Professional Documents

Culture Documents

Crane Brief

Uploaded by

moha198410 ratings0% found this document useful (0 votes)

25 views33 pagesOver 250,000 cranes in operation - 125,000 in construction - 80,000 general and maritime 80 fatalities per year One death per thousand crane operators in their working lifetime (45 years)

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentOver 250,000 cranes in operation - 125,000 in construction - 80,000 general and maritime 80 fatalities per year One death per thousand crane operators in their working lifetime (45 years)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views33 pagesCrane Brief

Uploaded by

moha19841Over 250,000 cranes in operation - 125,000 in construction - 80,000 general and maritime 80 fatalities per year One death per thousand crane operators in their working lifetime (45 years)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 33

1

Crane and Hoist Safety

PUBH 3310

November 13, 2009

2

Objectives

Know hazards associated with cranes

Become familiar with common types of

industrial and construction cranes

Understand rigging basics, including the

importance of sling angle

Be familiar with methods of controlling

crane hazards and preventing accidents

3

Outline

Crane Hazards

Crane types

Industrial cranes

Construction cranes

Rigging (and sling angle)

Controlling hazards

Inspections and training

Power lines

Equipment failure and crane stability

Other

4

Crane Hazards

Over 250,000 cranes in operation

125,000 in construction

80,000 general and maritime

80 fatalities per year

One death per thousand crane

operators in their working lifetime (45

years)

Risk to citizens and other workers

5

Causes of Crane Fatalities

Electrocution 39%

Crane assembly/disassembly 12%

Crane upset/overturn 7%

Rigging failure 7%

Overloading 4%

Struck by moving load 4%

Manlifts 4%

Struck by counterweight 2%

Two-blocking 2%

Hoist limitations 2%

Other 6%

A. Suruda,et al, Crane-Related Deaths in the U.S. Construction Industry, 1984-

94

6

Crane Types

"Industrial cranes

Overhead

Gantry

Jib

"Construction cranes

Mobile

Tower

Derricks

7

Industrial Cranes

Overhead Cranes

Common in industrial facilities

Supported by overhead rails

Components

Bridge

Trolley

Hoist

Often pendant or remote operated

Easy to use, little training required, no

stability problems

8

Industrial Cranes

Gantry cranes

Similar to overhead

cranes, but supported by

a mobile frame which

travels on the ground

Small (1000 10,000 pound

capacity) gantry crane

Large (600 ton capacity)

gantry crane

9

Industrial Cranes

Jib cranes

Pivot mounted

boom with trolley

and hoist

Wall-mounted jib crane

Floor-mounted

jib crane

10

Industrial Cranes

Power hoist

Usually electric

or air operated

Chain hoist (or

"chain fall")

Hand operated

11

Construction Cranes

Tower

cranes

Variable

height

climbing

cranes

Used for

building

construction

12

Construction Cranes

Mobile cranes

Crawler cranes

Truck cranes

Hydraulic cranes

Boom telescopes

May have jib

Equipped with

outriggers for stability

13

Hydraulic

Cranes

14

Hydraulic Cranes

15

Construction cranes

Derricks

Boom angle

changes to adjust

horizontal distance

Often used in

shipyards, building

construction, etc.

Gin pole

Chicago boom

Stiff-leg

Etc.

16

Stiff-leg construction derrick

Mine-shaft rescue using a

gin pole derrick improvised

from an extension ladder

17

Hay derrick

18

Rigging

Rigging: The hardware

and equipment used to

safely attach a load to a

lifting device

Wire rope

Usually a "core" member to

increase flexibility

Fiber Core (FC)

Wire Strand Core (WSC)

Independent Wire-rope

Core (IWRC)

19

Rigging

Fittings, sheaves

Shackles

Blocks

Sockets

Hooks

May have safety

latch

Eyes

Turnbuckles

20

Rigging

Always use rigging to connect the load to the

hook

Materials

Wire rope

Fabric

Chain

Slings

Straight (regular)

Choker

Basket

Double, triple, etc.

21

Rigging

Sling angle

Stress on sling legs

varies with the angle

Divide the load by the

number of sling legs,

and divide by sin of

the angle

For a two-legged sling,

2000 lb load and 60

degree, stress = 1155

lbs on the sling leg

leg

lbs 1155

60 sin

1

legs 2

lbs 2000

leg

lbs 2000

30 sin

1

legs 2

lbs 2000

22

Operators

18 years old

Physical exam

Knowledge (training)

Estimating load

weight

Signals

Operation

Skill (demonstration)

Controlling Crane Hazards

23

Controlling Crane Hazards

Inspection

Frequent

Daily, monthly

Hooks, rope, crane operation

Periodic

At least annually

Complete inspection - wear, damage,

deterioration, operation

slings

Testing

Records

24

Preventing Crane Accidents

Contact with energized power lines

(45% of accidents)

De-energize overhead lines

Maintain minimum distance

10 feet distance for 50 kv

Over 50 kv, add 4 inches per 10 kv

Use proximity alarms

Warn when energized line is near

No fatalities in 25 years, according

to mfg.

Warning signs

I-15 construction was a good example

Sigalarm

25

Warning label

26

Preventing Crane Accidents

Under hook lifting device problems

Inspect, proper use, etc.

Overturned cranes

Assure a level and stable base for the

crane

Comply with load charts

Weight

Boom angle and extension

Only vertical loads

Wind can cause a significant side load

27

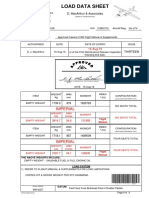

Load Chart

Load charts

inside the cab

include

Structural

capacity and

tipping limits for

the crane

Capacity is

highest for short

radius over front

loads with

outriggers

extended.

Load Chart

Radi

us

Rear Over Over Side Over Front

18.8'

Boom

24'

Boom

29.8'

Boom

18.8'

Boom

24'

Boom

29.8'

Boom

18.8'

Boom

24'

Boom

29.8'

Boom

6 65,600* 65,600* 66,720*

8 57,250* 56,510* 57,250* 56,510* 61,150* 56,510*

10 50,760* 49,230* 47,060* 50,760* 49,230* 47,060* 52,520* 49,230* 47,060*

12 44,970 43,250* 41,310* 45,540* 43,250* 41,310* 46,390* 43,250* 41,310*

15 33,180 33,290 33,350 39,370 37,090 35,080 39,620 37,090 35,080

18 25,960 26,250 26,310 27,540 28,370 28,490 27,540 32,471 30,730

20 22,940 23,010 22,910 23,030 29,820 28,430

25 16,910 15,330 23,770

29 13,030 11,870 16,750

29

Preventing Crane Accidents

Dropped loads

Operating anti-two block device (upper limit switch)

Proper rigging

Inspection

Boom collapse

Inspection

Stable base

No overloading

No horizontal loading

Crushing by the counter weight

Stay away from the rear of the crane

30

Preventing Crane Accidents

Proper outrigger use

Level

Fully extended

Stable base

Use cribbing to

distribute the load

31

Outrigger Use

Outrigger

with

cribbing

32

Preventing Crane Accidents

Rigging failure

Inspection

Proper use

temperature, angles, etc.

Falls

Fall protection for workers

suspended by crane "man

basket" or "suspended work

platform

33

Links

Managing Mobile Crane Hazards

http://www.elcosh.org/en/document/96/d

000104/managing-mobile-crane-

hazards.html

Crane, Derrick, and Hoist Safety

http://www.osha.gov/SLTC/cranehoistsafet

y/index.html

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- ISO Standards Collection - CranesDocument4 pagesISO Standards Collection - CranesJosé Rezende0% (1)

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- Reeving Information v2Document19 pagesReeving Information v2Giorgio Fer100% (2)

- Lea 4Document36 pagesLea 4Divina DugaoNo ratings yet

- Reciprocating Air Compressor PDFDocument2 pagesReciprocating Air Compressor PDFmoha19841100% (1)

- Pallets Pallets Pallets Pallets North American PalletsDocument2 pagesPallets Pallets Pallets Pallets North American Palletsmoha19841No ratings yet

- Drill Machine PDFDocument5 pagesDrill Machine PDFmoha19841No ratings yet

- Car PDFDocument6 pagesCar PDFmoha19841No ratings yet

- 0 ToolsDocument1 page0 Toolsmoha19841No ratings yet

- Davit Cranes PDFDocument2 pagesDavit Cranes PDFmoha19841No ratings yet

- Mobile Crane PDFDocument4 pagesMobile Crane PDFmoha19841No ratings yet

- Crane PDFDocument3 pagesCrane PDFmoha19841No ratings yet

- BS 4278 Eyebolts For Lifting Purposes PDFDocument14 pagesBS 4278 Eyebolts For Lifting Purposes PDFmoha1984167% (3)

- Mobile Crane Cop 2006Document71 pagesMobile Crane Cop 2006Matheus ZegattiNo ratings yet

- 0 Pump PDFDocument1 page0 Pump PDFmoha19841No ratings yet

- 0 Container PDFDocument4 pages0 Container PDFmoha19841No ratings yet

- Mobile Crane 80tDocument53 pagesMobile Crane 80tjillianixNo ratings yet

- Webbing SlingDocument3 pagesWebbing Slingmoha19841No ratings yet

- Wciagniki Linowe As F 7 AngielskiDocument48 pagesWciagniki Linowe As F 7 Angielskimoha19841No ratings yet

- Nfpa 45Document19 pagesNfpa 45moha19841100% (1)

- The American University in Cairo: Laboratory Safety Chemical Fume HoodsDocument21 pagesThe American University in Cairo: Laboratory Safety Chemical Fume Hoodsmoha19841No ratings yet

- OSHA LabSafetyDocument37 pagesOSHA LabSafetymoha19841No ratings yet

- The American University in Cairo: Compressed Gases & Gas Cylinders OSHA 29 CFR 1910.101Document14 pagesThe American University in Cairo: Compressed Gases & Gas Cylinders OSHA 29 CFR 1910.101moha19841No ratings yet

- Laboratory Safety PracticesDocument20 pagesLaboratory Safety Practicesmoha19841No ratings yet

- Reflections On Free MarketDocument394 pagesReflections On Free MarketGRK MurtyNo ratings yet

- Ytrig Tuchchh TVDocument10 pagesYtrig Tuchchh TVYogesh ChhaprooNo ratings yet

- Banjara EmbroideryDocument34 pagesBanjara EmbroideryKriti Rama ManiNo ratings yet

- The Rise of Populism and The Crisis of Globalization: Brexit, Trump and BeyondDocument11 pagesThe Rise of Populism and The Crisis of Globalization: Brexit, Trump and Beyondalpha fiveNo ratings yet

- Heavy LiftDocument4 pagesHeavy Liftmaersk01No ratings yet

- Transparency Documentation EN 2019Document23 pagesTransparency Documentation EN 2019shani ChahalNo ratings yet

- 30 Creative Activities For KidsDocument4 pages30 Creative Activities For KidsLaloGomezNo ratings yet

- Cancellation of Deed of Conditional SalDocument5 pagesCancellation of Deed of Conditional SalJohn RositoNo ratings yet

- Multispan LC 2046 Length Counter PDFDocument2 pagesMultispan LC 2046 Length Counter PDFvinod kumarNo ratings yet

- CH 1 India Economy On The Eve of Independence QueDocument4 pagesCH 1 India Economy On The Eve of Independence QueDhruv SinghalNo ratings yet

- The Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and CountriesDocument13 pagesThe Effectiveness of Risk Management: An Analysis of Project Risk Planning Across Industries and Countriesluisbmwm6No ratings yet

- 23 Things You Should Know About Excel Pivot Tables - Exceljet PDFDocument21 pages23 Things You Should Know About Excel Pivot Tables - Exceljet PDFRishavKrishna0% (1)

- Schmidt Family Sales Flyer English HighDocument6 pagesSchmidt Family Sales Flyer English HighmdeenkNo ratings yet

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiNo ratings yet

- BluetoothDocument28 pagesBluetoothMilind GoratelaNo ratings yet

- Unit Process 009Document15 pagesUnit Process 009Talha ImtiazNo ratings yet

- TAS5431-Q1EVM User's GuideDocument23 pagesTAS5431-Q1EVM User's GuideAlissonNo ratings yet

- Hayashi Q Econometica 82Document16 pagesHayashi Q Econometica 82Franco VenesiaNo ratings yet

- Ucm6510 Usermanual PDFDocument393 pagesUcm6510 Usermanual PDFCristhian ArecoNo ratings yet

- Online EarningsDocument3 pagesOnline EarningsafzalalibahttiNo ratings yet

- Load Data Sheet: ImperialDocument3 pagesLoad Data Sheet: ImperialLaurean Cub BlankNo ratings yet

- Low Cost Building ConstructionDocument15 pagesLow Cost Building ConstructionAtta RehmanNo ratings yet

- Cic Tips Part 1&2Document27 pagesCic Tips Part 1&2Yousef AlalawiNo ratings yet

- Condition Monitoring of Steam Turbines by Performance AnalysisDocument25 pagesCondition Monitoring of Steam Turbines by Performance Analysisabuhurairaqazi100% (1)

- WEEK6 BAU COOP DM NextGen CRMDocument29 pagesWEEK6 BAU COOP DM NextGen CRMOnur MutluayNo ratings yet

- Underwater Wellhead Casing Patch: Instruction Manual 6480Document8 pagesUnderwater Wellhead Casing Patch: Instruction Manual 6480Ragui StephanosNo ratings yet

- MDOF (Multi Degre of FreedomDocument173 pagesMDOF (Multi Degre of FreedomRicky Ariyanto100% (1)

- MORIGINADocument7 pagesMORIGINAatishNo ratings yet

- Catalog Celule Siemens 8DJHDocument80 pagesCatalog Celule Siemens 8DJHAlexandru HalauNo ratings yet