Professional Documents

Culture Documents

In-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol Inc

Uploaded by

Ruben AlvaradoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

In-Line Electronic Flow Switches: Ameritrol Inc. Ameritrol Inc

Uploaded by

Ruben AlvaradoCopyright:

Available Formats

In-Line

Electronic Flow

Switches

Ameritrol Inc.

Instruments and Controls

Industries

Petrochemical

Rening

Oil Production

Water Treatment

Pharmaceutical

Food and Beverage

Pulp and Paper

Power Production

Gas Processing

Mining

Biotechnology

Semiconductor

Ships/Marine

Defense Contractors

Pipelines

IM Series

Features

No Moving Parts

316L Stainless Steel

Temperatures to +250F

Pressures to 2000 PSIG

Low Flow Rate Detection

Tubing Connection

Reliable and Cost Effective

Simple Easy Field Calibration

Specications

Electronics

Housing: Standard: No housing (includes

circuit board mounting hardware)

Option Nema4X housing with

1 FNPT Electrical Connections

Temperature: -50 to +150F (-46 to +65C)

Power Input: 90-132 VAC, 50/60 Hz, 4 Watts;

Option 24 VDC/VAC, 200-240VAC

12 VDC

Relay Output: SPDT 3 Amps Resistive

Option DPDT and 10 Amps Res.

Dual Set Points

Shipping

Weight: 2 lbs

Sensor Head

Material of

Construction: 316L Stainless Steel Standard

Operating

Temperature: -50 to +250F (-46 to +177C) Standard

Operating

Pressure: Vacuum to 2000 PSIG (275 Bar)

Response Time: From 1 Second

Repeatability: +/-0.5% of Range at Constant Conditions

Process

Connection: Tubing Inlet and Outlet

Body Length: 6 Standard,Options Available

Cable Length: 10 standard, Option Specify Length

2

IM 2525

IM 2525 with MNPT Adapter Fittings

IM 2525 with Optional Housing

Operation

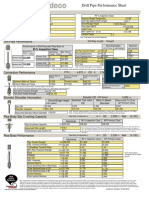

Figure 1

The IM series in-line ow switch is designed to easily

adapt to 1/4 tubing. Please refer to the IX or FX series

for larger line sizes. These switches offer an extremely

reliable and repeatable instrument for industrial process

control and feature no moving parts exposed to the product

being monitored.

The device operates by measuring a temperature

differential between a heated and a reference temperature

sensor. Within the body of the sensor head are the four

tubes as shown in gure 1. The temperature differential

is greatest at no ow and changes as ow is achieved

across the sensor. This allows use in applications requiring

a simple ow/no ow detection and for set-points at a

predetermined ow rate. Many different ow ranges are

shown in the set-point range section. A conversion table is

also provided to convert different engineering units.

Extremely low ow rates can be detected with a typical

turn down ratio of 300:1. The principle of operation allows

this ow switch to be used in practically all liquids, gases

and slurries.

Conversion Table

Convert to cc/sec on above chart

WATER/

AQUEOUS

AIR/GAS

Flow Switch Set-Point Range

FROM MULTIPLY BY: FROM MULTIPLY BY:

GAL/MIN 63.1 LITERS/HR 0.0278

GAL/HR 1.05 LITERS/DAY 0.0116

GAL/DAY 0.0438 CUBIC FT/MIN 471.95

LITERS/MIN 16.7 CUBIC MTR/HR 278.0

HYDROCARBON

Flow Volume

cc/sec

The electronics are available with single or dual

switch points. The instrument can be easily eld pro-

grammed to detect an increase or decrease of ow.

Relay outputs are standard and are offered with

several different congurations and contact ratings.

0 .05

5 .5 1.0 .1 10 1000 50 100

10,000

Temperature

Sensor #1

Temperature

Sensor #2

Heater

Temperature Differential =Temperature

Sensor #1 Minus Temperature Sensor #2

3

Circuit Board Options

Standard Single Switch Point Electronics

SPDT relay output with 3 or 10 amp contacts

DPDT relay option with 3 or 10 amp contacts

Wide selection of power inputs including 12 VDC, 24 VAC or VDC, 120 VAC, or

240 VAC

This circuit board is the standard used in the IM series ow switches. The electronics

offer constant current sensor excitation, precision signal amplication, and highly

repeatable switching circuitry for reliable operation in even the most demanding

applications.

Optional Dual Switch point Electronics

Two separately adjustable switch points

SPDT relay output for each set point with 3 or 10 amp contacts

Power inputs include 12 VDC, 24 VAC or VDC, 120 VAC, or 240 VAC

The optional dual switch point electronics provide two independently adjustable

switch points that can be used to detect any two combinations of decreasing and/or

increasing ow.

Single Switch Point Electronics with Additional Temperature Switch

Temperature switch point available from -50F to +350F

SPDT relay output for ow and temperature with 3 or 10 amp contact rating

Customer specied power inputs include 12 VDC, 24 VAC or VDC, 120 VAC, or

240 VAC

This optional circuit board monitors two process variables, ow and temperature,

with one instrument. Cost savings are realized by the user since the instrument has

only one process connection and one conduit run. Applications include monitoring

cooling water and all other applications shown on page 5 of this brochure.

4

Flow Switch Applications

Pump Protection: Automatic shut down on low or no ow

Bearing Lubrication: Detects loss of lubricant ow

Seal Leakage: Veries positive seal ow or detects excessive

leakage indicating maintenance requirement

Chemical Feed and Metering Pumps: Indicates low or no ow

of chemical additives to process

Spray Nozzles: Detects nozzle blockage in coating applications

Relief Valve/Rupture Disks: Alarms on ow or leakage of safety

relief valves or rupture disks

Chiller Lines: Automatic shut down of chillers on low or no ow

Analyzer/ Gas Chromatographs: Conrms continuous sample ow

to instruments

5

Flow Switch Calibrator Model MC-5

Displays mV output which is proportional to ow

Induces signal to electronics for setting specied switch point

Allows periodic switch point verication

This tool is not needed for a vast majority of users. It is useful when

a user has large quantity of units and requires periodic verication of

switch point calibrations.

This easy to use hand held, self powered instrument can be used in

conjunction with all single or dual switch point circuit boards. By sim-

ply plugging this instrument into the circuit board, the user can inter-

rogate all functions of the ow switch.

Optional Calibrator

PART NUMBER/ ORDER ENTRY SPECIFICATION

IM SERIES IN-LINE FLOW SWITCH

BODY LENGTH

6 STANDARD X

SPECIAL - SPECIFY

LENGTH IN INCHES

POWER INPUT

117 VAC (90-132VAC) X

12 VDC (-10%, +30%) B

24 VDC (-10%, +20%)

24 VAC (+/- 10%)

D

200-240 VAC E

PROCESS TEMPERATURE

-50F TO +250F X

RELAY OUTPUTS

SPDT 3 AMP RESISTIVE X

SPDT 10 AMP RESISTIVE J

DPDT 3 AMP RESISTIVE K

DPDT 10 AMP RESISTIVE L

1/4 TUBING INLET AND

OUTLET

2 5 2 5

PROCESS

CONNECTION

OPTIONS - NO ENTRY REQUIRED FOR BOXES WITH X

IM - -

Example 1: IM-2525-D

IM Series ow switch with 1/4 tube

inlet and outlet process connection, 6.0

body length, 24 VDC or VAC power

input, -50 to +250F process temperature,

single switch point with SPDT 3 amp

contact rating, no housing with 10 of

PVC cable.

Bulletin IM10-11

Ameritrol, Inc.

1185L Park Center Drive

Vista CA 92081

760-727-7273 Phone

760-727-7151 Fax

1-800-910-6689

Visit our website at www.ameritrol.com

DUAL SWITCH POINTS

SPDT 3 AMP RESISTIVE M

SPDT 10 AMP RESISTIVE N

ADDITIONAL TEMPERATURE SWITCH

SPDT 3 AMP RESISTIVE T 1

SPDT 10 AMP RESISTIVE T 2

SENSOR HEAD MATERIAL

316L STAINLESS STEEL X

OTHER ALLOYS

CONSULT MANUFACTURER

HOUSING

NONE STANDARD X

REMOTE NEMA 4X R

CABLE

10 PVC STANDARD X

SPECIAL - SPECIFY LENGTH IN FEET

STAINLESS STEEL TAG T

MILLIVOLT OUTPUT m V

Note Only one of these

options can be selected.

1

1

1

1

6

1

You might also like

- Digital Input Module SM 321 DI 16 X DC 24 V (6ES7321-1BH02-0AA0)Document3 pagesDigital Input Module SM 321 DI 16 X DC 24 V (6ES7321-1BH02-0AA0)Fabio CavalheiroNo ratings yet

- MK 201 ADocument4 pagesMK 201 AAli AhmadNo ratings yet

- (SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Document3 pages(SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Roberto Carlos TeixeiraNo ratings yet

- Calibration of Temperature Transmitter Anil Kumar KallaDocument5 pagesCalibration of Temperature Transmitter Anil Kumar KallaRamanathanNo ratings yet

- Datasheet Universal Rectifier 50v30ampDocument2 pagesDatasheet Universal Rectifier 50v30ampRonald Rosales Lopez100% (1)

- VFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedDocument5 pagesVFD Panels and SCCR: Short-Circuit Current Rating (SCCR) Is A Number You Need To HeedelengineerNo ratings yet

- AVFM-II Manual Series A.10 SpanishDocument47 pagesAVFM-II Manual Series A.10 SpanishVíctor Hugo Concha OrmeñoNo ratings yet

- Tilt Switch OldDocument2 pagesTilt Switch OldAngel Francisco NavarroNo ratings yet

- 722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)Document16 pages722222-CD-000-PIP-MTO-001 - Piping, Fitting, Flange, Gasket, Bolt - Nut - RA (Aboveground)rianafrian2611No ratings yet

- PCR PCRH Full lit-SP PDFDocument18 pagesPCR PCRH Full lit-SP PDFjuanfco1965100% (1)

- Cyl Tel CutsheetDocument2 pagesCyl Tel CutsheetaLeXiNNo ratings yet

- Lecture 5 - Power SuppliesDocument48 pagesLecture 5 - Power SuppliesNimsiri AbhayasingheNo ratings yet

- Nfpa2 ADocument1 pageNfpa2 APOLPMENo ratings yet

- Austdac GSW ManualDocument83 pagesAustdac GSW ManualMuhammad AzharNo ratings yet

- DeviceNet Troubleshooting by Robert D LawDocument13 pagesDeviceNet Troubleshooting by Robert D LawAntonio De Leon Garcia100% (1)

- SIMATIC - 002-Demo Projects For LOGODocument4 pagesSIMATIC - 002-Demo Projects For LOGOJorge_Andril_5370No ratings yet

- Document'S Code Attachment 10.3 Revision 0: ClientDocument4 pagesDocument'S Code Attachment 10.3 Revision 0: ClientrfriosEP100% (1)

- KSR KueblerDocument22 pagesKSR KueblerlavascudoNo ratings yet

- GLX, Catalogue 2004 - 09Document4 pagesGLX, Catalogue 2004 - 09victorNo ratings yet

- PPR VerdeDocument96 pagesPPR VerdeIonut SomneaNo ratings yet

- 2013 Siemon Full CatalogDocument248 pages2013 Siemon Full CatalogJuprayNo ratings yet

- Nfpa 2001Document1 pageNfpa 2001guruuptoNo ratings yet

- Test & Drain TechDataDocument1 pageTest & Drain TechDatajhoger2012No ratings yet

- Foxboro 823DPDocument3 pagesFoxboro 823DPMaria TipantuñaNo ratings yet

- Preconstruction MeetingDocument32 pagesPreconstruction MeetingMar OlacsNo ratings yet

- Imaje - s8 Classic Brochure HQ - S PDFDocument4 pagesImaje - s8 Classic Brochure HQ - S PDFjagarciarNo ratings yet

- C7015 Infrarroja PDFDocument16 pagesC7015 Infrarroja PDFAlfredo Mitzi HernandezNo ratings yet

- OpticalCON Power Budget CalculatorDocument1 pageOpticalCON Power Budget CalculatorGuido MartinezNo ratings yet

- Meta MEC Adjustable MCCBDocument16 pagesMeta MEC Adjustable MCCBECATOnlineNo ratings yet

- CCM M6 Con Variadores 8998DB0001R102 PDFDocument10 pagesCCM M6 Con Variadores 8998DB0001R102 PDFRobertoHerediaJacoboNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- BSB Opzv SeriesDocument2 pagesBSB Opzv SeriesEris Osman RifkiNo ratings yet

- DCS PLCDocument5 pagesDCS PLCpertejo157No ratings yet

- POLYMATEDocument2 pagesPOLYMATEDPMXXINo ratings yet

- D.P.transmitter Spriano 47B ManualDocument22 pagesD.P.transmitter Spriano 47B ManualBruno100% (1)

- Solar LaminatorDocument6 pagesSolar LaminatorAnonymous XoM50xp84yNo ratings yet

- CMS Power PointDocument23 pagesCMS Power PointNatarajan SubramanyanNo ratings yet

- Data Sheet 2800si Silica Analyzer enDocument2 pagesData Sheet 2800si Silica Analyzer enGuy MesikaNo ratings yet

- Series 9: Quick GuideDocument64 pagesSeries 9: Quick GuideKalle100% (1)

- Spray-Type Deaerating Heaters: TABLE 12.2Document2 pagesSpray-Type Deaerating Heaters: TABLE 12.2Yanuar KrisnahadiNo ratings yet

- Reference Manual: 800xa - AC800M Connect - Minerals LibraryDocument68 pagesReference Manual: 800xa - AC800M Connect - Minerals Libraryjuan bautista vezzosiNo ratings yet

- Sequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1Document1 pageSequence of Operation: Typical Ahu DDC Control Diagram - (Cav) System - 1JYOTHEESWARA NAIDU100% (1)

- ABB Ability System 800xa Select IO DatasheetDocument12 pagesABB Ability System 800xa Select IO Datasheetdave chaudhury100% (1)

- EasyPact TVS motor startersDocument26 pagesEasyPact TVS motor startersrhap_0925060No ratings yet

- AFS 650-655 Installation PDFDocument36 pagesAFS 650-655 Installation PDFMatijaDebogovićNo ratings yet

- HWS2000 ManualDocument30 pagesHWS2000 Manualmarius vasile0% (1)

- Introduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerDocument26 pagesIntroduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerKunal PandeyNo ratings yet

- WL705 Ultrasonic Water Level SensorDocument1 pageWL705 Ultrasonic Water Level SensorEdward YaoNo ratings yet

- Quick Start Manual 1.14.UK - GER.FR - SP.NL.02Document28 pagesQuick Start Manual 1.14.UK - GER.FR - SP.NL.02George GershwinNo ratings yet

- Y62013 - 2X16 AWG ShieldedDocument1 pageY62013 - 2X16 AWG ShieldedRicardo TitoNo ratings yet

- Thermostat AB-E 31-32: Adjustment Range 5 To 100°CDocument2 pagesThermostat AB-E 31-32: Adjustment Range 5 To 100°ChaggNo ratings yet

- FCS MBX Megablocks Rev3Document6 pagesFCS MBX Megablocks Rev3shareyhouNo ratings yet

- OMNI Modules - Installation OptionsDocument9 pagesOMNI Modules - Installation OptionsfarhanNo ratings yet

- KAM SR ™ Sample Receiver: Key Kam Advantages ApplicationsDocument2 pagesKAM SR ™ Sample Receiver: Key Kam Advantages ApplicationsbzkxtNo ratings yet

- U13192 001 RTS O&mDocument124 pagesU13192 001 RTS O&mDan Hidalgo QuintoNo ratings yet

- Install STS-1 Security Tamper SwitchDocument2 pagesInstall STS-1 Security Tamper SwitchRobel MTNo ratings yet

- BCC M323 Drag Chain ConnectorDocument2 pagesBCC M323 Drag Chain ConnectorAlberto AvilesNo ratings yet

- Ameritrol Electronic Thermal Flow SensorDocument2 pagesAmeritrol Electronic Thermal Flow SensorJavier AffifNo ratings yet

- XFC EspecificacionsDocument19 pagesXFC Especificacionsadesa2013No ratings yet

- 3095MFP Integral OrificemeterDocument10 pages3095MFP Integral Orificemeterابزار دقیقNo ratings yet

- NI Tutorial 13579 enDocument9 pagesNI Tutorial 13579 enRuben AlvaradoNo ratings yet

- Siemens TutorialDocument26 pagesSiemens Tutorialsundaramoor0% (1)

- High Speed Fuse Application GuideDocument40 pagesHigh Speed Fuse Application Guideangel1885No ratings yet

- CLD Exam Prep Guide EnglishDocument13 pagesCLD Exam Prep Guide Englishk_goulasNo ratings yet

- Ac Motors EbookDocument74 pagesAc Motors EbookHammad MalikNo ratings yet

- 597 0138 01 - RevCDocument44 pages597 0138 01 - RevCRuben AlvaradoNo ratings yet

- Tds Lifecamvx 800Document1 pageTds Lifecamvx 800Ruben AlvaradoNo ratings yet

- Bress Brief ToCDocument1 pageBress Brief ToCToddNo ratings yet

- Payload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotDocument2 pagesPayload: 80 KG: DX100 Controller Powerful Performance in A Mid-Size RobotRuben AlvaradoNo ratings yet

- InglesDocument1 pageInglesRuben AlvaradoNo ratings yet

- Vocabulary Connectives Openings and PunctuationDocument5 pagesVocabulary Connectives Openings and PunctuationRuben AlvaradoNo ratings yet

- Electric Circuits 3 QPDocument7 pagesElectric Circuits 3 QPPREM OfFiCiAlNo ratings yet

- GQRP Component Data Book: How It All WorksDocument27 pagesGQRP Component Data Book: How It All WorksGabriela GNo ratings yet

- TP5100 TopPowerDocument15 pagesTP5100 TopPowerEngin UzunNo ratings yet

- Electrical Power Engineering Training LabDocument96 pagesElectrical Power Engineering Training Labsayedmh100% (1)

- Commutator MaintenanceDocument18 pagesCommutator Maintenanceeko sunaryoNo ratings yet

- Ps8305 LV Acb MaintenanceDocument5 pagesPs8305 LV Acb MaintenancePhuc PhamNo ratings yet

- APsystems YC500A For Brazil Datasheet - Rev2.0 - 2016 08 27Document2 pagesAPsystems YC500A For Brazil Datasheet - Rev2.0 - 2016 08 27Diego LimaNo ratings yet

- Ec ProjectsDocument6 pagesEc ProjectsSurya KotamrajaNo ratings yet

- Bushong: Radiologic Science For Technologists, 11th EditionDocument4 pagesBushong: Radiologic Science For Technologists, 11th Editiongasai gasaiNo ratings yet

- Power Transformers - Hitachi EnergyDocument1 pagePower Transformers - Hitachi EnergychipulinoNo ratings yet

- ABB GridShieldDocument24 pagesABB GridShieldJuanes Cevallos100% (1)

- Distribution Systems OverviewDocument6 pagesDistribution Systems OverviewGilbertNo ratings yet

- Datasheet A1941 Y C5198Document3 pagesDatasheet A1941 Y C5198Samuel RivasNo ratings yet

- P-Q Diagram Photovoltaic Po Construction For Multi Ower Plant Connected T I-Inverter o MV GridDocument4 pagesP-Q Diagram Photovoltaic Po Construction For Multi Ower Plant Connected T I-Inverter o MV GridANTONIO SOLISNo ratings yet

- Datasheet ENG SolarEdge Hybrid SE 2200 6000HDocument3 pagesDatasheet ENG SolarEdge Hybrid SE 2200 6000Haddo_No ratings yet

- 7625 English TarjomeFaDocument12 pages7625 English TarjomeFaPEDDAKOTLA YASHODANo ratings yet

- TB 03700001 eDocument33 pagesTB 03700001 eRicardo LopezNo ratings yet

- ABB Technical Guide 1 - Direct Torque ControlDocument32 pagesABB Technical Guide 1 - Direct Torque ControlASM_213No ratings yet

- CTEK US800 ManualDocument10 pagesCTEK US800 ManualCTEK Battery ChargersNo ratings yet

- CXA1019 FM Radio Circuit Diagram GuideDocument5 pagesCXA1019 FM Radio Circuit Diagram Guidedeepakkr22781No ratings yet

- Shure fp42Document20 pagesShure fp42Denis ZhuravelNo ratings yet

- BGC-L Data Sheet 4921240306 UKDocument5 pagesBGC-L Data Sheet 4921240306 UKRafael Charry Andrade100% (1)

- 2SK2632 PDFDocument4 pages2SK2632 PDFMarcos DelmoralNo ratings yet

- Uv Visible SpectrosDocument6 pagesUv Visible SpectrosSnape the PrinceNo ratings yet

- EDC LAB Manual-JNTUA PDFDocument70 pagesEDC LAB Manual-JNTUA PDFVenkatesh ShankarNo ratings yet

- VLSI Design ManualDocument45 pagesVLSI Design ManualRafeyNo ratings yet

- Electromagnetism Homework: Magnetic Fields and Multipole ExpansionsDocument2 pagesElectromagnetism Homework: Magnetic Fields and Multipole Expansions丁安磊No ratings yet

- Automatic Restart of Essential Motors Using Micro Processor Based RelaysDocument21 pagesAutomatic Restart of Essential Motors Using Micro Processor Based RelaysJasa R ChoudharyNo ratings yet

- ALARM 410 (Excessive Position Error Amount During Stop)Document1 pageALARM 410 (Excessive Position Error Amount During Stop)Cicero MelloNo ratings yet

- Online Heat Transfer by Radiation 2021Document49 pagesOnline Heat Transfer by Radiation 2021Jason Yap Han YuenNo ratings yet