Professional Documents

Culture Documents

WEG Turbogenerator 10174576 Manual English

Uploaded by

anon_598655076Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WEG Turbogenerator 10174576 Manual English

Uploaded by

anon_598655076Copyright:

Available Formats

Motors | Automation | Energy | Paints

Turbogenerator

S Line

Installation, Operation and Maintenance Manual

www.weg.net

Line S Turbogenerator l 1

Installation, Operation and Maintenance Manual

Document No.: 9300.0050

Model: Line S Turbogenerator

Material: 10174576

Language: English

Revision 1

March, 2010

www.weg.net

2 l Line S Turbogenerators

February 2008

www.weg.net

Line S Turbogenerator l 3

Dear Customer

Thank you for purchasing a WEG generator. It is a product developed with high levels of

quality and efficiency to ensure excellent performance.

Electric energy plays an outstanding role in the comfort and well-being of humankind. Being

responsible for the production of this energy, the electric generator needs to be identified and

treated as a machine whose characteristics demand special care, particularly with regard to

storage, installation and maintenance procedures.

All efforts have been made to ensure that the information contained in this manual can be

reliably used for setting up and running the WEG generator.

So please read this manual carefully before the installation, operation or maintenance of your

generator for a continuous and safe operation and to ensure that all measures have been

taken for your safety and the safety of your facilities. If any doubts persist, please contact

WEG.

Keep this manual always close to the generator for prompt reference when required.

ATTENTION

1. It is absolutely necessary to follow the procedures contained in this manual for the warranty to be valid.

2. The generator installation, operation and maintenance must be executed by qualified personnel.

NOTES

1. The total or partial reproduction of the information supplied in this manual is authorized, provided that

reference is made to its source;

2. If this manual is lost, an electronic PDF file is available from our website www.weg.net or another

printed copy can be requested.

WEG EQUIPAMENTOS ELTRICOS S.A.

www.weg.net

4 l Line S Turbogenerators

www.weg.net

Line S Turbogenerator l 5

CONTENTS

1 INTRODUCTION.........................................................................................................................................9

2 GENERAL INSTRUCTIONS.....................................................................................................................10

2.1 QUALIFIED PERSONNEL ....................................................................................................................................... 10

2.2 SAFETY INSTRUCTIONS........................................................................................................................................ 10

3 OPERATING CONDITIONS AND STANDARDS.....................................................................................11

3.1 STANDARDS............................................................................................................................................................ 11

3.2 ENVIRONMENT CHARACTERISTICS................................................................................................................... 11

3.3 OPERATING CONDITIONS.................................................................................................................................... 11

4 RECEIVING AND STORAGE...................................................................................................................12

4.1 RECEIVING............................................................................................................................................................... 12

4.2 STORAGE................................................................................................................................................................. 12

4.2.1 Indoor storage ....................................................................................................................................12

4.2.2 Outside storage ..................................................................................................................................12

5 LONG STORAGE PERIODS....................................................................................................................13

5.1 INTRODUCTION...................................................................................................................................................... 13

5.2 GENERAL................................................................................................................................................................. 13

5.3 STORAGE LOCATION............................................................................................................................................ 13

5.3.1 Indoor storage ....................................................................................................................................13

5.3.2 Outdoor storage .................................................................................................................................13

5.4 SEPARATE PARTS.................................................................................................................................................. 14

5.5 SPACE HEATER...................................................................................................................................................... 14

5.6 INSULATION RESISTANCE.................................................................................................................................... 14

5.7 EXPOSED MACHINED SURFACES...................................................................................................................... 14

5.8 ROLLING BEARINGS.............................................................................................................................................. 14

5.8.1 Grease-lubricated bearing...................................................................................................................14

5.8.2 Oil-lubricated bearing..........................................................................................................................14

5.8.3 Sleeve Bearing....................................................................................................................................14

5.9 TERMINAL BOX....................................................................................................................................................... 15

5.10 PREPARATION FOR OPERATION AFTER LONG STORAGE............................................................................ 15

5.10.1 Cleaning .............................................................................................................................................15

5.10.2 Bearing lubrication ..............................................................................................................................15

5.10.3 Checking the insulation resistance ......................................................................................................15

5.10.4 Others ................................................................................................................................................15

5.11 INSPECTIONS AND RECORDS DURING THE STORAGE................................................................................. 15

5.12 MAINTENANCE PLAN TO BE FOLLOWED DURING THE STORAGE.............................................................. 16

6 HANDLING ...............................................................................................................................................17

7 INSULATION RESISTANCE....................................................................................................................18

7.1 SAFETY INSTRUCTIONS........................................................................................................................................ 18

7.2 GENERAL REMARKS............................................................................................................................................. 18

7.3 STATOR WINDING MEASUREMENT.................................................................................................................... 18

7.4 MEASUREMENT OF THE ROTOR WINDING RESISTANCE, EXCITER WINDING RESISTANCE AND

ACCESSORIES..................................................................................................................................................................... 18

7.5 CONVERSION OF THE MEASURED VALUES..................................................................................................... 19

7.6 MINIMUM INSULATION RESISTANCE.................................................................................................................. 19

7.7 POLARIZATION INDEX............................................................................................................................................ 19

8 CONSTRUCTION CHARACTERISTICS..................................................................................................20

8.1 STATOR.................................................................................................................................................................... 20

8.2 ROTOR..................................................................................................................................................................... 20

8.3 EXCITER................................................................................................................................................................... 20

www.weg.net

6 l Line S Turbogenerators

8.4 PERMANENT MAGNET GENERATOR (PMG)......................................................................................................20

8.5 DUMPING WINDING...............................................................................................................................................20

8.6 BEARINGS................................................................................................................................................................20

8.7 HEAT EXCHANGER................................................................................................................................................20

9 OPERATION PRINCIPLE........................................................................................................................ 21

9.1 EXCITATION.............................................................................................................................................................21

9.2 DEEXCITATION........................................................................................................................................................21

9.3 VOLTAGE REGULATOR.........................................................................................................................................22

9.4 UNDERFREQUENCY (U/F) PROTECTION............................................................................................................22

10 INSTALLATION....................................................................................................................................... 23

10.1 INSTALLATION SITE................................................................................................................................................23

10.2 PROTECTIONS........................................................................................................................................................23

10.3 DIRECTION OF ROTATION...................................................................................................................................23

10.4 FOUNDATIONS........................................................................................................................................................23

10.5 ANCHOR PLATE SET .............................................................................................................................................24

10.6 ALIGNMENT / LEVELING........................................................................................................................................25

10.7 COUPLING...............................................................................................................................................................25

10.8 ELECTRICAL AND GROUNDING CONNECTIONS.............................................................................................27

10.8.1 Main stator connections (power cables).............................................................................................. 27

10.8.2 Grounding.......................................................................................................................................... 27

10.8.3 Accessories ....................................................................................................................................... 27

10.9 THERMAL PROTECTIONS.....................................................................................................................................27

10.9.1 Protection location ............................................................................................................................. 27

10.9.2 Temperature sensors ......................................................................................................................... 27

10.9.3 Temperature limits for the windings .................................................................................................... 27

10.9.4 Thermal bearing protections............................................................................................................... 28

10.9.5 Alarm and disconnection temperatures .............................................................................................. 28

10.9.6 Ratio between temperature and the ohmic resistance of Pt 100 temperature sensors......................... 28

10.9.7 Space heater ..................................................................................................................................... 29

10.10 PANEL PROTECTIONS...........................................................................................................................................29

10.11 GENERATOR COOLING.........................................................................................................................................29

10.12 WATER RADIATORS...............................................................................................................................................30

11 ELECTRICAL CONNECTIONS AND ACCESSORIES........................................................................... 31

11.1 TERMINAL MARKINGS...........................................................................................................................................31

11.2 WIRING DIAGRAMS................................................................................................................................................31

11.2.1 Thermal protection on main stator winding......................................................................................... 32

11.2.2 Generator cooling system .................................................................................................................. 33

11.2.3 Bearings ............................................................................................................................................ 34

11.2.4 Space heater and exciter ................................................................................................................... 35

11.3 DESCRIPTION OF THE ACCESSORY FUNCTION..............................................................................................35

11.4 ACCESSORIES AND PROTECTIONS...................................................................................................................36

12 START-UP 37

12.1 BEFORE FIRST START-UP.....................................................................................................................................37

12.2 INITIAL MECHANICAL TURN.................................................................................................................................37

12.3 POWERING-UP.......................................................................................................................................................37

12.4 SYNCHRONIZATION AND LOAD..........................................................................................................................37

13 GENERATOR OPERATION.................................................................................................................... 38

13.1 SHAFT LIFTING SYSTEM (JACKING) ....................................................................................................................38

13.2 WATER RADIATORS...............................................................................................................................................38

13.3 BEARINGS................................................................................................................................................................38

13.4 VIBRATION LIMITS..................................................................................................................................................38

13.5 SHAFT VIBRATION LIMITS.....................................................................................................................................38

13.6 STOP 39

14 MAINTENANCE....................................................................................................................................... 40

14.1 GENERAL.................................................................................................................................................................40

14.2 GENERATOR CLEANING.......................................................................................................................................40

www.weg.net

Line S Turbogenerator l 7

14.3 STATOR, ROTOR AND EXCITER WINDING INSPECTIONS............................................................................... 40

14.4 WINDINGS CLEANING........................................................................................................................................... 40

14.5 INSPECTION AND CLEANING OF RADIATORS................................................................................................. 41

14.6 GENERATOR OUT OF SERVICE........................................................................................................................... 41

15 BEARINGS 42

15.1 SLEEVE BEARINGS................................................................................................................................................ 42

15.1.1 Bearing connections ...........................................................................................................................42

15.1.2 Bearings data .....................................................................................................................................42

15.1.3 Bearings installation and operation......................................................................................................42

15.1.4 Hydrostatic jacking system .................................................................................................................42

15.1.5 Setting of the bearing protections .......................................................................................................42

15.1.6 Lubrication..........................................................................................................................................42

15.1.7 Sealing ...............................................................................................................................................43

15.1.8 Bearing maintenance ..........................................................................................................................43

15.2 OIL BEARINGS......................................................................................................................................................... 43

15.2.1 Lubrication guidelines .........................................................................................................................43

15.2.2 Bearing operations..............................................................................................................................43

15.2.3 Protection device settings...................................................................................................................43

15.3 GREASE BEARINGS............................................................................................................................................... 44

15.3.1 Lubrication guidelines .........................................................................................................................44

15.3.2 Steps for bearing re-lubrication ...........................................................................................................44

15.3.3 Spring device for grease removal ........................................................................................................44

15.3.4 Protection settings..............................................................................................................................44

15.3.5 Bearing replacement...........................................................................................................................45

16 EXCITER 46

16.1 EXCITER................................................................................................................................................................... 46

16.2 DIODES TEST.......................................................................................................................................................... 46

16.3 DIODES REPLACEMENT ....................................................................................................................................... 47

16.4 VARISTORS TEST................................................................................................................................................... 47

16.5 VARISTORS REPLACEMENT................................................................................................................................ 47

17 GENERATOR PARTS..............................................................................................................................48

18 MAINTENANCE SCHEDULE...................................................................................................................49

19 TROUBLESHOOTING..............................................................................................................................50

20 ACCESSORIES AND SPARE PARTS.....................................................................................................52

21 DOCUMENTS...........................................................................................................................................53

22 WARRANTY CONDITIONS OF ENGINEERED PRODUCTS .................................................................54

www.weg.net

8 l Line S Turbogenerators

www.weg.net

Line S Turbogenerator l 9

1 INTRODUCTION

THE TURBOGENERATOR

The turbogenerator is a machine that operates as an electric power generator when its shaft is driven by a turbine.

THE THERMAL ELECTRIC POWER GENERATION PROCESS

The fuel is burned in a boiler. The boiler heats a water volume, which changes into steam. The steam drives the turbine rotor

that turns the generator shaft. The electromagnetic action inside the generator generates electric power that is supplied to

the consumer network.

TERMINOLOGY

S P W 1250

S GENERATOR LINE

S Line

EXCITATION TYPE

P - Brushless with auxiliary exciter

S - Brushless without auxiliary exciter

COOLING SYSTEM

W - Air-water heat exchanger

A Open, self-ventilated

D - Self-ventilated by ducts, air inlet and outlet

T - Forced ventilation, air inlet and outlet by ducts

V - Forced ventilation, ventilation on the generator

F - Self-ventilated with air-to-air heat exchanger on top of generator

I - Forced ventilation in the internal and external air circuit, air-to-air heat exchanger

L - Air-to-water heat exchanger, forced ventilation in the internal air circuit

IEC FRAME SIZE

Shaft-end height in mm (450 to 5000)

SAFETY WARNINGS IN THE MANUAL

Following safety warnings are used in this manual:

DANGER

The noncompliance with the procedures recommended in this warning may result in death, serious injuries

and considerable material damages.

ATTENTION

The noncompliance with the procedures recommended in this warning may result in material damages.

NOTE

The purpose of this text is to supply important information for the correct and good performance of this

product.

www.weg.net

10 l Line S Turbogenerators

2 GENERAL INSTRUCTIONS

ATTENTION

All the procedures and rules contained in

this manual must be followed accordingly

to ensure the good operation of the

equipment and safety of the personnel

involved in its operation. The compliance

with these procedures is equally important

to ensure the application of the warranty

terms on the back cover of this manual.

We strongly recommend a detailed reading

of this manual before the generator

installation and operation. However, in

case any doubt persists, please contact

your nearest WEG representative.

For practical reasons, it is impossible to supply in this

manual all the details regarding possible construction

alternatives. In addition, it is impossible to consider all the

imaginable cases of operation or maintenance.

For this reason, this manual contains only the required

information so that qualified and trained personnel may

perform the required services.

2.1 QUALIFIED PERSONNEL

People who, because of their education, experience,

instruction and knowledge of applicable standards and

safety procedures about the corresponding service

conditions, are duly authorized to operate and monitor

the generator. They must also be knowledgeable about

first-aid procedures and be capable of providing these

services if required.

It is assumed, that all commissioning, maintenance and

repair works will only be performed by qualified

personnel.

2.2 SAFETY INSTRUCTIONS

DANGER

During operation of this equipment, there will

be exposed energized or rotating parts with

high voltage or high temperatures.

Thus, its operation with open terminal boxes,

unprotected couplings or erroneous handling,

without considering the operation standards,

may cause serious personal injury and

property damage.

The people responsible for the installation safety must

assure that:

Only qualified personnel will perform the installation

and operation of the equipment;

These people will have in hand this manual and other

documents supplied with the generator and will also

perform the works, strictly complying with the service

instructions, standards and the product specific

documentation;

People not qualified will be forbidden to carry out

works on the electric equipment.

The noncompliance with the installation and safety rules

may void the product warranty.

Firefighting equipment and first aid warnings will be

located in the work site in visible and accessible places.

The following should also be observed:

All technical data regarding the allowed applications

(operating conditions, connections and installation

environment) contained in the catalog, purchase order,

operating instructions, manuals and other documents;

The specific determinations and conditions for the local

installation;

The use of proper tools and equipment for handling

and transport;

That the protection devices of the components are

removed little before the installation;

The individual parts must be stored in vibration-free

rooms, preventing falls and assuring that they are

protected against rodents and/or may pose risks to

people safety.

www.weg.net

Line S Turbogenerator l 11

3 OPERATING CONDITIONS AND STANDARDS

3.1 STANDARDS

WEG turbogenerators are specified, designed, manufactured and tested according to the following standards:

Specification

IEC-60034.1

VDE-0530

NBR 5117

Tests IEC-60034.2 NBR 5052

Degree of protection IEC-60034.5 NBR 6146

Cooling IEC-60034.6 NBR 5110

Mountings IEC-60034.7 NBR 5031

Noise IEC-60034.9 NBR 7565

Mechanical vibration IEC-60034.14 NBR 7094

Mechanical tolerances ISO 286 NBR 6158

Balancing ISO 1940 NBR 8008

Table 3.1: Standards

3.2 ENVIRONMENT CHARACTERISTICS

Turbogenerators are designed to be operated in following ambient conditions:

Ambient temperature: 15C to + 40C;

Altitudes: up to 1,000 m;

Environments without the presence of aggressive agents, such as: sea air, chemicals, etc.;

Environments according to the degree of protection of the generator.

ATTENTION

For turbogenerators fitted with air-to-water heat exchanger, ambient temperature should not be lower than +5C

and the cooling water temperature should be from +5C to +25C.

Special operation conditions can be met upon request and are indicated on the nameplate and data sheet specific for each

machine.

3.3 OPERATING CONDITIONS

The operating conditions of the generator must comply with the nameplate data, applicable standards and codes, as well as

with this manual in order to assure warranty coverage.

www.weg.net

12 l Line S Turbogenerators

4 RECEIVING AND STORAGE

4.1 RECEIVING

All generators are factory tested and supplied in perfect

operating conditions. The machined surfaces are

corrosion protected. The box or container must be

inspected right after receipt and checked for any damages

that may be caused during the transport.

ATTENTION

Any damage must be reported immediately to

the carrier, the insurance company and WEG.

If such a condition is not reported, the

warranty will be void.

ATTENTION

Parts supplied in additional packages or

volumes must be checked when received

according the complete packing list.

When the package (or container) is lifted, following

items must be checked: hoist components, the weight

indicated on the packaging or on the nameplate, hoist

capacity and operation.

Generators packed in wooden crates must be lifted

always by their own eyebolts or by suitable forklift and

never lifted by its wooden packing box.

Neither the generator nor its packaging should be

dropped or submitted to any impact. Place it on the

ground carefully (without impacts) to prevent bearing

damages.

Do not remove the protecting grease from the shaft end

nor the rubber seals or the plugs from the terminals

boxes.

These protections items must be kept in place until the

final installation has been concluded. After unpacking,

make a complete visual inspection of the generator.

Remove the shaft-lock device and kept it safe for future

transport of the generator.

ATTENTION

If any damage is detected, it must be

photographed, documented and reported

immediately to the carrier company and to

your nearest WEG representative.

4.2 STORAGE

Any damage to the painting or to the rust protections on

the machined surfaces must be retouched.

ATTENTION

The space heaters must be switched ON

always the generator is not operating.

4.2.1 Indoor storage

When the generator is not unpacked immediately, the box

should be stored in a place protected against moisture,

vapors, sudden change of temperature, rodents and

insects.

The site must be free of vibrations to prevent bearing

damage.

4.2.2 Outside storage

If possible, choose a dry site, free of floods and vibrations.

Repair all damages to the packages before storing the

equipment. This is required to ensure the appropriate

storage conditions.

Store the machines, devices and crates on pallets, wood

beams or foundations that provide protection against

ground moisture.

Prevent the equipment from sinking into the soil. Assure

free airflow under the equipment.

The covering or tarpaulin used to protect the equipment

against the weather should not be in contact with the

equipment surfaces. Assure appropriate air circulation by

placing wooden spacer blocks between the equipment

and the respective covering.

www.weg.net

Line S Turbogenerator l 13

5 LONG STORAGE PERIODS

5.1 INTRODUCTION

The instructions for long storage periods described below

are valid for generators that are stored during long time

before their commissioning and/or are not operated

during long periods.

5.2 GENERAL

The existing tendency, especially during the plant

construction, of storing generators for long periods

before their commissioning or when only some units are

installed immediately, results in the fact that the generator

is exposed to influences that may not be assessed in

advance for that period.

It is difficult to evaluate the atmospheric, chemical,

thermal and mechanical stresses imposed on the

generator that may occur during the storage, handling,

assembly, initial tests and waiting time until its definitive

commissioning.

Another essential factor is its transport. For example, the

general contractor may transport the generator or a unit

complete with the generator as a joint transport to the

installation site.

The hollow spaces inside the generator, bearings and

terminal box are exposed to the atmospheric air and

temperature fluctuations. Due to air moisture,

condensation of water may occur and, depending on the

type and degree of contamination in the air, aggressive

substances can penetrate the hollow spaces.

As a result, after long storage periods, internal

components such as the bearings, may rust, the

insulation resistance may decrease to values below those

regarded as accepted and the characteristics of the

bearing lubricants are affected adversely. This influence

increases the damage risk before the plant

commissioning.

ATTENTION

To keep the manufacturer's warranty valid,

you must assure that the preventive measures

described in this manual, such as:

construction aspects, preservation,

packaging, storage and inspections are

followed and recorded.

5.3 STORAGE LOCATION

In order to provide the best storage conditions to the

generator during long storage periods, the storage site

should comply strictly with the items below.

5.3.1 Indoor storage

Enclosed storage room with roof;

The storage location must be protected against

moisture, vapors, aggressive fume discharge, rodents

and insects.

Room must be free of corrosive gases, such as:

chlorine, sulfur dioxide or acids;

Location must be free of severe continuous or

intermittent vibrations.

Storage room must be provided with ventilation

system and filter;

Room temperature (5C, > t < 60C), with no sudden

changes in temperature;

Relative air humidity <50%;

Prevention against dirt and dust deposits;

Provided with a fire detection system.

Electric power supply for space heater and illumination

must be provided.

If some of these requirements cannot be provided in the

storage room, WEG suggests that additional protection

measures should be incorporated into the generator

packaging during the storage period as follows:

Storage the generator into a closed wooden box or

similar with electrical installation that allow the

connection of space heaters;

If there is any risk of fungus infestation and formation,

the packaging must be protected in the storage

location by spraying or painting it with appropriate

chemical agents.

The packaging must be prepared carefully by an

experienced person. The company hired for this purpose

shall be responsible for the machine packaging.

5.3.2 Outdoor storage

The outdoor storage of the generator is not

recommended.

If the outdoor storage is unavoidable, pack the generator

into a specific packaging for this condition, as described

below:

For outdoor storage, besides the packaging

recommended for indoor storage, cover the packaging

completely with some protection against dust,

moisture and other foreign matters by using a resistant

canvas or tarpaulin.

Store the packaging on pallets, wood beams or

foundations that provide protection against the ground

moisture.

Prevent the packing from sinking into the soil.

After covering the machine, a shelter must be built to

protect it from direct rain, snow and excessive sun

heat.

ATTENTION

It is recommended to check the storage place

and the generator conditions according to the

maintenance plan for long-term storage as

described in this manual.

www.weg.net

14 l Line S Turbogenerators

5.4 SEPARATE PARTS

If parts have been supplied separately (terminal boxes,

heat exchanger, endshields, etc.), these parts must be

packed as described above.

The air relative humidity inside the packaging should

not exceed 50% until the machine is unpacked.

5.5 SPACE HEATER

The space heaters installed in the generator must be

energized during the storage period to prevent the

moisture condensation inside the generator, thus

maintaining the winding insulation resistance at

acceptable levels.

ATTENTION

The generator space heater must be

mandatorily energized when the generator is

stored in a place with ambient temperature <

5C and relative air humidity > 50%.

5.6 INSULATION RESISTANCE

During the storage period and before installation, the

insulation resistance of the generator winding should

be measured very 3 months and recorded according

to item 2.3.5 of this manual

Eventual decrease of insulation resistance must be

investigated.

5.7 EXPOSED MACHINED SURFACES

All the exposed machined surfaces (for example, the

shaft end and flanges) are protected at the factory by

temporary protection film (rust inhibitor).

This protective coating must be reapplied at least every

6 months. When this coating is removed and/or

damaged, it must be applied again.

Recommended products:

Name: Dasco Guard 400 TX AZ, Manufacturer: D.A.

Stuart Ltda

Name: TARP, Manufacturer: Castrol

5.8 ROLLING BEARINGS

5.8.1 Grease-lubricated bearing

The bearings are factory lubricated for the performance

of the generator tests.

During the storage period, at every two months, the

shaft-locking device must be removed and the shaft

turned manually to keep the bearing in good lubrication

conditions.

After 6 months of storage and before starting the

operation, the bearings should be relubricated.

If the generator is stored for more than 2 years, the

bearings must be washed, inspected and lubricated

again.

5.8.2 Oil-lubricated bearing

Depending on its mounting position, the generator can

be transported with or without oil in the bearings.

The generator must be stored in its mounting position

with oil in the bearings;

The oil level must be respected, remaining in the sight

glass half.

During the storage period, at every two months, the

shaft-locking device must be removed and the shaft

turned manually to keep the bearing in good lubrication

condition.

After 6 months of storage and before starting the

operation, the bearings should be relubricated.

If the generator is stored for more than 2 years, the

bearings must be washed, inspected and relubricated.

5.8.3 Sleeve Bearing

Depending on the mounting position, the generator

can be transported with our without oil in the bearings

and must be stored in its mounting with oil in the

bearings;

The oil level must be respected, remaining in the sight

glass half.

During the storage period, at every two months, the

shaft-locking device must be removed and the shaft

rotated at 30 rpm to circulate the oil and keep the

sleeve bearing in good lubrication condition.

NOTE

If it is not possible to rotate the generator

shaft, the following procedure should be

adopted to protect the sleeve bearing

internally and the contact surfaces against

corrosion.

Drain all the bearing oil;

Disassemble the bearing following the procedure

described in this manual.

Clean the bearing;

Apply the anticorrosive protection (for example, TECTIL

511, Valvoline or Dasco Guard 400TXAZ) on top and

bottom bearing shell and on the generator shaft

contact surface;

Assemble the sleeve bearing following the procedure

described in this manual;

Close all threaded holes with plugs;

Seal the gaps between the shaft and the bearing seal

by applying a waterproof adhesive tape;

All the flanges (for example, oil inlet and outlet) must

be protected with blind caps;

Remove the bearing top sight glass and spray

anticorrosive protection inside the bearing;

Put some desiccant (silica gel) bags inside the bearing.

The desiccant absorbs moisture and prevents water

condensation inside the bearing;

Close the bearing with the top sight glass.

If the storage period is longer than 6 months:

Repeat the above described procedure;

Place new desiccant (silica gel) bags inside the bearing

If the storage period is longer than 2 years:

Disassemble the bearing;

Preserve and store the bearing parts.

www.weg.net

Line S Turbogenerator l 15

5.9 TERMINAL BOX

When the generator winding insulation resistance is

checked, the main terminal box and additional

terminal boxes must also be checked, particularly with

regard to the following aspects:

The terminal box inside must be dry and free of any

dust deposit.

The contacts must be free of corrosion.

The seals must be in good condition.

The cable entries must be sealed correctly.

If any of these items is not correct, the parts must be

cleaned or replaced.

5.10 PREPARATION FOR OPERATION AFTER

LONG STORAGE

5.10.1 Cleaning

The machine inside and outside must be free of oil,

water, dust and dirt. The generator inside must be

cleaned with compressed air at reduced pressure.

Remove the rust inhibitor from the exposed surfaces

using a cloth soaked in a petroleum-based solvent.

Remove the existing protection between the grounding

brush and the generator shaft.

Make sure that the bearings and cavities used for

lubrication are free of dirt and that the cavity plugs are

correctly sealed and tightened. Oxidations and marks on

the bearing seats and shaft must be carefully removed.

5.10.2 Bearing lubrication

Use the grease or oil specified for bearing lubrication.

This information is indicated on the bearing nameplate.

The bearings must be lubricated as described in the

"Maintenance" section of this manual according to the

bearing type.

NOTES

Sleeve bearings, where the anticorrosive

protection and desiccant were applied, must

be disassembled according to the procedure

described in this manual. The anticorrosive

protection and the desiccant must be washed

out and removed.

Assemble the bearings as described in this

manual and lubricate them again.

5.10.3 Checking the insulation resistance

Before starting the operation, the insulation resistance

must be checked following the procedure described in

this manual.

5.10.4 Others

NOTE

Follow other procedures supplied in the

"Commissioning" section in this manual

before starting the machine operation.

5.11 INSPECTIONS AND RECORDS DURING

THE STORAGE

The stored generator must be inspected from time to

time and the inspection records must be filed. Check

following aspects:

1. Physical damages.

2. Cleaning.

3. Signs of water condensation.

4. Protective coating conditions.

5. Painting conditions.

6. Signs of worms or insect action.

7. Satisfactory operation of the space heaters. It is

recommended to install a signaling or alarm system in

the storage location to detect any power failure

affecting the space heaters.

8. Record room temperature and the relative air

humidity around the machine, the winding

temperature (using RTDs), the insulation resistance

and the polarization index.

9. Inspect also the storage place that must comply with

the requirements described in the chapter LONG

STORAGE" .

www.weg.net

16 l Line S Turbogenerators

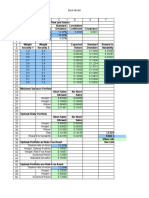

5.12 MAINTENANCE PLAN TO BE FOLLOWED DURING THE STORAGE

During the storage period, the generator maintenance must be performed and recorded according to the plan described in

the table 5.1:

Monthly

Every 2

months

Every 6

months

Every

2 years

Before

operation

Note

Storage Location

Inspect the cleaning conditions X X

Inspect moisture conditions and the

temperature

X

Check for insect infestation signs X

Measure the vibration level X

Packaging

Inspect for physical damages X

Inspect the inner relative humidity X

Change the desiccant in the packaging

(if any)

X When required

Space heater

Check the operating conditions X

Complete Generator

Clean generator outside X X

Check painting conditions X

Check the oxidation inhibitor on the

exposed parts

X

Replace the oxidation inhibitor X

Windings

Measure insulation resistance X X

Measure polarization index X X

Terminal box and grounding terminals

Clean box inside X X

Inspect the seals and gaskets

Roller bearings, grease or oil lubricated

Rotate the shaft X

Relubricate the bearing X X

Disassemble and clean the bearing X

Sleeve bearing

Rotate the shaft X

Apply rust inhibitor and desiccant X

Clean and relubricate the bearings X

Disassemble and store the parts X

Table 5.1: Storage plan

www.weg.net

Line S Turbogenerator l 17

6 HANDLING

Figure 6.1: Lifting the generator by its eyebolts Figure 6.2: Lifting the generator by the base eyebolts

To lift the generator, use only the eyebolts on the top or at base of the generator provided for this purpose, as shown in

the figure 6.1 and 6.2.

Consider the generator weight. Lift the generator smoothly and do not place it abruptly on the base to prevent bearing

damages.

The eyebolts on the heat exchanger, covers, bearings, radiator, terminal boxes, exciter, etc., were designed only to lift

these components.

Never use the shaft to lift the generator by means of cables, etc.

To move the generator, its shaft must be locked using the locking device supplied with the generator

ATTENTION

Ropes, rings and lifting equipment must be capable to support the generator weight.

www.weg.net

18 l Line S Turbogenerators

7 INSULATION RESISTANCE

7.1 SAFETY INSTRUCTIONS

DANGER

Before insulation resistance is measured,

machine must be switched off and stopped.

The winding under test must be connected to

the housing and the ground for a period until

all residual electrostatic charge has been

removed. Ground the capacitors (if supplied)

before disconnecting the lead terminals.

The noncompliance with these procedures

may result in personal injuries.

7.2 GENERAL REMARKS

When the generator is commissioned immediately after

receipt, it should be protected against moisture, high

temperature and dirt, thus preventing damages on the

insulation resistance.

The winding insulation resistance must be measured

before the generator operation.

If the ambient is very wet, the winding resistance must be

measured from time to time during the storage period. It is

difficult to prescribe fixed rules for the machine insulation

resistance values, since they change according to the

environment conditions (temperature, moisture), machine

cleaning conditions (dust, oil, grease, and dirt), quality and

conditions of the used insulating material. A considerable

dose of common sense, resulted from experience, must

be applied to conclude when a machine is or is not

suitable for service. Periodic records are useful for this

conclusion.

NOTE

The insulation resistance must be measured

using a MEGOHMMETER.

7.3 STATOR WINDING MEASUREMENT

The stator winding test voltage must comply with the table

7.1 according to IEEE43 standard.

Rated winding

voltage (V)

Insulation resistance test

(Continuous voltage) (V)

< 1000 500

1000 - 2500 500 -1000

2501 - 5000 1000 - 2500

5001 - 12000 2500 - 5000

> 12000 5000 - 10000

Table 7.1: Insulation resistance test voltage.

Before measuring the stator winding, check following:

If the CT secondary connections are not open;

If all the power cables are disconnected;

If the generator frame and the not measured windings

are grounded;

If the winding temperature has been measured;

If all the temperature sensors are grounded;

The stator winding insulation resistance must be

measured in the main terminal box

The megohmmeter must be connected between the

generator frame and the winding. The frame must be

grounded.

Figure 7.1: Megohmmeter connection

If the winding total measurement shows a value below the

recommended one, the neutral connections must be open

and the insulation resistance of each phase must be

measured separately.

7.4 MEASUREMENT OF THE ROTOR

WINDING RESISTANCE, EXCITER

WINDING RESISTANCE AND

ACCESSORIES

Measurement of the rotor winding resistance:

Disconnect the rotor cables from the diode set;

Record the winding temperature supplied by the

PT 100;

Connect the megohmmeter between the rotor winding

and the generator shaft. The measured current cannot

flow through the bearings.

Measurement of the stator winding resistance of the

exciter:

Disconnect the exciter power supply cables;

Connect the megohmmeter between the exciter stator

winding (I and K terminals) and the generator frame.

Measurement of the rotor winding resistance of the

exciter:

Disconnect the exciter rotor cables from the diode set;

Connect the megohmmeter between the rotor winding

and the generator shaft. The measured current can not

flow through the bearings

Measurement of the stator winding resistance of the PMG

- SP model generators --_:

Disconnect the cables that connect the PMG to the

voltage regulator

Connect the megohmmeter between PMG stator

winding (terminals 13, 14 and 15) and the generator

frame.

ATTENTION

After insulation resistance has been measured,

ground the tested winding to discharge it.

The test voltage for the rotor, exciter, PMG and

space heater must be 500 Vdc. The test

voltage for the accessories is 100 Vdc.

It is not recommended to measure the

insulation resistance of thermal protectors.

www.weg.net

Line S Turbogenerator l 19

7.5 CONVERSION OF THE MEASURED

VALUES

If the test is conducted at a different temperature, the read

values must be corrected to 40C by using an insulation

resistance variation curve according to the temperature

measured on the machine under test. If this curve is not

available, you can an approximate correction, as indicated

by the curve in Figure 7.2 as per NBR 5383 / IEEE43.

Figure 7.2: Coefficient of insulation resistance variation with

temperature.

With old machines, during longer time in service, the read

values for the winding resistance will be usually higher.

The comparison with values measured in previous tests on

the same machine with similar load, temperature and

moisture conditions is regarded as a better indication of

the insulation conditions than the value obtained in a

single test. Any great or sudden reduction is regarded as

suspect.

Insulation resistance Insulation evaluation

2M or less Bad

< 50M Dangerous

50...100M Regular

100...500M Good

500...1000M Very Good

> 1000M Optimum

Table 7.2: Orientative limits for the insulation resistance of

electrical machines.

7.6 MINIMUM INSULATION RESISTANCE

If the measured insulation resistance is lower than 100

M at 40C, the windings must be dried according to

the procedure below before the machine starts

operating:

Disassemble the generator by removing the rotor and

the bearings;

Take the housing with the stator winding to an oven

and heat it up to a temperature of 130C, leaving it at

this temperature for at least 8 hours. For large machines

(above IEC 630 frame size or 104XX NEMA series, a

dry time on oven of at least 12 hours may be required).

Check if the measured insulation resistance is within the

acceptable values as shown in table 7.2. Otherwise,

please contact WEG.

7.7 POLARIZATION INDEX

The polarization index is traditionally defined as the ratio

between the insulation resistance measured in 10 minutes

and the insulation resistance measured in 1 minute at a

relatively constant temperature.

Through the polarization index, it is possible to assess the

generator insulation conditions as per the table 7.3:

Polarization index Insulation evaluation

1 or less Bad

< 1.5 Dangerous

1.5 to 2.0 Regular

2.0 to 3.0 Good

3.0 to 4.0 Very Good

> 4.0 Optimum

Table 7.3: Polarization index (ratio between 10 and 1 minute).

DANGER

Right after measuring the insulation

resistance, ground the winding to prevent

accidents.

www.weg.net

20 l Line S Turbogenerators

8 CONSTRUCTION CHARACTERISTICS

8.1 STATOR

The stator lamination package, formed by silicon steel

laminations with insulation on both faces and low electric

losses, is pressed and fixed by metal beam or spar

system.

The windings of the high-voltage generators are

constructed with prefabricated rectangular wire coils with

class-F insulation resin and coated with mica tape

insulation that, after heat treatment process, provides

high mechanical resistance to the winding.

The coils are inserted into the stator slots and fixed by

fiberglass or magnetic wedges. The fixation of these

wedges is assured by the dovetail in slot and by using

expandable fiberglass lamination.

Highly absorbing materials are used for binding the coil

heads, thus ensuring the mechanical stiffness required to

withstand to the most severe operating conditions.

The high-voltage stators are then impregnated by the

epoxy VPI-impregnation system.

8.2 ROTOR

The rotor accommodates the field winding whose poles

are made of steel laminations.

A squirrel cage winding for absorbing purposes

compensates for parallel services and abnormal load

operation.

The rotor is dynamically balanced and designed to

withstand to the electrical and mechanical effects of

overspeed as required by the applicable standard and of

the triggering according to the design.

Manufactured with non-salient poles, the rotor has a

constant air gap along the whole iron core periphery. The

rotor has a cylindrical shape in whose periphery slots is

inserted the excitation winding. The field coils are made of

bars, wires or copper laminations insulated with a class-H

insulating material.

The non-salient pole rotor of the turbogenerator is

practically a monobloc with no overhangs or recesses. As

a result, it becomes sturdier and more resistant to

overspeed and coil triggering.

8.3 EXCITER

Installed at the non-drive end side of the generator, the

exciter is formed by fixed poles that accommodate the

excitation field coils, the armature and the rotating rectifier

bridge. Its purpose is to supply direct voltage to exciter

rotor. It supplies direct current controlled by the voltage

regulator according to the load requirements, thus

maintaining constant voltage for the main generator.

Exciter Stator

The poles accommodate the field coils which are series

connected, their ends being connected to the terminal

block (I(+) and K(-)). Its purpose is to supply the flux to the

exciter rotor. It is supplied with a direct current controlled

by the voltage regulator according to the load

requirements, thus keeping the main generator voltage

constant.

Exciter Rotor

The exciter rotor is mounted on the main shaft of the

machine. The rotor is formed by laminations with slots that

accommodate a star-connected three-phase winding.

The phases are connected to the rotating rectifying diode

set.

The rotor is induced by the flux from the exciter stator

using a three-phase AC voltage that is rectified in full wave

by the rotating rectifier.

Two wires come from the rectifier to feed the main

machine rotor (field).

NOTE

The rectifier is made up of six diodes and a

set of varistors for protection against reverse

overvoltage in the diodes.

8.4 PERMANENT MAGNET GENERATOR

(PMG)

(Only for the SP_ model generator)

Installed at the non-drive end side of the generator, the

PMG generates alternate voltage for supplying the voltage

regulator power circuit.

The rotor is formed by permanent magnet poles inserted

into the lamination package mounted on the main

generator shaft.

The stator is formed by a lamination package and a three-

phase winding that generates the voltage to supply the

power circuit of the electronic voltage regulator.

8.5 DUMPING WINDING

The dumping winding is constructed along the whole rotor

periphery, which is of fundamental importance for handling

sudden loads, such as motor starts, OFF/ON procedures

of heavy loads. The dumping winding has following

functions:

1. Dumping of load input and output at generator

terminals.

2. In case of an infinite busbar, the machine becomes

more stability against abrupt voltage variations.

3. Absorption of zero sequence and negative sequence

currents caused by load unbalance.

4. Loads with harmonic distortion of currents will also be

absorbed by dumping bars according to standard.

5. They increase the abrupt short-circuit at the machine

terminals.

8.6 BEARINGS

The bearings are mounted at the frame ends and their

purpose is to support the rotor mass and allow it to turn.

Sleeve bearings are lubricated with oil and the rolling

bearings can be lubricated with grease or oil.

Correct storage, operation and maintenance procedures

are determinant for their performance and useful life.

8.7 HEAT EXCHANGER

SPW and SSW turbo-generators are provided with an air-

to-water exchanger installed at the bottom or top section

of the generator. The SPF and SSF models are provided

with air-to-air heat exchanger, normally installed on top

side of the generator (see in this Manual the item "Cooling" ).

www.weg.net

Line S Turbogenerator l 21

9 OPERATION PRINCIPLE

Figure 9.1: Internal electrical circuits of the SP_ model generator

9.1 EXCITATION

After the primary machine is driven and reaches is rated

speed, starts the excitation process in the generator and

the voltage generated by PMG supplies the voltage

regulator power circuit.

When the voltage regulator is enabled, it rectifies this

voltage and supplies direct current to the stator of the

generator exciter.

The alternate current generated by the exciter rotor is

rectified by the rotating diodes and supplied to the main

rotor poles.

The generator voltage increases as ramp automatically

from its residual value up to the pre-established rated

voltage that is regulated by monitoring the reference

voltage in the electronic voltage regulator.

The reference voltage for the voltage regulator must be

obtained through reference TPs connected to the main

terminals of the generator.

The SS_ model turbogenerators (Shunt) are not provided

with PMG and the voltage regulator power circuit is

supplied by the generator output voltage using power

TPs.

ATTENTION

To start the shunt generator excitation

process, it may be necessary to use an

external pre-priming circuit (DC power

supply), since the residual generator

magnetism may not be sufficient for the

priming.

Check the procedures in the voltage regulator

manual for enabling this function during the

excitation process.

DANGER

When operated at no load with nominal speed

and without excitation voltage there is a

residual voltage present in the synchronous

generator terminals due to residual magnetism

in the exciter magnetic core.

These voltage levels can cause serious

accidents with risk of death. It is unwise to

manipulate the machine while the rotor is

turning.

Generators with rated voltage of 440V,

usually present 180V of residual voltage;

Generators with rated voltage of 13800V

easily present 1000V of residual voltage.

9.2 DEEXCITATION

The generator full deexcitation is performed by the

generator stoppage or voltage regulator shutdown.

When the voltage regulator is shut down, the generator

deexcitation is performed by a free-wheel circuit installed

in the voltage regulator panel. The excitation current flows

through a discharge resistance that promotes a faster

deexcitation of the main machine.

During the maintenance services, the machines must be

stopped, since the deexcitation alone is not enough.

AVR: Automatic Voltage Regulator

EPT: Main three-phase exciter

PMG: Exciter with permanent magnets

www.weg.net

22 l Line S Turbogenerators

9.3 VOLTAGE REGULATOR

The purpose of the electronic voltage regulator is to keep

the generator voltage constant, regardless of the load.

The generator excitation process starts from the moment

the voltage regulator is activated. This must always be

done when the generator reaches at least 90% of its rated

speed, thus preventing overcurrent in the generator

excitation windings.

Automatic operation mode

The voltage regulator is intended to keep the generator

output voltage equal to the previously programmed

reference value. To perform this function, the regulator

must be operated in automatic mode, where the generator

output voltage is used as feedback.

During the automatic operation mode, the reference

voltage can be used by other controls, such as:

acceleration Ramp, F/U Operation, PF/Q Correction and

others.

Manual operation mode

In this operation mode, the generator excitation is

conducted through the excitation voltage variation.

This operation mode is selected through a selector switch

(automatic/manual = open) and is used during the

generator commissioning tests.

For technical details, operation, functions, connections,

adjustments, abnormalities, etc., see the voltage

regulator manual.

The regulators are generally microprocessed and allow

parallel operation between two machines and with the

network. In this case, with power factor correction.

ATTENTION

Check for the correct wiring diagram in the

regulator manual.

An erroneous connection may burn the

regulator and / or the generator windings.

9.4 UNDERFREQUENCY (U/F) PROTECTION

When the generator frequency drops below the

programmed value for U/F in the voltage regulator, the

generator output voltage will decrease as programmed by

the Volt/Hz ratio.

www.weg.net

Line S Turbogenerator l 23

10 INSTALLATION

10.1 INSTALLATION SITE

Electric machines must be installed in locations of ease

access, allowing periodic inspections, local maintenance

services and, if required, the removal of equipment for

external maintenance services.

The following environmental characteristics must be

ensured:

Clean and well-ventilated place;

The installation of other equipment or walls should not

obstruct generator cooling;

The space around and above the generator must be

sufficient for its maintenance and handling;

The environment must comply with the generator

protection class.

10.2 PROTECTIONS

The generator is supplied with a shaft-locking device to

prevent damages to the bearings during the transport.

This locking device must be removed before the generator

installation.

ATTENTION

The shaft locking device must be used

whenever the generator is removed from its

base (decoupling from the drive machine) and

so prevent bearing damages during the

transport.

The shaft end is protected by a protective

grease coat. During the generator installation,

remove this shaft protection from the race

where the shaft grounding brush contacts it.

10.3 DIRECTION OF ROTATION

The generators are normally designed to operate in a

single direction of rotation as indicated by the arrow on

the frame at the drive end side.

Figure 10.1: Direction of Rotation

When generator rotation direction is changed, the phase

sequence will be changed too and the reversal of the two

phases will be required. Check the direction of rotation

and the phase sequence before operating the generator.

ATTENTION

Generators supplied with single direction of

rotation can only be operated in the specified

direction of rotation. If inversion of the

direction of rotation is desired, you must

contact the factory through your nearest WEG

representative.

10.4 FOUNDATIONS

The foundation or structure where the generator is to be

installed must be must be stiff enough, flat, free of

external vibrations and able to withstand to the

mechanical efforts to which it will be submitted during

the start-up or in case of generator short-circuits.

The type of foundation chosen depends on soil

condition or on the floor resistance.

If the foundation dimensions are not executed

accurately, serious vibration problems may occur with

the generator and drive machine as a whole.

The dimensioning of the foundation structure must be

executed by considering the dimensional drawing and

the information about the mechanical efforts on the

foundation, the anchoring procedures and the heat

exchanger details (if any).

ATTENTION

Provision must be made for a minimum

clearance of 2 mm between the anchor plate

and the generator feet for inserting the

compensation plates (wedges) used for the

alignment adjustment.

NOTE

The user is responsible for the foundation

dimensioning and construction.

DIRECTION OF

ROTATION

www.weg.net

24 l Line S Turbogenerators

10.5 ANCHOR PLATE SET

The anchor plate set comprises anchor plate, leveling bolts, leveling wedges, alignment bolts and anchor bolts.

Procedure for the assembly, leveling and grouting of the anchor plates

Step 1

Construct the foundation (1) using anchor bars (2)

as per the dimensional drawing, considering the

efforts to which this base will be submitted as

shown in the drawing.

Step 2

Position the anchor bolts (3) in the anchor bars

and the leveling bolts on the primary concrete

surface.

Step 3

Place the anchor plates (5) on the leveling bolts.

Step 4

Level the anchor plates by using the required

instruments. Please consider a 2 mm clearance

between the anchor plates and the generator

base for inserting the leveling wedges required for

the generator alignment.

Step 5

After the anchor plates have been leveled, they

must be grouted (6) together with the anchor

bolts for their definitive fixation.

Step 6

After the grout cure, place the generator on the

anchor plates, align it by using the horizontal

alignment bolts (7 and 8) and fix it in place

through it base holes and anchor bolts.

Figure 10.2: Anchor Plate

www.weg.net

Line S Turbogenerator l 25

Leveling and grouting with the anchor plates fixed the

generator

Figure 10.3: The anchor plate and the generator

The anchor plates can be leveled and grouted after they

have been fastened to the generator base with the 2 mm

wedges between the generator base and the anchor

plates.

For this purpose, place the generator with the anchor

plates on the leveling cap bolts, level off the base using

these leveling cap bolts and pre-align the generator using

the alignment bolts (7 and 8).

Secure the generator in place using the anchor bolts and

grout the anchor plate and anchor bolts for its definitive

fixation.

10.6 ALIGNMENT / LEVELING

The generator must be aligned correctly with the driving

machine, particularly in case of direct coupling.

An incorrect alignment may cause bearing damages,

vibrations and even the shaft rupture.

The alignment must be made according to the

recommendations of the coupling manufacturer.

It is necessary to make the machine parallel and angular

alignment as follows:

Parallel Alignment

Figure 10.4: Parallel misalignment

Figure 10.4 shows the parallel misalignment of the two

shaft ends and a practical way for making the

measurements is by using proper dial indicators.

The measurement is made at 4 points at 90 with two

half-couplings rotating together in order to eliminate the

effects caused by contact irregularities of the dial

indicators. Choosing the vertical top point 0, half of the

measuring difference of the dial indicator at the positions

of 0 and 180 represents the vertical coaxial error. This

error must be corrected properly by adding or removing

the assembly wedges. Half of the difference of the dial

indicator measurement at the positions of 90 and 270

represents the horizontal coaxial error.

This provides an indication when leveling (raising or

lowering) or moving to the right or to the left at the drive

end side is required to eliminate the coaxial error.

The half of the maximum difference of the dial indicator

measurement in a full revolution represents the maximum

eccentricity.

The maximum allowed eccentricity for rigid or semi-rigid

coupling is 0.03 mm.

When flexible couplings are used, values higher than those

above are acceptable, however the value defined by the

coupling manufacturer should not be exceeded.

We recommend keeping a safety margin for these values.

Angular Alignment

Figure 10.5: Angular misalignment

Figure 10.5 shows the angular misalignment and a

practical way for making the respective measurement.

The measurement is made at 4 different points displaced

by 90 each other with two half-couplings rotating

together in order to eliminate the effects caused by the

irregularities of the dial indicators on the contact surface.

Choosing the vertical top point 0, half of the measuring

difference of the dial indicator at the positions of 0 and

180 represents the vertical misalignment. This error must

be corrected properly by adding or removing the assembly

wedges. Half of the difference of the dial indicator

measurement at the positions of 90 and 270 represents

the horizontal misalignment.

This must be properly corrected by side/angular moving of

the generator.

Half of the maximum difference in the comparison clock

measurement in a full rotation represents the maximum

angular misalignment.

Half of the difference of the dial indicator measurement

during a complete revolution represents the maximum

angular misalignment.

The maximum allowed misalignment for the rigid or semi-

flexible coupling is 0.03 mm

When flexible couplings are used, values higher than those

above are acceptable, however the value defined by the

coupling manufacturer should not be exceeded.

We recommend keeping a safety margin for these values.

During the alignment/leveling procedures, consider the

temperature effects of the generator and the driving

machine. Different expansion levels of the coupled

machines can change the alignment/leveling during the

operation

10.7 COUPLING

Use only suitable couplings able to transmit pure torques

without generating transverse forces.

The generator shaft and the driving machine centers must

be in a single line, both for the elastic and rigid couplings.

The elastic coupling are intended for mitigating the

residual misalignment effects and preventing the vibration

transfer between the coupled machines, which is not the

case when rigid couplings are used.

The coupling must be assembled or removed only with the

use o appropriate devices and never by means of rustic

devices (hammer, mallet, etc.).

Radial measurement

Axial measurement

www.weg.net

26 l Line S Turbogenerators

Generators fitted with sleeve bearings

Figure 10.6: Sleeve Bearing

The generators fitted with sleeve bearings must be

coupled direct to the driving machine or by means of

reducer.

The coupling by belts and pulleys is not allowed.

The shaft end has three markings, the central mark (red

painted) is an indication of the magnetic center and the

two external markings indicate the limits of the rotor axial

movement.

Figure 10.7: Magnetic center marking

For the correct coupling of the generator, the following

factors should be considered:

Bearing axial play;

The axial displacement of the machine coupled to the

generator (turbine);

The maximum axial play of the opening allowed for the

coupling.

ATTENTION

Displace the shaft fully to the front side to