Professional Documents

Culture Documents

DSR Pune

Uploaded by

Asif Khan0 ratings0% found this document useful (0 votes)

232 views298 pagesDSR PUNE

Original Title

DSR PUNE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDSR PUNE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

232 views298 pagesDSR Pune

Uploaded by

Asif KhanDSR PUNE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 298

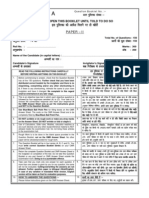

MAHARASHTRA JEEVAN PRADHIKARAN

( Government of Maharashtra Undertaking )

SCHEDULE OF RATES

FOR THE YEAR 2012 - 2013

( Effective from 24

th

December 2012 )

APPLICABLE FOR PUNE REGION

MAHARASHTRA JEEVAN PRADHIKARAN WORKS

Approved by the Chief Engineer - Water Management, Maharashtra Jeevan Pradhikaran,

Thanes Letter No. C.E. ( W. M. ) / TB-3 / CR46(C) / 3774 dated 31 / 12 / 2012.

COUNTERSIGNED FOR THE YEAR 2012 - 2013

Sd/-

CHIEF ENGINEER ( W.M. )

Maharashtra Jeevan Pradhikaran, Thane.

I N D E X

Section Name of Section Page Nos.

No. From To

List of Hilly Area 1 6

General Notes 7 10

A Materials 11 12

B Labour & Machinery 13 14

C Transportation 15 32

D Cement Consumption 33 34

E Excavation 35 40

F Iron and Structural Steel Work 41 42

G Plain & Reinforced Cement Concrete, Ready Mix Concrete 43 52

H Miscellaneous 53 58

I Pipes { Detail Index below } 59 204

J (I) Treatment Plant ( WTP & STP ) 205 222

(II) Moving Media Bio Reactor Technology 223 240

K (I) RCC GSRs & Sumps 241 244

(II) RCC ESRs 245 250

(III) Ancillary Items for Reservoirs 251 254

L Chambers, Manholes & Drainage Drops 255 264

M Well Sinking & River Infiltration Works 265 270

N Trial Run 271 272

O Type Designs 273 294

DETAIL INDEX FOR I SECTION ( PIPES )

Section Name of Sub-Section Page Nos.

I From To

( I ) C.I. / D. I. Pipes 59 68

( II ) A.C. Pipes 69 72

( III ) P.V.C. Pipes 73 78

( IV ) G.I. Pipes 79 82

( V ) Stoneware Pipes 83 84

( VI ) R.C.C. Pipes 85 90

( VII ) P.S.C. Pipes 91 98

( VIII ) B.W.S.C. Pipes 99 104

( IX ) G.R.P. / F.R.P. Pipes 105 112

Section Name of Sub-Section Page Nos.

I From To

( X ) H.D.P.E. Pipes 113 118

( XI ) M.D.P.E. Pipes 119 128

( XII ) P.C.C. Pipes 129 136

( XIII ) Pipe Appurtenances 137 154

( XIV ) Mechanical Joints / Fittings 155 162

( XV ) M.S. Pipes 163 184

( XVI ) Fabrication of M.S. Pipes &

Specials

185 190

( XVII ) M.S. Pipe Laying 191 204

1

emgZ {ZU`, Jm_{dHmg {d^mJ H. Jmnmnw-1090 / grAma-163/39-A

{X.7 {S>g|~a 1990 Mo ghn

n[a{e> - 1

am`mVrb S>m|Jar {d^mJmMo jo Xe{dUmao {ddaUn

|=-r| -|==| -| s|t| ||-

=|r | s|t|=

+|+

+ -|

-|=|- -~

+| =|=- +

=|r -| +

++ -| -|=|-

-~ +| =|=- +

-~ +| =-| +

=|r -| ++

nt|

. =| . -||s| =n|;| ++- t||

+=; -. +|s| +|a- =|

. nr|+t +|a- =| + ()

. -t+|s +|a- =| + ()

-. =r|t +|a- =| + (-)

. +=; +|a- =| --- ++ () ++ |

. |+s| +|a- =| --- ++ (-) +-|t +|a- |

-. t|s . ==- +|a- =| + ()

. |=|+t +|a- =| + ()

. =|s +|a- =| + ()

. t|r| +|a- =| + ()

-. -||+ +|a- =| + ()

. -r|s +|a- =| + ()

. +|=|:+t +|a- =| + (-)

-. + +|a- =| + ()

. -=s +|a- =| + ()

. -r==| +|a- =| + (-)

. +++= +|a- =| --- ++ () :| |

. t+||t| . s +|a- =| + ()

-. |=+= +|a- =| + ()

-. =-t +|a- =| + ()

--. =|=| +|a- =| + ()

-. t|=|+t +|a- =| + (-)

-. -ss +|a- =| --- ++ () +-|t=s|= |

. |=: --. ===+=| +|a- =| + (-)

-. =|+-+|s| +|a- =| + (--)

-. :+s +|a- =| + (-)

-. =s|= +|a- =| + (-)

-. +++|s| +|a- =| + (--)

. -|=+ +|a- =| --- ++ (-) ++ |

2

|=-r| -|==| -| s|t| ||-

=|r | s|t|=

+|+

+ -|

-|=|- -~

+| =|=- +

=|r -| +

++ -| -|=|-

-~ +| =|=- +

-~ +| =-| +

=|r -| ++

nt|

-. +||n= . ;-+t| +|a- =| + (-)

-. +||n= +|a- =| + (-)

. |:s|t| +|a- =| + (-)

. += +|a- =| + ()

-. =t| +|a- =| + ()

. ==+ +|a- =| + (-)

. +|=|+ (=||) +|a- =| + ()

. |=t +|a- =| + ()

. =r-:+t . ==|=| +|a- =| + (-)

. =-+t +|a- =| + (-)

. + . =t =n|;| ++- t|| + ()

-. =|+|+ =n|;| ++- t|| + ()

. s (t|==+t) =n|;| ++- t|| + ()

. -|+= =n|;| ++- t|| + ()

-. r+=| =n|;| ++- t|| + ()

. -=n| =n|;| ++- t|| + ()

. +-r =n|;| ++- t|| + (-)

. |t =n|;| ++- t|| + ()

. +t:t =n|;| ++- t|| + ()

. =|-|t| -. =|-|t| =n|;| ++- t|| + (-)

-. +|; =n|;| ++- t|| + ()

--. +|| =n|;| ++- t|| + ()

-. =|+=| =n|;| ++- t|| + ()

-. -r|+=t =n|;| ++- t|| + ()

--. |+ =n|;| ++- t|| + (-)

-. s|=| =n|;| ++- t|| + (-)

-. =|t|+ =n|;| ++- t|| + (--)

-. =t|s =n|;| ++- t|| + ++ () ++=s|= +|a- |

- ++ () ++=s|=, :|=s|=, +-|t=s|=,

+|a-=s|= =|r| |

. == =n|;| ++- t|| + ++ () :|=s|= + ++=s|= =|r| |

. =|=| . |nt|=| =n|;| ++- t|| + (-)

. =|-r|+t -. n|r+|s| =n|;| ++- t|| + (-)

. +-r|=| =n|;| ++- t|| + (--)

. =t+|t =n|;| ++- t|| + (-)

-. ++|+s| =n|;| ++- t|| + (-)

. t||+t| =n|;| ++- t|| + (-)

3

|=-r| -|==| -| s|t| ||-

=|r | s|t|=

+|+

+ -|

-|=|- -~

+| =|=- +

=|r -| +

++ -| -|=|-

-~ +| =|=- +

-~ +| =-| +

=|r -| ++

nt|

. =|= =n|;| ++- t|| + (-)

. :ts +|a- =| + ()

. =|=t| +|a- =| + ()

. =:s +|a- =| + (-)

. s|r== +|a- =| + ()

. = -. =|=| +|a- =| + ()

. ++|+t| +|a- =| + (-)

. ====+| =|-+s| s|t + ()

-. ==|| =|-+s| s|t + ()

. |nt+t =|-+s| s|t + ()

. nr|:| =|-+s| s|t --- ++ () ++=s|= + |s| +-|t=s|= |

. -=|:| =|-+s| s|t --- ++ () +-|t=s|= |

-. ==|+ . =|+s| =|-+s| s|t --- ++ () +-|t=s|= |

. +=| =|-+s| s|t --- ++ (-) +-|t=s|= |

. t|+t =|-+s| s|t --- ++ () +-|t=s|= |

-. |:=|+|: =|-+s| s|t --- ++ () +-|t=s|= + ++=s|= =|r| |

. =-t|+-| . |t| =|-+s| s|t + ()

. |==:t| =|-+s| s|t + ()

. +--|= -. +=: =|--|=| t|| --- ++ (-) +-|t +|a-=s|= |, |s| --

|

. =-ts =|--|=| t|| --- ++ () +-|t=s|= + ++=s|= |

-. +|:s . |=++ =|--|=| t|| + ()

. ==|=| . +|-t =|==|= s|t --- ++ () :| + ++

. +=c|| . |-|+ =|==|= s|t --- ++ () +-|t + ++=s|= |

. =|t|+|: . =s =|==|= s|t --- ++ () +-|t + ++=s|= |

. =-|+|: =|==|= s|t --- ++ (-) -=| + :|=s|= |

-. =||+ =|==|= s|t + (-)

. |=|s =|==|= s|t --- ++ (-) +-|t=s|= + |s| :| +|a-=s|=

|

. +t| . |r|=| =|==|= s|t --- ++ (--) :|=s|= |

-. ==-+t| =|==|= s|t --- ++ (-) :|=s|= |

4

emgZ {ZU`, Jm_{dHmg {d^mJ H. Jmnmnw-1090 / grAma-163/39-A

{X.7 {S>g|~a 1990 Mo ghn

n[a{e> - 2

VmbwHmdma mXrVrb CnJQ hUyZ Kmo{fV Hobom VmbwmVrb JmdmMr mXr Xe{dUmao {ddaUn

|=-r| -r+

=||+- ===|

-|==|

++ -|=+|-|= |+|=| +|+

=|

. +=;

) =|:= -) |-+|=| ) |n++|=| ) +|+=| -) +=|+ ) +|t|= ) |nt+=| ) ===|| ) +=; ) =|t+ ) =|=t

-) |+= ) +=| ) =||=+=| -) :|++=| ) =|=t| ) |s=t ) |s| ) |== - ) t -) =:| --)

=s|= -)|--r= -) =|+ --) -t-|t| -) |+=+s| -) | -) :s|+t| -) =||-+=| ) |s| ) :s| -) :s|+ )

+|-+ ) =|= -) =|-r| ) =|=| ) |==|| ) r|+|=+

-. |+s| ) n+t| -) +s+=| ) +=|+ ) |s|+ -) =|:|+|s| ) |+|| ) +||r=| ) +|+=| ) -|=|+|t ) +=|=| )

+=+|s| +|s| -) =|+t|; +|s| ) |t ) s=| : -) |++=n- ) s=| +;= ) |=+|= ) =r|+|s| ) =r|

-) =|+|+|s| -) :++|s| ==;+|s| --) +||+ -) +|| -) +=++|s| --) |+s|+|s| -) |t|+ -) |+| -)

=|=+=| -) |==+|s| ) |t|+|s| ) s|=t+|+|s| -) ===|=t|

t|s

. +++=

) -||==t -) =|s=|++| ) =|++| ) +|-|t| -) +|-:+| ):+=|=| ) o|++| ) =|=+=| ) =|t=|; ) =|+|

) =|=+ -) =|ts| ) :+| ) +==s| -) ==+s| ) =t|s|+ ) +|+=t ) =|r| ) :|+|+=| -) :+-=| -)

=|+=| --) =t+|r| -) ==| -) +s|+| --) =|t= -) :== -) =|=| -) |:=|t| -) r|-+s|

t+||t|

. -ss

) =+|++| +;= -) ==|==t ) =|t| ) r-| -) |t|+|s| ) ++| ) +|st| ) +|s+| ) =+t= ) |r=|; ) t| -)

=|=t++ ) -r|+- ) rs=t -) -|| ) =|rt| ) |t= ) =|t ) |+= -) +-r|=| -) t| --) -|t+=| -)

=|+ -) +t --) =|t= -) =s= -) r=|; -) +| -) ===| ) =|s=| -= r=|; ) +s = -) : )

|n|+ ) =|s| -) -==t ) |=s| ) +|=t|= ) |-| ) +|t ) |+| ) |-=t -) =|-|| )

|+s|

|=:

-. -|=+

) ==|= -) ===s| ) +|+| ) +==|t -) ||t|+ ) |+|+| ) |nt|+s ) t||+s ) =|=| ) +|n )

|r+|= -) =|+=| ) |= ) s s = -) +|+|+s ) +|t+ ) +|;+ ) +=t ) +|s-| +| -) ++| +| -)

|=+ --) s|=+= -) =|+|= -) =-|- --) +|:|=| -) |-t|+s -) +|t= -) sr=

=|-|t|

. =t|s

) -t=| -) =|t=+|s| ) =|t|+= ) +=:|t -) -r|+ ) |=+|s| ) =|=s| ) = ) =|= ) ==t ) -=+

-) =+|: ) =|=+|s| ) r+=+|s| -) -r|=|=| ) n ==+|s| ) -+ ) +-| ) =t|=+|s| -) r--+|s|

-) |=|+ --) =|+ -) |t+|s| -) n+|s| --) t+|s| -) =|=|nt- -) -r|ts+|s| -) |=-| -) ==|;+|s|

) =|=|t|nt- ) |+s| -) |=+|+|s| ) |=+= ) |s-|;+|s| -) -=t ) r+t+|s| ) +||=| +|s|

) -|=+|s| ) =|+||s| ) |nt|+ ) -=| -) +|= ) rt+=+|s| ) |t=+s -) +=-| =|=s| ) =|=t

) -|++ ) =|t+|s| ) -+|s| -) -|=+|s| -) s|=+|s| --) +|ct|+|s| -) =| -) =|++s --) -|= -)

+|++|s| -) |n-=+|s| -) |=t+s| -) =t=: ) =|-| ) +|=t| -) =t+s| ) r=t|t -|=| ) +|+t -|=| -)

+++|= -|=| ) t|=-|=| ) ) |+t ) =|t|+ ) =|+ ) +s|+ r++=| -) n+|=| =|=+s

5

|=-r| -r+

=||+- ===|

-|==|

++ -|=+|-|= |+|=| +|+

. == ) =|=+ -) =|:=|: ) =|==|+t ) =|t|= -) +|=|n| ) =|+s| ) -|++|s| ) =|s=+|;+|s| ) +=|n| ) +==+

) :|++|s| -) |t+|s| ) |t+| ) -|=+|s| -) +s=+|s| ) =|== ) |s=| : ) :|+| ) =|+=|

-) =|:s -) =t+|=| +.

. -|+ ) ====t+|s| -) |s+|s| ) |s| +;= ) +|=+ -) -|s= ) +=+|s| ) |n:| +;= ) |n|+t ) |s=|

) ;=-|- ) ===|s| -) |+t=| ) |+t=| ) ==s+|s -) - ) =|=+|s| ) +|t+|s| ) |=t==|s )

|r-|+s -) |:+s| -) +|ct|+|s| --) =+t++|++|s| -) |n:| +;= -) +|

=

. n|r:|

) =|=t: : -) =|=t: +;= ) =|c|+= ) =|:==| -) |=ts ) +=s +;= ) -=|+ ) =|+| ) :t| ) t||+t|

) =|==+t -) -|+-|s| ) +|=t| ) =s| +=+| -) ==s+|s ) - ) =||s+t : ) t+| )

+||+ -) |==t| -) +| --) =|=|t|= -) =|:+t -) :| --) ;=t|= -) =|=t -) |+t+t

. -=|:| ) =|=t+|s| -)-|=: ) =||+ : ) =|=s n -) s| : ) =|=|t ) +|t| ) s| +;= ) =+|| ) =||+t

) -|= -) -|t|-|= ) =|+| r| )=|-+|+=| -) +|-+| ) -=+| ) t|=|+t

==|+

. =|+s|

) -t|=| -) =+|=+ ) |st| ) |t|=s| -) +-t| ) |+|+|s| ) =-|+t ) |-|+|s| ) |+=|+t ) -=|+-|t )

n-+|| -) +|=t=+-| ) -|=|+t ) |++|+t -) +|t-=| ) ==|| ) -=|+| ) :r|t|

-. +=| ) -++|; :+=|+ -) =s| =|+| ) c -| ) =|--| -) +=-=| ) rt|+t| ) +|:+| ) +|==|t ) =|=t|+|t|

. t|+t ) |-s| -) =|t-|=| ) -|r-|s| ) |==|s| -) |=-s| ) |ts| ) -|r-|s=| =+ ) |++=s ) +|= ) -|tr|=

) |=-=| -) |ts ) =r=+|= ) =|=-|-|

. |:=|+|: ) :; -) ===| ) =|-|+ ) s|=ts -) +|:+= ) +|= ) =|t=| ) :+| -:|t ) -|t|=t| ) =|+s

) =|=|s| -) r=s|

+=c||

-. |-|+

) |t|=| -) ;=|=+|s| ) |==s+| ) ==s|+ -) |==s+s ) n;| ) -|s| ) +|| ) s| ) +|=| ) |ts

-) |t|s| ) |t ) -|t|+ -) |==s ) =|-| ) ==t ) |++t| ) +t ) =|++|s| : ) +-|+t

-) |+-s| -) |r+ts| --) |+t|s|

==|=|

. +|-t

) =+|t| -) |+|=| ) +=+= ) +==|+t -) |=: =:|=| ) +s| =|-t|; ) +|s=| ) |+|+t ) =|=s:|t| ) =|=|t|

+;= ) +|== -) =|=|+ ) -|=t|=t| ) =|+ts -) |==s +|-t ) n=|+t ) =|=| ) =|t-=| ) t-

-) +|:| -) =|++| --) |==+|r= -) =|s| -) =|+ --) |==s -) |=|+ -) =||t =|+| -) |+s|+ -)

=|+t|+

+--|=

. +=:

) |++=|+ -) r|=|+t ) +|-++|s| ) =|-r|= -) r=| ) =|s| ) |===| ) :+r| ) +=r| ) =|-+| :

) -|ts -) +s|| ) +|t+| ) +|:| : -) =|=| ) +-r|=| ) -|=t=+=| :| ) -|=t=+=| )

=|+--|= -) r++-s -) -|t+|s| --) =--+t -)+-= -) =+== --) +++++|s| -) t|-+t+t -) :|t|

-) =+|= -) =|++|;=t ) |n=|+|

6

|=-r| -r+

=||+- ===|

-|==|

++ -|=+|-|= |+|=| +|+

. +-ts ) |:s|=| -) +|s| ) |+t=| ) ||+:+t -)=t=| ) =|- ) ==|=| ) =|-|t| ) -== ) +|s| ) =+=|

-) |++=|+ ) +|s| ) +| -) +:|+t ) =|+t|+ ) +t|| ) +|+| ) +|t| -) ts| -) +++|=|

--) =|+:|-| -) =+| -) -|t=s| --) =|=+| -) |==| -) t|-+t -) +|t|+ -) s|t|+ ) s|=| ) |;t

-) ++=|=+t ) |:= ) =|| -) =+=| ) +r=| ) +|+|t| ) |n+|=|+t ) =+t|=| ) +-t| ) ==|=|

-) =+|=|=+t ) +s|+ ) :|-=t| -) |t +;= ) =ts| ) :t|t| ) -t|+t

=|t|+|:

. |=|s

) +|n+|s| -) +|=|+ ) +|t| ) +|+t| -) -|-|+|+|: ) =r| ) +||+ +;= ) =|t| ) =|-+| ) =-t|+-|

) =||+|:| -) +t:n|+|s| ) =|t+t ) |+s| -) =|t+|s| ) =s|+ ) |=t=|- ) +|-|+ ) =|-=

-) r|=:| -) |++=:t| --) -+|t -) +|=t| -) t|=| --) =|==| -) =+|s -) =|-=t| -) +|t+| -) +s|=|

-. =s ) -|:=+|s| -) ++=| ) --=|+t ) +=s+|s| -) =|s+|s| ) =-|| ) +s+t ) =+|=| ) =|+| ) =|-s| ) t=

-) ==s ) +|:|t+|s| ) |r+ts -) +s|=| ) =-s ) -|=|+ c|== ) |t+| ) -|=|+ =||s

-) -|r|s| -) r=-| --) -|r|+ -) =s=t -) +==| : --) =|+=| -) |=:t| -) |t|++=| -) =+s +;=

-) |++ts| ) ==||+|: ) s=| -) |+n|t ) |-+|s| ) +|=t| -) |+|t| ) +-ts ) =|+t|+ )

|-| ) =|++|s| +;= ) -r ) r|t+|s| -) +s|+ ) =|=| ) +|t| -) |++|s| ) =|++|s| ) |n+=|

) |=-|+t ) +||+t -) =t=s -) ts=|+ --) +++t -) =|n| -) |==| --) =-t -) =|r|+

-. =-|+|: ) +s|+ -) +|s=| ) |nt|= +;= ) =|+ts| -) =|| ) +|s= ) =-|+|: ) |-|+ ) =:=|+t ) |+ts|

+;= ) |++t| -) =-|=+|s| ) -r=-|= ) |nt=-|= -) |==| : ) =|-+|s ) +-= ) -+|+t )

=-|+|: -) =t|; -) +:=|+|; --) +:+|: -) -|+=|=| -) t==+t --) n=t+t+|s| -) =|+s| -) |s| -)

=|+s| -) =| ) =|-+|+ ) |-+|+t -) |+t-|+

+t|

--. |r|=|

) +t=| -) =|r|+ ) =+=| ) |++=| -) +|t=| ) ==|+ ) n=|+ ) =|+|+ ) |++ts ) :+=| ) =+|+++|s|

-) ===|+t ) -|| ) -|-=|+t -) =rt|++t| ) |=t ) |:== ) s=+| ) +s=+| -) =|c| -)

r+-|+:t| --) |n+=|t -) =|-=| -) =|-:+ --) +=|+t -) +|=| -) =|== -) -+=|r| -) -|s||+ ) t|

) =|-t| : -) +|t| ) +|t|=| ) +|:t| -) =s+| ) =|-+s ) +n+t| ) =|+ ) =|-=+ ) +|ts|

) =|+ -) |t|= ) -=|+ ) =|=+ -) ===| +;= ) ===| ) |n:+= ) +t+|s| ) =+=s

-) +|=|+ -) |t|+ --) +|s|: -) +n+|s| -) |++t| +|+= --) +|ts -) |=+| -) s|=| -) |==|=|

-) +=t| ) =|s|+ ) :+=| -) =|=|+ ) ==|s ) =+==| -) =||+| ) :+=|

-. ==-+t| ) s -) |+|+t ) |+| ) =-t|=| -) |nt= : ) |nt= +;= ) |s= +|+| ) |++t| ) =|s= ) t=t ) +t|s|

-) s=- +;= ) s== : ) -:|t| -) |ts ) -rt| : ) s=- ) += ) :t| -) |==|=|

-) |s-=| --) +s|+ -) s|| -) +|:t| --) +|=|+t| -) -=|+ -) =|+| -) |-= +;= -) =|+= ) |n+| )

-|=+|s| -) :|s|+ ) -|-|=|t ) |+;=+|s| -) |++t| +: ) =|+|+ ) =|+| ) :||s| ) +=| )

-|t|+

GENERAL NOTES

7

MAHARASHTRA JEEVAN PRADHIKARAN PUNE REGION

SCHEDULE OF RATES FOR THE YEAR 2012-2013

GENERAL NOTES

1 These rates are applicable to all MJP works in the PUNE REGION with effect from 24/12/2012.

2 Item of excavation is inclusive of normal manual dewatering; however, separate item for

dewatering shall be proposed in the estimate where underground water is anticipated in

significant magnitude.

3 The rates of excavation for O&M works where limited working space is available and work is

required to be carried out on emergency basis, should be adopted as per the actual rate

analysis which shall be approved by concerned S.E. for that particular work only.

4 Rates for all items are inclusive of all taxes levied by Central, State Govt. or local bodies.

Labour rates are inclusive of EPF (12.5%). These rates are applicable only for tendered works

and should be reduced by 12.5% of labour part when works are to be carried out on piecemeal

works and other small works without tendering.

Note : As per Govt. notification No. 25/2012 / service tax dtd. 20 June 2012 point No. 12-E Service Tax

is exempted for pipeline, conduit or plant for (i) water supply, (ii) water treatment or (iii) sewerage

treatment or disposal. Hence service tax is not considered in rate analysis.

5 For all completed items, initial lead of 5 kms is considered for collection of materials like sand,

bricks, metal, stone, etc. Appropriate addition for lead charges excluding loading, unloading for

these materials shall be done while estimation.

6 These rates are applicable to water supply and sewerage schemes and its allied works only.

Rates for items required for general construction, buildings, roads, Irrigation Works, etc. shall

be adopted from the Current Schedule of Rates of PWD or Irrigation Department in respective

areas. For bore wells, CSR of GSDA shall be followed. Increase in percentage over normal

Schedule of Rates will also be as per norms of respective CSR.

7 For mechanical and electrical items related to water supply and sewerage schemes, CSR for

2012-13 prepared by Superintending Engineer (Mechanical), Maharashtra Jeevan Pradhikaran

shall be adopted.

8 Following increase in % over normal Schedule of Rates of MJP for 2012-2013 will be

applicable (Ref. PWD GR No. DSR/1091/CR-6577/Planning-3, dated 08/07/2003)

Area % Increase

a Works in Corporation area 5%

b Works in Municipal areas 2%

c Works in tribal area / hilly and inaccessible areas 10%

d Sugarcane area 5%

e Prison / Jail area 15%

f Defence area 20%

g Excavation for pipeline work along National Highway 10%

h Excavation for distribution system pipe lines, sewerage system in towns 10%

8

GENERAL NOTES

9 In any case, more than one percent increase on basic rates becomes admissible, instead of

adding both, the higher percentage only be taken. (e.g. if any Municipal Council falls in hilly

area, then additional percentage in rates will be only 10% and not 2%+10 %). This additional

percentage is only on completed item of work and not applicable to items of providing of

materials like steel, pipes, valves, specials, etc.

10 For hilly and inaccessible areas / tribal areas approved by Government, Planning Department's

Circular Nos. (1) 1089/CR-66/Plan-19, dt.23/11/1990 and (2) 1094/P-36/K-1455 dt.02/09/1994,

shall be followed (refer pages 347 onwards); in addition to amendment notified by the Planning

Deptt. from time to time.

11 For Action Plan Notified Area, Government's Circular in force from time to time shall be

followed.

12 Whenever basic rates of completed items are increased by percentage given at Sr. No.8, the

issue rates of materials to be supplied by the Department (if any) for these items shall be

increased by same percentage.

13 This Schedule of Rates is based on following basic rates for important materials -

Material Rate in Rs. Per MT

a Cement 6200/-

b Mild Steel 48000/-

c Tor Steel / CTD bars 48500/-

d Structural Steel 51000/-

e Corrosion Resistant Steel (Fe 500) 48300/-

f M.S. Plate 49000/-

14 Details of standard cement consumption and standard weight of various pipes are incorporated

in this CSR.

15 Rates for supply of various types of pipes, specials and valves are inclusive of excise duty,

central sales tax and VAT, third party inspection charges, storage charges, overhead charges

and transportation of materials upto divisional stores / site and stacking.

16 Cost of carting of pipes and valves from departmental stores to site of work is not considered in

rate analysis; hence, this item must be incorporated in each scheme. While inviting tenders, if

supply is from departmental stores, then this item shall appear in the tender, and if the supply is

by contractor, then this item shall not appear in the tender, eventhough same is provided in

sanctioned scheme, because the contractor is supposed to bring the pipes and valves directly

at site.

17 Though the contractor is required to do refilling before hydraulic testing, to avoid traffic hurdle,

no payment for refilling of the trenches of pipeline shall be payable till satisfactory hydraulic

testing is given. Re-excavation required if any, during testing, shall be done by the contractor at

his own cost.

18 10% of cost of items of water retaining structures, such as GSR/ESR/MBR shall be retained till

satisfactory hydraulic testing is given as per IS code.

19 10% of cost of total sub-work of pipeline work shall be retained till satisfactory hydraulic testing

is given as per IS code.

20 In case of supply of pipes / valves etc. by contractor, only 85% payment shall be released after

supply and 15% after satisfactory hydraulic testing.

21 AC / PVC / HDPE pipes shall not be used in Urban Areas.

GENERAL NOTES

9

22 Provision for octroi charges for pipes, specials and valves is not considered in the CSR 2012-

2013. Provision of 4% of cost of pipes, specials and valves to be used in corporation area shall

be made while framing the estimate for works included in corporation limit. Octroi charges shall

be reimbursed to contractor on production of receipt for payment for materials actually to be

used in corporation area, if there is specific provision to that effect in the contract.

23 For use of ready mix cement concrete, prior permission of the Chief Engineer must be

obtained.

24 For Dams, Balancing Tanks, Aerated Lagoons and similar structures, the rates for film

membranes as per prevailing rates for Irrigation Department will be followed.

25 Capacity of ESR / GSR to be constructed shall be rounded to nearest 1000 litres always on

higher side i.e. if required capacity is 1,23,570 litres, it shall be rounded to 1,24,000 litres.

Similarly, if required capacity is 8,26,070 litres, it shall be rounded to 8,27,000 litres.

26 Capacity of Unconventional / Conventional Treatment Plants shall be rounded to nearest 0.5

Mld - always on higher side i.e. if WTP of 2.37 Mld is required; it shall be rounded to 2.5 Mld.

For WTP having capacity less than 0.5 Mld, Package Type WTP should be considered.

27 Provision for insurance @1% is considered in Rate Analysis of CSR 2012-13. These rates are

applicable only for tendered works and should be reduced by 1% of total rate when works are

to be carried out on piecemeal works and other small works without tendering.

28 Rates given in this CSR are for estimation purpose only.

29 The makes of Sluice / Butterfly Valves etc. to be used for inlet / outlets of ESRs / GSRs /

MBRs / Pumping Main / Rising Main and WTP should be from approved makes of MJP.

30 Mechanical CSR rates for respective items shall be followed while estimation and the list of

approved makes shall be given in the item.

31 As per Govt. Circular No. 859/50/2002-CX dtd. 6/9/2002, Notification No. 6/2006-Central Excise

dtd. 1/3/2006, Notification No. 6/2007-Central Excise dtd. 1/3/2007 and Notification No.

26/2009-Central Excise dtd. 4/12/2009

a All items of machinery, including instruments, apparatus & appliances, auxiliary

equipments & their components/ parts required for setting of water treatment plant;

b Pipes needed for delivery of water from its source to the plant (including the clear

treated water reservoir, if any, thereof) and from there to the first storage point;

c Pipes of outer diameter exceeding 100 mm, when such pipes are integral part of the

water supply project; are exempted from excise duty. However, necessary certificate

from Project Authority i.e. District Collector / Dy. Commissioner shall be obtained.

32 The Royalty Charges are considered in the rate analysis of CSR 2012-13 as per Govt.

Resolution No. Rev & Forest Dept. Gaukhani 10 / 1009 / Pra.Kra. 309 / Kha. Mantralaya dtd.

11/02/2010.

33 As per Govt. Circular No. DSR-1090/CR-6453/PLN-3 dtd. 14/07/1993, 1% for labour amenities

is not considered in the DSR except concrete item while arriving the rates.

34 As per Govt. in industries and power G.R. No. BCA-2009/CR-108/Labour 7-A dtd. 17/06/2010,

1% cess on labour welfare is not considered in the DSR while arriving the rates.

Sr.

No.

Description Unit Rate (Rs.)

2012-13

Rate (Rs.)

2013-14

SECTION - A : MATERIAL

11

MATERIALS

1 Acetylene gas No 506.00

2 Alum Grade-I ( ex-factory ) MT 8000.00

3 Binding wire Kg 57.00

4 Black enamel paint ( anti-corrosive ) Lit 193.00

5 Bricks No 6.90

6 Bullies, struts ( 125 mm dia 1.5 M long ) RMT 194.00

7 C.C.T.W. planks ( 3" x 6" ) Cum 7400.00

8 Cement ( bags ) Bags 310.00

9 Cement ( MT ) MT 6200.00

10 Cement sulpher resistant MT 6840.00

11 Charcoal Kg 33.00

12 Corrosion resistant steel MT 48300.00

13 Diesel Lit 51.75

14 Epoxy paint Kg 435.00

15 Fuse No 25.00

16 Gun powder Kg 132.00

17 Liquid chlorine ( 100 Kg. Dept. container ) No --

18 Liquid chlorine ( 100 Kg. Supplier container ) No --

19 Liquid chlorine ( 900 Kg. Dept. container ) No 16000.00

20 Lubricant oil Lit 230.00

21 M.S. angle ( 50 mm x 50 mm x 6 mm ) Kg 48.30

22 M.S. bars MT 48000.00

23 M.S. bars ( in Kgs. ) Kg 48.00

24 M.S. flats ( 40 mm x 3 mm ) Kg 48.30

25 M.S. plate Kg 49.00

26 Mild steel grill ready Kg 70.00

27 Mild steel grill railing MT 70.00

28 Mobile oil Lit 230.00

29 Murum Cum 340.00

30 Nails Kg 74.00

31 Nut bolts Kg 90.00

32 Oxygen gas ( refill )

Cylndr

345.00

33 Poling boards Cum 20000.00

34 Quarry spalls Cum 200.00

35 R.S. joists, channels, etc. MT 51000.00

36 Rapid sand gravity filter media at source ( Godhra sand ) Cum 1265.00

Sr.

No.

Description Unit Rate (Rs.)

2012-13

Rate (Rs.)

2013-14

12

SECTION - A : MATERIAL

37 Rapid sand gravity filter gravel at source ( Godhra ) Cum 1265.00

38 Ready mixed lead / zinc paint Lit 231.00

39 Ready mixed oil paint Lit 231.00

40 Ready mixed primer for steel Lit 165.00

41 Rubber gasket ( 6 mm thick ) Kg 99.00

42 Sand Cum 1150.00

43 Godra sand for mortar lining work @ source Cum 1265.00

44 Spun yarn Kg 88.00

45 Stone aggregate 10 mm Cum 900.00

46 Stone aggregate 20 mm Cum 850.00

47 Stone aggregate 40 mm Cum 800.00

48 Stone at quarry Cum 405.00

49 Structural steel MT 5100.00

50 TCL ( bleaching powder ) Grade - I ( 5 kg pack ) Kg 25.00

51 TCL ( bleaching powder ) Grade - I ( 10 kg pack ) Kg 25.00

52 TCL ( bleaching powder ) Grade - I ( 25 kg pack ) Kg 25.00

53 Teak wood Cum 69200.00

54 Tor steel MT 48500.00

55 Walling ( 100 mm x 100 mm ) Cum 16500.00

56 Welding rod having weight 5.25 kg Box 1450.00

57 Welding rod having weight 5.25 kg - 4.0 M Box --

58 White cement Kg 33.00

59 White lead Kg 150.00

60 Wire Kg 71.00

61 Plywood commercial ( 12 mm thk. Waterproof for centering ) Sqm 720.00

(Taken in analysis for RCC items only)

Sr.

No.

Description Unit Rate (Rs.)

2012-13

Rate (Rs.)

2013-14

SECTION - B : LABOUR & MACHINERY

13

LABOUR

1 Assistant fitter No 352.00

2 Bandhani No 351.00

3 Bhisti with pakahal No 267.00

4 Blacksmith ( IInd class ) No 303.00

5 Breaker No 339.00

6 Carpenter ( Ist class ) No 399.00

7 Carpenter ( IInd class ) No 363.00

8 Chiseller No 339.00

9 Excavator No 303.00

10 Fitter ( Ist class ) No 399.00

11 Glazier No 303.00

12 Helper No 267.00

13 Hole driller No 339.00

14 Mason ( Ist class ) No 436.00

15 Mason ( IInd class ) No 399.00

16 Mazdoor ( female ) No 267.00

17 Mazdoor ( heavy ) No 303.00

18 Mazdoor ( light ) No 267.00

19 Mazdoor ( male ) No 267.00

20 Mistri No 363.00

21 Mukadam No 363.00

22 Painter ( for colouring ) No 333.00

23 Painter No 351.00

24 Polisher No 333.00

25 Pump driver No 339.00

26 Stone cutter or dresser No 399.00

27 Tile layer No 399.00

28 Welder No 399.00

29 Welder for pipeline No 399.00

30 Whitewasher No 333.00

31 Tile turner No 363.00

32 L.M.V. driver No 339.00

33 Electrician No 339.00

Sr.

No.

Description Unit Rate (Rs.)

2012-13

Rate (Rs.)

2013-14

14

SECTION - B : LABOUR & MACHINERY

MACHINERY

1 Rent for chain pulley block with tripod Day 510.00

2 Rent for pump including operator & excluding fuel HP/Day 190.00

3 Rent for mechanical mixer with fuel and crew Day 2600.00

4 Rent for vibrator with fuel and crew Day 850.00

5 Plate bender Day 850.00

6 Rent for welding set with electric set Day 1100.00

7 Rent for welding set with generator Day 2400.00

8 Rent for compressor with fuel Day 2100.00

9 Rent for concrete breaker and compressor Day 2350.00

10 Rent for poclain Hr 2100.00

11 Rent for crane Hr 1200.00

12 Rent for JCB Hr 1100.00

13 Truck hire charges upto 20 km Day 2600.00

14 Truck hire charges for 20 km to 50 km Day 2300.00

15 Truck hire charges for 50 km and above Day 2050.00

NEW ITEMS

16 Pipe cutter with operator Day 1250.00

17 Desludging / Desilting mud pump with operator Day 2400.00

18 Jeep hire charges with driver ( upto 300 km ) & fuel Day 3000.00

SECTION - C : TRANSPORTATION

15

STATEMENT I

Rate (Rs.)

2012-13

Sr.

No.

Item of Work Unit Collecting the

railway receipt

etc. & unloading

the consignment

from railway

wagon &

keeping

on railway

platform

Consignment

booked in

Lifting the

materials from

railway

platform,

loading

into truck

Loading the

material into

truck from

Departmental

stores or

site of work.

Unloading the

material from

truck including

stacking in

Departmental

stores or site

of work.

1 2 3 4 5 6 7

(A) MANUAL HANDLING

( Weight upto and including

300 kg)

1 C.I. / D.I. / M.S. / H.D.P.E.

pipes of all classes upto and

including 200 mm dia pipes of

any length

MT 233.00 285.00 75.00 75.00

2 R.C.C. pipes of all classes

upto and including 350 mm

dia

MT 233.00 285.00 75.00 75.00

3 A.C. pipes of all classes and

dia.

MT 123.00 174.00 44.00 44.00

4 P.V.C. pipes of all classes and

dia.

MT 123.00 174.00 44.00 44.00

5 All other materials such as

C.I. specials of individual

weight upto 300 kg.

MT 233.00 285.00 75.00 75.00

6 Mild steel / Tor steel / R.S.J. MT 147.00 199.00 112.00 112.00

7 Cement / Bleaching powder /

Alum

MT 71.00 108.00 57.00 57.00

(B) CRANE HANDLING

(Materials having individual

weight above 300 kg)

1 C.I./ D.I./ B.W.S.C./ M.S./

R.C.C. pipes of all classes

having individual weight more

than 300 kg. and also other

heavy materials, valves,

machinery having individual

weight more than 300 kg.

MT 165.00 210.00 150.00 150.00

1) The above rates in column 1 to 5 are applicable only for railway clearance purpose only and not for other carting.

2) The rates given in column 6 to 7 shall be adopted for estimate purpose only, however, actual quotations/ 'D' tender

will prevail.

3) Irrespective of supply of CI / DI pipes as per rate contract, when pipes are directly supplied by the firms by road,

railway freight upto destination station and carting as per schedule from railway station to work site is allowed. In such

cases, rate of Mathadi Kamgar shall not be applicable for carting and normal loading, unloading, carting shall be

allowed.

16

SECTION - C : TRANSPORTATION

STATEMENT II

INCLUDING LOADING, UNLOADING AND STACKING

Lead in

km

L

Av.

Speed

S

No. of

Trips

(N)= 8/

((2L/S)

+1)

Km.

Done

(2NL

+6)

Litres of

diesel

consumed

cost of

diesel

@

Litres of

mobile oil

consumed

cost of

M.Oil

@

cost of 6

mazdoor

per day

Hire

charges

of truck

Rs. per

day

Total cost

(6+8+9

+10)

Add 10%

overhead

charges

Total

11+12

cost per

trip (13/3)

1 2 3 4 5 6 7 8 9 10 11 12 13 14

0.5 15 7.5 13.50 4.50 232.88 0.096 22.08 2045.25 2600 4900.21 490.02 5390.23 718.70

1 16 7.11 20.22 6.74 348.80 0.144 33.12 2045.25 2600 5027.17 502.72 5529.89 777.76

1.5 16.5 6.77 26.31 8.77 453.85 0.188 443.24 2045.25 2600 5142.34 514.23 5656.57 835.53

2 17 6.48 31.92 10.64 550.62 0.228 52.44 2045.25 2600 5248.31 524.83 5773.14 890.92

2.5 17.25 6.2 37.00 12.33 638.08 0.264 60.72 2045.25 2600 5344.05 534.41 5878.46 948.14

3 17.5 5.96 41.76 13.92 720.36 0.298 68.54 2045.25 2600 5434.15 543.42 5977.57 1002.95

3.5 17.75 5.74 46.18 15.39 796.43 0.330 75.90 2045.25 2600 5517.58 551.76 6069.34 9057.38

4 18 5.54 50.32 16.77 867.85 0.359 82.57 2045.25 2600 5595.67 559.57 6155.24 1111.05

4.5 18.25 5.36 54.24 18.08 935.64 0.387 89.01 2045.25 2600 5669.90 566.99 6236.89 1163.60

5 18.5 5.19 57.90 19.30 998.78 0.414 95.22 2045.25 2600 5739.25 573.93 6313.18 1216.41

6 18.75 4.88 64.56 21.52 1113.66 0.461 106.03 2045.25 2600 5864.94 586.49 6451.43 1322.01

7 19 4.61 70.54 23.51 1216.64 0.504 115.92 2045.25 2600 5977.81 597.78 6575.59 1426.38

8 19.183 4.36 75.76 25.25 1306.69 0.541 124.43 2045.25 2600 6076.37 607.64 6684.01 1533.03

9 19.6 4.17 81.06 27.02 1398.29 0.579 133.17 2045.25 2600 6176.71 617.67 6794.38 1629.35

10 20 4 86.00 28.67 1483.67 0.614 141.22 2045.25 2600 6270.14 627.01 6897.15 1724.29

15 25 3.64 115.20 38.40 1987.20 0.823 189.29 2045.25 2600 6821.74 682.17 7503.91 2061.51

20 25 3.08 129.20 43.07 2228.87 0.923 212.29 2045.25 2600 7086.41 708.64 7795.05 2530.86

25 25 2.67 139.50 46.50 2406.38 0.996 229.08 2045.25 2300 6980.71 698.07 7678.78 2875.95

30 25 2.35 147.00 49.00 2535.75 1.050 241.50 2045.25 2300 7122.50 712.25 7834.75 3333.94

35 30 2.4 174.00 58.00 3001.50 1.243 285.89 2045.25 2300 7632.64 763.26 8395.90 3498.29

40 30 2.18 180.40 60.13 3111.73 1.289 296.47 2045.25 2300 7753.45 775.35 8528.80 3912.29

45 30 2 186.00 62.00 3208.50 1.329 305.67 2045.25 2300 7859.42 785.94 8645.36 4322.68

50 30 1.85 191.00 63.67 3294.92 1.364 313.72 2045.25 2300 7953.89 795.39 8749.28 4729.34

60 30 1.6 198.00 66.00 3415.50 1.414 325.22 2045.25 2050 7835.97 783.60 8619.57 5387.23

SECTION - C : TRANSPORTATION

17

Lead in

km

L

Av.

Speed

S

No. of

Trips

(N)= 8/

((2L/S)

+1)

Km.

Done

(2NL

+6)

Litres of

diesel

consumed

cost of

diesel

@

Litres of

mobile oil

consumed

cost of

M.Oil

@

cost of 6

mazdoor

per day

Hire

charges

of truck

Rs. per

day

Total cost

(6+8+9

+10)

Add 10%

overhead

charges

Total

11+12

cost per

trip (13/3)

1 2 3 4 5 6 7 8 9 10 11 12 13 14

70 30 1.41 203.40 67.80 3508.65 1.453 334.19 2045.25 2050 7938.09 793.81 8737.90 6192.84

80 30 1.26 207.60 69.20 3581.10 1.483 341.09 2045.25 2050 8017.44 801.74 8819.18 6999.35

90 30 1.14 211.20 70.40 3643.20 1.509 347.07 2045.25 2050 8085.52 808.55 8894.07 7801.82

100 40 1.33 272.00 90.67 4692.17 1.943 446.89 2045.25 2050 9234.31 923.43 10157.74 7637.40

125 40 1.1 0 281.00 93.67 4847.42 2.007 461.61 2045.25 2050 9404.28 940.43 10344.71 9404.28

150 40 0.94 288.00 96.00 4968.00 2.057 473.11 1922.54 2050 9413.65 941.37 10355.02 11015.98

175 40 0.82 293.00 97.67 5054.42 2.093 481.39 1677.11 2050 9262.92 926.29 10189.21 12425.87

200 40 0.73 298.00 99.33 5140.33 2.129 489.67 1493.03 2050 9173.03 917.30 10090.33 13822.37

250 40 0.59 301.00 100.33 5192.08 2.150 494.50 1206.70 2050 8943.28 894.33 9837.61 16673.92

300 45 0.56 342.00 114.00 5899.50 2.443 561.89 1145.34 2050 9656.73 965.67 10622.40 18968.57

420 45 0.41 350.40 116.80 604440 2.503 575.69 838.55 2050 9508.64 950.86 10459.50 25510.98

540 45 0.32 351.60 117.20 6065.10 2.511 577.53 654.48 2050 9347.11 934.71 10281.82 32130.69

660 45 0.26 349.20 116.40 6023.70 2.494 573.62 531.77 2050 9179.09 917.91 10097.00 38834.62

780 45 0.22 349.20 116.40 6023.70 2.494 573.62 449.96 2050 9097.28 909.73 10007.01 45486.41

900 45 0.20 366.00 122.00 6313.50 2.614 601.22 409.05 2050 9373.77 937.38 10311.15 51555.75

1020 45 0.17 352.80 117.60 6085.80 2.520 579.60 347.69 2050 9063.09 906.31 9969.40 58643.53

1140 45 0.15 348.00 116.00 6003.00 2.486 571.78 306.79 2050 8931.57 893.16 9824.73 65498.20

Notes 1) No. of trips in a working of 8 hours N = 8 / ( 2(L+S) + 1 ) where L = Lead in km and S = speed, 1 hour is allowed for loading

2) Consumption of diesel taken as 3 km / litre

3) Consumption of Mobile oil taken as 140 km / litre

4) In col. 4, 6 hours has been added for movement from parking place to duty and back

5) Hire charges will remain Rs. 500.00 for 1200 and above km lead

6) Labour required for loading unloading and stacking after the No. of trips reduced below 1 is factorised with actual number of trip.

18

SECTION - C : TRANSPORTATION

STATEMENT III

EXCLUDING LOADING, UNLOADING AND STACKING

Lead in

km

L

Av.

Speed

S

No. of

Trips

(N)= 8/

((2L/S)

+1)

Km.

Done

(2NL

+6)

Litres of

diesel

consumed

cost of

diesel

@

per lit

Litres of

mobil oil

consumed

cost of

M.Oil @

per lit

cost of 6

mazdoor

@

320.705/

day

Hire

charges

of truck

Rs. Per

day

Total cost

(6+8+9

+10)

Add 10%

overhead

charges

Total

11+12

cost per

trip (13/3)

1 2 3 4 5 6 7 8 9 10 11 12 13 14

0.5 15 7.5 13.50 4.50 232.88 0.096 22.08 0 2600 2854.96 285.50 3140.46 418.73

1 16 7.11 20.22 6.74 348.80 0.144 33.12 0 2600 2981.92 298.19 3280.11 461.34

1.5 16.5 6.77 26.31 8.77 453.85 0.188 43.24 0 2600 3097.09 309.71 3406.80 503.22

2 17 6.48 31.92 10.64 550.62 0.228 52.44 0 2600 3203.06 320.31 3523.37 543.73

2.5 17.25 6.20 37.00 12.33 638.08 0.264 60.72 0 2600 3298.80 329.88 3628.68 585.27

3 17.5 5.96 41.76 13.92 720.36 0.298 68.54 0 2600 3388.90 338.89 3727.79 625.47

3.5 17.75 5.74 46.18 15.39 796.43 0.330 75.90 0 2600 3472.33 347.23 3819.56 665.43

4 18 5.54 50.32 16.77 867.85 0.359 82.57 0 2600 3550.42 355.04 3905.46 704.96

4.5 18.25 5.36 54.24 18.08 935.64 0.387 89.01 0 2600 3624.65 362.47 3987.12 743.87

5 18.5 5.19 57.90 19.30 998.78 0.414 95.22 0 2600 3694.00 369.40 4063.40 782.93

6 18.75 4.88 64.56 21.52 1113.66 0.461 106.03 0 2600 3819.69 381.97 4201.66 861.00

7 19 4.61 70.54 23.51 1216.64 0.504 115.92 0 2600 3932.56 393.26 4325.82 938.36

8 19.183 4.36 75.76 25.25 1306.69 0.541 124.43 0 2600 4031.12 403.11 4434.23 1017.03

9 19.6 4.17 81.06 27.02 1398.29 0.579 133.17 0 2600 4131.46 413.15 4544.61 1089.83

10 20 4.00 86.00 28.67 1483.67 0.614 141.22 0 2600 4224.89 422.49 4647.38 1161.85

15 25 3.64 115.20 38.40 1987.20 0.823 189.29 0 2600 4776.49 477.65 5254.14 1443.45

20 25 3.08 129.20 43.07 2228.87 0.923 212.29 0 2600 5041.16 504.12 5545.28 1800.42

25 25 2.67 139.50 46.50 2406.38 0.996 229.08 0 2300 4935.46 493.55 5429.01 2033.34

30 25 2.35 147.00 49.00 2535.75 1.050 241.50 0 2300 5077.25 507.73 5584.98 2376.59

35 30 2.40 174.00 58.00 3001.50 1.243 285.89 0 2300 5587.39 558.74 6146.13 2560.89

40 30 2.18 180.40 60.13 3111.73 1.289 296.47 0 2300 5708.20 570.82 6279.02 2880.28

45 30 2.00 186.00 62.00 3208.50 1.329 305.67 0 2300 5814.17 581.42 6395.59 3197.80

SECTION - C : TRANSPORTATION

19

Lead in

km

L

Av.

Speed

S

No. of

Trips

(N)= 8/

((2L/S)

+1)

Km.

Done

(2NL

+6)

Litres of

diesel

consumed

cost of

diesel

@

per lit

Litres of

mobil oil

consumed

cost of

M.Oil @

per lit

cost of 6

mazdoor

@

320.705/

day

Hire

charges

of truck

Rs. Per

day

Total cost

(6+8+9

+10)

Add 10%

overhead

charges

Total

11+12

cost per

trip (13/3)

1 2 3 4 5 6 7 8 9 10 11 12 13 14

50 30 1.85 191.00 63.67 3294.92 1.364 313.72 0 2300 5908.64 590.86 6499.50 3513.24

55 30 1.71 194.10 64.70 3348.23 1.386 318.78 0 2050 5717.01 571.70 6288.71 3677.61

65 30 1.50 201.00 67.00 3467.25 1.436 330.28 0 2050 5847.53 584.75 9432.28 4288.19

75 30 1.33 205.50 68.50 3544.88 1.468 337.64 0 2050 5932.52 593.25 6525.77 4906.59

85 30 1.20 210.00 70.00 3622.50 1.500 345.00 0 2050 6017.50 601.75 6619.25 5516.04

95 40 1.39 270.10 90.03 4659.05 1.929 443.67 0 2050 7152.72 715.27 7867.99 5660.42

105 40 1.28 274.80 91.60 4740.30 1.963 451.49 0 2050 7241.79 724.18 7965.97 6223.41

130 40 1.07 284.20 94.73 4902.28 2.030 466.90 0 2050 7419.18 741.92 8161.10 7627.20

155 40 0.91 288.10 96.03 4969.55 2.058 473.34 0 2050 7492.89 749.29 8242.18 9057.34

180 40 0.80 294.00 98.00 5071.50 2.100 483.00 0 2050 7604.50 760.45 8364.95 10456.19

230 40 0.64 300.40 100.13 5181.73 2.146 493.58 0 2050 7725.31 772.53 8497.84 13277.88

280 45 0.60 342.00 114.00 5899.50 2.443 561.89 0 2050 8511.39 851.14 9362.53 15604.22

400 45 0.43 350.00 116.67 6037.67 2.500 575.00 0 2050 8662.67 866.27 9528.94 22160.33

520 45 0.33 349.20 116.40 6023.70 2.494 573.62 0 2050 8647.32 864.73 9512.05 28824.39

640 45 0.27 351.60 117.20 6065.10 2.511 577.53 0 2050 8692.63 869.26 9561.89 35414.41

760 45 0.23 355.60 118.53 6133.93 2.540 584.20 0 2050 8768.13 876.81 9644.94 41934.52

880 45 0.20 358.00 119.33 6175.33 2.557 588.11 0 2050 8813.44 881.34 9694.78 48473.90

1000 45 0.18 366.00 122.00 6313.50 2.614 601.22 0 2050 8964.72 896.47 9861.19 54784.39

1120 45 0.16 364.40 121.47 6286.07 2.603 598.69 0 2050 8934.76 893.48 9828.24 61426.50

20

SECTION - C : TRANSPORTATION

STATEMENT IV

INCLUDING LOADING, UNLOADING AND STACKING

Lead in km Cost per trip Cement

pay load 9.00 MT

Steel

pay load 9.00 MT

Bulk Asphalt in

Bouzer

pay load 4.50 MT

M.S. Bar

9.0 MT

Sand

5.75 cum

1 2 3 4 5 6 7

0.5 718.70 79.86 79.86 159.71 79.86 124.99

1 777.76 86.42 86.42 172.84 86.42 135.26

1.5 835.53 92.84 92.84 185.67 92.84 145.31

2 890.92 98.99 98.99 197.98 98.99 154.94

2.5 948.14 105.35 105.35 210.70 105.35 164.89

3 1002.95 105.35 105.35 222.88 105.35 174.43

3.5 1057.38 117.49 117.49 234.97 117.49 183.89

4 1111.05 123.45 123.45 246.90 123.45 193.23

4.5 1163.60 129.29 129.29 258.58 129.29 202.37

5 1216.41 135.16 135.16 270.31 135.16 211.55

6 1322.01 146.89 146.89 293.78 146.89 229.91

7 1426.38 158.49 158.49 316.97 158.49 248.07

8 1533.03 170.34 170.34 340.67 170.34 266.61

9 1629.35 181.04 181.04 362.08 181.04 283.37

10 1724.29 191.59 191.59 383.18 191.59 299.88

15 2061.51 229.06 229.06 458.11 229.06 358.52

20 2530.86 281.21 281.21 562.41 281.21 440.15

25 2875.95 319.55 319.55 639.10 319.55 500.17

30 3333.94 370.44 370.44 740.88 370.44 579.82

35 3498.29 388.70 388.70 777.40 388.70 608.40

40 3912.29 434.70 434.70 889.40 434.70 680.40

45 4322.68 480.30 480.30 960.60 480.30 751.77

50 4729.34 525.48 525.48 1050.96 525.48 822.49

60 5387.23 598.58 598.58 1197.16 598.58 936.91

70 6192.84 688.09 688.09 1376.19 688.09 1077.02

80 6799.35 777.71 777.71 1555.41 777.71 1217.28

90 7801.82 866.87 866.87 1733.74 866.87 1356.84

100 7637.40 848.60 848.60 1697.20 848.60 1328.24

125 9404.28 1044.92 1044.92 2089.84 1044.92 1635.53

150 11015.98 1224.00 1224.00 2448.00 1224.00 1915.82

175 12425.87 1380.65 1380.65 2761.30 1380.65 2161.02

200 13822.37 1535.82 1535.82 3071.64 1535.82 2403.89

250 16673.92 1852.66 1852.66 3705.32 1852.66 2899.81

300 18968.57 2107.62 2107.62 4215.24 2107.62 3298.88

420 25510.98 2834.55 2834.55 5669.11 2834.55 4436.69

540 32130.69 3570.08 3570.08 7140.15 3570.08 5587.95

660 38834.62 4314.96 4314.96 8629.92 4314.96 6753.85

780 45486.41 5054.05 5054.05 10108.09 5054.05 7910.68

900 51555.75 5758.42 5758.42 11456.83 5758.42 8966.22

1020 58643.53 6515.95 6515.95 13031.90 6515.95 10198.87

1140 65498.20 7277.58 7277.58 14555.16 7277.58 11390.99

SECTION - C : TRANSPORTATION

21

STATEMENT V

EXCLUDING LOADING, UNLOADING AND STACKING

Lead in km Cost per trip Cement

pay load 9.00 MT

Steel

pay load 9.00 MT

Bulk Asphalt in

Bouzer

pay load 4.50 MT

1 2 3 4 5

0.5 418.73 46.53 46.53 93.05

1 461.34 51.26 51.26 102.52

1.5 503.22 55.91 55.91 111.83

2 543.73 60.41 60.41 120.83

2.5 585.27 65.03 65.03 130.06

3 625.47 65.03 65.03 130.06

3.5 665.43 73.94 73.94 147.87

4 704.96 78.33 78.33 156.66

4.5 743.87 82.65 82.65 165.30

5 782.93 86.99 86.99 173.98

6 861.00 95.67 95.67 191.33

7 938.36 104.26 104.26 208.52

8 1017.03 113.00 113.00 226.01

9 1089.83 121.09 121.09 242.18

10 1161.85 129.09 129.09 258.19

15 1443.45 160.38 160.38 320.77

20 1800.42 200.05 200.05 400.09

25 2033.34 225.93 225.93 451.85

30 2376.59 264.07 264.07 528.13

35 2560.89 284.54 284.54 569.09

40 2880.28 320.03 320.03 640.06

45 3197.80 355.31 355.31 710.62

50 3513.24 390.36 390.36 780.72

55 3677.61 408.62 408.62 817.25

65 4288.19 476.47 476.47 952.93

75 4906.59 545.18 545.18 1090.35

85 5516.04 612.89 612.89 1225.79

95 5660.42 628.94 628.94 1257.87

105 6223.41 691.49 691.49 1382.98

130 7627.20 847.47 847.47 1694.93

155 9057.34 1006.37 1006.37 2012.74

180 10456.19 1161.80 1161.80 2323.60

230 13277.88 1475.32 1475.32 2950.64

280 15604.22 1733.80 1733.80 3467.60

400 22160.33 2462.26 2462.26 4924.52

520 28824.39 3202.71 3202.71 6405.42

640 35414.41 3934.93 3934.93 7869.87

760 41934.52 4659.39 4659.39 9318.78

880 48473.90 5385.99 5385.99 10771.98

1000 54784.39 6087.15 6087.15 12174.31

1120 61426.50 6825.17 6825.17 13650.33

22

SECTION - C : TRANSPORTATION

STATEMENT VI

INCLUDING LOADING, UNLOADING AND STACKING

Lead in Kms

(L)

Cost / trip Lime murum

building

rubbish

Earth Manure or

sludge

Excavated

rock

Sand stone

aggregate

40 mm &

below

Aggregate

40 mm &

above

Soling stone Concrete

block (form)

Timber

Pay load 6.0 cum 4.8 cum 5.52 cum 3.0 cum 5.75 cum 5.5 cum 4.7 cum 6.0 cum 5.0 Cum

Unit per Cum per Cum per Cum per Cum per Cum per Cum per Cum per Cum Per Cum

1 2 3 4 5 6 7 8 9 10 11

0.5 718.70 119.78 149.72 130.20 239.57 124.99 130.67 152.91 119.78 124.99

1 777.76 129.63 162.03 140.90 259.25 135.26 141.41 165.48 129.63 135.26

1.5 835.53 139.26 174.07 151.36 278.51 145.31 151.91 177.77 139.26 145.31

2 890.92 148.49 185.61 161.40 296.97 154.94 161.99 189.56 148.49 154.94

2.5 948.14 158.02 197.53 171.76 316.05 164.89 172.39 201.73 158.02 164.89

3 1002.95 167.16 208.95 181.69 334.32 174.43 182.35 213.39 167.16 174.43

3.5 1057.38 176.23 220.29 191.55 352.46 183.89 192.25 224.91 176.23 183.89

4 1111.05 185.58 231.47 201.28 370.35 193.23 202.01 236.39 185.18 193.23

4.5 1163.60 193.93 242.42 210.80 387.87 202.37 211.56 247.57 193.93 202.37

5 1216.41 202.74 253.42 220.36 405.47 211.55 221.17 258.81 202.74 211.55

6 1322.01 220.34 275.42 239.49 440.67 229.91 240.37 281.28 220.34 229.91

7 1426.38 237.73 297.16 258.40 475.46 248.07 259.34 303.49 237.73 248.07

8 1533.03 255.51 319.38 277.72 511.01 266.61 278.73 326.18 255.51 266.61

9 1629.35 271.56 339.45 295.17 543.12 283.37 296.25 346.67 271.56 283.37

10 1724.29 287.38 359.23 312.37 574.76 299.88 213.51 366.87 287.38 299.88

15 2061.51 343.59 429.48 373.46 687.17 358.52 374.82 438.62 343.59 358.52

20 2530.86 421.81 527.26 458.49 843.62 440.15 460.16 538.48 421.81 440.15

25 2875.95 479.33 599.16 521.01 958.65 500.17 522.99 611.90 479.33 500.17

30 3333.94 555.66 694.57 603.97 1111.31 579.82 606.17 709.35 555.66 579.82

35 3498.29 583.05 728.81 633.75 1166.10 608.80 636.05 744.32 583.05 608.40

40 3912.29 652.05 815.06 708.75 1304.10 680.40 711.33 832.40 652.05 680.40

45 4322.68 720.45 900.56 783.09 1440.89 751.77 785.94 919.72 720.45 751.77

SECTION - C : TRANSPORTATION

23

Lead in Kms

(L)

Cost / trip Lime murum

building

rubbish

Earth Manure or

sludge

Excavated

rock

Sand stone

aggregate

40 mm &

below

Aggregate

40 mm &

above

Soling stone Concrete

block (form)

Timber

Pay load 6.0 cum 4.8 cum 5.52 cum 3.0 cum 5.75 cum 5.5 cum 4.7 cum 6.0 cum 5.0 Cum

Unit per Cum per Cum per Cum per Cum per Cum per Cum per Cum per Cum Per Cum

1 2 3 4 5 6 7 8 9 10 11

50 4729.34 788.22 985.28 856.76 1576.45 822.49 859.88 1006.24 788.22 822.49

60 5387.23 897.87 1122.34 975.95 1795.74 936.91 979.50 1146.22 897.87 936.91

70 6192.84 1032.14 1290.18 1121.89 2064.28 1077.02 1125.97 1317.63 1032.14 1077.02

80 6799.35 1166.56 1458.20 1268.00 2333.12 1217.28 1272.61 1489.22 1166.56 1217.28

90 7801.82 1300.30 1625.38 1413.37 2600.61 1356.84 1418.51 1659.96 1300.30 1356.84

100 7637.40 1272.90 1591.13 1383.59 2545.80 1328.24 1388.62 1624.98 1272.90 1328.24

125 9404.28 1567.38 1959.23 1703.67 3134.76 1635.53 1709.87 2000.91 1567.38 1635.53

150 11015.98 1836.00 2295.00 1995.65 3671.99 1915.82 2002.91 2343.83 1836.00 1915.82

175 12425.87 2070.98 2588.72 2251.06 4141.96 2161.02 2259.25 2643.80 2070.98 2161.02

200 13822.37 2303.73 2879.66 2504.05 4607.46 2403.89 2513.16 2940.93 2303.73 2403.89

250 16673.92 2778.99 3473.73 3020.64 5557.97 2899.81 3031.62 3547.64 2778.99 2899.81

300 18968.57 3161.43 3951.79 3436.34 6322.86 3298.88 3448.83 4035.87 3161.43 3298.88

420 25510.98 4251.83 5314.79 4621.55 8503.66 4436.69 4638.36 5427.87 4251.83 4436.69

540 32130.69 5355.12 6693.89 5820.78 10710.23 5587.95 5841.94 6836.32 5355.12 5587.95

660 38834.62 6472.44 8090.55 7035.26 12944.87 6753.85 7060.84 8262.69 6472.44 6753.85

780 45486.41 7581.07 9476.34 8240.29 15162.14 7910.68 8270.26 9677.96 7581.07 7910.68

900 51555.75 8592.63 10740.78 9339.81 17185.25 8966.22 9373.77 10969.31 8592.63 8966.22

1020 58643.53 9773.92 12217.40 10623.83 19547.84 10198.87 10662.46 12477.35 9773.92 10198.87

1140 65498.20 10916.37 13645.46 11865.62 21832.73 11390.99 11908.76 13935.79 10916.37 11390.99

24

SECTION - C : TRANSPORTATION

STATEMENT VII

INCLUDING LOADING, UNLOADING AND STACKING

Lead in km Cost / trip Cement

stone block,

GI CI CC AC

Pipes below

120 mm dia

Tar bitumen

Asphalt

roofing felt &

Flooring

Asphalt etc.

Steam coal Matting

thatching

bambu

ceiling board

rubber PVC

pipes fittings

Sheet &

plate glass

in packs

Paints &

Distempers

AC Sheets &

fittings iron

fittings and

iron sheets

Bricks

modular

bricks &

Traditional

bricks

Tiles half

round tiles &

Roofing tiles

cement

flooring tiles

Glass blocks

(hollow)

200x200

x120 mm

Empty cement

bags

Pay load 7.0 Mt 4.5 MT 5.5 MT 3.0 MT 7.0 MT 3500 Nos. 3200 Nos. 1000 Nos. 2000 Nos.

Unit per 1 M.T. per 1 M.T. per 1 M.T. Per 1 M.T. per 1 M.T. per 1000

Nos.

per 1000

Nos.

per 1000

Nos.

per 1000 Nos.

1 2 3 4 5 6 7 8 9 10 11

0.5 718.70

102.67 159.71 130.67

239.57

102.67 205.34 224.59 71.87 359.35

1 777.76

111.11 172.84 141.41

259.25

111.11 222.22 243.05 77.78 388.88

1.5 835.53

119.36 185.67 151.91

278.51

119.36 238.72 261.10 83.55 417.77

2 890.92

127.27 197.98 161.99

296.97

127.27 254.55 278.41 89.09 445.46

2.5 948.14

135.45 210.70 172.39

316.05

135.45 270.90 296.29 94.81 474.07

3 1002.95

143.28 222.88 182.35

334.32

143.28 286.56 313.42 100.30 501.48

3.5 1057.38

151.05 234.97 192.25

352.46

151.05 302.11 330.43 105.74 528.69

4 1111.05

158.72 246.90 202.01

370.35

158.72 317.44 347.20 111.11 555.53

4.5 1163.60

166.23 258.58 211.56

387.87

166.23 332.46 363.63 116.36 581.80

5 1216.41

173.77 270.31 221.17

405.47

173.77 347.55 380.13 121.64 608.21

6 1322.01

188.86 293.78 240.37

440.67

188.86 377.72 413.13 132.20 661.01

7 1426.38

203.77 316.97 259.34

475.46

203.77 407.54 445.74 142.64 713.19

8 1533.03

219.00 340.67 278.73

511.01

219.00 438.01 479.07 153.30 766.52

9 1629.35

232.76 362.08 296.25

543.12

232.76 465.53 509.17 162.94 814.68

10 1724.29

246.33 383.18 313.51

574.76

246.33 492.65 538.84 172.43 862.15

15 2061.51

294.50 458.11 374.82

687.17

294.50 589.00 644.22 206.15 1030.76

20 2530.86

361.55 562.41 460.16

843.62

361.55 723.10 790.89 253.09 1265.43

25 2875.95

410.85 639.10 522.90

958.65

410.85 821.70 898.73 287.60 1437.98

30 3333.94

476.28 740.88 606.17

1111.31

476.28 952.55 1041.86 333.39 1666.97

35 3498.29

499.76 777.40 636.05

1166.10

499.76 999.51 1093.22 349.83 1749.15

40 3912.29

558.90 889.40 711.33

1304.10

558.90 1117.80 1222.59 391.23 1956.15

45 4322.68

617.53 960.60 785.94

1440.89

617.53 1235.05 1350.84 432.27 2161.34

SECTION - C : TRANSPORTATION

25

Lead in km Cost / trip Cement

stone block,

GI CI CC AC

Pipes below

120 mm dia

Tar bitumen

Asphalt

roofing felt &

Flooring

Asphalt etc.

Steam coal Matting

thatching

bambu

ceiling board

rubber PVC

pipes fittings

Sheet &

plate glass

in packs

Paints &

Distempers

AC Sheets &

fittings iron

fittings and

iron sheets

Bricks

modular

bricks &

Traditional

bricks

Tiles half

round tiles &

Roofing tiles

cement

flooring tiles

Glass blocks

(hollow)

200x200

x120 mm

Empty cement

bags

Pay load 7.0 Mt 4.5 MT 5.5 MT 3.0 MT 7.0 MT 3500 No. 3200 No. 1000 No. 2000 No.

Unit per 1 M.T. per 1 M.T. per 1 M.T. Per 1 M.T. Per 1 M.T. per 1000

Nos.

per 1000

Nos.

per 1000

Nos.

per 1000 Nos.

1 2 3 4 5 6 7 8 9 10 11

50 4729.34

675.62 1050.96 859.88

1576.45

675.62 1351.24 1477.92 472.93 2364.67

60 5387.23

769.60 1197.16 979.50

1795.74

769.60 1539.21 1683.51 538.72 2693.62

70 6192.84

884.69 1376.19 1125.97

2064.28

884.69 1769.38 1935.26 619.28 3096.42

80 6799.35

999.91 1555.41 1272.61

2333.12

999.91 1999.81 2187.30 699.94 3499.68

90 7801.82

1114.55 1733.74 1418.51

2600.61

1114.55 2229.09 2438.07 780.18 3900.91

100 7637.40

1091.06 1697.20 1388.62

2545.80

1091.06 2182.11 2386.69 763.74 3818.70

125 9404.28

1343.47 2089.84 1709.87

3134.76

1343.47 2686.94 2938.84 940.43 4702.14

150 11015.98

1573.71 2448.00 2002.91

3671.99

1573.71 3147.42 3442.49 1101.60 5507.99

175 12425.87

1775.12 2761.30 2259.25

4141.96

1775.12 3550.25 3883.08 1242.59 6212.94

200 13822.37

1974.62 3071.64 2513.16

4607.46

1974.62 3949.25 4319.49 1382.24 6911.19

250 16673.92

2381.99 3705.32 3031.62

5557.97

2381.99 4763.98 5210.60 1667.39 8336.96

300 18968.57

2709.80 4215.24 3448.83

6322.86

2709.80 5419.59 5927.68 1896.86 9484.29

420 25510.98

3644.43 5669.11 4638.36

8503.66

3644.43 7288.85 7912.18 2551.10 12755.49

540 32130.69

4590.10 7140.15 5841.94

10710.23

4590.10 9180.20 10040.84 3213.07 16065.35

660 38834.62

5547.80 8629.92 7060.84

12944.87

5547.80 11095.61 12135.82 3883.46 19417.31

780 45486.41

6498.06 10108.09 8270.26

15162.14

6498.06 12996.12 14214.50 4548.64 22743.21

900 51555.75

7365.11 11456.83 9373.77

17185.25

7365.11 14730.21 16111.17 5155.58 25777.88

1020 58643.53

8377.65 13031.90 10662.46

19547.84

8377.65 16755.29 18326.10 5864.35 29321.77

1140 65498.20

9356.89 14555.16 11908.76

21832.73

9356.89 18713.77 20468.19 6549.82 32749.10

26

SECTION - C : TRANSPORTATION

STATEMENT VIII

INCLUDING LOADING, UNLOADING AND STACKING

Lead in

km

Cost /

trip

R.C.C. STEEL CYLINDER, R.C.C. PIPES, C.I. PIPES, UNREINFORCED CEMENT PIPES, PRECAST CONCRETE PIPES

100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 300 &

400 mm

450 & 500

mm

600, 700 &

750 mm

800, 900 &

1000 mm

1200 & 1800

MM

Pay load

in Rmt

292.8 219.6 183 109.8 80.52 62.22 54.9 29.28 18.183 15 5

1 2 3 4 5 6 7 8 9 10 11 12 13

UNIT PER 100 RMT

0.5 718.70 245.46 327.28 392.73 654.55 892.57 1155.09 1309.11 2454.58 2927.32 4791.33 14374.00

1 777.76 265.63 354.17 425.01 708.34 965.92 1250.02 1416.68 2656.28 4250.05 5185.07 15555.20

1.5 835.53 285.36 380.48 456.57 760.96 1037.67 1342.86 1521.91 2853.59 4565.74 5570.20 16710.60

2 890.92 304.28 405.70 486.84 811.40 1106.46 1431.89 1622.81 3042.76 4868.42 5939.47 17818.40

2.5 948.14 323.82 431.76 518.11 863.52 1177.52 1523.85 1727.03 3238.18 5181.09 6320.93 18962.80

3 1002.95 342.54 456.72 548.06 913.43 1245.59 1611.94 1826.87 3425.38 5480.60 6686.33 20059.00

3.5 1057.38 361.13 581.50 577.80 963.01 1313.19 1699.42 1926.01 3611.27 5778.03 7049.20 21147.60

4 1111.05 379.46 505.94 607.13 1011.89 1379.84 1785.68 2023.77 3794.57 6071.31 7407.00 22221.00

4.5 1163.60 397.40 529.87 635.85 1059.74 1445.11 1870.14 2119.49 3974.04 6358.47 7757.33 23272.00

5 1216.41 415.44 553.92 664.70 1107.84 1510.69 1955.01 2215.68 4154.41 6647.05 8109.40 24328.20

6 1322.01 451.51 602.01 722.41 1204.02 1641.84 2124.73 2408.03 4515.06 7224.10 8713.40 26440.20

7 1426.38 487.15 649.54 779.44 1299.07 1771.46 2292.48 2598.14 4871.52 7794.43 9509.20 28527.60

8 1533.03 523.58 698.10 837.72 1396.20 1903.91 2463.89 2792.40 5235.76 8377.21 10220.20 30660.60

9 1629.35 556.47 741.96 890.36 1483.93 2023.53 2618.69 2967.85 5564.72 8903.55 10862.33 32587.00

10 1724.29 588.90 785.20 942.23 1570.39 2141.44 2771.28 3140.78 5888.97 9422.35 11495.27 34485.80

15 2061.51 704.07 938.76 1126.51 1877.51 2560.25 3313.26 3755.03 7040.68 11265.08 13743.40 41230.20

20 2530.86 864.36 1152.49 1382.98 2304.97 3143.14 4067.60 4609.95 8643.65 13829.84 16872.40 50617.20

25 2875.95 982.22 1309.63 1571.56 2619.26 3571.72 4622.23 5238.52 9822.23 15715.57 19173.00 57519.00

30 3333.94 1138.64 1518.19 1821.83 3036.38 4140.51 5358.31 6072.75 11386.41 18218.25 22226.27 66678.80

35 3498.29 1194.77 1593.03 1911.63 3186.06 4344.62 5622.45 6372.11 11947.71 19116.34 23321.93 69965.80

40 3912.29 1336.16 1781.55 2137.86 3563.11 4858.78 6287.83 7126.21 13361.65 21378.63 26081.93 78245.80

45 4322.68 1476.33 1968.43 2362.12 3936.87 5368.46 6947.41 7823.73 14763.25 23621.20 28817.87 86453.60

SECTION - C : TRANSPORTATION

27

Lead in

km

Cost /

trip

R.C.C. STEEL CYLINDER, R.C.C. PIPES, C.I. PIPES, UNREINFORCED CEMENT PIPES, PRECAST CONCRETE PIPES

100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 300 &

400 mm

450 & 500

mm

600, 700 &

750 mm

800, 900 &

1000 mm

1200 & 1800

MM

Pay load

in Rmt

292.8 219.6 183 109.8 80.52 62.22 54.9 29.28 18.183 15 5

1 2 3 4 5 6 7 8 9 10 11 12 13

UNIT PER 100 RMT

50 4729.34 1615.21 2153.62 2584.34 4307.23 5873.50 7601.00 8614.46 16152.12 25843.39 31528.93 94586.80

60 5387.23 1839.90 2453.20 2943.84 4906.40 6690.55 8658.36 9812.81 18399.01 29438.42 35944.87 107774.60

70 6192.84 2115.04 2820.05 2384.07 5640.11 7691.06 9953.13 11280.22 21150.41 33840.66 41285.60 123856.80

80 6799.35 2390.49 3187.32 3724.78 6374.64 8692.69 11249.36 12749.27 23904.88 38247.81 46662.33 139987.00

90 7801.82 2664.56 3552.74 4263.29 7105.48 9689.29 12539.09 14210.97 26645.56 42632.90 52012.13 156036.40

100 7637.40 2601.40 3477.87 4173.74 6955.74 9485.10 12274.83 13911.48 26084.02 41734.43 50916.00 152748.00

125 9404.28 3211.84 4282.46 5138.95 8564.92 11679.43 15114.56 17229.84 32118.44 51389.51 62695.20 188085.60

150 11015.98 3762.29 5016.38 6019.66 10032.77 13681.05 17704.89 20065.54 37622.88 60196.61 73439.87 220319.60

175 12425.87 4243.81 5658.41 6790.09 11316.82 15432.03 19970.86 22633.64 42438.08 67900.93 82839.13 248517.40

200 13822.37 4720.75 6294.34 7553.21 12588.68 17166.38 22215.32 25177.36 47207.55 75532.08 92149.13 276447.40

250 16673.92 5694.64 7592.86 9111.43 15185.72 20707.80 26798.33 30371.44 56946.45 91114.32 111159.47 333478.40

300 18968.57 6478.34 8637.78 10365.34 17275.56 23557.59 30486.29 34551.13 64783.37 103653.39 126457.13 379371.40

420 25510.98 8712.77 11617.02 13940.43 23234.04 31682.79 41001.25 46468.09 87127.66 139404.26 170073.20 510219.60

540 32130.69 10973.60 14631.46 17557.75 29262.92 39903.99 51640.45 58525.85 109735.96 175577.54 214204.60 642613.80

660 38834.62 13263.19 17684.25 21221.10 35368.51 48229.78 62415.01 70737.01 132631.90 212211.04 258897.47 776692.40

780 45486.41 15534.98 20713.30 24855.96 41426.60 56490.82 73105.77 82853.21 155349.76 248559.62 303242.73 909728.20

900 51555.75 17607.84 23777.12 28172.54 46954.23 64028.50 82860.41 93908.47 176078.38 281725.41 343705.00 1031115.00

1020 58643.53 20028.53 26704.70 32045.64 53409.41 72831.01 94251.90 106818.82 200285.28 320456.45 290956.87 1172870.60

1140 65498.20 22369.60 29826.14 35791.37 59652.28 81344.01 105268.72 119304.55 223696.04 357913.66 436664.67 1309964.00

28

SECTION - C : TRANSPORTATION

STATEMENT IX

INCLUDING LOADING, UNLOADING AND STACKING

STONEWARE PIPES

Lead in

km

Cost/trip 100 mm 150 mm 200 mm 230 mm 250 mm 300 mm 350 mm 400 mm

Pay Load 480 m 240 m 135 m 105 m 84 m 66 m 43 m 27 m

1 2 3 4 5 6 7 8 9 10

Unit Per 100 Rmt

0.5 718.70 149.72 299.46 532.37 684.48 855.60 1088.94 1671.40 2661.85

1 777.76 162.03 324.07 576.12 740.72 925.90 1178.42 1808.74 2880.59

1.5 835.53 174.07 348.14 618.91 795.74 994.68 1265.95 1943.09 3094.56

2 890.92 185.61 371.22 659.94 848.50 1060.62 1349.88 2071.91 3299.70

2.5 948.14 197.53 395.06 702.33 902.99 1128.84 1436.58 2204.98 3511.63

3 1002.95 208.95 417.90 742.93 955.19 1193.99 1519.62 2332.44 3714.63

3.5 1057.38 220.29 440.58 783.24 1007.03 1258.79 1602.09 2459.02 3916.22

4 1111.05 231.47 462.94 823.00 1058.14 1322.68 1683.41 2583.84 4115.00

4.5 1163.60 242.42 484.83 861.93 1108.19 1385.24 1763.03 2706.05 4309.63

5 1216.41 253.42 506.84 901.04 1158.49 1448.11 1843.05 2828.86 4505.22

6 1322.01 275.42 550.84 979.27 1259.06 1573.82 2003.05 3074.44 4896.33

7 1426.38 297.16 594.33 1056.58 1358.46 1698.07 2161.18 3317.16 5282.89

8 1533.03 319.38 638.76 1135.58 1460.03 1825.04 2322.77 3565.19 5677.89

9 1629.35 339.45 678.90 1206.93 1551.76 1939.70 2468.71 3789.19 6034.63

10 1724.29 359.23 718.45 1277.25 1642.18 2052.73 2612.56 4009.98 6386.26

15 2061.51 429.48 858.96 1527.04 1963.34 2454.18 3123.50 4794.21 7635.22

20 2530.86 527.26 1054.53 1874.71 2410.34 3012.93 3834.64 5885.72 9373.56

25 2875.95 599.16 1198.31 2130.33 2739.00 3423.75 4357.50 6688.26 10651.67

30 3333.94 694.57 1389.14 2469.59 3175.18 3968.98 5051.42 7753.35 12347.93

35 3498.29 728.81 1457.62 2591.33 3331.70 4164.63 5300.44 8135.56 12956.63

40 3912.29 815.06 1630.12 2897.99 3725.99 4657.49 5927.71 9098.35 14489.96

45 4322.68 900.56 1801.12 3201.99 4116.84 5146.05 6549.52 10052.74 16009.93

50 4729.34 985.28 1970.56 3503.21 4504.13 5630.17 7165.67 10998.44 17516.07

60 5387.23 1122.34 2244.68 3990.54 5130.70 6413.37 8162.47 12528.44 19952.70

70 6192.84 1290.18 2580.35 4547.29 5897.94 7372.43 9383.09 14401.95 22936.44

80 6799.35 1458.20 2916.40 5184.70 6666.05 8332.56 10605.08 16277.56 25923.52

90 7801.82 1625.38 3250.76 5779.13 7430.30 9287.88 11820.94 18143.77 28895.63

100 7637.40 1591.13 3182.25 5657.33 7273.71 9092.14 11571.82 17761.40 28286.67

125 9404.28 1959.23 3918.45 6966.13 8956.46 11195.57 14248.91 21870.42 34830.67

150 11015.98 2295.00 4589.99 8159.99 10491.41 13114.26 16690.88 25618.56 40799.93

175 12425.87 2588.72 5177.45 9204.35 11834.16 14792.70 18827.08 28997.37 46021.74

200 13822.37 2879.66 5759.32 10238.79 13164.16 16455.20 20942.98 32145.05 51193.96

250 16673.92 3473.73 6970.47 12351.05 15879.92 19849.90 25263.52 38776.56 61755.26

300 18968.57 3951.79 7903.57 14050.79 18065.30 22581.63 28740.26 44112.95 70253.96

420 25510.98 5314.79 10629.58 18897.02 24296.17 30370.21 38653.00 59327.86 94485.11

540 32130.69 6693.89 13387.79 23800.51 30600.33 38250.82 48682.46 74722.53

119002.5

6

660 38834.62 8090.55 16181.09 28766.39 36985.35 46231.69 58840.33 90313.07

143831.9

3

780 45486.41 9476.34 18952.67 33693.64 43320.39 54150.49 68918.80

105782.3

5

164468.1

9

900 51555.75 10740.78 21481.56 38189.44 49100.71 61375.89 78114.77

119897.0

9

190947.2

2

1020 58643.53 12217.40 24434.80 43439.65 55850.98 69813.73 88853.83

136380.3

0

217198.2

6

1140 65498.20 13645.46 27290.92 48517.19 62379.24 77974.05 99239.70

152321.4

0

242585.9

3

SECTION - C : TRANSPORTATION

29

STATEMENT SHOWING STANDARD WEIGHT OF PIPES TO BE FOLLOWED

FOR CARTING OF VARIOUS DIAMETERS AND TYPES OF PIPES

I) C.I. Pipes ( IS : 1536-1989 )

Diameter of Pipe in mm Class of Pipes and Its Weight in Kg. per Metre Length

LA A B

80 16.00 17.38 18.46

100 19.82 21.82 23.27

125 25.82 28.18 30.36

150 32.10 35.27 38.00

200 47.09 51.09 55.27

250 63.45 69.09 74.73

300 81.82 89.45 96.91

350 103.09 111.82 121.27

400 125.45 137.09 140.00

450 151.27 166.10 179.27

500 177.09 192.91 208.73

600 236.00 257.64 335.01

700 304.55 335.73 359.45

750 341.09 372.91 404.55

800 381.00 416.00 450.00

900 465.09 507.45 549.80

1000 558.73 610.36 659.64

II) M.S. Pipes

Note : Weight of M.S. Pipes is to be computed by considering density of steel as 7850 Kg./Cum considering the

diameter and thickness of plate used for manufacturing of M.S. Pipes.

III) A.C. Pressure Pipes ( IS0-160 )

Diameter of Class of pipes and its weight in Kg. per meter length

Pipe in mm Class - 5 Class 10 Class - 15 Class - 20

80 6.00 6.20 6.40 6.80

100 7.60 7.70 8.20 10.30

125 9.57 9.80 11.00 13.30

150 11.87 12.20 15.30 19.00

200 15.57 19.30 25.60 32.70

250 19.25 25.20 32.70 41.50

300 24.97 32.30 45.10 58.10

350 39.77 47.52 55.27 71.42

400 49.20 60.20 71.36 93.10

450 56.92 70.27 83.63 111.37

500 72.84 89.54 104.25 136.52

600 102.50 137.32 148.35 193.16

30

SECTION - C : TRANSPORTATION

IV) D.I. K-9 PIPES INCLUDING WEIGHT OF MORTAR LINING PER M LENGTH

(1) Barrel Mass as per IS-8329-1994 (2) Socket Mass as per IS-8329-1994 (3) Cement Mortar Lining Wt as per ISO-4179-1985

Nominal Diameter Weight / M Length of D.I. K-9 Pipes of

4 M 5 M 5.50 M 6 M

80 mm wt. of DI pipe / M 13.00 13.00 12.91 12.67

Weight Mortar / M 1.56 1.56 1.56 1.56

Total Weight / M 14.56 14.56 14.47 14.23

100 mm wt. of DI pipe / M 16.25 16.00 16.00 15.86

Weight Mortar / M 1.93 1.93 1.93 1.93

Total Weight / M 18.18 17.93 17.93 17.79

125 mm wt. of DI pipe / M 20.50 20.00 20.00 19.83

Weight Mortar / M 2.42 2.42 2.42 2.42

Total Weight / M 22.92 22.42 22.42 22.25

150 mm wt. of DI pipe / M 24.75 24.20 24.18 24.00

Weight Mortar / M 2.90 2.90 2.90 2.90

Total Weight / M 27.65 27.10 27.08 26.90

200 mm wt. of DI pipe / M 33.25 32.60 32.54 32.33

Weight Mortar / M 3.88 3.88 3.88 3.88

Total Weight / M 37.13 36.48 36.42 36.21

250 mm wt. of DI pipe / M 43.75 43.00 42.73 42.50

Weight Mortar / M 4.84 4.84 4.84 4.84

Total Weight / M 48.59 47.84 47.57 47.34

300 mm wt. of DI pipe / M 55.50 54.60 54.18 53.83

Weight Mortar / M 5.80 5.80 5.80 5.80

Total Weight / M 61.30 60.40 59.98 59.63

350 mm wt. of DI pipe / M 69.25 68.00 67.45 67.17

Weight Mortar / M 12.12 12.12 12.12 12.12

Total Weight / M 81.37 80.12 79.57 79.29

400 mm wt. of DI pipe / M 82.75 81.40 80.91 80.33

Weight Mortar / M 13.82 13.82 13.82 13.82

Total Weight / M 96.57 95.22 94.73 94.15

450 mm wt. of DI pipe / M 98.75 97.00 96.36 95.83

Weight Mortar / M 15.53 15.53 15.53 15.53

Total Weight / M 114.28 112.53 111.89 111.36

500 mm wt. of DI pipe / M 115.00 112.80 112.00 111.50

Weight Mortar / M 17.26 17.26 17.26 17.26

Total Weight / M 132.26 130.06 129.26 128.76

600 mm wt. of DI pipe / M 152.00 149.00 147.82 147.00

Weight Mortar / M 20.75 20.75 20.75 20.75

Total Weight / M 172.75 169.73 168.57 167.75

700 mm wt. of DI pipe / M 193.75 189.80 188.36 187.70

Weight Mortar / M 29.45 29.45 29.45 29.45

Total Weight / M 223.20 219.25 217.81 211.15

750 mm wt. of DI pipe / M 217.50 213.00 211.45 210.00

Weight Mortar / M 31.56 31.56 31.56 31.56

Total Weight / M 249.06 244.56 243.01 241.56

800 mm wt. of DI pipe / M 240.75 235.80 233.82 232.33

Weight Mortar / M 33.69 33.69 33.69 33.69

Total Weight / M 274.44 269.49 267.51 266.02

900 mm wt. of DI pipe / M 292.75 286.20 283.82 281.83

Weight Mortar / M 37.89 37.89 37.89 37.89

Total Weight / M 330.64 324.09 321.71 319.72

1000 mm wt. of DI pipe / M 349.75 341.60 338.55 336.17

Weight Mortar / M 42.08 42.08 42.08 42.08

Total Weight / M 391.83 383.68 380.63 378.25

Note : These weights are as per the circular issued by Superintending Engineer (HQ) vide

Lt No. MJP / 10 - 2000 / SE (H/Q) / DI / 15 / AMDT / Stores / 255 dt. 26.06.2000

SECTION - C : TRANSPORTATION

31

V) P.V.C. Pipes ( IS : 4985-1988 )

Diameter of Class of Pipes and its weight in Kg. per meter length

Pipe in mm 4.00 Kg./Sq.cm. 6.00 Kg./Sq.cm. 10.00 Kg./Sq.cm.

63 0.47 0.67 1.01

75 0.67 0.93 1.44

90 0.92 1.33 2.05

110 1.32 1.89 3.08

140 2.13 3.10 4.99

160 2.78 3.92 6.56

180 3.56 5.07 8.10

200 4.26 7.00 10.20

225 5.48 7.84 12.56

250 6.63 10.19 15.31

280 8.34 12.16 19.80

315 10.55 15.37 25.00

VI) R.C.C. Pipes

Diameter of Class of Pipes and its weight in Kg. per meter length

Pipe in mm P - 1 P 2 P - 3 NP - 2 NP - 3 NP - 4

100 23.56 23.56 23.56 21.20 21.20 21.20

150 33.00 33.00 33.00 29.40 29.40 29.40

200 42.10 42.10 42.10 37.90 37.90 37.90

250 51.84 63.40 75.18 57.10 67.60 77.20

300 74.64 102.50 117.10 92.25 105.40 119.10

350 92.28 134.30 168.10 120.80 151.30 170.20

400 104.16 169.60 208.10 152.60 187.30 212.40

450 127.92 188.70 235.23 169.90 211.70 240.80

500 141.36 229.90 261.37 206.90 235.23 270.50

600 192.96 305.70 313.64 275.10 282.27 320.20

700 225.59 325.80 365.92 293.20 329.32 370.90

800 257.82 345.19 418.19 310.60 376.30 425.40

900 290.00 389.58 470.47 350.60 423.00 482.30

1000 322.28 443.98 510.00 399.80 459.00 531.40

VII) P.S.C. Pipes of all classes and B.W.S.C. Pipes of all classes

Diameter of Pipe in mm Weight of pipe per meter length

for all classes in Kg/m

Diameter of Pipe in mm Weight of pipe per meter

length for all classes in Kg/m

350 197.50 1100 947.50

400 240.00 1200 1115.00

450 257.50 1300 1190.00

500 292.50 1400 1370.00

600 375.00 1500 1560.00

700 432.50 1600 1767.50

800 582.50 1700 1987.50

900 705.00 1800 2205.50

1000 825.00

Sr.

No.

Description Unit Rate (Rs.)

2012-13

Rate (Rs.)

2013-14

SECTION - D : CEMENT CONSUMPTION

33

STANDARD CEMENT CONSUMPTION TO BE

FOLLOWED FOR VARIOUS ITEMS OF WORK

A P.C.C. / R.C.C. Works

1 1 : 1 : 1 (M-300) with finishing in CM 1:3 proportion Cum 9.20 bags

2 1: 1: 2 (M-250) with finishing in CM 1:3 proportion Cum 8.50 bags

3 1: 1 : 3 (M-200) with finishing in CM 1:3 proportion Cum 6.90 bags

4 1: 1 : 3 (M-200) without finishing Cum 6.80 bags

5 1 : 2 : 4 (M-150) with finishing in CM 1:3 proportion Cum 5.90 bags

6 1 : 2 : 4 (M-150) without finishing Cum 5.80 bags

B Brick Masonry Works

1 BB Masonry - IInd sort in CM 1:6 proportion Cum 1.44 bags

2 BB Masonry - IInd sort in CM 1:5 proportion Cum 1.62 bags

3 BB Masonry - IInd sort in CM 1:4 proportion Cum 2.30 bags

4 Half brick walls in CM 1:4 proportion Cum 0.22 bags

C Stone Masonry Works

1 U.C.R. Masonry - IInd sort in CM 1:6 proportion Cum 1.77 bags

2 U.C.R. Masonry - IInd sort in CM 1:4 proportion Cum 2.65 bags

3 Random Rubble Masonry - IInd sort in CM 1:6 proportion Cum 1.77 bags

4 Random Rubble Masonry - IInd sort in CM 1:4 proportion Cum 2.65 bags

5 C.R. Masonry - IInd sort in CM 1:4 proportion Cum 2.65 bags

6 C.R. Masonry - IInd sort in CM 1:6 proportion Cum 1.50 bags

D Waterproofing Works

1 Damp-proof course 50 mm thick in 1:2:4 proportion with

bitumen layer W.P. compound.

Sqm 0.35 bags

2 Integral finishing to newly laid slab in CM 1:3 proportion

with W.P. compound.

Sqm 0.06 bags

3 Waterproofing treatment over old slab with W.P. cement

slurry as tack coat 12 mm thick, W.P. plaster in CM 1:3

proportion, brickbat coba average 9.50 cm thick in CM

1:6 proportion and 20 mm thick W.P. cement plaster over

it in CM 1:3 proportion and finishing with cement slurry

with novelling.

Sqm. 0.37 bags

E Plastering and Pointing Works

1 12 mm thick plaster

a) CM 1:2 proportion Sqm 0.16 bags

b) CM 1:3 proportion Sqm 0.12 bags

c) CM 1:4 proportion Sqm 0.10 bags

Sr.

No.

Description Unit Rate (Rs.)

2012-13

Rate (Rs.)

2013-14

34

SECTION - D : CEMENT CONSUMPTION

2 20 mm thick plaster

a) CM 1:2 proportion Sqm 0.27 bags

b) CM 1:3 proportion Sqm 0.19 bags

c) CM 1:4 proportion Sqm 0.15 bags

3 25 mm thick plaster

a) CM 1:2 proportion Sqm 0.34 bags

b) CM 1:3 proportion Sqm 0.25 bags

c) CM 1:4 proportion Sqm 0.19 bags

4 Cement pointing in CM 1:3 proportion Sqm 0.03 bags

5 Tuck cement pointing in CM 1:3 proportion Sqm 0.05 bags

6 Sand faced plaster in CM 1:4 proportion including base

coat 15 mm thick in CM 1:4 proportion with W.P.

compound.

Sqm 0.22 bags

7 Rough cast cement plaster in CM 1:4 proportion in two

coats.

Sqm 0.22 bags

F Flooring Works

1 I.P.S. flooring - 40 mm thick Sqm 0.30 bags

2 I.P.S. flooring - 50 mm thick Sqm 0.37 bags

3 Rough Shahabad - any other similar flooring in CM 1:4

proportion bedding

Sqm 0.15 bags

4 All types of cement / kadappa / polished / mosaic tiles

flooring or skirting / dado set on CM 1:4 proportion

bedding

Sqm 0.18 bags

5 Glazed / ceramic tiles flooring or skirting / dado fixed with

plain cement slurry

Sqm 0.22 bags

Sr. Description Unit Rate (Rs.) 2012-13 Rate (Rs.) 2013-14

No. Complete Labour Complete Labour

SECTION - E : EXCAVATION

35

1 Excavation for foundation / pipe

trenches in earth, soils of all types,

sand, gravel and soft murum, including

removing the excavated material upto a

distance of 50 metres and lifts as below,

stacking and spreading as directed,