Professional Documents

Culture Documents

Belső Audit Kérdéslista

Uploaded by

Mózes Brassói0 ratings0% found this document useful (0 votes)

172 views10 pagesGMP+

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGMP+

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

172 views10 pagesBelső Audit Kérdéslista

Uploaded by

Mózes BrassóiGMP+

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

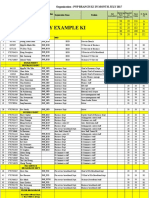

GMP+FSA module

version March, 2013 GMP+International 1

Art. Possible items for attention Freq. Interpretation Category 1 Interpretation Category 2

2.1

2.1 See A1, A2, A3 and A4 3

2.2

2.2 3

2.3 #It only applies to deliveries to Dutch

poultry farmers. #a positive Salmonella

analysis must be classified. #Reporting to

the poultry farmer and the Feed Safety

Database - monitoring of a positive result

and the classification must have taken

place. #Corrective measures must be

communicated to and harmonised with the

poultry farmer.

3 #The company repeatedly takes

no action with respect to a

positive Salmonella result.

#A positive result from a larger

series has been forgotten

(carelessness). #The report has

been made to the poultry farmer

but the details have not been sent

to the Feed Safety Database -

monitoring #The positive result

has been reported but the

classification has not been done.

#The reporting has not taken

place within 6 hours of receipt. #

No suitable corrective measures

have been taken

2.4 #This only applies to Dutch companies. 3

Art. Possible items for attention Freq. Interpretation Category 1 Interpretation Category 2

4.1

GMP+B3 (2007) Trade, collection and storage & transhipment

Description Interpretation Category 3

02 NORMATIVE REFERENCES

GMP+documents

Does the company comply with the

requirements specified in the A documents?

Statutory compliance

Does the participant comply with community

legislation, national legislation and good

manufacturing practice?

Has the participant implemented the duty to

report a positive Salmonella analysis in the

correct way?

Does the participant comply with the PDV

Regulation on Medicated Feed 2003?

Description Interpretation Category 3

04 FEED SAFETY SYSTEM

Management Responsibility

GMP+FSA module

version March, 2013 GMP+International 2

4.1 #Raising awareness of the importance of

feed safety, compliance with the

requirements of the customer and

compliance with the feed legislation. #

Assemble the HACCP team. #Make

sufficient resources available. #

Management review at least 1x/12 months.

3 #No demonstrable management

review carried out.

4.2

4.2 "The person that is responsible for quality: -

establishes the feed safety system - reports

to top management - ensures awareness of

feed safety in the organisation."

3

4.3

4.3 #The scope must in any event include all

feed ingredients and all activities which

relate to this. #The participant must also

describe all activities and/or products which

do not relate to feed.

3 #A section of the process is

excluded with a reason.

4.4

4.4.1 #Description of the scope. #HACCP

documentation #Required GMP+

procedures, instructions and records.

3 #Not in accordance with the

norm in essential areas.

4.4.2 #Documentation must be reviewed at least

every year by a competent person. #

Documentation must always be available to

and understandable by the personnel who

have to carry out the requirements of the

procedure. #Retention period for records is

at least three years.

3 #Necessary modifications not

implemented or not fully and the

situation in practice is behind the

current situation in the company

or the regulations. #There is a

backlog (>2 months) in the

relevant records. #Records are

not kept for the required period of

time.

Art. Possible items for attention Freq. Interpretation Category 1 Interpretation Category 2

5.0

5.0 #Reason for excluded prerequisites. #The

additional prerequisites have been worked

out and implemented.

3

5.1

Is management demonstrably involved in the

development and the implementation of the

feed safety system?

#No (quality) objectives laid

down.

Person responsible for quality

Is an employee appointed that is responsible

for feed safety?

Requirements for the feed safety system

Has the scope of the feed safety system,

including any particularities or exclusions,

been established and recorded?

#Not all non-GMP+activities are

fully described.

Documentation and registration

Does the manual include the required

sections?

#No full or correct representation

of what happens in practice.

Are documents and record details checked

and kept and maintained properly?

#Necessary modifications not

implemented or not fully but the

situation in practice corresponds

to the regulations. #Relevant

records have been overlooked or

are out of date (<2 months). #No

up-to-date description of the

method of archiving. #Relevant

records are not easily accessible.

Description Interpretation Category 3

05 PREREQUISITE PROGRAMMES

Prerequisite programme

Does the participant have an effective

prerequisites programme?

Personnel

GMP+FSA module

version March, 2013 GMP+International 3

5.1.1 #Organisational chart. #Descriptions of

the qualifications and the responsibilities of

supervisory personnel. #Rules with respect

to the wearing of protective clothing, eating,

drinking and smoking in the production and

storage areas are laid down.

3

5.1.2 #This applies in particular to the HACCP

team and to the other functions which

influence feed safety.

3 #Personnel do not understand

the procedures. #Principle of

HACCP is not known to the

personnel.

5.2

5.2.1 #If the environment does present risks the

the participant must show by way of an

analysis that the risks are satisfactorily

controlled.

3

5.2.2.1 #Production area and plant fit for

production and storage.

3

5.2.2.2 #Contamination should be avoided by

creating good conditions. #The intrusion of

rainwater and contaminated water should

be prevented during loading, unloading and

storage

3

5.2.2.3 #Suitable floors, walls and ceilings. 3

5.2.2.4 #In this section there are various

requirements with which the equipment

must comply.

3

5.2.3 3

5.2.4.1 #Residue norms in GMP+BA1 and the

carry-over test in accordance with GMP+

BA4 (if applicable)

3

5.2.4.2 3

5.2.4.3 #Quality of the water. 3

Are all personnel aware of their responsibility

for feed safety?

Are personnel expert and do they have the

necessary qualifications for carrying out the

work involved in the package of tasks and

has this been recorded and communicated?

#No suitable record of the

training courses, experience etc.

of employees. #Lack of relevant

refresher training.

Infrastructure

Does the environment present a hazard to

feed ingredients?

Do the production buildings present a hazard

for feed ingredients?

Are there sufficient areas for the reception

and loading and unloading of feed

ingredients and for potentially harmful

products?

Are there sufficient areas for the storage of

feed ingredients and for potentially harmful

products?

Is all the equipment which will be used for

the production of feed ingredients suitable for

their purpose?

Has an access regulation been established

for the production areas?

Have technical and organisational measures

been taken to prevent cross-contamination

and errors as much as possible?

Has the participant evaluated the risk of the

airflow which can possibly act as a means of

transport for pathogens and taken the

necessary precautions?

Is water or steam been used during cleaning

or in the processing of feeds safe for

animals?

GMP+FSA module

version March, 2013 GMP+International 4

5.2.4.4 #Effects of residues of processing aids on

the ready feeds.

3

5.2.4.5 3

5.3

5.3.1 #Also agreements with external companies

in relation to hygiene and safety.

3 #Structural non-compliance with

the established procedure.

5.3.2 #Dosage equipment for technical aids and

processing aids.

3

5.3.3 #Is the chosen cleaning method effective?

#An authorised person must carry out the

inspections with respect to the status of the

cleaning and maintain a record of this.

3 #Hygienic operation

unsatisfactory

5.3.4 #Permitted methods and means. #

Employees must have permission in

accordance with national legislation to carry

out pest control operations. #Waiting times

are taken into consideration (for example

during fumigation)

3 #Insufficiently effective

measures taken to deal with

vermin.

5.3.5 3 #Real risk that waste and

material which is not suitable for

feed becomes mixed with feed.

#Products which are not suitable

for delivery are not identified.

5.3.6 3

5.4

5.4.1 #Register with relevant details of the

purchase, production and sale by which

products can be recalled immediately,

specifically and accurately. #Details must

be available within 4 hours (or less if the

competent authority demands this)

3 #Insufficient records for tracking

& tracing.

5.4.2 #Sampling and storage in accordance with

GMP+BA13. #The samples must be

sealed and/or not openable and must be

clearly identifiable.

3

5.5

Has the participant carried out a risk

assessment of the use of processing aids to

show that there is no harmful effect to

humans, animals or the environment?

Is the packaging suitable for the feed in

question and for the chosen method of

delivery and transportation?

Maintenance and hygiene

Has the participant drawn up and

implemented a (documented) programme of

planned maintenance for all the relevant

areas and equipment?

#Incidental non-compliance with

the established procedure.

Is all the inspection, measurement and

testing equipment which is used calibrated at

intervals of a maximum of 12 months?

Are the production, storage and transport

facilities cleaned in such a way that the

safety of the feed ingredients can be

maintained?

Is use made of effective programmes for the

control of vermin or harmful organisms and is

this recorded?

#Demonstrability and

implementation not up-to-date.

Is waste stored and identified separately?

Are glass and breakable materials a hazard

for the feeds?

Identification and traceability / sampling

Are there suitable measures by which the

effective traceability of animal feeds is

guaranteed?

#Difficult to trace.

Are sufficient samples taken from the

incoming and/or outgoing feeds?

EWS and Recall

GMP+FSA module

version March, 2013 GMP+International 5

5.5 #If there is a potential hazard which can

not be controlled by the participant in

question and which may also cause

damage to others then the participant is

obliged to inform GMP+International

(procedure according to GMP+BA5). #A

recall simulation must be carried out at

least once per year

3 #The company omits to keep the

competent authority and GMP+

International informed

immediately.

Art. Possible items for attention Freq. Interpretation Category 1 Interpretation Category 2

6.1

6.1 #HACCP plan 3

6.2

6.2 #Carry out hazards analysis in accordance

with guidelines in chapter 6. #Should

consist of personnel from all the relevant

business activities and positions and at

least one member will have demonstrable

experience and knowledge of HACCP.

3 #No operational HACCP team. #Poorly functioning HACCP

team; no minutes from the

HACCP team meeting.

6.3

6.3.1 #Legal provisions and relevant GMP+

requirements. #Customer requirements. #

If the participant produces a feed material

then it should be included in the Feed

Safety Database with an identical

production method.

3 #Not in possession of required

legal certificates, records or

permits.

#No action taken as a result of

analysis results which are outside

the tolerances.

6.3.2 #This also applies to services. 3

6.3.3 #Waste flows and contracted out process

steps should also be included in the flow

diagram.

3

6.4

6.4.1 #This also applies to the processes in the

prior links such as raw materials and

additives.

3 #No hazards analysis. #Not all hazards specified.

6.4.2 3 #No risk estimation carried out. #Not all risk assessment hazards

identified. #No reasoning

recorded.

Is there a procedure available with respect to

EWS and has a recall-procedure been

established and implemented?

Description Interpretation Category 3

06 HACCP

Planning of the realisation of safe feed

Has the participant ensured that one or more

written procedures on the basis of HACCP

principles have been introduced,

implemented and maintained?

HACCP-Team

Has a HACCP team been established with

sufficient expertise from various different

disciplines?

#Lack of reasons for the

frequency of HACCP team

meetings. #Not all departments

represented. #Function of

advisor not established (if use is

made of this).

Description of products and processes

Has the participant determined and specified

all the (safety) requirements with respect to

the feeds to be produced?

#Not all norms are recorded,

complete, applied or analysed.

Has the participant also specified the raw

materials and other products which are used

during production?

Has the HACCP team drawn up a description

of the production process in the form of flow

diagrams?

Hazards analysis

Has the HACCP team identified and

documented all the potential hazards?

Has the HACCP team carried out a risk

assessment for each identified hazard?

GMP+FSA module

version March, 2013 GMP+International 6

6.5

6.5.1 #More than one control measure may be

necessary to control a risk and more than

one risk may be controlled by a single

control measure.

3

6.5.2 #The motivation for the CCP must be laid

down.

3 #The lacking of a motivation for a

CCP #Not all significant CCPs

have been identified

6.6

6.6 #See GMP+BA1 3

6.7

6.7 #Is the reasoning for the monitoring

programme available and is it demonstrably

based on the product norms from GMP+

BA1 and GMP+BA4. #Is there a check on

whether products comply with the product

specifications and the minimum product

requirements in GMP+BA1 and GMP+

BA4. #Are proper measures taken in the

event of deviation. #In the event of the

minimum requirements in GMP+BA1 and

GMP+BA4 being exceeded is the product

removed from use and are proper records

of this maintained. Duty to report in the

event of Salmonella contamination. #This

plan must at least comply with the

inspections established in this GMP+FSA

module. #Laboratory must comply with the

requirements of the GMP+FSA module.

See GMP+B10 for the requirements with

respect to the use of an external laboratory

3 #Analyses are carried out by an

uncertified laboratory.

#No records of controls and

inspections at the required points

(backlog of more than two

months). #Non-standard number

of sample tests. #No full insight

into whether the laboratory

complies with GMP+certification

for all analyses.

6.8

6.8 3 #No procedure available or

applied.

6.9

6.9.1 #If it is impossible to put together an

independent validation team then this must

be explained.

3

Establishing control measures and CCPs

(critical control points)

Has the HACCP team laid down and

implemented control measures for controlling

all risks which can have a negative effect on

feed safety?

Has the HACCP team assessed whether the

control measures form the last measure in

the process for the controlling of the risk?

Determination of standards

Has the HACCP team determined for each

CCP which parameters must be measured,

analysed or observed and which product

norms apply to these parameters?

Monitoring

Has a monitoring plan been drawn up in

writing and has it been implemented?

#Records of controls and

inspections have a backlog of

less than two months #No

description of the method of

sampling

Corrective actions

Have the non-conformities (in the animal

feed or process) with respect to this GMP+

standard been established and controlled?

#The procedure is incomplete.

Validation and verification

Has the HACCP system been validated by

an independent validation team?

GMP+FSA module

version March, 2013 GMP+International 7

6.9.2 3

Art. Possible items for attention Freq. Interpretation Category 1 Interpretation Category 2

7.1

7.1.1 3

7.1.2 3

7.1.2.1 See GMP+BA10. 3

7.1.2.2 See GMP+BA10. 3

7.1.2.3 See GMP+BA10. 3

7.1.3 #The suppliers should be assessed at

least once a year. #For the assessment of

growers its possible to be assessed as a

group of dentical' growers.

3

7.1.4 3 #No proper entry check or

sampling of delivered feed

materials. #No purchasing

requirements or specifications

check on supplied products.

7.1.5 The procedure should include: #

identification of the batch; #documentation

for the management of the non-standard

products; #assessment of the cause of the

non-conformity; #separation of the batch;

#communication with the parties involved; #

preventive or corrective actions to prevent

reoccurrence of the nonconformity.

3

7.1.6 The sepcification of feeds relates to safety

requirments

3

Has the participant verified the HACCP

system?

Description Interpretation Category 3

07 CONTROL OF OPERATIONAL ACTIVITIES

Trade in feeds

Did the participant draw up a procedure for

the whole trading process?

Do the purchased feeds and any other

products and services comply with the

specified purchasing requirements?

Did the participant assess his suppliers?

Does the participant comply with the

additional requirements for the purchase of

feed additives under gatekeeper conditions?

Does the participant comply with the

additional requirements for the purchase of

grains, seeds and legumes from uncertified

origin?

Does the participant comply with the

additional requirements for the purchase of

palm oil from uncertified origin?

Are the inspection activities established and

implemented to verify that the purchased

feeds are in accordance with the specified

requirements?

Does the participant have a procedure for

handling non-standard products?

Did the participant confirm the specification

of the feed in a contract?

GMP+FSA module

version March, 2013 GMP+International 8

7.1.7 "If a participant trades non-GMP+certified

feeds then the status of these must be

reported to the customer in writing. This

applies in the event of delivery to GMP+

certified customers or customers who are

certified in another certification scheme

which has been declared to be equivalent

to the GMP+scheme (see GMP+BA10

Minimum Requirements for Purchasing).

3

7.2

7.2.2 #Gatekeeper feed additives: product is in

the original packaging. #Does the transport

meet the requirements set (minimum check

on the GMP certification of the carrier,

compliance with loading sequence, prior

loads and implementation of necessary

cleaning regimes, oil leaks). #In the event

of doubt are the specifications verified

using analyses.

3 No proper entry check or

sampling of delivered feed

materials.

7.2.3 #Crosscontamination is prevented #Check

on fungus. #Usage of legally allowed

protectionagents is documented according

to requirements. #Storage and

transhipment at a third party will be

according to the requirements of this

standard.

3

7.2.4 Sieving: - sieve maintenance plan, - person

responsible for checks, - random sample

visual inspection of the sieved batches

3

7.2.5 #The fuels used for direct drying are

compliant with Appendix 1 of this

standard.#Responsible person checks the

moisture content after drying or

ventilation.#Implemented maintenance

plan for driers and fans.

3 Use of prohibited fuels. Use of fuel not based on risk

assessment.

7.2.6 See paragraph 1.3 for the other activities

which are allowed to be carried out with this

certificate.

3

Are the batches accompanied by the legally-

required product information?

Storage

Is each incoming delivery of feed verified in

accordance with an established procedure?

Are the storage and transhipment activities

of the participant controlled with the

participants own feed safety system

according to the requirements of this

standard?

Is the presence of contaminants such as

glass, wood or earth in the feeds limited as

much as possible?

Are the right methods used for drying and

ventilating feed?

Are other activities, if any, controlled on the

basis of the HACCP principles?

GMP+FSA module

version March, 2013 GMP+International 9

7.2.7 The procedure comprises at any rate the

following parts: #identification of batch / lot

; #documentation on management #

assessment of the cause of the deviation; #

separation of the batch / lot concerned;

#communication with parties involved;

preventive or corrective actions to avoid

repetition.

3

7.2.8 #Are the responsibilities clear /

demonstrable and verifiable? #Does the

participant also comply with any other

requirements as agreed with the client?

3

7.3

7.3.1 3 Unintentional mixing and

microbiological contamination can

not be prevented.

7.3.2 #Is there minimally worked in accordance

with the procedures GMP+International

published on the IDTF website. #Transport

of packaged products is exempted from

certification.

3 #No cleaning programme

present or not implemented if

necessary. #No release by

competent authority / inspection

body after a banned cargo and

for transport of feed.

#Cleaning programme is

incomplete or is not complied with

properly. #Use of disinfection

after transport of products with

cleaning regime D is not

demonstrable. #No validation of

effectiveness of cleaning.

7.3.3 See the GMP+standard for the various

requirements for transport within and

outside the Netherlands and the see GMP+

BA10 Minimum Requirements for

Purchasing #If a participant makes use of

an external carrier for the transport of

packaged feed then this external carrier

and / or fright broker does not have to be

GMP+certified or equivalent (Risk

assessments must consider any potential

hazards). #Transport of packaged raw

materials or feed ingredients must take

place in a clean and dry loading

compartment. #Under certain conditions

sealed loading units are considered to be

packaged products and therefore non-

certified external carriers can be used

(allowed when non-certified external carrier

has no influence on the transported raw

3

Has the participant implemented a procedure

for dealing with deviating products?

If the participant stores animal feed by

means of service, does the participant meet

all relevant GMP+conditions?

Transport

Does transport lead to undesired

contamination of the feed?

Is road transport carried out in accordance

with the certification requirements of this

standard?

Validation of cleaning

effectiveness is not carried out

satisfactorily.

Does the road transport carried out by a

service provider comply with the GMP+

requirements?

GMP+FSA module

version March, 2013 GMP+International 10

7.3.4 #Transport to a GMP B1 company:

Affreightment of inland waterways in

Europe is GMP B4.2-certified; carriers

within Europe are GMP B4.3 certified;

affreightment of sea transport is GMP B4.4

certified; affreightment of rail transport is

GMP B4.5 certified. #Transport to other

companies: LCI by an inspection agency at

EN 17020 level or a company loading

inspector. The shipper may not undertake

his own LCI.

3

7.3.5 3

Art. Possible items for attention Freq. Interpretation Category 1 Interpretation Category 2

8.1

8.1 #Complaints registration 3

8.2

8.2 3 #Essential sections /

departments were not audited. #

Insufficient depth / insufficient

reporting on findings,

improvement measures not

demonstrable. #Internal audit

was carried out more than a 12

months ago.

8.3

8.3 #Documented procedure. #Corrective

actions #Preventive measures.

3

Is transport by inland waterway, sea or train

carried out in accordance with the

certification requirements of this standard?

If a third party is responsible for the road

transport, has the participant taken

reasonable precautions to prevent potential

hazards?

Description Interpretation Category 3

08 VERIFICATION AND IMPROVEMENT

Complaints

Is there a documented procedure for

handling customer complaints?

Is there a regular assessment of whether the

feed safety system can be improved?

Internal audit

Are internal audits carried out at least once

per 12 months?

#Improvement measures from

the internal audit are not

demonstrably monitored /

followed up.

Assessment of the management system and

improvements

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Quanta To QuarksDocument32 pagesQuanta To QuarksDaniel Bu100% (5)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Mathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XDocument32 pagesMathematics - Mathematics of Magic - A Study in Probability, Statistics, Strategy and Game Theory XHarish HandNo ratings yet

- Guideline - Research ProposalDocument38 pagesGuideline - Research ProposalRASNo ratings yet

- Republic of The Philippines Division of Bohol Department of Education Region VII, Central VisayasDocument6 pagesRepublic of The Philippines Division of Bohol Department of Education Region VII, Central VisayasJOHN MC RAE RACINESNo ratings yet

- 9881 enDocument345 pages9881 enSaid BenNo ratings yet

- Measurement and Scaling Techniques1Document42 pagesMeasurement and Scaling Techniques1Ankush ChaudharyNo ratings yet

- DCN Dte-Dce and ModemsDocument5 pagesDCN Dte-Dce and ModemsSathish BabuNo ratings yet

- A Semi-Detailed Lesson Plan in MAPEH 7 (PE)Document2 pagesA Semi-Detailed Lesson Plan in MAPEH 7 (PE)caloy bardzNo ratings yet

- Barrett Beyond Psychometrics 2003 AugmentedDocument34 pagesBarrett Beyond Psychometrics 2003 AugmentedRoy Umaña CarrilloNo ratings yet

- June 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelDocument16 pagesJune 2017 (IAL) MS - Unit 1 Edexcel Physics A-LevelNyraStardollNo ratings yet

- Sheltered 2 Item Recycle ListDocument5 pagesSheltered 2 Item Recycle ListRachel GNo ratings yet

- Chapter 2.3.3 History of Visual Arts Modernism Post ModernismDocument17 pagesChapter 2.3.3 History of Visual Arts Modernism Post ModernismKim Ashley SarmientoNo ratings yet

- Unbound DNS Server Tutorial at CalomelDocument25 pagesUnbound DNS Server Tutorial at CalomelPradyumna Singh RathoreNo ratings yet

- Nfpa 1126 PDFDocument24 pagesNfpa 1126 PDFL LNo ratings yet

- Inventions Over The Last 100 YearsDocument3 pagesInventions Over The Last 100 YearsHombreMorado GamerYTNo ratings yet

- SDN Van NotesDocument26 pagesSDN Van Notesmjsmith11No ratings yet

- PNP Ki in July-2017 AdminDocument21 pagesPNP Ki in July-2017 AdminSina NeouNo ratings yet

- ETNOBotanica NombresDocument188 pagesETNOBotanica Nombresjalepa_esNo ratings yet

- Lesson 1 Q3 Figure Life DrawingDocument10 pagesLesson 1 Q3 Figure Life DrawingCAHAPNo ratings yet

- PetrifiedDocument13 pagesPetrifiedMarta GortNo ratings yet

- FINAL BÁO-CÁO-THỰC-TẬP.editedDocument38 pagesFINAL BÁO-CÁO-THỰC-TẬP.editedngocthaongothi4No ratings yet

- Coal Bottom Ash As Sand Replacement in ConcreteDocument9 pagesCoal Bottom Ash As Sand Replacement in ConcretexxqNo ratings yet

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDocument18 pagesGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDNo ratings yet

- E-Mobility and SafetyDocument77 pagesE-Mobility and SafetySantosh KumarNo ratings yet

- EngHub How To Break HabitsDocument13 pagesEngHub How To Break HabitsViktoria NovikovaNo ratings yet

- Liquitex Soft Body BookletDocument12 pagesLiquitex Soft Body Booklethello belloNo ratings yet

- All India Civil Services Coaching Centre, Chennai - 28Document4 pagesAll India Civil Services Coaching Centre, Chennai - 28prakashNo ratings yet

- Cambridge IGCSE: CHEMISTRY 0620/42Document12 pagesCambridge IGCSE: CHEMISTRY 0620/42Khairun nissaNo ratings yet

- ET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsDocument5 pagesET4254 Communications and Networking 1 - Tutorial Sheet 3 Short QuestionsMichael LeungNo ratings yet

- Veritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationDocument64 pagesVeritas™ High Availability Agent For WebSphere MQ Installation and Configuration Guide / WebSphere MQ InstallationkarthickmsitNo ratings yet