Professional Documents

Culture Documents

Tranor Brochure

Uploaded by

DANIEL DIAZOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tranor Brochure

Uploaded by

DANIEL DIAZCopyright:

Available Formats

19365 Sherwood Avenue

Detroit, MI 48234-2899

Phone (313) 733-4888

Fax (313) 733-4886

www.tranorindustries.com

Stamping Dies

Machining

Die Construction

Prove Out

CMM

Tranor Industries, LLC

Executive Staff

Executive Staff

Chris Woodall

President

Office# (313) 733-4888 ext. 238

Email: chris@tranorindustries.com

Michael Coker

Vice President / General Manager

Office# (313) 733-4888 ext. 203

Email: mcoker@tranorindustries.com

Tranor Industries, LLC

A Global Supplier of Automotive Tooling & Parts

Tranor Industries, LLC

Quality Policy Statement

Tranor Industries is committed to be the best World Class Supplier of

body stamping dies targeting constant improvement in the areas of durability,

reliability, maintainability, quality, timing and cost.

Tranor Industries, LLC

A Global Supplier of Automotive Tooling & Parts

Our Goals

Continuously improve the total system of Customer/Supplier involvement in

Feasibility, Process, Design, Construction, and Tryout of Stamping Dies

and related Tooling.

Emphasizing Tranors Transfer of Knowledge Principle, involve the total

Tranor Work Force in the culture of continuous improvement in all activities related

to customer satisfaction.

Promote Process Thinking, Problem Solving, Team Involvement, and

Continuous Education of Tranors Work Force.

Strive for Defect Prevention and Prompt Corrective Action in our Engineering

Services and Products.

Concentrate on our People, our most important asset. They determine our

reputation and are key to accomplishing our mission. Their Safety, Knowledge,

Daily Involvement, and Positive Attitude are critical to the vitality of the company.

Continue to Grow and Build as a profitable Full-Service Die Supplier. Profits are

the measurement of our internal Efficiencies and are necessary for the company to

Survive and Grow.

Tranor Industries, LLC

Aiming for World Class

Quality, Timing, Cost Efficiency Reliability,

Maintainability and Durability

Tranor Industries, LLC

A Global Supplier of Automotive Tooling & Parts

Our Customers

*Chrysler LLC

*Auto Steel Partnership

*Narmco

*Magna International

*Auto Die

*Vicount

*Nissan

Tranor Industries, LLC

Transfer of Knowledge

Tranor Industries, LLC

A Global Supplier of Automotive Tooling & Parts

Development / Simulation

Engineering / Design / Process - working alliance with

Superior Engineering and M & M Global Services

Machining

Die Construction

Prove Out

CMM

Tranor Industries, LLC

Transfer of Knowledge

Development / Simulation

Superior Engineering's experience in development with a focus on production hard die

intent saves costs and development time for customers. If your requirements involve

complex panels, such as inner & outer doors, then Superior Engineerings experience

will assure quality development and prove-out.

Throughout the Inception-to-Production process of die making, the Superior

Engineering team works closely with your team, emphasizing each individual phase

as an integral part of the whole. The result is world class products and service.

Superior Engineering

www.thesuperiorengineering.com

Tranor Industries, LLC

Transfer of Knowledge

Engineering / Design / Process

The Inception-to-Production approach to M & M Global Services assures the customer

that knowledge gained through die design & development is transferred from prototype

to hard dies to the customers home production line. Tranor Industries broad experi-

ence with state of the art CAD systems (with all industry protocols capability) and tradi-

tional design systems assures the customer of continuous improvements in quality,

timing, and cost.

Solid Model Information Retrieval

Technology

M & M Global Services LLC

www.mmglobalservices.net

CATIA V5UG

SMIRT

Tranor Industries, LLC

Transfer of Knowledge

Machining

2200 watt (2.2kw)

Table size: 75x122

(1900 x 3100 mm)

Table travel:

X = 122 (3100 mm)

Y = 75 (1900 mm)

Z = 31 (800 mm) from table top

CATIA V5UG

5-Axis Laser

Cutting Machine

Tranor Industries has continued to enhance its

machining capabilities. A 5-axis Bridge Rail Mill

37 2/3 x 12, compliments our comprehensive

CNC machining system. Heavy die machining

capabilities are supported by smaller CNC mills,

manual mills, our grinding room, and scores of

miscellaneous equipment. All of our equipment

is inspected, certified, and well-maintained to

insure a professional job is done every time.

Tranor Industries, LLC

Transfer of Knowledge

Schienke DCM 410

Made in Romeo, MI

1999 Schienke DCM 410

Fidia CNC Controllers

96 x 120 Bed

60,000# capacity

Spindle Speed up to 10,000 RPM

Tranor Industries, LLC

Transfer of Knowledge

Die construction

Tranor Industries continuously

improves on building stamping dies

and related tooling utilizing innovation,

proven technologies, statistical

methods, and world class standards

all aiming to exceed customer

requirements and expectations.

Bench Assembly

There are many of the highly skilled

employees at Tranor Industries. All share a

commitment to quality and accuracy through

continuously improving their skills. The

company further promotes employee

education through its affiliation with

local colleges. This focus on continuous

education is a primary corporate objective.

Tranor Industries, LLC

Transfer of Knowledge

Die constructionProgressive Dies

Tranor Industries, LLC

Transfer of Knowledge

Prove Out

The Ravne Press gives Tranor Industries

large 220 progressive die capabilities.

Using building block principlesfirst stages, wire

burned as a blank; second stages as form sta-

tions; final stages as trim/pierce/flange/cut-off.

Tranors Dallas Decoiler completes our large

progressive die operational capabilities.

Tranor Industries has the capacity to set

several lines of dies simultaneously for

medium to large parts during prove out.

Working closely with you, the customer, the

focus is on production ready quality dies.

This assures easy start-up, reliability and

maintainability throughout your press run.

Tranor Industries, LLC

Transfer of Knowledge

CMM (Inspection)

Inspection & Quality Control

Tranor Industries computer controlled

automatic coordinate measuring machine

(CMM), housed in an environmentally

controlled on-site room, assures the

accuracy of parts and dies.

Measuring Machine

Brown & Sharp Validator CMM Series 3000, model

360 Automatic. X= 112 (2844.8 mm) Y= 66 (1676.4

mm) Z= 81 (2057.4 mm)

Tranor Industries, LLC

Transfer of Knowledge

CNC Mills

Cincinnati (Sidewinder) bridge type Rail Mill Three axis, with two axis contouring head - for

full five axis capability. 6000 RPM spindle. Travels: X=524 Y=144 Z=39 3/8

(11,481 x 3657 x 100mm).

Cincinnati Milacron 10 x 15 traveling column Bar type Three axis, 75 H.P. horizontal mill-

ing machine. Cincinnati 950 profile control. 8-1/8 diameter spindle. Travels: X= 180 Y= 80

Z= Bar (40 travel), Quill (36 travel).

Cincinnati Milacron Wolverine vertical slave machine (1973A), single spindle, 60 H.P.

Three Axis Acramatic 950 Computer Numerical Control. Travels: X= 120 Y= 80 Z= 30 (3048

x 2032 x 763 mm).

Cincinnati Milacron Wolverine vertical slave machine (1973A), single spindle, 60 H.P.

Three axis Acramatic 950 Computer Numerical Control. Travels: X= 120 Y= 80 Z= 30 (3048

x 2032 x 763 mm).

Pratt & Whitney Wolverine vertical slave machine (M1973), single spindle, 60 H.P. Three

axis Teammate CNC III control system.Travels: X= 120 Y= 80 Z= 30 (3048 x 2032 x

762mm).

Pratt & Whitney Wolverine vertical master machine (M1974). Three axis, P&W comb.

Teammate CNC III / Tracemate electronic tracer control. High speed spindle attachment. 6000

R.P.M. 15 H.P. motor. Travels: X= 120 Y= 77 Z= 36 (3048 x 2057 x 914 mm).

5-Axis Laser Cutting Machine 2200 watt (2.2kw) Table size: 75x122 (1900 x 3100 mm)

Table travel: X = 122 (3100 mm) Y = 75 (1900mm) Z = 31 (800 mm) from table top.

Schienke DCM 410 (1999); Fidia CNC Controllers; Bed size: 96 x 120; Capacity 60,000#;

Spindle speed: up to 10,000 rpm

Boring Mills

Giddings & Lewis Horizontal table type boring, drilling, & milling machine, model 70-D5-T.

5 diameter spindle, table size 60 x 120. Digital read out X= 108 Y= 83

Giddings & Lewis Horizontal table type boring, drilling, & milling machine, model 350-T. 5

diameter

40 ton with 20 ton assist

30 ton with 15 ton assist

30 ton single

20 ton single

15 ton single

10 ton single

5 ton single - CMM Room

15 ton single - Grinding Room

Tranor Crane Capacity

Tranor Industries, LLC

CAD/CAM Capabilities

Changing standards to make us an Industry

leader in CAD Design and NC Programming

UNIGRAPHICS

Unigraphics Workstations

CATIA

Catia V5 Workstations

CAM Tranor Shop Support

WORKNC Workstations

VISI Modeler

DNC Workstation

AutoFormSIGMA

Communications &

Data Transfer

E-MailInternet

AUTOWEB

Tranor Industries, LLC

Presses

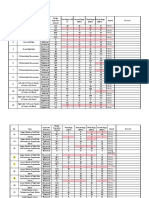

*PRESSES WITH ROLLING BOLSTERS **PRESSES WITH TWO ROLLING BOLSTERS

NOTE: ALL SHUT HEIGHTS (S.H.) ARE STROKE DOWN ADJUSTED UP (S.D.A.U.) W/O BOLSTERS

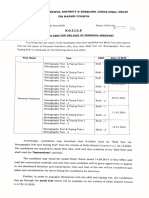

Tranor Industries, LLC

Facility Layout

Shop Area 81,000 sq. ft.

Office Area / Estimating 8,250 sq. ft.

CAM Programming / CAD 3,250 sq. ft.

Engineering / Die Design 5,000 sq. ft.

Laser 4,750 sq. ft.

Tooling Aids 1,800 sq. ft.

Warehouse 7,500 sq. ft.

Storage Area 2,500 sq. ft.

Total 114,050 sq. ft.

The floor plan at Tranor is laid out to maximize

Inception-to-Production approach to die manufacturing

Tranor Industries, LLC

19365 Sherwood

Detroit, MI 48234-2899

Ph (313) 733-4888 * Fax (313) 733-4886

www.tranorindustries.com

If you would like to set up a personal tour of Tranor Industries, LLC,

Please contact Michael Coker for more information

We look forward to hearing from you!

TRANOR

TRANOR

INDUSTRIES

You might also like

- Succulent Chanterelles!: Plus Star Lore, Weather Lore and More..Document36 pagesSucculent Chanterelles!: Plus Star Lore, Weather Lore and More..DANIEL DIAZNo ratings yet

- Artistic CraftDocument5 pagesArtistic CraftDANIEL DIAZNo ratings yet

- Bizen Osafune Sword Museum Low ResDocument75 pagesBizen Osafune Sword Museum Low RescatiiNo ratings yet

- Examining The Origin of Soshu-Den OldDocument11 pagesExamining The Origin of Soshu-Den OldDANIEL DIAZNo ratings yet

- Examining The Origin of Soshu-DenDocument13 pagesExamining The Origin of Soshu-DenDANIEL DIAZNo ratings yet

- Artistic CraftDocument5 pagesArtistic CraftDANIEL DIAZNo ratings yet

- When Does A Weapon Become A Work of Art?Document10 pagesWhen Does A Weapon Become A Work of Art?Brian RobinsonNo ratings yet

- l04 Simulation Sheetmetalforming 2 PDFDocument45 pagesl04 Simulation Sheetmetalforming 2 PDFNhan LeNo ratings yet

- Yakiire (Edge Hardening) and CurvatureDocument1 pageYakiire (Edge Hardening) and CurvatureDANIEL DIAZNo ratings yet

- Sword Forging CompetitionDocument3 pagesSword Forging CompetitionDANIEL DIAZNo ratings yet

- Bob Engnath Knife PatternsDocument43 pagesBob Engnath Knife Patternsherpaderpadood100% (13)

- ZT 300 SmallDocument1 pageZT 300 SmallDANIEL DIAZNo ratings yet

- Flowers in SteelDocument5 pagesFlowers in SteelBrian RobinsonNo ratings yet

- BalDocument4 pagesBalDANIEL DIAZNo ratings yet

- Bal k2 DMZ PDFDocument5 pagesBal k2 DMZ PDFDANIEL DIAZNo ratings yet

- S - Pyderco - Model PDFDocument2 pagesS - Pyderco - Model PDFDANIEL DIAZNo ratings yet

- Bal 2Document2 pagesBal 2DANIEL DIAZNo ratings yet

- Yojimbo ModelDocument5 pagesYojimbo ModelDANIEL DIAZNo ratings yet

- Santoku CustomDocument4 pagesSantoku CustomDANIEL DIAZNo ratings yet

- Logo SDocument1 pageLogo SDANIEL DIAZNo ratings yet

- Benchmade 42 Custom PDFDocument2 pagesBenchmade 42 Custom PDFDANIEL DIAZNo ratings yet

- Yojimbo Model PDFDocument5 pagesYojimbo Model PDFDANIEL DIAZNo ratings yet

- S - Pyderco - Model PDFDocument2 pagesS - Pyderco - Model PDFDANIEL DIAZNo ratings yet

- Z Atvarak Unk PDFDocument2 pagesZ Atvarak Unk PDFDANIEL DIAZNo ratings yet

- Yagi Model PDFDocument2 pagesYagi Model PDFDANIEL DIAZNo ratings yet

- M Icrotech Lightfoot PDFDocument2 pagesM Icrotech Lightfoot PDFDANIEL DIAZNo ratings yet

- Die DesignDocument30 pagesDie Designshaomin_liang89No ratings yet

- Mags Laid Out 2Document11 pagesMags Laid Out 2DANIEL DIAZNo ratings yet

- 02 - New Use of Dual-Phase Steels in The 2007 Saturn Aura Body StructureDocument29 pages02 - New Use of Dual-Phase Steels in The 2007 Saturn Aura Body StructureDANIEL DIAZNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Erection Procedures of Earthing Arrangements TNC TNS TNCS and TTDocument7 pagesErection Procedures of Earthing Arrangements TNC TNS TNCS and TTPierre Enrique Carrasco Fuentes0% (1)

- w170 w190 w230c - 30644gb 123bbDocument20 pagesw170 w190 w230c - 30644gb 123bbJIMISINGNo ratings yet

- Operating Manual: Wheel Loader L538 - 432 From 13100Document284 pagesOperating Manual: Wheel Loader L538 - 432 From 13100Jacques Van Niekerk80% (5)

- Expansion Indicator Boiler #1Document6 pagesExpansion Indicator Boiler #1Muhammad AbyNo ratings yet

- ICBC Motorcycle Handbook (British Columbia)Document212 pagesICBC Motorcycle Handbook (British Columbia)BNo ratings yet

- A. Marakani - FEA and Design of A Plane TrussDocument7 pagesA. Marakani - FEA and Design of A Plane TrussLe Thanh PhanNo ratings yet

- Summer Training ReportDocument133 pagesSummer Training ReportRitesh Meena100% (3)

- LTE KPI StatisticsDocument11 pagesLTE KPI Statisticskhurramrno100% (1)

- Agro IndustrialDocument126 pagesAgro IndustrialKt PalominoNo ratings yet

- STAT4GDocument1 pageSTAT4GjoramiandrisoaNo ratings yet

- Machxo2™ Family Data Sheet: Ds1035 Version 3.3, March 2017Document116 pagesMachxo2™ Family Data Sheet: Ds1035 Version 3.3, March 2017Haider MalikNo ratings yet

- Find Study Resources: Answered Step-By-StepDocument3 pagesFind Study Resources: Answered Step-By-StepJohn KingNo ratings yet

- PSM 1-6-7 (Ic) Emma Work Cards R 20 (30-11-18)Document322 pagesPSM 1-6-7 (Ic) Emma Work Cards R 20 (30-11-18)Héctor SánchezNo ratings yet

- Plastic, Rubber & Recycling IndustryDocument7 pagesPlastic, Rubber & Recycling IndustryPassionate_to_LearnNo ratings yet

- Filler Efect in ShotcreteDocument24 pagesFiller Efect in ShotcreteOscar NietoNo ratings yet

- Labtech 20121120 - SS HIRE Bro C 2Document24 pagesLabtech 20121120 - SS HIRE Bro C 2Carlos PereaNo ratings yet

- CBBEDocument23 pagesCBBECharuJagwaniNo ratings yet

- Control Systems Vs Machine LearningDocument2 pagesControl Systems Vs Machine LearningSufiyan N-YoNo ratings yet

- 7 - GEH-6370 MK V Time SynchronizationDocument44 pages7 - GEH-6370 MK V Time SynchronizationBouazzaNo ratings yet

- K13 High-Flex Waterproofing SlurryDocument3 pagesK13 High-Flex Waterproofing SlurryAmila SampathNo ratings yet

- CHE463 Heat TransferDocument1 pageCHE463 Heat TransferEitrah Tasnim Mohamat KasimNo ratings yet

- Harry BerryDocument2 pagesHarry BerryLuisNo ratings yet

- DD FC Basix ConfDocument18 pagesDD FC Basix ConfwstanzlNo ratings yet

- UTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal AssistantDocument2 pagesUTDEC 2020: Sub: Skill Test/Typing Test For The Post of Personal Assistantneekuj malikNo ratings yet

- Functional Buttons and Auto Power Off: International Electrical SymbolsDocument2 pagesFunctional Buttons and Auto Power Off: International Electrical SymbolsVentas SA TabNo ratings yet

- Brother Service Manual 7440NDocument64 pagesBrother Service Manual 7440NAlicia Smith100% (1)

- User Manual: Touch Control LED LampDocument1 pageUser Manual: Touch Control LED LampHector LuisNo ratings yet

- Agent CompatibilityDocument9 pagesAgent Compatibilityajilani2014No ratings yet

- Title Proposal Form For StudentsDocument3 pagesTitle Proposal Form For StudentsHelen AlalagNo ratings yet

- ENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enDocument5 pagesENSET Buea 2019 - 1ere Annee Du 2nd Cycle - enStéphanie Océane NadjiNo ratings yet