Professional Documents

Culture Documents

ME4213

Uploaded by

هاني زيادة0 ratings0% found this document useful (0 votes)

64 views2 pagescourse outlines

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcourse outlines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

64 views2 pagesME4213

Uploaded by

هاني زيادةcourse outlines

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

ME 4213 Materials Selection and Failure Analysis (Elective)

Catalog Description: ME 4213 Materials Selection and Failure Analysis (3-0-3)

Prerequisites: COE 3001 Deformable Bodies

Principles of selecting both materials and processes required for mechanical

design as well as failure analysis. Mechanics and materials knowledge used in

solving practical problems.

Textbook: Michael F. Ashby, Materials Selection in Mechanical Design, 3rd Edition,

Butterworth-Heinemann, 2005.

Topics Covered:

1. Course goals and overview of the design process

2. Engineering materials and their properties

3. Sources of material property data

4. Introduction to materials selection software

5. Materials selection charts

6. Materials selection without shape

7. Case studies of material selection without shape

8. Selection of material and shape

9. Case studies of selection of material and shape

10. Material processing and process charts

11. Case studies of selection of process

12. Aesthetics and environmental considerations

13. Principles of failure analysis

14. Case studies of failure analysis for metals, ceramics, polymers and composites

Course Outcomes:

Outcome 1: To provide the students a thorough systematic approach to the selection of metals, ceramics,

polymers, and composites required for mechanical design.

1.1 Students will demonstrate knowledge of mechanics analysis for a variety of components.

1.2 Students will demonstrate how performance indexes based on mechanics analyses can be

overlaid on material property charts to identify promising materials for specific applications using

both manual and computer techniques.

Outcome 2: To familiarize the students with material properties and materials fabrication processes and an

approach for selecting a process capable of producing a component possessing the size, shape, properties,

and cost dictated by the design.

2.1 Students will construct and use material property charts to identify a small set of materials

meeting mechanical, physical, and cost requirements for numerous case studies.

2.2 Students will use material processing charts to select suitable fabrication processes considering

size, section thickness, complexity of shape, tolerance, surface finish, hardness, melting point,

cost, and environmental impact.

Outcome 3: To introduce the students to the principles of failure analysis for metals, ceramics, polymers,

and composites so that the causes of failures may be identified and avoided.

3.1 Students will demonstrate recognition of failure mechanism and identify alternate materials

and/or service conditions that prolong component life.

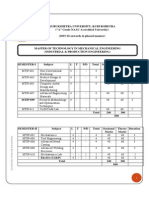

Correlation between Course Outcomes and Program Educational Outcomes:

ME 4213

Mechanical Engineering Program Educational Outcomes

Course Outcomes a b c d e f g h i j k l

Course Outcome 1.1 X X X X

Course Outcome 1.2 X X X X X X

Course Outcome 2.1 X X X X X X X X X

Course Outcome 2.2 X X X X X X X X X

Course Outcome 3.1 X X X X X X X

Prepared by: Richard W. Neu

You might also like

- MA2004 Engineering Materials and Manufacturing Processes 23082021Document7 pagesMA2004 Engineering Materials and Manufacturing Processes 23082021Aloysius TobiasNo ratings yet

- Mse 4793Document3 pagesMse 4793aeromatNo ratings yet

- Bioen 492 - Surface Analysis Techniques and ApplicationsDocument4 pagesBioen 492 - Surface Analysis Techniques and ApplicationsMahir MahmoodNo ratings yet

- ME-406 Manufacturing and DesignDocument2 pagesME-406 Manufacturing and DesignFaraz JamshaidNo ratings yet

- Met Met382syllabusDocument4 pagesMet Met382syllabusOyunbat GansukhNo ratings yet

- Me770, Me770a - Course OutlineDocument3 pagesMe770, Me770a - Course OutlinePrakhar GuptaNo ratings yet

- Fem PDFDocument65 pagesFem PDFManda Ramesh BabuNo ratings yet

- Kerala University Mtech - Me - Ind Refrigeration 2013 SchemeDocument59 pagesKerala University Mtech - Me - Ind Refrigeration 2013 SchemerebyroyNo ratings yet

- Mechanical Technology and Machine ToolsDocument8 pagesMechanical Technology and Machine ToolsGeoffrey MichaelNo ratings yet

- Course File RRDocument32 pagesCourse File RRRaj RajendranNo ratings yet

- ME 4214 Mechanical Behavior of Materials (Elective) : Catalog DescriptionDocument2 pagesME 4214 Mechanical Behavior of Materials (Elective) : Catalog DescriptionengineerNo ratings yet

- ME 215 - Engineering Materials and ProcessesDocument3 pagesME 215 - Engineering Materials and Processesnatural recipeNo ratings yet

- Unit 202 Principles of Engineering Technology: 26 Level 2 Certificate and Diploma in Engineering (2850-20)Document5 pagesUnit 202 Principles of Engineering Technology: 26 Level 2 Certificate and Diploma in Engineering (2850-20)Eóin O Ceranaigh100% (2)

- Elective SyllabusDocument8 pagesElective SyllabusMadhukar SamathamNo ratings yet

- Velammal Institute of Technology Mechanical Engineering Course Outcomes Program OutcomesDocument54 pagesVelammal Institute of Technology Mechanical Engineering Course Outcomes Program OutcomesshivakeesNo ratings yet

- EGM 311 - Solving Mechanical ProblemsDocument38 pagesEGM 311 - Solving Mechanical ProblemsAnthony MulengaNo ratings yet

- EMCH332Document2 pagesEMCH332mhdagungpratamaNo ratings yet

- (Yang Hsien Huang) Pavement Analysis and DesignDocument2 pages(Yang Hsien Huang) Pavement Analysis and DesignOmid HosseinzehiNo ratings yet

- Co Po Peo ComputerDocument21 pagesCo Po Peo ComputerHARSH MAGHNANINo ratings yet

- Master Chemical Engineering CoursesDocument23 pagesMaster Chemical Engineering Courseskiranpatil1014532No ratings yet

- Unit 7: Materials Engineering Learning Hours: 60 NQF Level 4: BTEC Higher National - H1 Description of UnitDocument5 pagesUnit 7: Materials Engineering Learning Hours: 60 NQF Level 4: BTEC Higher National - H1 Description of UnitSebastien PaulNo ratings yet

- 3rd Year Eng - Outline PDFDocument7 pages3rd Year Eng - Outline PDFkingNo ratings yet

- Dme Question Bank by Syam Prasad AmmineniDocument22 pagesDme Question Bank by Syam Prasad AmmineniDharmendra SharmaNo ratings yet

- 12 .B.Tech - Mechanical 1222 1283Document62 pages12 .B.Tech - Mechanical 1222 1283An andNo ratings yet

- BGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomesDocument23 pagesBGS Institute of Technology B.G.Nagar-571448: Course Objectives & OutcomeshemarajuNo ratings yet

- Mechanics of MaterialsDocument13 pagesMechanics of MaterialsJack jacksonNo ratings yet

- 4 - B - Tech - Mechanical Engg - 4th Year Pages 57Document57 pages4 - B - Tech - Mechanical Engg - 4th Year Pages 57Aniket JhaNo ratings yet

- The Master of EngineeringDocument17 pagesThe Master of Engineeringaurea_yansikuNo ratings yet

- MENG 2013 Machine Design II OutlineDocument6 pagesMENG 2013 Machine Design II OutlineHazAuditoreNo ratings yet

- ENGR 54 Materials Science CourseDocument2 pagesENGR 54 Materials Science Coursezihk_15No ratings yet

- Syllabus ME215 Spring 2012Document2 pagesSyllabus ME215 Spring 2012Anwär AlmöjarkeshNo ratings yet

- Course IntroductionDocument13 pagesCourse Introduction维尔No ratings yet

- IFYDP Topics PDFDocument26 pagesIFYDP Topics PDFGreen MichaelsNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Applications of Finite Element Analysis For Undergraduates 1Document7 pagesApplications of Finite Element Analysis For Undergraduates 1oai.etu2No ratings yet

- CHEE 2331 Syllabus Spring 2011Document11 pagesCHEE 2331 Syllabus Spring 2011Kieu Phuong PhamNo ratings yet

- Machine Elements Design CourseDocument7 pagesMachine Elements Design CourseSripriyan KaruthapandiNo ratings yet

- EC1002 Lab Manual: Electronics Engineering PracticesDocument82 pagesEC1002 Lab Manual: Electronics Engineering PracticesChaithanya SureshNo ratings yet

- Selection of Joining Methods in Mechanical DesignDocument12 pagesSelection of Joining Methods in Mechanical Designac.diogo487No ratings yet

- BTEC - Specialist Units (Nat Mech Eng)Document224 pagesBTEC - Specialist Units (Nat Mech Eng)Steve BeresfordNo ratings yet

- Mechanical Eng Study GuideDocument31 pagesMechanical Eng Study Guideeng bassimNo ratings yet

- Scheme & Syllabus III & IV Semester B.E Computer Science and Engineering (2012 Scheme)Document46 pagesScheme & Syllabus III & IV Semester B.E Computer Science and Engineering (2012 Scheme)Lalit KumarNo ratings yet

- ME401 Course Objectives OutcomesDocument2 pagesME401 Course Objectives OutcomesHarjit Singh MangatNo ratings yet

- CEN - 213 Lec 01Document10 pagesCEN - 213 Lec 01najmussakibsohan4No ratings yet

- CEPD101 study guide for 2024Document14 pagesCEPD101 study guide for 2024Sydney Jaydean KhanyileNo ratings yet

- Design and Fabrication Project: L T P CDocument18 pagesDesign and Fabrication Project: L T P CNellai RagulNo ratings yet

- Sneakers As A First Step in Chemical Engineering Author Margot Vigeant, Richard MooreDocument12 pagesSneakers As A First Step in Chemical Engineering Author Margot Vigeant, Richard MooreTyler VintNo ratings yet

- Cae 315Document4 pagesCae 315draqbhattiNo ratings yet

- MACHINEDESIGNDocument35 pagesMACHINEDESIGNBrandon AllenNo ratings yet

- MEC 322 OutlineDocument3 pagesMEC 322 OutlineBob jonesNo ratings yet

- MCE 417 Course CompactDocument7 pagesMCE 417 Course CompactKEHINDE BABALOLANo ratings yet

- CE 360 Structural Analysis Course SyllabiDocument3 pagesCE 360 Structural Analysis Course Syllabimagdy bakryNo ratings yet

- Finite Element Techniques Course OverviewDocument3 pagesFinite Element Techniques Course OverviewPavaniNo ratings yet

- Microfabrication Technologies CourseDocument2 pagesMicrofabrication Technologies Coursemohitsinghal25No ratings yet

- IIT Jodhpur Proposed ME M.Tech Program CurriculumDocument8 pagesIIT Jodhpur Proposed ME M.Tech Program CurriculumAmit ANo ratings yet

- CourseoutcomesDocument121 pagesCourseoutcomesSrinivasa Reddy NallimilliNo ratings yet

- Assessment of Material Science Activities in Undergraduate Reverse Engineering Projects PDFDocument10 pagesAssessment of Material Science Activities in Undergraduate Reverse Engineering Projects PDFeddunbarNo ratings yet

- ADP Connection For PayForce Requirements20303Document2 pagesADP Connection For PayForce Requirements20303claokerNo ratings yet

- VB 6.0 TutorialsDocument19 pagesVB 6.0 TutorialsSantoshNo ratings yet

- Lifetime Estimation and Monitoring of Power Transformer Considering Annual Load Factors (2013)Document8 pagesLifetime Estimation and Monitoring of Power Transformer Considering Annual Load Factors (2013)Macro DemolitionNo ratings yet

- Basic Excel FormulasDocument164 pagesBasic Excel FormulasShubhamShuklaNo ratings yet

- Brochure Marketing MaterialsDocument34 pagesBrochure Marketing MaterialsmjengineerswebNo ratings yet

- Troubleshooting: LunarDocument54 pagesTroubleshooting: Lunarsmm100% (1)

- EXP1 - Significant Figures ErrorsDocument18 pagesEXP1 - Significant Figures ErrorsHeba BazlamitNo ratings yet

- ResearchpapereditedDocument20 pagesResearchpapereditedjopethNo ratings yet

- Advanced Operating Systems Fall 2023 AustinDocument11 pagesAdvanced Operating Systems Fall 2023 AustinnntuonNo ratings yet

- Malicious Cryptography Cryptovirology and KleptographyDocument13 pagesMalicious Cryptography Cryptovirology and KleptographySpoe3400No ratings yet

- 06-823 PC Link HLI Modbus Protocol PN 68-517Document58 pages06-823 PC Link HLI Modbus Protocol PN 68-517khalil.assaf.84No ratings yet

- Quotation Quotation: Modern Electronics Company LTDDocument1 pageQuotation Quotation: Modern Electronics Company LTDOsama MalikNo ratings yet

- Field-Guide CyprusDocument8 pagesField-Guide CyprusValeriu ChiperNo ratings yet

- WCDMA RAN Protocols and ProceduresDocument38 pagesWCDMA RAN Protocols and ProceduresJihad DaoukNo ratings yet

- Manual Quite Imposing 3.0 PlusDocument138 pagesManual Quite Imposing 3.0 PlusFernando Torres100% (1)

- Mobile ComputingDocument5 pagesMobile ComputingAjay Dubey0% (1)

- Csat Gs Almost Revision ManualDocument483 pagesCsat Gs Almost Revision ManualVarun Mohanakumaran RajambikaNo ratings yet

- BioTime 7.0 User Manual V1.1 PDFDocument63 pagesBioTime 7.0 User Manual V1.1 PDFASNo ratings yet

- Dataisgood BrochureDocument12 pagesDataisgood BrochureSyed Ayaan AsifNo ratings yet

- Mastercam2024 pb4 Resolved IssuesDocument22 pagesMastercam2024 pb4 Resolved Issuessanath deltronNo ratings yet

- BCM AgentRolloutDocument38 pagesBCM AgentRolloutpedirstuffNo ratings yet

- New Microsoft Word DocumexcvbnntDocument13 pagesNew Microsoft Word Documexcvbnntasdfg7140No ratings yet

- AN1078 Tuning Procedure ReadMeDocument30 pagesAN1078 Tuning Procedure ReadMeHồ Trung ChíNo ratings yet

- 2e9ecsoftware Testing and Quality AssuranceDocument1 page2e9ecsoftware Testing and Quality AssuranceharryamanNo ratings yet

- Handbook of Research On Green ICT TechnologyDocument756 pagesHandbook of Research On Green ICT TechnologyGeoffrey TanuiNo ratings yet

- DeltaV Services App - User GuideDocument13 pagesDeltaV Services App - User GuideSilvia Del RíoNo ratings yet

- 3.reading Importing Raw Data Into SasDocument5 pages3.reading Importing Raw Data Into SasNarendrareddy RamireddyNo ratings yet

- Tai Lieu Bien Tan Frecon Fr150a EN-1Document125 pagesTai Lieu Bien Tan Frecon Fr150a EN-1Ankhuong NguyenNo ratings yet

- AdvantageCalibration Quick Ref CardDocument36 pagesAdvantageCalibration Quick Ref CardDario Fernando Flores Cotto100% (1)

- 1200.2 SAS SSD Compatibility Report Summary RevD 2Document14 pages1200.2 SAS SSD Compatibility Report Summary RevD 2haibin qiNo ratings yet