi PDFRossoNo ratings yet

- CBH-21-012 Stud Bolt M12 X 2000 HDG 8.8Document1 pageCBH-21-012 Stud Bolt M12 X 2000 HDG 8.8qualityNo ratings yet

- Cimcool Cimstar 585Document2 pagesCimcool Cimstar 585tribolasNo ratings yet