Professional Documents

Culture Documents

Pressure Drop

Uploaded by

Nyandoro E-max MaxmoreCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pressure Drop

Uploaded by

Nyandoro E-max MaxmoreCopyright:

Available Formats

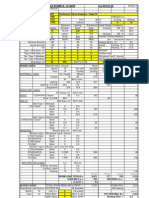

Where:

P=

Q=

L=

V=

D

4

=

Value Unit

Input= Gallons/Min

Input= Poise

Input= Feet

Input= Inches

Input= Inches

Input= 60 Feet/Min

60 = Standard

Value Unit

Output= 0 Inches

Output= 0.00 Gallons/Min

Output= 0.00 Gallons/Min

Output= 0 Feet

Output= 0 Poise

Output= 0

Tube Run

Tube Size

Tube factor (4th power of diameter in inches)

*calculate pressure drop in pipe or tube length by use of the following formula

Midway Industrial Systems

4759 Old Hwy 8, Mounds View, MN 55112

Name

Viscosity

Fluid Pressure Loss Calculations

Phone: 763-780-3000 Toll Free: 1-800-279-1401

www.midwayis.com

D

4

Flow rate in gallons per minute (GPM)

Length of pipe in feet

Viscosity of fluid in poise (100 centipoise = 1 poise)

V =Viscosity

D =Inside Tube Diameter

Q =Total Flow Rate

L =Tube Run Distance

(insert values in the green boxes and the tubing

characteristics will be calculated below)

Output

PSI Pressure Loss =

Inside Diameter

Circulation Flow Rate

Total Spray Rate

Name

Wall Thickness

Circulation Rate

Input

P=

0.0273 * Q * V * L

Pressure drop in pounds per square inch(PSI) over the length of

the tube/pipe

Factor D

4

0.0039

0.18

0.059

0.15

0.46

1.21

3.6

6.65

*Below 18.3

Pipe 180 Tee Tee

Size Gate Globe 45 90 Close Thru Thru

Inches Valve Valve Elbow Elbow Ret. Run Branch

1/2" 0.41 18.5 0.78 1.67 3.71 0.93 3.33

3/4" 0.54 24.5 1.03 2.21 4.9 1.23 4.41

1" 0.69 31.2 1.31 2.81 6.25 1.56 5.62

1 1/4 0.9 41 1.73 3.7 8.22 2.06 7.4

1 1/2 1.05 48 2.15 4.31 9.59 2.4 8.63

2 1.35 61.5 2.59 5.55 12.3 3.08 11.6

1/2 Schedule 40 Pipe

1 Schedule 40 Pipe

2 Schedule 40 Pipe

3/4 Schedule 40 Pipe

1 1/4 Schedule 40 Pipe

1 1/2 Schedule 40 Pipe

0.622

1/4 I.D. Nylon Tube

Tube or Pipe Size (inches)

Standard Tube and Pipe Factors

Factor D

0.25

1/4 Schedule 40 Pipe 0.65

0.493 3/8 Schedule 40 Pipe

0.824

Equivalent Length of standard pipe in feet

1.049

1.38

1.61

2.07

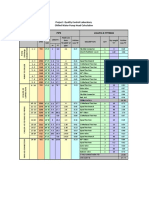

Where:

P=

Q=

L=

V=

D

4

=

Value Unit

Input= 0.375 Gallons/Min

Input= 1.9 Poise

Input= 276 Feet

Input= 0.75 Inches

Input= 0.035 Inches

Input= 0 Feet/Min

0.68 Inches

0 Gallons

Q= GPM

L= feet

V= poise

D= inches

2.07

0.65

0.493

0.0273 * Q * V * L

*Auto Calculator (insert valvues for Q,L,V, and D and the pressure drop will be

calculated in the red box labeled P below)

* note D not D

4

0.824

D

4

Tube factor (4th power of diameter in inches)

Pressure drop in pounds per square inch(PSI) over the length

of the tube/pipe

1.049

1.38

1.61

Inside Thicknes

Circulation Flow Rate

Total Spray Rate

0.622

Name

Viscosity

Tube Run

Tube Size

Wall Thickness

Circulation Rate

276

1.9

0.68

Pressure Loss = 25.11

0.375

PSI

1/4 I.D. Nylon Tube

Tube or Pipe Size (inches) Factor D

4

Standard Tube and Pipe Factors

Factor D

0.25

3/4 Schedule 40 Pipe

1 1/4 Schedule 40 Pipe

1 1/2 Schedule 40 Pipe

1/4 Schedule 40 Pipe

3/8 Schedule 40 Pipe

1/2 Schedule 40 Pipe

1 Schedule 40 Pipe

2 Schedule 40 Pipe

0.0039

0.18

0.059

0.15

0.46

1.21

3.6

6.65

18.3

Flow rate in gallons per minute (GPM)

Length of pipe in feet

Viscosity of fluid in poise (100 centipoise = 1 poise)

Fluid Pressure Loss Calculations

Phone: 763-780-3000 Toll Free: 1-800-279-1401

Web: www.midwayis.com

*calculate pressure drop in pipe or tube length by use of the following formula

P=

Pipe 180 Tee Tee

Size Gate Globe 45 90 Close Thru Thru

Inches Valve Valve Elbow Elbow Ret. Run Branch

1/2" 0.41 18.5 0.78 1.67 3.71 0.93 3.33

3/4" 0.54 24.5 1.03 2.21 4.9 1.23 4.41

1" 0.69 31.2 1.31 2.81 6.25 1.56 5.62

1 1/4 0.9 41 1.73 3.7 8.22 2.06 7.4

1 1/2 1.05 48 2.15 4.31 9.59 2.4 8.63

2 1.35 61.5 2.59 5.55 12.3 3.08 11.6

*Below is a list of equivilent lengths (a length in feet of tubing that is equivilent to the pressure loss

caused by a fitting, valve or elbow.) These lengths can be added to the length of the circulating

system you are calculating to take into account all pressure loss as seen by the system. This table

is broken down first by Nominal tubing size, and then gives the equivilent length in feet.

Equivalent Length of standard pipe in feet

You might also like

- Sample Calculations of Boiler Pumps and IDDocument5 pagesSample Calculations of Boiler Pumps and IDMati Dalam Penantian CintamuNo ratings yet

- Pump CalculationDocument4 pagesPump CalculationHai LeNo ratings yet

- Chapter-3 Air Handling UnitsDocument3 pagesChapter-3 Air Handling UnitsFaquruddin AliNo ratings yet

- Cooling Coil SizingDocument4 pagesCooling Coil SizingRanu JanuarNo ratings yet

- Hazen Williams Pressure Loss CalculatorDocument2 pagesHazen Williams Pressure Loss Calculatorchristian1909No ratings yet

- Yazd-System Description For Clean Drain System PDFDocument7 pagesYazd-System Description For Clean Drain System PDFace-winnieNo ratings yet

- Piping FormulaeDocument9 pagesPiping FormulaeVashish RamrechaNo ratings yet

- LASTlifting Pump PDSDocument3 pagesLASTlifting Pump PDSsunii19847908No ratings yet

- Ventilation DesignDocument4 pagesVentilation DesignPhyu Mar Thein KyawNo ratings yet

- Pipe Sizing Tabel From Program PipeSizer by McQuayDocument1 pagePipe Sizing Tabel From Program PipeSizer by McQuayMihailo Filipovič JelicNo ratings yet

- Heat Load CalculationDocument24 pagesHeat Load CalculationpradeepqNo ratings yet

- Relief Valve SizingDocument3 pagesRelief Valve SizingcutefrenzyNo ratings yet

- Chiller Size CalculatorDocument4 pagesChiller Size CalculatormpokeNo ratings yet

- RTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20Document1 pageRTS Heating and Cooling Loads GDS - SI Units Rev 2010-01-20alvinchuanNo ratings yet

- Hvac Chilled Water Pipe Size CalculationDocument16 pagesHvac Chilled Water Pipe Size CalculationAdedayo AdebimpeNo ratings yet

- Cooling Towers Certified by CTIDocument7 pagesCooling Towers Certified by CTIvsrajguruNo ratings yet

- Hazen Williams EquationDocument1 pageHazen Williams EquationNur IzzaidahNo ratings yet

- Density of WaterDocument5 pagesDensity of WaterJean Pajuelo0% (1)

- UPVC Pipe SizeDocument2 pagesUPVC Pipe Sizeahmedomar_953724702No ratings yet

- HDPE Manual: LamasatDocument51 pagesHDPE Manual: LamasatMalay Kar0% (1)

- Flow Velocity (FT/S) To GPM Conversion ChartDocument1 pageFlow Velocity (FT/S) To GPM Conversion Chartmonaco59No ratings yet

- Chilled Water Pump Head Calcultion: Section Valves & Fitings Pipe Size (Inch) Description of The Pipe RunDocument3 pagesChilled Water Pump Head Calcultion: Section Valves & Fitings Pipe Size (Inch) Description of The Pipe Runganesh gundNo ratings yet

- COMEP Duct Weight - ReturnDocument11 pagesCOMEP Duct Weight - ReturnAbdullah RamadanNo ratings yet

- SBD 6479 WaterCalcWorksheet 01 12Document4 pagesSBD 6479 WaterCalcWorksheet 01 12NghiaNo ratings yet

- 2.4 Static Pressure Spreadsheet 1Document4 pages2.4 Static Pressure Spreadsheet 1Jitendra KadamNo ratings yet

- DbA CalculationDocument4 pagesDbA Calculationthanh_79No ratings yet

- NFPA Pipe Sizing EXAMPLEDocument4 pagesNFPA Pipe Sizing EXAMPLEMatt AndersonNo ratings yet

- AE7E33 Excel Template Forced Convection H T Coeff Turb Pipe Flow Si UnitsDocument3 pagesAE7E33 Excel Template Forced Convection H T Coeff Turb Pipe Flow Si UnitsjnmanivannanNo ratings yet

- Heat Load Sheet - Individual RoomDocument2 pagesHeat Load Sheet - Individual RoomAnonymous 78q4M6g3RNo ratings yet

- Chilled Water Pump Head CalculationDocument18 pagesChilled Water Pump Head CalculationPeshoMagdyNo ratings yet

- Prima Usaha ACMV Duct Sizing Table 2017 LockedDocument1 pagePrima Usaha ACMV Duct Sizing Table 2017 LockedShaikh Tauseef100% (2)

- Chilled Water Flow, Pipe SizeDocument3 pagesChilled Water Flow, Pipe SizeSatya N.GNo ratings yet

- Copper Pipes (Based On Silver Book) : Purpose AssumptionsDocument3 pagesCopper Pipes (Based On Silver Book) : Purpose AssumptionscesNo ratings yet

- Hazen WilliamsDocument2 pagesHazen WilliamssushilkumarNo ratings yet

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectDocument1 pageDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyNo ratings yet

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- 2.4 Static Pressure Spreadsheet 1Document4 pages2.4 Static Pressure Spreadsheet 1Swapnil Pratap SinghNo ratings yet

- Design Calculation Sheet: A-Water DemandDocument1 pageDesign Calculation Sheet: A-Water DemandrahulrampNo ratings yet

- TIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredDocument3 pagesTIGERFLOW Booster Sizing Worksheet: I. Pressure RequiredAnonymous BJ9omONo ratings yet

- Water Pressure Loss Calculator Colebrook WhiteDocument5 pagesWater Pressure Loss Calculator Colebrook Whitebahus911No ratings yet

- ASHRAE 90 1 Kadj Calculator Revision 5Document9 pagesASHRAE 90 1 Kadj Calculator Revision 5Basil OguakaNo ratings yet

- Sizing Duct Work SheetDocument4 pagesSizing Duct Work SheetMaulana MaftuhiNo ratings yet

- Return Air Square: Ceiling DiffuserDocument1 pageReturn Air Square: Ceiling DiffuserEnak Cenir100% (1)

- Basics of Refrigeration - EvaporatorsDocument32 pagesBasics of Refrigeration - Evaporatorsfarazgazanfar-1No ratings yet

- Performance NT100M HVDocument1 pagePerformance NT100M HVAnonymous 3fTYXaW7WNo ratings yet

- Electrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)Document2 pagesElectrcial Room Ventilation System Calculation: X 1.005 X 5 Airflow (m3/hr)psjjoshiNo ratings yet

- World Highest Building (Burj Kalifa) Air DisruptionDocument40 pagesWorld Highest Building (Burj Kalifa) Air DisruptionPrabu RajaNo ratings yet

- Fans Static Head Calculation SheetDocument1 pageFans Static Head Calculation SheetraifaisalNo ratings yet

- Duck Work Calculation (Inch)Document2 pagesDuck Work Calculation (Inch)pratheeshNo ratings yet

- Calculation of Air Pipe SizeDocument6 pagesCalculation of Air Pipe SizePhyu Mar Thein Kyaw100% (1)

- K-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Document1 pageK-Flex Calculation Based On Ambient Temperature 30°C, RH 75% & H 11 (Final)Ah BengNo ratings yet

- tinh tổn thất áp lựcDocument2 pagestinh tổn thất áp lựcNghia Huynh NgocNo ratings yet

- FMV Spreadsheets-Master-FMVIDocument15 pagesFMV Spreadsheets-Master-FMVIadrianaortizv100% (1)

- Pipe SizingDocument2 pagesPipe Sizinggroup2sd1314No ratings yet

- Pressure DropDocument4 pagesPressure Dropsrishanthi82No ratings yet

- Fluid Pressure Loss Calculations: P 0.0273 Q V L DDocument7 pagesFluid Pressure Loss Calculations: P 0.0273 Q V L DsanjibkrjanaNo ratings yet

- Pump Head CalculationDocument1 pagePump Head CalculationMFaiz RHamiraNo ratings yet

- Paxtonengineeringbulletin PipingDocument4 pagesPaxtonengineeringbulletin PipingMuhammadObaidullahNo ratings yet

- Engineering FormulaeDocument49 pagesEngineering FormulaedestresscallNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Fire ExtinguishersDocument175 pagesFire ExtinguishersNyandoro E-max MaxmoreNo ratings yet

- Newsday 161122Document20 pagesNewsday 161122Nyandoro E-max MaxmoreNo ratings yet

- Tender Document: Directorate: Finance Supply Chain Management Unit Knysna Municipality PO Box 21 Knysna 6570Document46 pagesTender Document: Directorate: Finance Supply Chain Management Unit Knysna Municipality PO Box 21 Knysna 6570Nyandoro E-max MaxmoreNo ratings yet

- Fire Evacuation Plan A3 MultilanguageDocument1 pageFire Evacuation Plan A3 MultilanguageNyandoro E-max MaxmoreNo ratings yet

- Fire Equipment Tender DocumentDocument87 pagesFire Equipment Tender DocumentNyandoro E-max MaxmoreNo ratings yet

- The Warehousing of Aerosols: A BAMA Guide To Safe StorageDocument39 pagesThe Warehousing of Aerosols: A BAMA Guide To Safe StorageNyandoro E-max MaxmoreNo ratings yet

- Designing With BIM For Infrastructure On Large Transportation ProjectsDocument11 pagesDesigning With BIM For Infrastructure On Large Transportation ProjectsNyandoro E-max MaxmoreNo ratings yet

- AutoCAD MEP TutorialsDocument226 pagesAutoCAD MEP Tutorialsleonrio88% (17)

- Hyper-Heating INVERTER: Bringing Year-Round Comfort Solutions To Extreme ClimatesDocument8 pagesHyper-Heating INVERTER: Bringing Year-Round Comfort Solutions To Extreme ClimatesNyandoro E-max MaxmoreNo ratings yet

- Acoustic Louvre: Type NLDocument8 pagesAcoustic Louvre: Type NLNyandoro E-max MaxmoreNo ratings yet

- Re-Circulated Hot Water Bath Vaporizer: For Chlorine, Sulphur Dioxide and AmmoniaDocument3 pagesRe-Circulated Hot Water Bath Vaporizer: For Chlorine, Sulphur Dioxide and AmmoniaNyandoro E-max MaxmoreNo ratings yet

- Full Product Line Cataloque 2010 Split-Type - Air - ConditionersDocument268 pagesFull Product Line Cataloque 2010 Split-Type - Air - ConditionersNyandoro E-max MaxmoreNo ratings yet

- HVAC Layout 3DDocument1 pageHVAC Layout 3DNyandoro E-max MaxmoreNo ratings yet

- CI6401 - Corridor Deconstruction PDFDocument11 pagesCI6401 - Corridor Deconstruction PDFNyandoro E-max MaxmoreNo ratings yet

- Application For Contractor Registration Grade 2 - 9 (July 2016)Document16 pagesApplication For Contractor Registration Grade 2 - 9 (July 2016)Raymund WatsonNo ratings yet

- MP2531 - Revit MEP Fast Families For EngineersDocument10 pagesMP2531 - Revit MEP Fast Families For EngineersNyandoro E-max MaxmoreNo ratings yet

- Theory of Relativity Understanding Shared CoordinatesDocument14 pagesTheory of Relativity Understanding Shared CoordinatesNyandoro E-max MaxmoreNo ratings yet

- Imm MarketingDocument7 pagesImm MarketingNyandoro E-max MaxmoreNo ratings yet

- Refrigerant Charge Volume For R410A Heat Recovery Model Correction of Service Manual Si39-306Document12 pagesRefrigerant Charge Volume For R410A Heat Recovery Model Correction of Service Manual Si39-306Nyandoro E-max MaxmoreNo ratings yet

- AB3733 - The Autodesk® Revit® Theory of Relativity Understanding Shared Coordinates Presentation PDFDocument7 pagesAB3733 - The Autodesk® Revit® Theory of Relativity Understanding Shared Coordinates Presentation PDFNyandoro E-max MaxmoreNo ratings yet

- Link ClickDocument1 pageLink ClickNyandoro E-max MaxmoreNo ratings yet

- Pipe Sizing ChartDocument1 pagePipe Sizing ChartNyandoro E-max MaxmoreNo ratings yet

- Noise Level CalcDocument1 pageNoise Level CalcNyandoro E-max MaxmoreNo ratings yet

- Best Collaboration Practices Architect Structural Engineer Autodesk RevitDocument9 pagesBest Collaboration Practices Architect Structural Engineer Autodesk RevitNyandoro E-max MaxmoreNo ratings yet

- Pressed Steel TanksDocument10 pagesPressed Steel TanksNyandoro E-max MaxmoreNo ratings yet

- Automated Pressure Drop Calculator Rev 15Document7 pagesAutomated Pressure Drop Calculator Rev 15Nyandoro E-max MaxmoreNo ratings yet

- Pressure Drop CalculatorDocument5 pagesPressure Drop CalculatorNyandoro E-max Maxmore100% (4)

- KR - Air Cooled Screw (R134a - 50Hz - 60Hz) - HP - MFL61764718 - OCHAC-01A (101101)Document110 pagesKR - Air Cooled Screw (R134a - 50Hz - 60Hz) - HP - MFL61764718 - OCHAC-01A (101101)Nyandoro E-max MaxmoreNo ratings yet

- Ahu PD 22-07-2010Document40 pagesAhu PD 22-07-2010Nyandoro E-max MaxmoreNo ratings yet

- Pipeline QuestionnaireDocument3 pagesPipeline QuestionnairePasquale CutriNo ratings yet

- Hydraulic Unit: C P B M 0 0 0 - 2Gh - 1Document14 pagesHydraulic Unit: C P B M 0 0 0 - 2Gh - 1MoshMedNo ratings yet

- 13.375 in Casing Cement Ops PlanDocument2 pages13.375 in Casing Cement Ops PlanMohamed AbozeimaNo ratings yet

- Western Dam Engineering Technote-Vol1issue1Document13 pagesWestern Dam Engineering Technote-Vol1issue1Mark ReinhardtNo ratings yet

- Solenoid ValveDocument1 pageSolenoid Valvejayesh_1686No ratings yet

- PGS2 1997Document184 pagesPGS2 1997Pieter GrendelNo ratings yet

- A) Actuation of Hydraulic Cylinder To Find Pressure Vs Force AimDocument5 pagesA) Actuation of Hydraulic Cylinder To Find Pressure Vs Force AimChandrasekhar PrabhakaranNo ratings yet

- 4236.UNP.001.TKL.18 Merdare2 (Repaired) PDFDocument69 pages4236.UNP.001.TKL.18 Merdare2 (Repaired) PDFperfilma2013No ratings yet

- Me2134 2Document18 pagesMe2134 2FlancNo ratings yet

- Hydraulic Parts Hidros Pumps Motors Price ListDocument92 pagesHydraulic Parts Hidros Pumps Motors Price ListGiuro KralevNo ratings yet

- Fluidization and Its Applications To Food ProcessingDocument18 pagesFluidization and Its Applications To Food ProcessingAnonymous yPWi8p3KkANo ratings yet

- CHAPTER 3 ChillingDocument29 pagesCHAPTER 3 ChillingMADELNo ratings yet

- ChE132 - Case Study WriteupDocument20 pagesChE132 - Case Study WriteupKim Gines0% (1)

- Venturi Flowmeter Specification Sheet: Venturi Meter GAH Downstream Design Data DimensionsDocument1 pageVenturi Flowmeter Specification Sheet: Venturi Meter GAH Downstream Design Data Dimensionshardik033No ratings yet

- Weir Experiments.02Document14 pagesWeir Experiments.02alex100% (2)

- Drainage CapacityDocument33 pagesDrainage Capacityfan_luc89No ratings yet

- Unit 5 - Boundary LayerDocument110 pagesUnit 5 - Boundary LayerSREEJAUN T J (RA2111025010015)No ratings yet

- Chme 401 Chemical Engineering Laboratory Ii Experiment 401-4 Chemical Reactors ObjectiveDocument4 pagesChme 401 Chemical Engineering Laboratory Ii Experiment 401-4 Chemical Reactors ObjectiveDyako D TaherNo ratings yet

- A Model Study of Thermal Characteristics of Decarburization Annealing Furnace For Silicon Steel Strip PDFDocument8 pagesA Model Study of Thermal Characteristics of Decarburization Annealing Furnace For Silicon Steel Strip PDFد. علا محمد حداويNo ratings yet

- Refrigeration SystemsDocument50 pagesRefrigeration SystemsSneha RajasekarNo ratings yet

- Pump Course Material Chapter 1Document8 pagesPump Course Material Chapter 1engr victorNo ratings yet

- 1.85 Water and Wastewater Treatment Engineering Homework 3Document1 page1.85 Water and Wastewater Treatment Engineering Homework 3MuhammadUsmanNo ratings yet

- CO2 Presentation LAM 2003 06 PDFDocument81 pagesCO2 Presentation LAM 2003 06 PDFzikhail93No ratings yet

- Grundfos MTR SPK CRK MTCDocument7 pagesGrundfos MTR SPK CRK MTCEaster KongNo ratings yet

- حلول كتاب الهيت للدكتور عباس عليويDocument16 pagesحلول كتاب الهيت للدكتور عباس عليوينزار الدهاميNo ratings yet

- Distillation Equipment Parts and FunctionsDocument1 pageDistillation Equipment Parts and FunctionsNika Lutfiana60% (5)

- Gas Lift in Heavy Oil ManuscriptDocument9 pagesGas Lift in Heavy Oil Manuscriptmahmoud korieshNo ratings yet

- AL-905-R-11202 Spec AG01 Rev. T02Document3 pagesAL-905-R-11202 Spec AG01 Rev. T02altipatlarNo ratings yet

- Kala Amb ValleyDocument3 pagesKala Amb ValleyShivani SoniNo ratings yet

- Polymer Flooding IntroductionDocument50 pagesPolymer Flooding IntroductionAlexandra Cuellar GuasdeNo ratings yet