Professional Documents

Culture Documents

CH2103 Part1-1

Uploaded by

Nhân TrầnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH2103 Part1-1

Uploaded by

Nhân TrầnCopyright:

Available Formats

CP2103

lluld SysLems

Lau Wal Man, 8aymond

Cmce: n1.2-82-32

hone: 6316 8830

Lmall: wmlau[nLu.edu.sg

Loo Sun Sun, Leslle

Cmce: n1.2-81-12

hone: 6790 6737

Lmall: ssloo[nLu.edu.sg

Course CuLllne

Macroscoplc lluld Mechanlcs

lnLroducuon

Mass, Lnergy and MomenLum 8alances

lluld llow ln lpes

ulmenslonal Analysls

umps and Compressors

Mlcroscoplc lluld Mechanlcs

(Covered by ur. Leslle Loo)

Cradlng

Conunuous AssessmenL ~30

llnal Lxamlnauon ~ 70

1exLbook

!"#$%& ( !ames C. Wllkes

)"*+,-$.& ( earson

/012 ( 9780131482128

lluld Mechanlcs for Chemlcal Lnglneers

wlLh Mlcrouldlcs & Clu 2

nd

ed

CA policy

If student misses CA due to following reasons:

valid MC (not from Chinese doctor)

passing away of immediate family (parents, siblings,

grandparents)

participate in an activity representing NTU

then the CA component will be counted towards the

final exam. There will be no makeup CA.

Otherwise student gets 0 for CA.

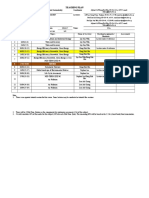

Tentative Schedule

- Tutorial Week

- Quiz

- Holiday

Week of Mon Tue Wed Thu Fri

11/8/2012

National

Day

LT LT

18/8/2012 LT LT

25/8/2012 LT LT Union Day

1/9/2012 LT LT

8/9/2012 LT LT

15/9/2012 LT Quiz

22/9/2012 LT LT

29/9/2012 RECESS WEEK

6/10/2012

Hari Raya

Haji

LT LT

13/10/2012 LT LT

20/10/2012 LT Deepavali

27/10/2012 LT LT

3/11/2012 LT LT

10/11/2012 LT LT

lluld mechanlcs

lluld mechanlcs ls a sLudy of ulds and Lhe

forces acung on Lhem.

lluld sLaucs - SLudy of uld aL resL

lluld dynamlcs - SLudy of uld ln mouon

Why sLudy uld mechanlcs?

Chemlcal Lnglneers

eLrochemlcal lndusLry

harmaceuucal lndusLry

8lomedlcal lndusLry

ower planLs

non-Chemlcal Lnglneers

Alrplane/Car/8oaL deslgn

8lomechanlcs

SporLs

WeaLher forecasL

LxpecLed Learnlng CuLcomes

Able Lo vlsuallze uld ow problems and seLup

approprlaLe governlng equauons

undersLand Lhe dlerence beLween lamlnar

and LurbulenL plpe ow problems and solve

deslgn problems lnvolvlng pumps and Lurblnes

undersLand Lhe concepL of drag on dlerenL

geomeLrles and apply ln dlerenL deslgn

problems

WhaL ls a uld?

Cas? Llquld? Sollds?

roperues LhaL classlfy a subsLance as uld

ueformable?

llowable?

Conunuous phase?

uenluon of a uld

A uld ls a subsLance LhaL deforms conunuously

under Lhe appllcauon of a shear (Langenual) force

Sollds can deform under shear forces buL can reLurn

Lo lLs orlglnal form when Lhe shear forces ls

removed

lluld normally Lakes Lhe form of llquld or gas

roperues of uld

lluld sLaucs

uenslLy

vlscoslLy

Surface Lenslon

Mass

volume

1emperaLure

ressure

lluld mechanlcs

veloclLy

SLress

Lach properLy can change wlLh locauon

(x,y,z) and ume (L)

0

0

0

0

) , , , (

=

=

=

=

=

dz

d

dy

d

dx

d

dt

d

t z y x

!

!

!

!

! !

sLeady sLaLe

none of Lhem valld =

3-ulmenuonal ow

1 of Lhem valld =

2-ulmenuonal ow

2 of Lhem valld =

1-ulmenuonal ow

All of Lhem valld = ?

1lmellnes: llne formed by ad[acenL uld parucles ln a ow eld

aL a glven lnsLanL

aLhllnes: paLh or LragecLory Lraced ouL by a movlng parucle

SLreakllnes: llne formed by parucles passlng Lhrough a xed

locauon ln a space over a perlod of ume

SLreamllnes: llne LangenL Lo dlrecuon of ow aL every polnL ln

ow eld (LangenL Lo veloclLy vecLor ln ow eld)

aLhllnes, sLreakllnes and sLreamllnes are ldenucal under

sLeady sLaLe

1lmellnes vs aLhllnes vs SLreakllnes vs SLreamllnes

Pathlines (Red) vs Streaklines (Blue) vs Streamlines (Grey) [Wikipedia]

lorces and sLress

SLress ls force per unlL

area

normal sLress

lorce acLs perpendlcular

Lo surface

1enslle

Compresslve (e.g.

pressure)

Shear SLress

lorce acLs Langenually Lo

surface

lor a glven shear raLe,

Lhe shear sLress ls

dlrecLly proporuonal Lo

Lhe vlscoslLy of uld

ressure

ln hydrosLauc slLuauons (uld aL resL)

uld molecules are ln a sLaLe of compresslon

degree of compresslon ls measured by

pressure (scalar quanuLy)

8y denluon, p = l/A (has unlLs of a sLress)

1he value of pressure aL a polnL ls lndependenL

of Lhe orlenLauon of any area assoclaLed wlLh

lL (Work Lhls ouL wlLh reference Lo llg. 1.3)

ln movlng ulds, Lhe normal sLresses

lnclude boLh a pressure and exLra sLresses

caused by Lhe mouon of Lhe uld

(dlscussed laLer ln ChapLer 3)

AbsoluLe pressure = gauge pressure +

aLmospherlc pressure

8aslc laws

1o undersLand Lhe baslc prlnclples and

concepL of uld mechanlcs, we need forms

of Lhe followlng:

Conservauon of mass (ConunulLy)

newLons second law of mouon

1he rsL law of Lhermodynamlcs

uL slmply, Lhe laws of uld mechanlcs

amounL Lo conservauon of mass, energy,

and momenLum.

ulmenslons and unlLs

SysLems of ulmenslons

ulmenslons: physlcal quanuues (e.g. l, t, M, 1)

[M], [l], [t], and [1]

[l], [l], [t], and [1]

[l],[M], [l], [t], and [1]

LengLh and ume, and mass or force, are ptlmoty

(boslc) Jlmeosloos (from whlch oLhers can be

formed (derlved)) ln all dlmenslonal sysLems ln

common use.

SysLems of unlLs

MLL1[Sl (kg, m, s, k)}, [cgs (cm-g-s)}

lLL1[8rlush CravlLauonal (lb

f

, , s,

o

8)}

lMLL1[Lngllsh Lnglneerlng (lb

f

, lb

m

, , s,

o

8)}

referred SysLems of unlLs

Sl (kg, m, s, k) (ref. 1able 1.8)

1 n = 1 kg m/s

2

8rlush CravlLauonal (lb

f

, , s,

o

8)

1 slug = 1 lb

f

s

2

/

1 slug = 32.2 lb

m

Always (repeaL, always) lnclude Lhe unlL wlLh any

englneerlng quanuLy you have wrluen down.

lf wrluen wlLhouL unlLs, our quanuLy ls

meanlngless.

ConverL Lhe unlLs uslng approprlaLe converslon

facLors (1able 1.11).

Lxample 1.1: unlLs Converslon

Lxpress 63 mph ln (a) km/hr, and (b) m/s

(a)

(b)

hr

km

6 . 04 1

m 1000

km 1

ft

m

3048 . 0

mile

ft

5280

hr

mile

65

hr

mile

65 = ! ! ! =

s

m

06 . 9 2

3600s

hr

ft

m

3048 . 0

mile

ft

5280

hr

mile

65

hr

mile

65 = ! ! ! =

uenslLy and speclc gravlLy of a uld

uenslLy depends on mass of an lndlvldual

molecule and Lhe number of such

molecules LhaL occupy a unlL of volume

lor llqulds, denslLy depends prlmarlly

on Lhe parucular llquld, and Lo a smaller

exLenL on LemperaLure

Speclc gravlLy, s of a uld ls Lhe rauo of

Lhe denslLy Lo Lhe denslLy of a reference

uld aL some sLandard condluon (e.g.

speclc LemperaLure and pressure)(p

5c

):

lor llqulds, p

5c

ls usually Lhe denslLy of

waLer aL 4C

lor gases, Lhere ls no slngle sLandard

(care musL be Laken when lnLerpreung

publlshed daLa)

P & T same at both

3 3

3

g/cm or kg/m is unit

L

M

] [

volume

mass

!

!

"

#

$

$

%

&

=

=

= =

air

gas

gas

SC

s

s

'

'

'

'

'

uenslues of gases

lor ldeal gases ( pv = ok1 )

! p = absoluLe pressure

! v = volume of gas

! o = number of mole of gas

! k = gas consLanL (1able 1.2)

! 1 = absoluLe LemperaLure

lor nonldeal gases

! compresslblllLy (2 = 2(p,1)) ls Laken lnLo accounL (2

lJeol qos

= 1)

! CompresslblllLy: a measure of Lhe relauve volume change of

uld or solld as a response Lo a pressure (or mean sLress)

change

! bulk modulus (or lncompresslblllLy):

w w

M

RT

p

M

V

n

= = !

w w

M

ZRT

p

M

V

n

= = !

V

p

V

!

!

" = #

vlscoslLy

vlscoslLy (or dynamlc or absoluLe vlscoslLy) ls a

measure of lnLernal, frlcuonal reslsLance Lo ow

under an applled sLress.

newLonlan llulds

MosL of Lhe common ulds (e.g. waLer, alr)

Llnear ulds: shear sLress proporuonal Lo shear raLe,

and Lhe proporuonallLy consLanL, ls Lhe vlscoslLy of

Lhe uld

has unlLs: kg/ms or g/cms or as (1 g/cms = 1

polse, 1 as = 1 ns/m

2

, and 1 cenupolse (c) =

0.01 , whlch ls Lhe vlscoslLy of waLer aL room

LemperaLure )

vlscoslues of llqulds

! Cenerally vary approxlmaLely wlLh absoluLe LemperaLure 1

(decreases wlLh LemperaLure)

1here ls a cerLaln molecular lnLerchange beLween ad[acenL

layers ln llqulds - buL as Lhe molecules are so much closer

Lhan ln gasses, Lhe coheslve forces hold Lhe molecules ln

place much more rlgldly

Coheslon plays an lmporLanL roll ln Lhe vlscoslLy of llqulds.

lncreaslng Lhe LemperaLure of a uld reduces Lhe coheslve

forces and lncreases Lhe molecular lnLerchange.

8educlng coheslve forces reduces shear sLress, whlle

lncreaslng molecular lnLerchange lncreases shear sLress.

! Lo a good approxlmauon are lndependenL of pressure

T b a

e T b a

ln

or ln ln

+

! + !

o and b are vlscoslLy parameLers (1able 1.4)

vlscoslLy of gases

! lncreases wlLh lncreaslng LemperaLure

1he molecules of gasses are only weakly kepL ln posluon by

molecular coheslon (as Lhey are so far aparL).

As ad[acenL layers move by each oLher Lhere ls a conunuous

exchange of molecules. Molecules of a slower layer move Lo

fasLer layers causlng a drag, whlle molecules movlng Lhe

oLher way exerL an accelerauon force. MaLhemaucal

conslderauons of Lhls momenLum exchange can lead Lo

newLons law of vlscoslLy.

lf Lhe LemperaLure of a gas lncreases, Lhe momenLum

exchange beLween layers wlll lncrease Lhus lncreaslng

vlscoslLy.

! lndependenL of pressure and denslLy

vlscoslLy wlll also change wlLh pressure - buL under normal

condluons Lhls change ls negllglble ln gasses.

n

T

T

!

!

"

#

$

$

%

&

'

0

0

0

= vlscoslLy aL absoluLe

reference LemperaLure 1

0

(1able 1.3)

MeasuremenL of vlscoslLy

8heomeLer

vlscomeLer

Coaxlal-cyllnder

8heomeLer

arallel-plaLe

8heomeLer

Cone-and-plaLe

8heomeLer

Surface 1enslon

Lendency of Lhe surface of llquld Lo behave llke a

sLreLched elasuc membrane

caused by auracuve forces ln llquld

Lwo non-mlxlng ulds (e.g., a llquld and a gas) wlll form

an lnLerface

molecules below Lhe lnLerface acL on each oLher wlLh

forces equal ln all dlrecuons, whereas Lhe molecules

near Lhe surface acL on each oLher wlLh lncreased

forces due Lo Lhe absence of nelghbors l.e. Lhe

lnLerface acLs llke a sLreLched membrane

Lendency or eorL of each

molecule aL Lhe surface Lo

reach Lhe cenLre causes Lhe

uld Lry Lo Lake Lhe shape

LhaL wlll have Lhe greaLesL

number of molecules

nearesL Lhe surface, a

sphere

oLher forces such as gravlLy

oen oppose surface

Lenslon forces so LhaL Lhe

uld Lrles Lo decrease lLs

surface area Lo a mlnlmum

depends on llquld Lype and

Lype of surface wlLh whlch lL

shares an lnLerface

o has unlL dyne/cm or n/m

F

!

=!L =! ! 2"r

P

1

" P

2

=!

1

r

1

+

1

r

2

#

$

%

&

'

(

r

P

2

P

1

F

!

F

!

"

#h

r1

r2

Note: r1 = r2 =/= radius of capillary tube

r1

r2

The meniscus in a spherical shaped

capillary tube has the radius of

curvature that extends to form a

sphere.

Top view of the center

plane of the sphere formed

from the radius of curvature

of the meniscus.

r1

r2

r1

r2

Elliptical shaped capillary tube

Meniscus forms an ellipsoid based

on the two radius of curvature at the

elliptical shaped capillary tube. Top view of the center plane of

the ellipsoid formed from the

radius of curvature of the

meniscus.

r

P

2

P

1

F

!

F

!

"

#h

Force balance on the liquid column:

F

!

=! ! 2"r

F

g

= #g"r

2

"h

Upward force:

Downward force:

F

!

= F

g

!h =

2!

"gr

F

!

cos" =! ! 2#r ! cos"

F

!

cos" = F

g

=V#g

V = $r

2

!h

"!h =

2! cos"

#gr

PydrosLaucs (lluld sLaucs)

PydrosLaucs ls abouL pressure/force exerLed

by a uld aL resL

CompuLe forces on submerged ob[ecLs

uevelop lnsLrumenLs for measurlng pressure

ueLermlne forces developed ln hydraullc sysLems

ln appllcauons

ressure

arlses due Lo Lhe conunual Lransfer of

momenLum from lndlvldual molecules

durlng colllslons wlLh Lhe walls

AbsoluLe pressure

force per unlL area LhaL Lhe molecules

lnslde a chamber exerL on Lhe chamber

walls.

always posluve

Cauge pressure

Lhe dlerence beLween Lhe absoluLe

pressure and Lhe aLmospherlc pressure

(chamber ls lmmersed ln Lhe

aLmosphere)

can be negauve lf pressure ln chamber

ls less Lhan aLmosphere

aLmospherlc pressure

ls 101,000 n/m

2

aL sea-level (1 a = 1

n/m

2

)

ressure varlauon ln a sLauc uld

Cauge pressure = AbsoluLe pressure - ALmospherlc pressure

lncompresslble uld under gravlLy:

gH p ! = "

polnL1

polnL2

H

ressure aL polnL1 = 1 aLm

ressure aL polnL2 = 1 aLm + !qn

ressure dlerence beLween polnL1 and

polnL2 = p1-p2 = - !qn

( )

2 1 2 1

1

2

1

2

z z g p p

dz g dp g

dz

dp

z

z

p

p

! ! = ! "

! = " ! =

# #

$

$ $

z

?

?

?

l

ln5

= !

wotet

qb

J

-!

olt

qb

2

-!

oll

qb

1

-l

otm

l

kn5

= !

wotet

qb

4

-l

otm

l

ln5

=l

kn5

8earrange:!

oll

=(!

wotet

b

4

- !

wotet

b

J

-!

olt

b

2

)/b

1

lor slmpllclLy, !

olt

can be neglecLed because

!

olt

<<!

wotet

!

oll

=!

wotet

(b

4

-b

J

)/b

1

s

oll

= !

oll

/!

wotet

=(b

4

-b

J

)/b

1

=(J.0-1.0)/2.5=0.80

Lxample - ressure balance of a manomeLer

lor a u-Lube manomeLer shown ln Lhe gure,

whaL ls Lhe speclc gravlLy of oll?

waLer

alr

oll

roperLy of manomeLer: 1he pressure aL Lhe same helghL of Lhe

manomeLer connecLed wlLh Lhe same uld should be balanced

aLm

aLm

1

2

h

1

= 2.3

h

2

= 0.3

h

3

= 1.0

h

4

= 3.0

)

340

)

540

Compresslble uld: p=consLanL (e.g. a gas)

uenslLy of gases generally depends on , 1

ldeal Cas equauon of sLaLe accuraLely models Lhe

behavlor of mosL gases under englneerlng condluons

w

M

RT

p

nRT pV = = ! or

dp = !!gdz = !

pg

RT

M

w

dz "

dp

p

p

0

p

#

= ln

p

p

0

= !

g

RT

M

w

dz

0

z

#

" p = p

0

exp !

g

RT

M

w

z

$

%

&

'

(

)

ln

p

p

0

= !

g

R

M

w

dz

T z

( )

0

z

#

lor consLanL LemperaLure:

lor LemperaLure LhaL varles

wlLh z ( 1=1(z) ):

PydrosLauc force on submerged surface

neL force on a dam or lock gaLe of a canal

Some facLs:

no shear sLresses ln a sLauc uld, Lhe hydrosLauc force acLs

normal Lo Lhe surface.

1he resulLanL force acung on surface ls found by summlng Lhe

conLrlbuuons of Lhe lnnlLeslmal forces over Lhe enure area.

AL depLh b, Lhe pressure, p =p

0

+ pqb

h

1

h

2

0 for

2

1

2

1

2

2

2

2

1

2

1

2

1

= =

!

"

#

=

= = =

=

=

$ $ $

$

h gwh

h

gw

hdh gw ghwdh ghdA F

gh p

pdA F

h

h

h

h

h

h A

A

% %

% % %

%

Slnce p ls noL consLanL LhroughouL Lhe area, lnLegral meLhod ls needed.

gh p p ! + =

0

w

h

h

1

h

2

PydrosLauc force on submerged ob[ecL

Slmllar derlvauon as submerged surface

V g dV g hdA g ghdA F

gh p

pdA F

V A A

A

! ! ! !

!

= = = =

=

=

" " "

"

V g F

buoyancy

! =

Weight of

displaced fluid

Pressure of fluid

Archlmedes prlnclple

8uoyancy

8uoyancy ls Lhe neL verucal force, due Lo llquld

pressure (hydrosLauc pressure), acung on an ob[ecL

lmmersed ln a llquld, or oaung on Lhe llqulds

surface.

1he submerged ob[ecL need noL be a solld

Pydrogen bubbles: rlse slowly ln a suspendlng uld

(e.g. waLer) as Lhey are swepL along by Lhe ow

osluvely buoyanL

WaLer dropleLs: slnk ln oll

negauvely buoyanL

neuLrally-buoyanL parucles are used as ow Lracer Lo

Lrace ow pauerns uslng vlsuallzauon Lechnlques

8uoyancy lorce: Alr

1o whaL LemperaLure musL Lhe alr ln a hoL alr balloon

(approxlmaLed as a sphere) be heaLed Lo ll a baskeL load?

Weight of plastic skin of

balloon is negligible

Volume of basket is negligible

F

buoyancy

= !

air

gV

balloon

F

y

= 0

!

F

y

= F

buoyancy

!W

hot air

!W

load

"

= !

atm

gV

ballon

! !

hot air

gV

ballon

!W

load

= 0

!

hot air

= !

atm

!

W

load

gV

ballon

p

atm

MW

air

RT

hot air

=

p

atm

MW

air

RT

atm

!

W

load

gV

ballon

Apply ideal gas law:

8uoyancy force: lmmlsclble ulds

What fraction of

wood is below

the gasoline-

water interface?

gasoline

V

water

V

!

gasoline

gV

gasoline

+ !

water

gV

water

! !

wood

gV

gasoline

! !

wood

gV

water

= 0

V

gasoline

!

wood

! !

gasoline

( )

= V

water

!

water

! !

wood

( )

V

gasoline

V

water

=

!

water

! !

wood

!

wood

! !

gasoline

=

1!0.96

0.96 !0.72

= 0.167

Fraction of wood in water =

1

1+0.167

= 0.857

Wood

s=0.96

Gasoline s=0.72

Water

8aslc Lquauons

1o undersLand Lhe baslc prlnclples and concepL of

uld mechanlcs, we need forms of Lhe followlng:

6%7-.&89:%7 %; <9--

2.=#%7- -.>%7? +9= %; <%:%7

@$. A&-# +9= %; #$.&<%?B79<,>-

uL slmply, Lhe lows of folJ mecboolcs omooot to

coosetvouoo of moss, eoetqy, ooJ momeotom.

Conservauon Laws applled Lo lluld Mechanlcs

8ased on Lhree exLenslve properues

Mass

usually LoLal, buL someumes of one or more lndlvldual

chemlcal specles

1oLal energy

Lhe sum of lnLernal, klneuc, poLenual, and pressure energy

MomenLum

boLh llnear and angular

lor a sysLem, conversauon means LhaL Lhere ls

nelLher neL galn nor loss of any of Lhese

properues wlLhln a sysLem (Lhere may be some

redlsLrlbuuon)

1yplcal mechanlsms of lnLeracuon beLween sysLem and

surroundlngs

A owlng sLream enLerlng and/or leavlng Lhe sysLem

A conLacL force on Lhe boundary, normal or

Langenual Lo lL (or Lhe sLress)

A body force due Lo exLernal eld LhaL acLs

LhroughouL Lhe sysLem (e.g. gravlLy)

useful work such as elecLrlcal energy enLerlng a

moLor or sha work leavlng a Lurblne

Ceneral Conservauon Law

non-reacung SysLem (x = mass, energy,

momenLum)

8eacung sysLem (x = mass, l = specles)

Lxpressed on Lhe basls of unlL ume, or raLes

system out in

X X X ! = "

i

system

i

destroyed

i

created

i

out

i

in

X X X X X ! = " + "

dt

dX

x x

system

out in

= !

! !

8aslc Laws for a SysLem

Conservauon of Mass (e.g.)

Mass, M, of Lhe sysLem ls consLanL

! !

= =

= "

=

#

$

%

system system

V M

system

system

out in

system

V d dm M

dt

dM

m m

dt

dM

&

0

! !

1ranslenL Mass 8alance and SLeady SLaLe

for non-reacung sysLem

lf sLeady-sLaLe slLuauons

exLenslve properues ln a sysLem are consLanL or

do noL change wlLh ume

A rlver wlLh a ow raLe LhaL ls consLanL wlLh ume

A Lank LhaL ls dralnlng Lhrough lLs base, buL ls also

supplled wlLh an ldenucal ow raLe of llquld Lhrough an

lnleL plpe, so LhaL Lhe llquld level ln Lhe Lank remalns

consLanL wlLh ume

dt

dM

m m

system

out in

= !

! !

0 =

dt

dM

system

Steady-state mass balance equation

is also known as Continuity Equation

MeLhods of Analysls

SysLem (or Closed SysLem

ln 1hermodynamlcs)

llxed, ldenuable quanuLy of

mauer, e.g. mass

SysLem boundarles (xed or

movable) separaLe sysLem

from surroundlng, no mass

crosses sysLem boundarles

ConLrol volume (or Cpen

SysLem ln 1hermodynamlcs)

ArblLrary volume ln space

Lhrough whlch uld ows

CeomeLrlc boundary ls called

conLrol surface (real or

lmaglnary, aL resL or ln

mouon)

ln uld mechanlcs, lL ls more

convenlenL Lo focus auenuon

on a conLrol volume Lhan on a

xed ldenuable quanuLy of

mass

Lxample - Mass balance for Lank evacuauon

( )

V

Qt

p

p

dt

V

Q

p

dp

p

V

Q

dt

dp

RT

p M

Q

dt

dp

RT

M

V

dt

d

V

dt

dV

Q m

dt

V d

dt

dM

m m

p

p

t

w w

out

system

out in

! = " ! = "

! = " ! = "

+ = ! = ! "

= = !

# #

0

0

ln

0

$

$ $

$

!

! !

RT

pM

V

nM

w w

= = !

hrs 56 . 2 s 9210 = = !t

Lxample - Leakage aL a plpe [olnL

(Leak)

Assumpuons:

(1) sLeady ow

(2) lncompresslble ow

(3) unlform properues aL all secuons

m/s 5 . 4

0

2

4 3 3 1 1

2

4 3 3 2 2 1 1

! =

! !

=

= ! " ! " ! "

= !

A

Q A u A u

u

Q A u A u A u

dt

dM

m m

system

out in

! !

!

C

D EFC <

C

u

1

u

3

1ank leakage

Pow long would lL Lake

for Lhe Lank of

meLhane Lo drop from

300 ka Lo 400 ka?

MeLhane

v = 10 m

3

1 = 23 C

Leakage rate:

RT

pA

m 66 . 0 = !

Hole size = 10

-7

m

2

!

m

in

!

!

m

out

=

dM

system

dt

!

!

m

out

=V

d!

dt

!0.66

pA

RT

=

V

RT

dp

dt

dp

p

p

0

p

"

=

!0.66A RT

V

dt

0

t

"

t =

1.52V

A RT

ln

p

0

p

= 8.6#10

4

s $1 day

R = 516 J/kg-K

Conservauon of Lnergy

1ransfer lnvolves boLh mass and energy

Lnergy Lo Lhe sysLem = PeaL

Lnergy by Lhe sysLem = Work

SysLem

JM

lo

JM

oot

PeaL added, JO

Work done, Jw

dE dW dQ = !

Work done by SysLem on lLs Surroundlngs

Sha work

llow Work

Work done by normal SLresses (pressure) aL CS

Work done by Shear SLresses aL CS

CLher work (e.g. elecLrlcal, elecLromagneuc)

other f s

W W W W + + =

system

out

out

in

in

u

gz e M d dW dQ

u

gz

p

e dM

u

gz

p

e dM

!

"

#

$

%

&

'

'

(

)

*

*

+

,

+ + = - +

'

'

(

)

*

*

+

,

+ + + -

'

'

(

)

*

*

+

,

+ + +

2

2 2

2

2 2

. .

lnLernal

Lnergy

llow

Work

oLenual

Lnergy

klneuc

Lnergy

Work has same unlL as energy

ower ls dened as raLe of work and can be

expressed dlerenLly for dlerenL sysLems:

llowlng sLream: mass ow raLe ! work per unlL

mass

lorce dlsplacemenL: force ! dlsplacemenL veloclLy

8oLaung sha: 1orque ! angular veloclLy

ump: volume ow raLe ! pressure lncrease

Sl unlL for power ls W or !/s

Sha Work

uened as work oLher Lhan ow work

usually done Lhrough a sha

Commonly assoclaLed wlLh a pump or Lurblne:

ump

Machlne LhaL does work on Lhe ow, Lhereby lncreaslng

Lhe energy of Lhe ow

lrom Lhermodynamlc denluon: negauve work

When emclency ln lnvolved:

1urblne

Machlne LhaL exLracLs energy from Lhe ow, dolng work

on Lhe surroundlngs

lrom Lhermodynamlc denluon: posluve work

When emclency ls lnvolved:

s

W

p t s

W W W ! =

supplied

W W

p p

! =

t t

W W ! =

obtained

llow Work

8aLe of work done by pressure forces as Lhe

sysLem moves Lhrough Lhe space

Can be expressed ln Lerms of pressure or veloclLy

!

!

"

#

$

$

%

&

' =

!

!

"

#

$

$

%

&

+

!

!

"

#

$

$

%

&

' =

+ ' =

+ =

1

1

2

2

2

2

2

1

1

1

2 2 2 1 1 1

2 1

( ( ( (

p p

m p

m

p

m

p A u p A u

W W W

f

!

! !

! ! !

1

u

!

2

u

!

t u !

2

p

1

p

2

A

1

A

2

Lnergy balance aL sLeady sLaLe

lor sLeady ow, Lhe energy accumulauon Lerm ls

zero and JM

lo

=JM

oot

=

o ls a correcuon facLor for klneuc energy

When Lhe veloclLy prole ln a plpe ls unlform, o = 1

When Lhe veloclLy prole ln a plpe ls parabollc, o = 2

1he equauon can also be grouped lnLo mechanlcal

energy and Lhermal energy Lerms:

!

"

#

$

%

&

'

'

(

)

*

*

+

,

+ + + -

'

'

(

)

*

*

+

,

+ + + = -

2 2

2

1

1 1 1

1

2

2

2 2 2

2

u

e gz

p u

e gz

p

m W Q

s

.

/

.

/

!

! !

m

!

( ) Q e e m W

u

gz

p u

gz

p

m

s

!

!

!

!

! ! = !

"

#

$

%

&

'

(

(

)

*

+

+

,

-

+ + !

(

(

)

*

+

+

,

-

+ +

1 2

2

2

2 2

2

2

1

1 1

1

2 2

.

/

.

/

SeparaLe w

s

lnLo w

p

and w

t

and conslder o = 1,

Lhen dlvlde Lhe energy equauon by g m

!

( )

g m

Q

g

e e

g m

W

g m

W

g

u

z

p

g

u

z

p

p

t

!

!

!

!

!

!

!

!

=

"

"

#

$

%

%

&

'

! !

(

)

*

+

,

-

"

"

#

$

%

%

&

'

+ + !

"

"

#

$

%

%

&

'

+ +

1 2

2

2

2

2

2

1

1

1

2 2 . .

Head loss

Pump head Turbine head

L p t

h h h

g

u

z

p

g

u

z

p

= + !

"

#

$

%

&

'

(

(

)

*

+

+

,

-

+ + !

(

(

)

*

+

+

,

-

+ +

2 2

2

2

2

2

2

1

1

1

. .

Pead loss can be consldered as energy loss due Lo overcome

of frlcuon

( ) Q e e m W

u

gz

p u

gz

p

m

s

!

!

!

!

! ! = !

"

#

$

%

&

'

(

(

)

*

+

+

,

-

+ + !

(

(

)

*

+

+

,

-

+ +

1 2

2

2

2 2

2

2

1

1 1

1

2 2

.

/

.

/

Specific Weight = $"g

Lxample - umplng n-enLane

3 in ID pipe

Friction loss =

Pump efficiency = 75%

u

m

= 25 ft/s

n-pentane density = 39.3 lb

m

/ft

3

!

"

#

$

%

&

2

2

2

ft

5 . 2

s

u

m

Find the power required to drive the pump

The pressure at the inlet of the pump

The pressure at the outlet of the pump

4.5 ft

4 ft

40 ft

Supply tank

Storage tank

Assumpuons

SLeady-sLaLe

lncompresslble ow

neglecL frlcuon of Lhe shorL plpe aL Lhe lnleL of Lhe pump

1ake Lhe supply Lank as (1) and ouLleL Lo sLorage Lank as (2)

8oLh (1) and (2) are open Lo aLmosphere

Supply Lank ls large compare Lo Lhe plpe

( )

ft 2 . 98

2 . 32 2

25

40

2 . 32

25 5 . 2

2

5 . 2

2 2

2

2

2 1

2

2

=

!

!

"

#

$

$

%

&

'

( ( (

'

=

)

*

+

,

-

.

( ( ( =

p

p

h

g

u

z z

g

u

h

L p t

h h h

g

u

z

p

g

u

z

p

= + !

"

#

$

%

&

'

(

(

)

*

+

+

,

-

+ + !

(

(

)

*

+

+

,

-

+ +

2 2

2

2

2

2

2

1

1

1

. .

[ ] ft

5 . 2

2

g

u

h

m

L

=

Friction loss check unit

4.5 ft

4 ft

40 ft

Supply tank

Storage tank

4.5 ft

4 ft

40 ft

Supply tank

Storage tank

kW 56 . 8

s

lb ft

317 , 6

ft lb

s lb

2 . 32

1

ft

75 . 0

3 . 98 2 . 32 2 . 48

f

m

2

f s

ft

s

lb

supplied

2

m

=

!

=

!

!

"

#

#

$

%

&

&

'

(

)

! !

" "

=

= * =

p

p

p p

W

W gh m W

+

!

!

!

( )

s

lb

2 . 48

12

3

4

25 3 . 39

m

2

= ! ! = =

"

# A u m

m

!

1o nd Lhe pressure aL Lhe lnleL of Lhe pump, apply energy balance

beLween Lhe supply Lank (1) and Lhe pump lnleL (2):

( )

( )

psig 42 . 1

0

2 . 32 2

25

5 . 4

2 . 32

2 . 32

3 . 39

144 0

0

2

2

2

2

2

2

2 1

2 1

! =

=

"

!

+ +

"

" !

=

!

+ ! +

!

p

p

g

u

z z

g

p p

#

L p t

h h h

g

u

z

p

g

u

z

p

= + !

"

#

$

%

&

'

(

(

)

*

+

+

,

-

+ + !

(

(

)

*

+

+

,

-

+ +

2 2

2

2

2

2

2

1

1

1

. .

1o nd Lhe pressure aL Lhe ouLleL of Lhe pump, apply energy balance

beLween Lhe pump lnleL (1) and ouLleL (2):

( )

( )

psig 2 . 25

0 2 . 98 5 . 0

2 . 32

2 . 32

3 . 39

144 42 . 1

0

2

2

2 1

2 1

=

= + !

"

" ! !

= + ! +

!

p

p

h z z

g

p p

p

#

L p t

h h h

g

u

z

p

g

u

z

p

= + !

"

#

$

%

&

'

(

(

)

*

+

+

,

-

+ + !

(

(

)

*

+

+

,

-

+ +

2 2

2

2

2

2

2

1

1

1

. .

llnd Lhe raLe of power

generauon.

h

L

=1.5 m

"

t

= 0.87

# = 9810 N/m

3

Q = 14.1 m

3

/s

L p t

h h h

g

u

z

p

g

u

z

p

= + !

"

#

$

%

&

'

(

(

)

*

+

+

,

-

+ + !

(

(

)

*

+

+

,

-

+ +

2 2

2

2

2

2

2

1

1

1

. .

Assumptions:

Pressures at point 1 and point 2 are both atmospheric

Velocities at point 1 and point 2 are nearly zero

No pump

h

t

= z

1

! z

2

( )

!h

L

= 61!1.5

= 59.5 m

!

W

t

=

!

mgh

t

!

W

obtained

=!

t

!

W

t

=!

t

Q"h

t

= 0.87"14.1"9810"59.5

= 7.16"10

6

W

= 7.16 MW

8ernoullls Lquauon

A reduced form of Lnergy Lquauon by lmposlng a cerLaln

assumpuons:

llow ls sLeady (applles Lo boLh)

lluld ls lncompresslble, l.e. denslLy ls consLanL (applles Lo boLh)

no work eecLs (or sha works), l.e. Lhe uld nelLher performs work

(as ln Lurblne), no work has been performed on lL (as ln a pump)

llow ls frlcuonless, l.e. lnvlscld (nonvlscous) ow (no shear eecL) or

no head loss

Applled beLween Lwo polnLs along a sLreamllne (We wlll revlslL Lhls

polnL whlch ls lmporLanL ln derlvlng Lhe 8ernoullls Lquauon)

SLrlcLly, Lhe ow plpe ls a small sLream Lube encloslng a

sLreamllne, l.e. o = 1 (or Lhe ow ls unlform aL each cross secuon l.e.

Lhe veloclLy ls consLanL)

2

2

2 2

1

2

1 1

2 2

gz

u p

gz

u p

+ + = + +

! !

nouce LhaL each Lerm, from Lhe energy polnL of

vlew, has dlmenslon of energy per unlL mass of uld

l.e. pressure energy, kL, L.

As such, we can Lhlnk of Lhe 8ernoulll Lquauon as a

mechanlcal energy balance: Lhe mechanlcal energy

(sum of pressure + klneuc + poLenual energles)

beLween 2 polnLs on a sLreamllne wlll be a consLanL.

streamline a along constant,

2

2

= + + gz

u p

!

kg

J

kg

mN

s

m

kg

kg

m

s

m

2 2

2

= = =

1 2 3

1 2 3

Lach Lerm can also be expressed ln Lerm of lengLh

(dlvldlng each by q), and represenLs a cerLaln Lype of

head: pressure, elevauon (or sLauc), veloclLy

2

2

2 2

1

2

1 1

2 2

z

g

u p

H z

g

u p

+ + = = + +

! !

Pressure increase across a

pump, !p= head increase

!h = !p/"g

(energy equation applies)

2

streamline a along constant,

2

2

= + + z

g

u

p

!

Appllcauon of 8ernoullls rlnclple: measuremenL of

sLauc and sLagnauon pressures (lLoL 1ube)

8L relaLes changes ln speed and pressure along a

sLreamllne ln an lncompresslble, frlcuonless ow.

SLauc ressure (Lhermodynamlc pressure)

ressure seen by uld parucle as lL moves

uynamlc ressure:

2

2

1

u !

Stagnation Pressure

- pressure obtained when a flowing

fluid is decelerated to zero velocity

by a frictionless process

- measured using a stagnation

pressure probe (pitot tube)

lLoL 1ube: useful for measuremenL of veloclLy

of movlng cra such as a boaL or an alrplane

2

0

2

2

0 0

2

1

2 2

u p p

u p

u p

!

! !

+ = "

+ = +

stagnation

pressure

static

pressure

dynamic

pressure

( )

!

p p

u

"

= #

0

2

SLagnauon pressure ls Lhe LoLal pressure

lncludlng Lhe sLauc pressure and dynamlc

pressure (when klneuc energy ls converLed

lnLo pressure energy)

Lxample - SLeady alr ow Lhough a nozzle

Nozzle: by

definition is a

device for

accelerating

flow.

Slnce Lhls ls regardlng gas ow, whlch ls a compresslble uld by

naLure, we need Lo check lf we can assume lncompresslble ow.

Introduce a dimensionless number: Mach Number (M) = V/c;

V = flow speed of gas, c = local speed of sound (~343 m/s in air)

M < 0.3: gas flow can be treated as incompressible as the density change is <

5 % (M = 0.3 in air at standard conditions corresponds to a gas flow speed of

~100 m/s)

WhaL ls Lhe pressure needed Lo generaLe a gas veloclLy of 30 m/s?

8ernoullls equauon

2

2

2 2

1

2

1 1

2 2

gz

u p

gz

u p

+ + = + +

! !

Assumptions:

(1) steady flow.

(2) incompressible flow.

(3) frictionless flow.

(4) flow along a streamline.

(5) uniform flow at sections 1 and 2.

(6) z

1

= z

2

.

8earrange

( )

2

1

2

2 2 1

2

u u p p ! = !

"

Apply continuity equation

1

2

2 1

2 2 1 1

A

A

u u

A u A u

= !

=

!

!

"

#

$

$

%

&

'

'

(

)

*

*

+

,

- = - .

2

1

2

2

2

2 1

2 A

A

u u p p

atm

/

Lxample - llow Lhough a Slphon

Assumpuons:

(1) sLeady ow.

(2) lncompresslble ow.

(3) frlcuonless ow.

(4) ow along a sLreamllne.

(3) reservolr ls large compared

Lo Lhe slphon.

(6) olnL 1 and 2 are boLh aL

aLmospherlc pressure

WhaL ls Lhe veloclLy of waLer leavlng Lhe slphon?

WhaL ls Lhe pressure of waLer aL polnL A?

Free jet

2

2

2 2

1

2

1 1

2 2

gz

u p

gz

u p

+ + = + +

! !

A

!"## %#&

'

!"## %#&

'

8earrange

1o deLermlne Lhe pressure aL A, apply 8L beLween

polnL 1 and A (or beLween A and 2):

Apply conunulLy equauon:

8earrange

( )

1 2 2

2 z z g u ! ! =

A

A A

gz

u p

gz

u p

+ + = + +

2 2

2

1

2

1 1

! !

2

u u

A

=

( )

2

2

2

1 1

u

z z g p p

A A

! ! " " + =

Cauuons on Lhe use of 8ernoullls Lquauon

Subsonlc dluser (dlverglng secuon or sudden expanslon)

adverse pressure gradlenL led Lo growLh of boundary layer and ow

separauon (aL besL an approxlmauon)

llow Lhrough a machlne e.g. propeller, pump, Lurblne,

wlndmlll

Movlng surfaces, lmposslble Lo have locally sLeady ow and

sLreamllnes

llow Lhrough a hydraullc [ump (abrupL change ln depLh and

energy loss)

vlolenL mlxlng occurs, lmposslble Lo ldenufy sLreamllnes

Alr ow Lhrough heaung elemenL

1emperaLure changes cause slgnlcanL change ln denslLy of gases

Compresslble gas ow

uenslLy changes (M 0.3)

MomenLum

newLons Second Law of Mouon:

applled Lo many problems lnvolvlng force

and accelerauon ln solld mechanlcs

1he law ls equally useful ln uld mechanlcs

for analysls of:

forces on plpe bends

LhrusL produced by a Lurbo[eL

accelerauon of a rockeL

eLc

MomenLum Lransfer

MomenLum ls belng Lransferred durlng Lhls process.

1he uld Louchlng Lhe Lop plaLe wlll move aL Lhe same

veloclLy as Lhe plaLe whlle Lhe uld Louchlng Lhe

bouom plaLe wlll noL be movlng. (no-sllp condluon)

MomenLum ls belng Lransferred by forces.

Moving plate

Stationary plate

Force

u

x

t

2

t

0

t

1

When Lop plaLe ls moved by a

force, Lhe llquld beLween Lhe

Lwo plaLes wlll also move

because of Lhe lnLernal

frlcuonal reslsLance ln Lhe uld

and Lhe frlcuon beLween Lhe

uld and Lhe plaLe.

x

y

MomenLum 8alance

MomenLum = mass x veloclLy

lorce can be vlewed as Lhe momenLum ow raLe:

A momenLum balance ls a balance of forces:

MomenLum balance aL sLeady sLaLe lnvolves a

balance of all forces:

2

2 2

2

1 1 2 2 1 1 2 1

u A u A u m u m

dt

d

F ! ! " = " = " = =

#

! !

"

M M

M

( )

( )

2

Au u Au u m

dt

u m d

F ! ! = = = = =

!

"

!

"

M

T

ML

] [= = u m

!

!

M

0 = =

!

dt

d

F

M

!

!

( ) Lg

D

DL p p

D

dt

d

F

w

4 4

2

2 1

2

!

" ! #

!

$ $ $ = =

%

M

!

lor plpe ow, Lhe forces lnvolved lncludes

pressure force, shear sLress, and gravlLy

s w

A !

1hls equauon ls one way Lo deLermlne Lhe shear sLress. AL sLeady sLaLe,

Lhe forces are balance:

( )

( )

4 4

0

4 4

2 1

2

2 1

2

Dg

L

p p D

Lg

D

DL p p

D

dt

d

F

w

w

!

"

#

! # "

#

$

$

=

= $ $ $ = =

%

M

!

lf a change ln mass ls lnvolved, Lhe momenLum

balance wlll need Lo be rewrluen as:

( )

dt

dm

u

dt

du

m

dt

mu d

dt

d

F + = = =

!

M

!

Lxample - accelerauon from a waLer [eL

Jet at velocity, u

Nozzle of area, A

Cart moving at velocity, v

Apply momentum balance:

( ) v u m

dt

dM

v

dt

dv

M F ! = + = !

M

Au m ! = !

( ) v u A ! "

( ) ( )

( )

M

v u A

dt

dv

v u Au v u A v

dt

dv

M

2

on accelerati

!

= =

! " = ! " +

#

# #

Lxample - 1hrusL of a 1oy 8ockeL

llnd Lhe force need Lo supporL Lhe rockeL.

u = 450 m/s

" = 0.5 kg/m

3

m = 40 g

1 cm

F

s

?

Draw force diagram on the rocket

mg

F

s

m

j

u

N 56 . 7

450

4

01 . 0

5 . 0 81 . 9 04 . 0

0

2

2

! =

"

"

" ! " =

" ! =

! =

= ! + =

#

$

% u Au mg

u m mg F

mg u m F F

j s

j s y

!

!

-ve sign means F

s

should be downwards

(prevent the rocket from flying up)

Lxample - ConcreLe owlng lnLo a carL

lorce balance:

mu

m

cart+concrete

g

T

N 5471

3600 60 sin 3 1 . 0 2400

60 sin

0 sin

N 1080

60 cos 3 1 . 0 2400

60 cos

0 cos

2

2

2

2

=

+ ! ! ! =

+ =

= " + =

=

! ! ! =

=

= " =

#

#

g m Au N

N g m mu F

Au T

T mu F

cart

cart y

x

$

%

$

%

N

3 m/s

Find

(a)the weight on the scale, and

(b) tension on the cable

at the instance

the weight of cart + concrete = 3600 N

cable

" = 2400 kg/m

3

Area of concrete stream = 0.1 m

2

Lxample - lorce on a plpe bend

lorce dlagram

1 m

Crude oil

S = 0.94

2 m

3

/s

p = 75 kPa (gauge)

Find the force needed at the bolted

flange to hold the bend in place

m

bend+oil

g

mu

mu

R

x

R

y

+

( )

( )( ) ( )

( )

kN 53 . 8

30 cos 1 5 . 0 000 , 75

5 . 0

2

940

cos 1 cos 1

0 cos cos

2

2

2

=

!

"

"

#

$

%

%

&

'

( ( +

(

( =

!

"

#

$

%

&

'

+ = ! + =

= ! ! + ! + =

)

*

*

+ , +

+ +

pA

A

Q

Q pA u m R

R u m pA pA u m F

x

x x

!

! !

pA

pA

Top view

( )

( )

kN 8 . 31

30 sin 5 . 0 000 , 75

5 . 0

2

940

sin sin

0 sin sin

2

2

2

2

! =

"

"

#

$

%

%

&

'

( ( +

(

( ! =

"

"

#

$

%

%

&

'

+ ! = + ! =

= ! ! + =

)

*

*

+ , +

+ +

pA

A

Q

pA u m R

u m R pA F

y

y y

!

!

Weight of the bend = 4 kN

Volume of the bend = 1.2 m

3

Lxample: 1ank uralnlng (Case l)

Assumpuons:

SLeady, frlcuonless ow

lncompresslble uld

Cross-secuonal area of Lank ls large

Llquld descendlng slowly: no frlcuonal

dlsslpauon unless uld ls very vlscous

and vlrLually sLeady ow

8ounded nozzle or orlce:

sLreamllnes parallel aL exlL and

pressure ls unlformly aLmospherlc

no exLernal work

Apply BE between points 1 and 2 along a streamline:

2

2

2 2

1

2

1 1

2 2

gz

u p

gz

u p

+ + = + +

! !

gh A Au Q

gh u

2

2

2

2

= = !

= !

The fluid velocity is exactly the same as the velocity the fluid would attain by falling

freely from rest a distance h (Torricelis Equation).

Lxample: 1ank uralnlng (Case ll)

Assumpuons:

SLeady, frlcuonless ow

lncompresslble uld

Cross-secuonal area of orlce

conslderable compared Lo Lhe Lank

surface

1he Llquld wlll descend wlLh

measurable kL

8ounded nozzle or orlce:

sLreamllnes parallel aL exlL and

pressure ls unlformly aLmospherlc

no exLernal work

Apply BE between points 1 and 2 along a streamline:

2

2

2 2

1

2

1 1

2 2

gz

u p

gz

u p

+ + = + +

! !

?

2

= u

With 2 unknowns; we need another equation to solve the problem.

Using the mass balance for the fluid, we can solve for u

1

in terms of

u

2

, A

1

and A

2

; substitution in BE, we can obtain u

2

and hence u

1

.

1ank dralnlng Lhrough a sharp orlce

lf Lhe orlce ls sharp-edged wlLh area A:

Lhe cross-secuonal area of Lhe [eL wlll conunue Lo

conLracL aer lL leaves Lhe orlce because of lnerua Lo a

value o aL a locauon known as vena conLracLa, where Lhe

sLreamllnes are parallel Lo one anoLher

a coemclenL of conLracuon, dened as Lhe rauo of area o

Lo A ls used Lo obLaln Lhe ow raLe

cases) most (in

63 . 0

2

!

=

=

c

c

c

C

gh A C Q

A C a

ConunulLy Lquauon

8ernoullls Lquauon (appllcable upsLream)

p

1

!

+

u

1

2

2

=

p

2

!

+

u

2

2

2

p

1

! p

2

!

=

u

2

2

!u

1

2

2

=

1

2

A

1

2

A

2

2

u

1

2

!u

1

2

"

#

$

%

&

'

=

u

1

2

2

A

1

2

A

2

2

!1

"

#

$

%

&

'

llow measuremenL uslng an orlce plaLe

3

Unknown location

2

1 1

2 1 3 3 3 2 2 1 1

and

A

A u

u u u A u A u A u m = = ! = = = " " "

!

2

A

3

A

mu

2

mu

3

MomenLum 8alance:

2

A -

3

A + mu

2

+ (-mu

3

) = 0

$

( )

2 3

1

3 2

u u

A

m

p p ! = !

!

ressure drop ln downsLream secuon:

Cverall pressure drop:

lL can be seen LhaL p

3

ls always less Lhan p

1

,

lndlcaung an overall loss of energy or useful work.

( ) ( )

!

!

"

#

$

$

%

&

' = ' = ' =

'

2

1

2

1 2 1 1 2 3

1

3 2

1

A

A

u u u u u u

A

m p p

( (

!

p

1

! p

3

!

=

p

1

! p

2

!

"

#

$

%

&

'

+

p

2

! p

3

!

"

#

$

%

&

'

=

u

1

2

2

A

1

2

A

2

2

!2

A

1

A

2

+1

"

#

$

%

&

'

=

u

1

2

2

A

1

A

2

!1

"

#

$

%

&

'

2

8oLameLers

varlable area meLers

has nearly consLanL pressure and

depend on changlng cross secuonal

area Lo lndlcaLe ow raLe

are exLremely slmple, robusL devlces

LhaL can measure ow raLes of boLh

llqulds and gasses

uld ows up Lhrough Lhe Lapered Lube

and suspends a oaL ln Lhe column of

uld

Lhe equlllbrlum posluon of Lhe oaL

lndlcaLes Lhe ow raLe on a marked scale

rlnclple of llow MeasuremenL by a 8oLameLer

1he roLameLer depends on Lhe change of an annular area

a beLween Lhe oaL and Lhe Lube, whlch ls a funcuon of

Lhe verucal locauon of Lhe oaL, Lo yleld an essenually

xed pressure drop aL all ow raLes

1he annular area funcuons as an orlce of varlable area

1he ow raLe can be deLermlned from Lhe equlllbrlum

posluon of Lhe oaL

vlscous eecLs are unlmporLanL (Lrue for ma[orlLy of

lndusLrlally lmporLanL ulds)

An analysls of Lhe ow and equlllbrlum posluon of Lhe oaL

2 2 1 1

A u A u m ! ! = =

!

2

2

2 2

1

2

1 1

2 2

gz

u p

gz

u p

+ + = + +

! !

( ) ( ) 0

1 2 2 1 2 1

= !

"

"

#

$

%

%

&

'

! ! ! ! + ! Mg g

M

A z z mu mu A p p

f

(

(

MomenLum equauon

neglecL sllghL Laperlng of Lube

Covernlng equauons:

ConunulLy or mass conservauon

8ernoullls equauon

llow raLe, can be found by solvlng Lhe Lhree governlng

equauons:

1

2

2

2

1

1

1 1

2

1

1 2

A

Mg

A

A

A

A

Mg

A Au Q

f

!

!

!

!

"

#

#

$

%

&

&

'

(

)

#

#

$

%

&

&

'

(

)

= =

p <<p

f

A

2

<<A

1

8oLh A

1

and A

2

are a funcuon of z, so can be correlaLed

Lo locauon (scale on roLameLer)

A

1

/A

2

You might also like

- U1 Chem MattersDocument76 pagesU1 Chem Mattersapi-268467602No ratings yet

- Bioelectricity Week 1 Slides Feb 2013Document94 pagesBioelectricity Week 1 Slides Feb 2013darkneslifeNo ratings yet

- Future Climate ChangeDocument63 pagesFuture Climate ChangeManu SinghNo ratings yet

- 3 Ch05 Thermal enDocument12 pages3 Ch05 Thermal enMumtaz Ahmad QaisraniNo ratings yet

- Tunnel AnalysisDocument45 pagesTunnel AnalysisMary BrendaNo ratings yet

- CCC C C CCC C C C CCC C C C C CCCCCC C CCCCCCCCCCC CCCC R CDocument31 pagesCCC C C CCC C C C CCC C C C C CCCCCC C CCCCCCCCCCC CCCC R CNnaer Ortiz NasupmilacNo ratings yet

- Garay Midterm Review Sheet 2011 2012-2Document23 pagesGaray Midterm Review Sheet 2011 2012-2api-241577069No ratings yet

- ANDRE BAKKER Dartmouth CollegeDocument36 pagesANDRE BAKKER Dartmouth CollegeCarlos Alberto Dutra Fraga FilhoNo ratings yet

- Research Project DescriptionDocument17 pagesResearch Project DescriptionutongNo ratings yet

- Job No 3Document7 pagesJob No 3naveedsidhuNo ratings yet

- Thermodynamic Properties of MethanolDocument24 pagesThermodynamic Properties of MethanolJessica FernandesNo ratings yet

- Silicon Wafer Manufacturing: A CEP Cer Fica On CourseDocument51 pagesSilicon Wafer Manufacturing: A CEP Cer Fica On CourseShailendraBaraniyaNo ratings yet

- SylengphDocument16 pagesSylengphAlankar GuptaNo ratings yet

- Physics IADocument13 pagesPhysics IANaufal Hakim100% (1)

- Introduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerDocument26 pagesIntroduc) On To Wear: Surfaces, Interfaces, and Their Applica) Ons II Nicholas D. SpencerKunal PandeyNo ratings yet

- Year 10 Science Yearly NotesDocument27 pagesYear 10 Science Yearly Notesunstoppable1234No ratings yet

- Current and Charge: I DQ DT Q It DTDocument6 pagesCurrent and Charge: I DQ DT Q It DTumutkarabacak4282No ratings yet

- 12 ClusteringDocument46 pages12 ClusteringdadhichakhileshNo ratings yet

- Competitive Comparison - With Linacs - 2011OCT AAP (2013-06-07) PDFDocument3 pagesCompetitive Comparison - With Linacs - 2011OCT AAP (2013-06-07) PDFMalu Paras LacsonNo ratings yet

- SHC 310 Hydraulics Kinematics or Fluid Dynamics ObjectivesDocument12 pagesSHC 310 Hydraulics Kinematics or Fluid Dynamics ObjectivesBrendon GovaNo ratings yet

- Wastewater Treatment 2Document14 pagesWastewater Treatment 2Adnan ChowdhuryNo ratings yet

- Migration and CC - McElweeDocument30 pagesMigration and CC - McElweeJan DashNo ratings yet

- Physics 121D, Autumn 2013 Lecture Instructor: Nikolai Tolich Oct 25, 2013Document24 pagesPhysics 121D, Autumn 2013 Lecture Instructor: Nikolai Tolich Oct 25, 2013Jeanette YangNo ratings yet

- Model ManualDocument43 pagesModel ManualMol ChoyNo ratings yet

- Gerrit&Jan Knaap March 21, 2014 Special Thanks To Ting MaDocument54 pagesGerrit&Jan Knaap March 21, 2014 Special Thanks To Ting MaThe Washington PostNo ratings yet

- Patent ES0225316 Hogan Jakovlewich ENGLISH PDFDocument19 pagesPatent ES0225316 Hogan Jakovlewich ENGLISH PDFhanon9No ratings yet

- BIO2A03-Muscle Lecture Notes 1Document22 pagesBIO2A03-Muscle Lecture Notes 1JeevikaGoyalNo ratings yet

- Dscripti Stats Prev IncidDocument11 pagesDscripti Stats Prev IncidCecilia CabanagNo ratings yet

- Engineering-Related Concepts and Associated MathematicsDocument25 pagesEngineering-Related Concepts and Associated Mathematicschesspalace2No ratings yet

- BIO2A03-Respiration Lecture NotesDocument67 pagesBIO2A03-Respiration Lecture NotesJeevikaGoyalNo ratings yet

- Component - Resolved Near - Infrared Spectra of Mul4ple Asteroid SystemsDocument1 pageComponent - Resolved Near - Infrared Spectra of Mul4ple Asteroid SystemsFranck MarchisNo ratings yet

- Kinetic-Molecular Theory: Ideal Gas Equation PV NRTDocument9 pagesKinetic-Molecular Theory: Ideal Gas Equation PV NRTVidhuPandey100% (1)

- Clinical Observation (Case Report/case Series) Cross Sectional StudiesDocument7 pagesClinical Observation (Case Report/case Series) Cross Sectional StudiesAndie AlbinoNo ratings yet

- 4 Internal FlowDocument40 pages4 Internal FlowMarilaine ColnagoNo ratings yet

- Unit 4Document63 pagesUnit 4api-268467602No ratings yet

- Notes On Applied MechanicsDocument7 pagesNotes On Applied Mechanicsa_j_sanyal259No ratings yet

- Example 1Document4 pagesExample 1kristenlianneNo ratings yet

- Analy&cal Methods in Chemistry (CH - 429)Document58 pagesAnaly&cal Methods in Chemistry (CH - 429)Surender MalikNo ratings yet

- Lecture1 2Document12 pagesLecture1 2ppyxamsNo ratings yet

- Clot or BleedDocument52 pagesClot or BleedUriel Baez100% (4)

- AdsorptionDocument20 pagesAdsorptionCheska BiolenaNo ratings yet

- Fluid ContinuumDocument1 pageFluid ContinuumHugo ContrerasNo ratings yet

- Chapter 1 - Part ADocument30 pagesChapter 1 - Part AQiang LoNo ratings yet

- Chemical and Plasma Rocket PropulsionDocument44 pagesChemical and Plasma Rocket PropulsionflorenceprasadNo ratings yet

- Planificacion Sistemas y CircuitosDocument5 pagesPlanificacion Sistemas y CircuitosIsel NufioNo ratings yet

- PE ReviewStructure Mechanics of Materials Tension and CompressionDocument7 pagesPE ReviewStructure Mechanics of Materials Tension and CompressionImtiaz KhanNo ratings yet

- Final Volume OneDocument60 pagesFinal Volume Oneapi-256107179No ratings yet

- MLA, APA & CMS Citation Comparison ChartDocument11 pagesMLA, APA & CMS Citation Comparison ChartVicki AyalaNo ratings yet

- ACM-ICPCTCGroupB EngForProblemSolving PrintversionDocument23 pagesACM-ICPCTCGroupB EngForProblemSolving PrintversionnabilshfNo ratings yet

- Transport Across Cell Membrane IIIDocument19 pagesTransport Across Cell Membrane IIITurky TurkyNo ratings yet

- Model Paper 1Document2 pagesModel Paper 1yashvirsingh21No ratings yet

- Principles of Food EngineeringDocument29 pagesPrinciples of Food EngineeringSahil GoelNo ratings yet

- Lectures For ES912, Term 1, 2003Document49 pagesLectures For ES912, Term 1, 2003getsweetNo ratings yet

- Advisory Team Meeting December 9, 2011 NYSDEC Hudson River National Estuarine Research Reserve Norrie Point Environmental Center, Staatsburg, NYDocument5 pagesAdvisory Team Meeting December 9, 2011 NYSDEC Hudson River National Estuarine Research Reserve Norrie Point Environmental Center, Staatsburg, NYHRNERRNo ratings yet

- Bonding SolidsDocument12 pagesBonding SolidsIzyan NurainiNo ratings yet

- L5 RiskDocument17 pagesL5 RiskJohannes AitNo ratings yet

- CLEDHI PosterDocument1 pageCLEDHI PosterLauren BiddleNo ratings yet

- Unit Conversion From US/UK Customary Unit To SI Unit (Metric Unit)Document1 pageUnit Conversion From US/UK Customary Unit To SI Unit (Metric Unit)Nhân TrầnNo ratings yet

- Teaching Plan: WK No Date (HR No) Topics Name of Lecturer Reading Assignments/ Handouts AssessmentDocument2 pagesTeaching Plan: WK No Date (HR No) Topics Name of Lecturer Reading Assignments/ Handouts AssessmentNhân TrầnNo ratings yet

- Sat Test MathDocument7 pagesSat Test MathNhân TrầnNo ratings yet

- Ab1601 Course Outline Semester 2 Jan 2013 Version 4.0Document16 pagesAb1601 Course Outline Semester 2 Jan 2013 Version 4.0Nhân TrầnNo ratings yet

- Tran Trong Nhan - Assignment 2Document4 pagesTran Trong Nhan - Assignment 2Nhân TrầnNo ratings yet

- Course OutlineDocument9 pagesCourse OutlineNhân TrầnNo ratings yet

- Exercises For DryingDocument1 pageExercises For DryingNhân TrầnNo ratings yet

- CH1131 - Biomolecular Engineering Outline - Aug 2013Document8 pagesCH1131 - Biomolecular Engineering Outline - Aug 2013Nhân TrầnNo ratings yet

- OverviewDocument6 pagesOverviewNhân TrầnNo ratings yet

- Ch2802: Lab Report Instructions Jan 2015: Plagiarism of Any Form Shall Get All Parties Involved A Direct ZeroDocument2 pagesCh2802: Lab Report Instructions Jan 2015: Plagiarism of Any Form Shall Get All Parties Involved A Direct ZeroNhân TrầnNo ratings yet

- 5 People I Met in Heaven The Kite Runner The Five Love Language Tuesdays With MorrieDocument1 page5 People I Met in Heaven The Kite Runner The Five Love Language Tuesdays With MorrieNhân TrầnNo ratings yet

- Course Outline BU8201 Jan 2014Document4 pagesCourse Outline BU8201 Jan 2014Nhân TrầnNo ratings yet

- CH1131 Biomolecular Engrg Lipid Metabolism To Coordination Summary 2013Document4 pagesCH1131 Biomolecular Engrg Lipid Metabolism To Coordination Summary 2013Nhân TrầnNo ratings yet

- MH1810 Tut 1 2013 ComplexDocument3 pagesMH1810 Tut 1 2013 ComplexNhân TrầnNo ratings yet

- FUCHS LUBRITECH Product RangeDocument76 pagesFUCHS LUBRITECH Product RangeBurak GüleşNo ratings yet

- Analisis Keterampilan Berpikir Kritis Mahasiswa Pada Materi KinematikaDocument11 pagesAnalisis Keterampilan Berpikir Kritis Mahasiswa Pada Materi KinematikaTrisnaNo ratings yet

- Lexus JTJBT20X740057503 AllSystemDTC 20230702045631Document2 pagesLexus JTJBT20X740057503 AllSystemDTC 20230702045631Venerable DezzyNo ratings yet

- Identifying - Explaining Brake System FunctionsDocument39 pagesIdentifying - Explaining Brake System FunctionsJestoni100% (1)

- Vital Judo Throwing TechniquesDocument193 pagesVital Judo Throwing TechniquesJuan Jose Opazo Carvajal100% (1)

- Digital Logic DesignDocument38 pagesDigital Logic DesignAri BaderNo ratings yet

- R OR K C S V: EG Epair Its For Ylinder and Ervice AlvesDocument5 pagesR OR K C S V: EG Epair Its For Ylinder and Ervice AlvesLeonardoFabioCorredorNo ratings yet

- GP 24-21 - Fire Hazard AnalysisDocument53 pagesGP 24-21 - Fire Hazard AnalysisJohn DryNo ratings yet

- Dumel James Melchor DuayDocument3 pagesDumel James Melchor DuayBle DuayNo ratings yet

- Yehuda Berg Satan PDFDocument77 pagesYehuda Berg Satan PDFOswaldo Archundia100% (7)

- A Duality Principle For The Entanglement Entropy of Free Fermion SystemsDocument12 pagesA Duality Principle For The Entanglement Entropy of Free Fermion SystemsCroco AliNo ratings yet

- Monitoring:: Steps of Adding New SiteDocument8 pagesMonitoring:: Steps of Adding New SiteMohammad ZakoutNo ratings yet

- Agricultural Machinery in PakistanDocument19 pagesAgricultural Machinery in PakistanBadar NiaziNo ratings yet

- 520l0553 PDFDocument52 pages520l0553 PDFVasil TsvetanovNo ratings yet

- Bahir Dar NDP UDP - Final ReportDocument188 pagesBahir Dar NDP UDP - Final ReportWorkuMamo100% (1)

- Kia September 2020 Price List: Picanto ProceedDocument2 pagesKia September 2020 Price List: Picanto ProceedCaminito MallorcaNo ratings yet

- MGE UPS Comissioning GuideDocument19 pagesMGE UPS Comissioning GuideAldo Rodriguez MaturanaNo ratings yet

- Igorot Village: Get To Know..Document11 pagesIgorot Village: Get To Know..Elain RagosNo ratings yet

- The Pole and Zeros PDFDocument24 pagesThe Pole and Zeros PDFKim KeatNo ratings yet

- EPP V6 - V7 - ETS - Removal Switch - Sensor Reactivation V12Document15 pagesEPP V6 - V7 - ETS - Removal Switch - Sensor Reactivation V12Rabin TinkariNo ratings yet

- HP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessDocument4 pagesHP Prodesk 400 G6 Microtower PC: Reliable and Ready Expansion For Your Growing BusinessPằngPằngChiuChiuNo ratings yet

- Blood Glucose Units Conversion Table: Endocrinology & Diabetes UnitDocument1 pageBlood Glucose Units Conversion Table: Endocrinology & Diabetes UnitDrFarah Emad AliNo ratings yet

- Moving Money Box: Pig (Assembly Instructions) : The Movements Work Better With Heavier CoinsDocument6 pagesMoving Money Box: Pig (Assembly Instructions) : The Movements Work Better With Heavier CoinsjuanNo ratings yet

- Concrete ON MALDIVESDocument55 pagesConcrete ON MALDIVESKãrthìçk JkrNo ratings yet

- Materi Asking and Offering For HelpDocument9 pagesMateri Asking and Offering For HelpFranky ArdanaNo ratings yet

- TL K1 2 1 04 VSD35 Varyset DE enDocument25 pagesTL K1 2 1 04 VSD35 Varyset DE enAkilaJosephNo ratings yet

- High Performance Liquid Chromatography: University of Santo Tomas Faculty of Pharmacy Department of BiochemistryDocument32 pagesHigh Performance Liquid Chromatography: University of Santo Tomas Faculty of Pharmacy Department of BiochemistryMa. Ellah Patricia M. GutierrezNo ratings yet

- Toda People in IndiaDocument9 pagesToda People in IndiaAmoona KopiKoNo ratings yet

- PT3 Guided WritingDocument8 pagesPT3 Guided WritingDayang Haffizah Abg AbdillahNo ratings yet

- Servo Controlled FBW With Power Boost Control, Operations & Maint. ManualDocument126 pagesServo Controlled FBW With Power Boost Control, Operations & Maint. ManualKota NatarajanNo ratings yet